Straight hit type wind power generation equipment unit adopting air collecting machines

A technology for wind power generation equipment and wind collectors, which is applied to a combination of wind power generators, a wind power generator that is consistent with the wind direction, and a wind power generator that is at right angles to the wind direction, etc. high cost problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

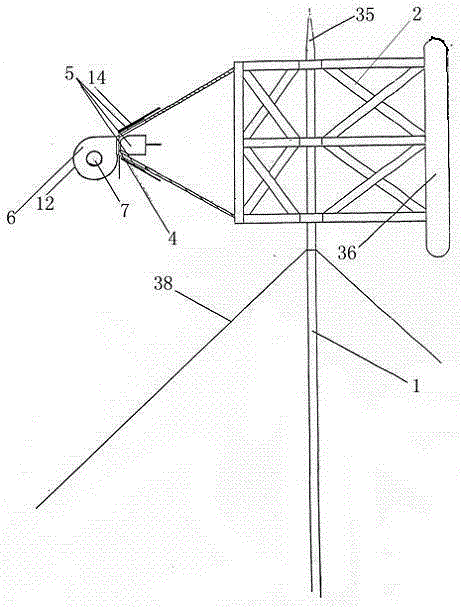

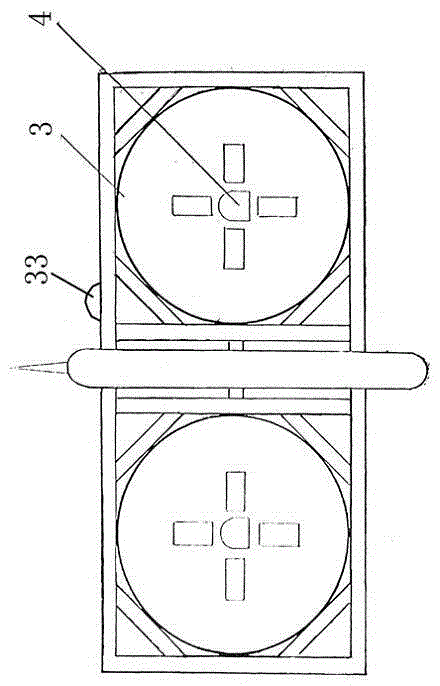

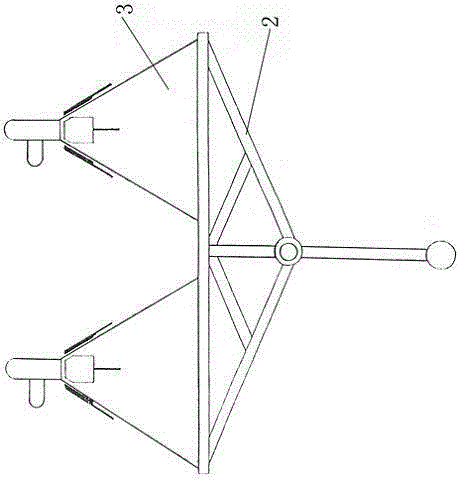

[0049] Embodiment 1: The direct impact type wind power generation equipment unit adopting the wind collector of this example, such as figure 1 , figure 2 , image 3 , including a tower tube 1, a diagonal stay rod 38 is connected to the tower tube, a tower frame 2 is fixed on the tower tube, a lightning rod 35 is provided on the tower frame, and a counterweight 36 is provided at the front end of the tower frame. The rear portion of the tower is fixed with a double-connected horn-shaped wind collector 3, and the plane of the opening of the horn-shaped wind collector is circular. The tower frame is located directly in front of the gap between the two horn-shaped air collectors. An air outlet 4 is provided in the middle of the rear of the horn-shaped air collector, and an air outlet 5 is provided around the air outlet. The air outlets are up, down, left, and right. 4 evenly distributed, the rear end of the trumpet-shaped air collector is connected with the wind impeller box 6 a...

Embodiment 2

[0053] Embodiment 2: The direct impact type wind power generation equipment unit adopting the wind collector of this example, such as figure 1 , figure 2 , image 3 , The plane of the opening of the trumpet-type air collector 3 is a square, and the rest are the same as in Embodiment 1.

Embodiment 3

[0054] Embodiment 3: The direct-impact wind power generation equipment unit using the wind collector in this example is a low-level horizontal axis unit, such as Figure 10 , the wind impeller box 6 is connected with the wind impeller box frame 17, the lower end of the wind impeller box frame is provided with a revolving wheel 18, the revolving wheel is connected on the revolving track 19 of the wind turbine, and the wind impeller box frame and the tower frame 2 are fixed There is wind impeller box support file 20.

[0055] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com