Double-row keel sound-isolation wall body

A keel and wall technology, applied in the field of double-row keel sound insulation walls, can solve the problems of excessive occupation of indoor space, high construction costs, unsatisfactory sound insulation effect of sound insulation walls, etc., and reduce the thickness of the wall body. , The effect of reducing the self-weight of the wall and high sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. The embodiments of the present application and the combinations of the various features in the embodiments without conflict are within the protection scope of the present invention.

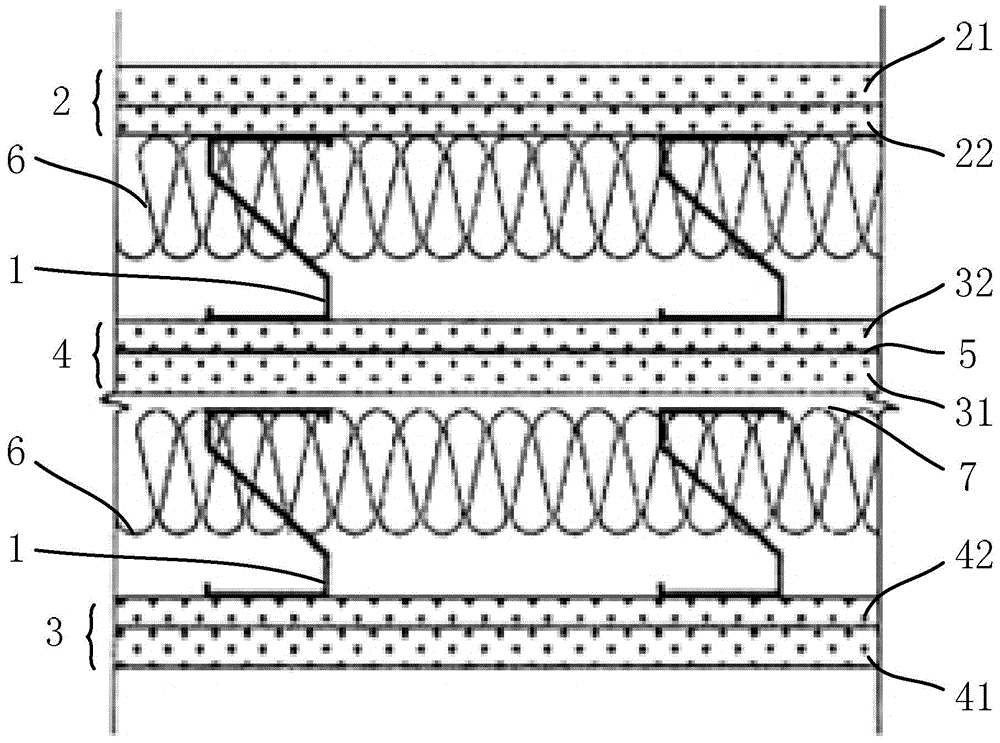

[0017] The double-row keel sound insulation wall of the embodiment of the present application mainly uses the double-row Z-shaped keel as the skeleton, and paper-faced gypsum board layers are arranged on both sides of the double-row Z-shaped keel, and the double-row Z-shaped keel There are also layers of plasterboard and sound insulation felt in between. The cavity between two adjacent layers of gypsum boards is filled with rock wool, and the thickness of the rock wool is smaller than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com