Connecting structure for air filter

A connection structure and air filter technology, which is applied in the direction of fuel air filter, etc., can solve the problems of easy deformation, large amount of wear, poor sealing, etc., and achieve the effect of improving reliability and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

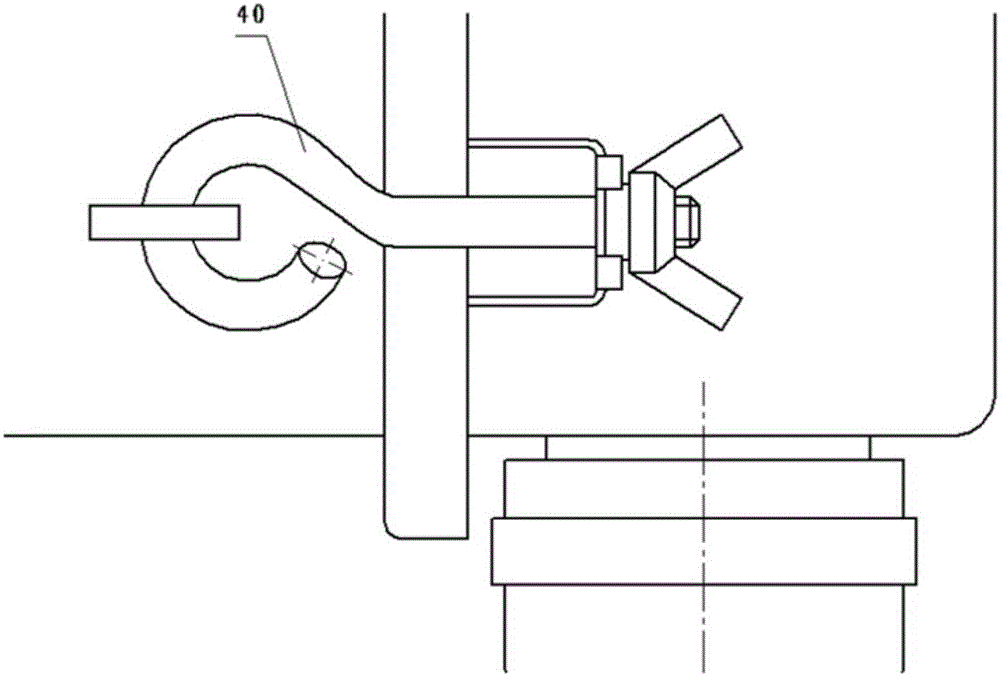

[0026] Another example is the second embodiment: the tightening part includes a pull rod 40, a mounting hole 111 provided on the first bracket 11, and a slot 121 provided on the second bracket 12, one end of the pull rod 40 has a hook 41, and the other end has a threaded section 42 , the hook 41 is hooked in the installation hole 111 , and the threaded section 42 is embedded in the slot 121 and fastened by the threaded connector 50 . In this solution, the position where the threaded coupling is screwed to the threaded section can adjust the tension force, and the pull rod is a cylinder with high strength and small deformation under the action of tension. Compared with the first embodiment, the maintenance and replacement frequency Low, high tensile force, better sealing performance, therefore, the second embodiment is a preferred embodiment of the present invention.

[0027] In order to facilitate the cooperation of the pull rod with the first bracket and the second bracket, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com