Tensile test device

A technology of tensile test and rotary drive device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to rotate the test piece, 360° scanning, etc., and achieve convenient control, convenient detection, and transmission structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

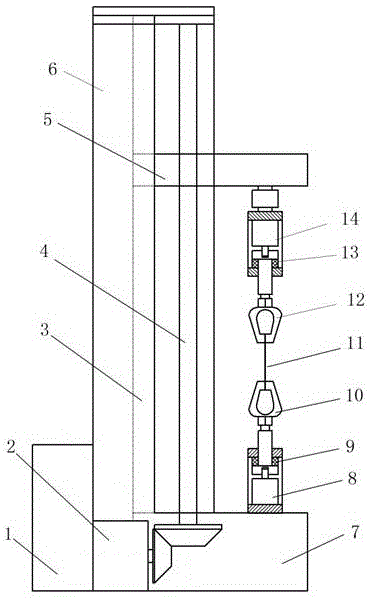

[0013] Embodiment one of the tensile test device of the present invention: as figure 1 Shown, comprise base 7, be provided with stand 6 on the base 7, the right side of stand 6 is provided with the lead screw 4 that extends up and down, screw thread is equipped with nut holder 5 on the lead screw 4, and stand 6 is provided with and Lead screw 4 is parallel to the guide rail 3, and the left end of nut holder 5 is provided with the slide block that guides and slides with guide slide 3 in the up and down direction, and can be aligned in the circumferential direction by the guide slide of slide block and guide slide. The nut holder carries out position limiting, the lead screw 4 is fixed in the up and down direction and can rotate around its axis in the circumferential direction, the nut holder 5 is provided with an upper clamp 12 at one end extending towards the right side, and the base 7 is located at the position corresponding to the upper clamp up and down There is a lower cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com