Method for manufacturing multi-colored model by utilizing linear material

A multi-color and model technology, applied in spray/jet textile material processing, special data processing applications, instruments, etc., can solve problems such as cumbersome process, low efficiency, complex multi-color model process, etc., to improve color accuracy and benefit , Reduce the effect of dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, taking the manufacturing method of a multi-color knitted fabric model as an example.

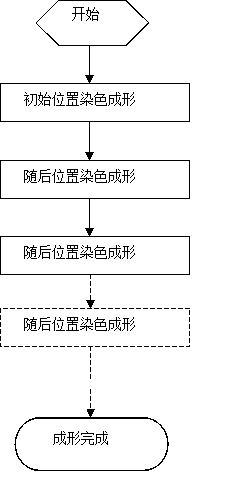

[0046] 1. Use computer-aided design software such as AutoCAD to design and produce the data model of the required multi-color knitted fabric model, determine the knitted fabric color, knitting position and weaving range, etc., such as figure 1 shown.

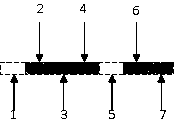

[0047] 2. Design the predetermined color and position to be dyed in the multi-color knitted fabric model, such as figure 2 shown.

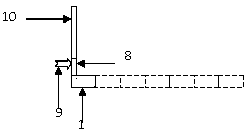

[0048] 3. According to the predetermined color and position to be dyed in the multi-color knitted fabric model, start from the starting position 1 of the model, such as image 3 As shown, the red unit area 1 of the starting part on the required weaving model is in one-to-one correspondence with the starting knitting unit part on the provided linear braiding material 10, and according to the red feature required by the starting part, the The supplied material is dyed red8 while weaving to f...

Embodiment 2

[0056] Embodiment 2, taking the manufacturing method of a seven-layer multi-color three-dimensional model as an example.

[0057] 1. Use AutoCAD and other computer-aided design software to design and produce the data model of the required seven-layer multi-color solid model, Figure 10 As shown, this model is divided into seven layers, and each layer is composed of nine kinds of color forming units. Pink, purple, colorless (undyed) composition. The size of each layer is 9cm×9cm, and the thickness of the edge is 1cm. The size of the nine color units in each layer is 3cm×3cm, and the thickness of the edge is 1cm.

[0058] 2. Design the nine predetermined positions and nine colors that need to be dyed according to the top layer of the multi-color cube model, starting from the starting position layer of the linear ABS forming material, and the line shape required by these nine predetermined positions and nine predetermined colors The ABS molding material area corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com