Automobile water storage bottle pressure cover with good sealing performance

A sealing, water storage bottle technology, used in engine cooling, machine/engine, mechanical equipment, etc., can solve problems such as pressure cap leakage, product qualification rate reduction, spring distortion, etc., to improve sealing and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

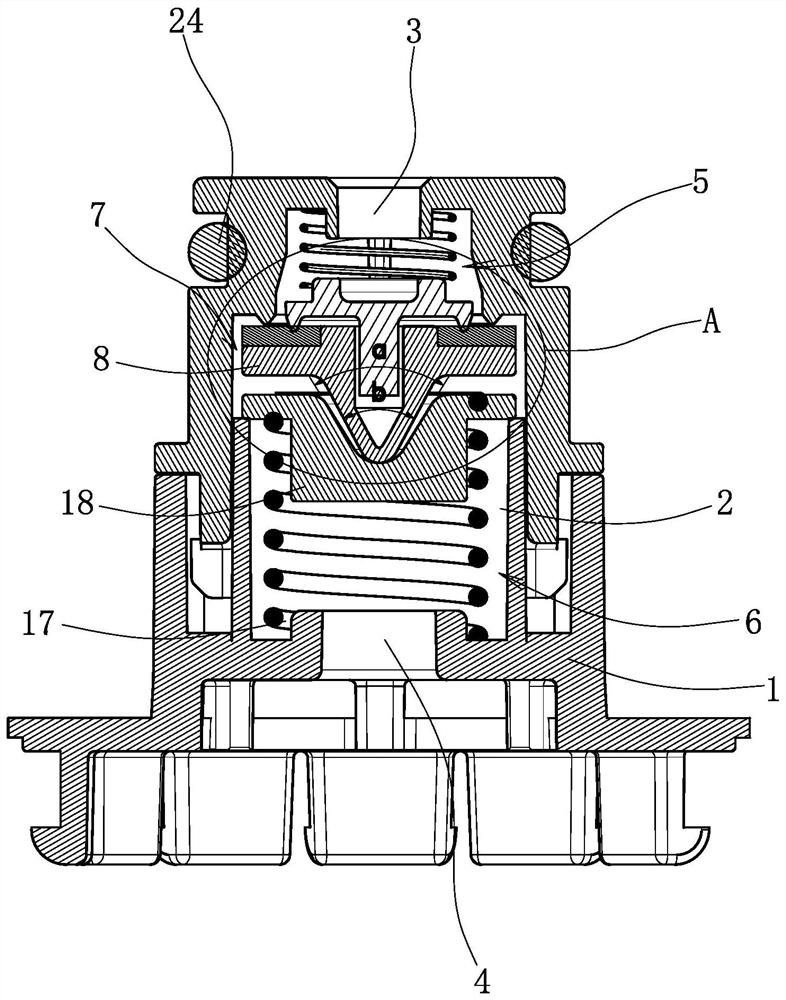

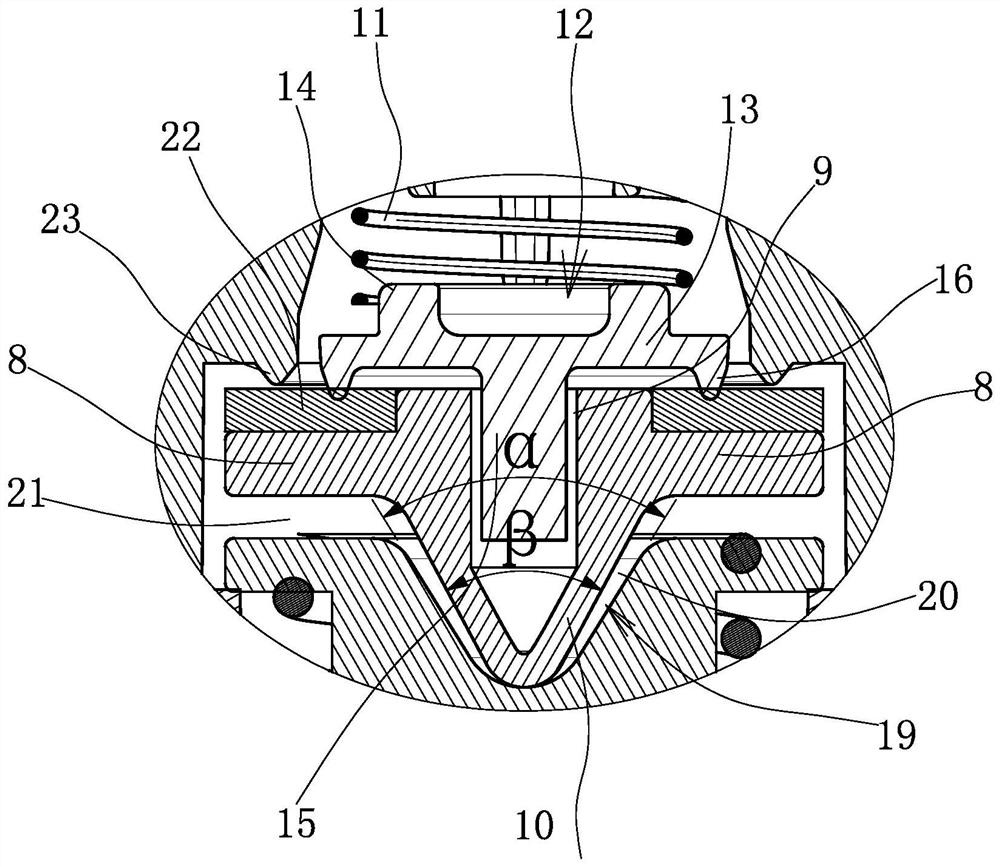

[0020] The present invention will be further described below with reference to the accompanying drawings.

[0021] like figure 1 , figure 2 As shown in the figure, a pressure cap for a car water bottle with good sealing performance includes a cap body 1 with a hollow chamber 2 in the cap body 1. The upper opening 3 and the lower opening 4, the chamber 2 is provided with a first sealing component 5 and a second sealing component 6 that are used for sealing the upper opening 3 and the lower opening 4 and can move up and down. An adjustment compensation plate 7 is arranged between the assembly 5 and the second sealing assembly 6, the upper end of the adjustment compensation plate 7 abuts on the first sealing assembly 5, and the lower end of the adjustment compensation plate 7 is in movable contact with the second sealing assembly 6, A sealing ring 24 is sleeved on the outer surface of the upper end of the cover body 1 .

[0022] In this embodiment, when the upper end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com