Display panel and making method and display device thereof

A display panel and display area technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of easy oxidation, flickering, corrosion and even falling off, and achieve the effect of eliminating the accumulation of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

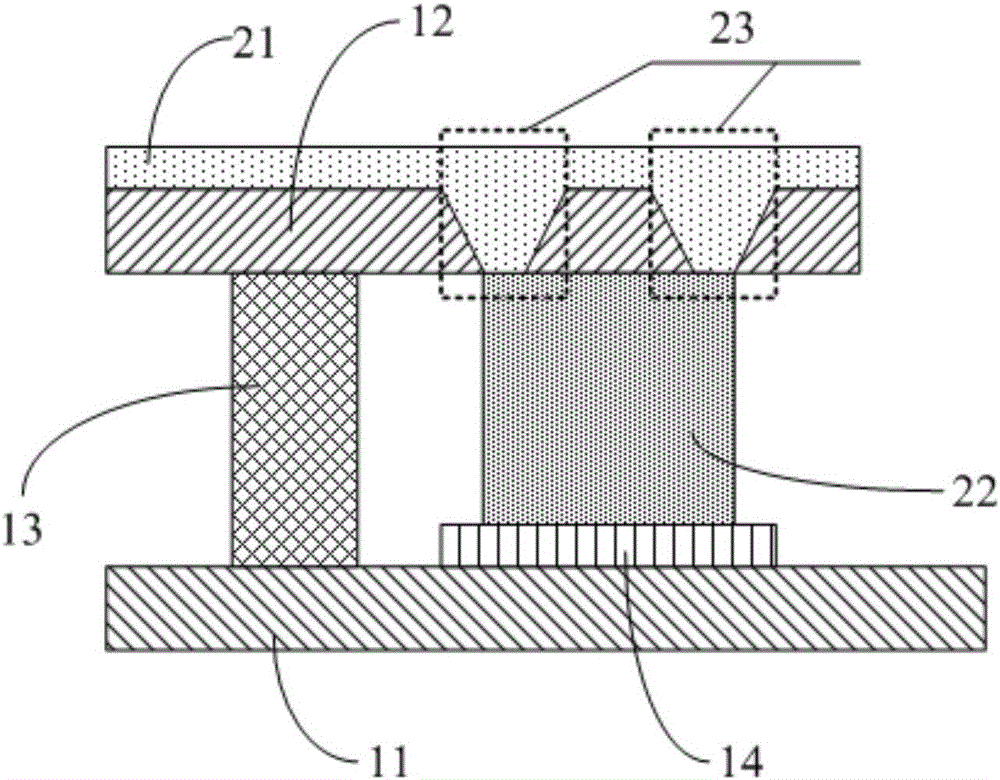

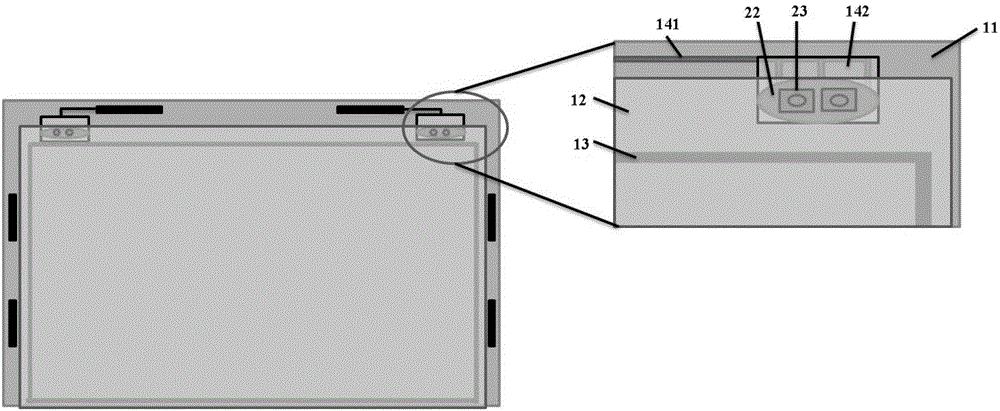

[0053] Such as Figure 4 As shown, the color filter substrate 12 in the specific embodiment of the present invention further includes a metal 40 disposed in the connection hole, and the transparent conductive layer 21 is connected to the conductive glue 22 through the metal 40 disposed in the connection hole. In the specific embodiment of the present invention, the material of the metal 40 may be aluminum (Al), molybdenum (Mo), etc., and the specific embodiment of the present invention does not specifically limit the material of the metal 40 .

[0054] Due to the small resistance of the metal 40, when the transparent conductive layer 21 is connected to the conductive glue 22 through the metal 40, the connection resistance will be reduced, so that the transparent conductive layer 21 can be better connected with the grounding wire 14 on the array substrate 11, thereby It can better eliminate the static electricity accumulation on the color filter substrate.

Embodiment 2

[0056] Such as Figure 5 As shown, the color filter substrate 12 in the specific embodiment of the present invention also includes a metal 40 arranged in the connection hole, and a metal wire 50 connected to the metal 40 and arranged on the side of the color filter substrate 12 facing away from the array substrate 11, transparent The conductive layer 21 is connected to the conductive glue 22 through the metal wire 50 and the metal 40 disposed in the connection hole, wherein the orthographic projection of the metal wire 50 on the array substrate 11 is located in the peripheral lead area of the array substrate. The material of the metal wire 50 in the specific embodiment of the present invention can be aluminum (Al), molybdenum (Mo), etc. The specific embodiment of the present invention does not specifically limit the material of the metal wire. 40 and metal wire 50 are made of the same material.

[0057] Embodiment 2 of the present invention Compared with Embodiment 1, the m...

Embodiment 3

[0060] Such as Figure 6 As shown, the color filter substrate 12 in the specific embodiment of the present invention also includes a metal 40 arranged in the connection hole, and a metal wire 60 connected to the metal 40 and arranged on the side of the color filter substrate 12 facing the array substrate 11, which is transparent and conductive The layer 21 is connected to the conductive glue 22 through the metal wire 60 and the metal 40 disposed in the connection hole, wherein the orthographic projection of the metal wire 60 on the array substrate 11 is located in the peripheral lead area of the array substrate. The material of the metal wire 60 in the specific embodiment of the present invention can be aluminum (Al), molybdenum (Mo), etc., the specific embodiment of the present invention does not specifically limit the material of the metal wire, during specific implementation, in the specific embodiment of the present invention The material of the metal wire 60 is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com