Camera module group and first and second circuit boards thereof

A technology of camera modules and circuit boards, which is applied in the direction of image communication, TV, color TV parts, etc., can solve the problems of increased production costs, micro-camera module manufacturing sample cycle (long proofing cycle, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The camera module and its first circuit board and second circuit board will be further described below in conjunction with the drawings and specific embodiments.

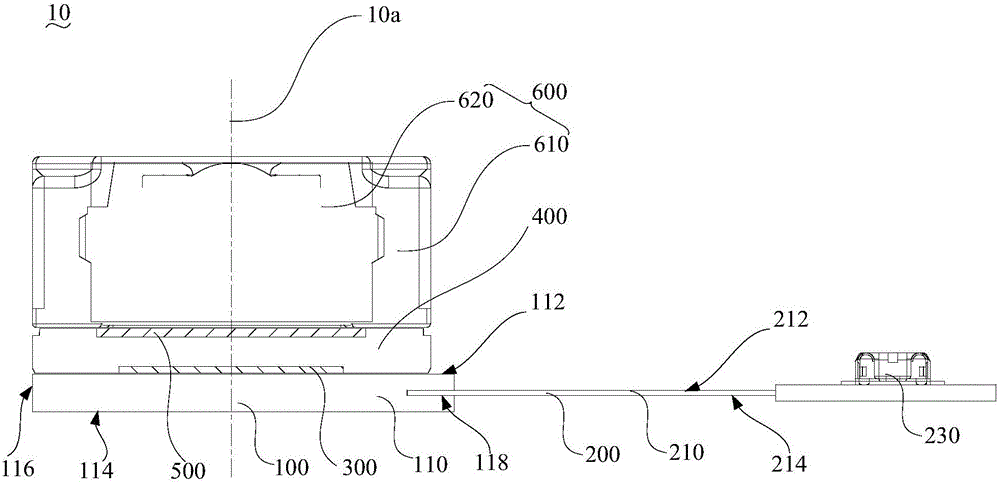

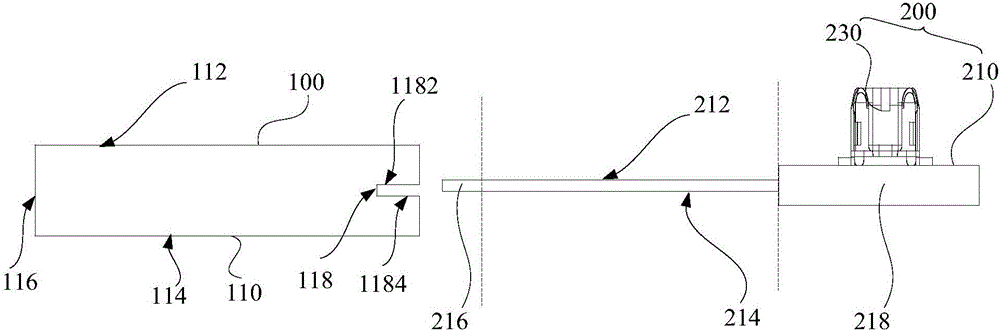

[0039] like figure 1 As shown, the camera module 10 of an embodiment includes a first circuit board 100 , a second circuit board 200 , an image sensing chip 300 , a bracket 400 , a filter 500 and a lens assembly 600 .

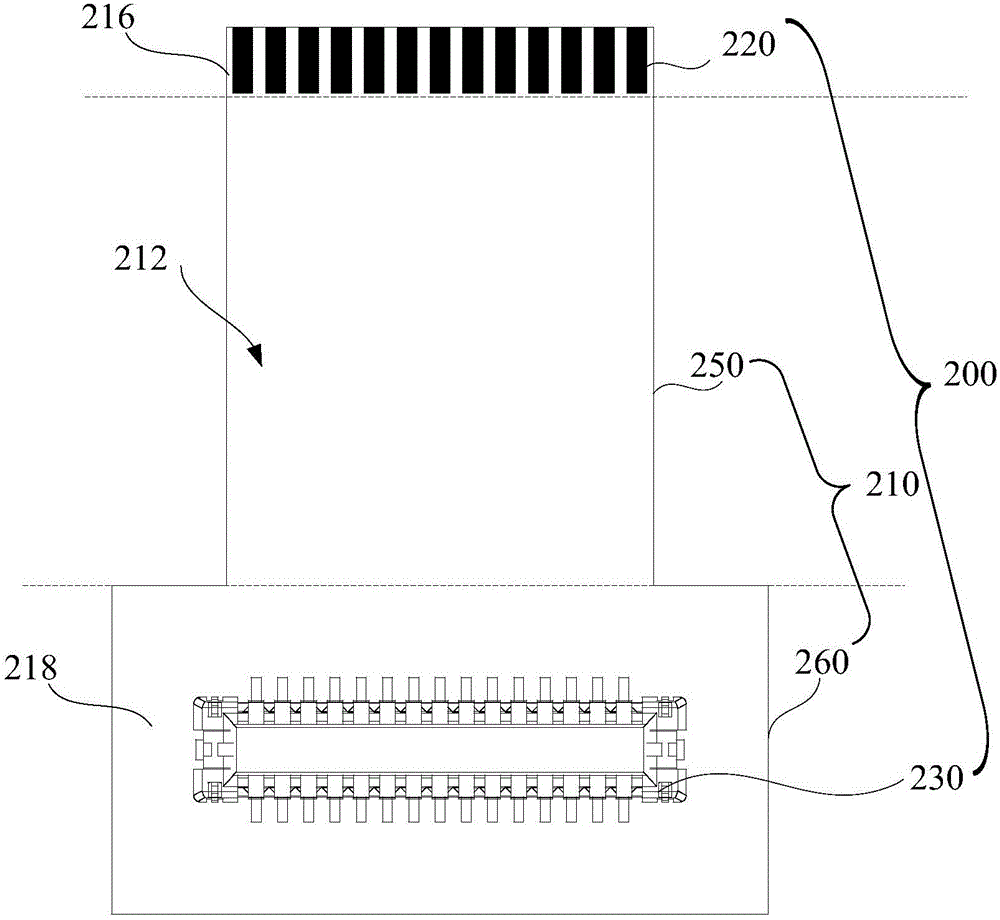

[0040] like figure 1 and figure 2 As shown, the first circuit board 100 includes a ceramic substrate 110 , a basic circuit (not shown) integrated in the ceramic substrate 110 and two sets of first golden fingers (not shown).

[0041] The ceramic substrate 110 has a mounting surface 112 and a connecting surface 114 opposite to each other, and a side surface 116 connecting the mounting surface 112 and the connecting surface 114 . The mounting surface 112 is used for mounting the image sensor chip 300 . A card slot 118 is formed inwardly on the side surface 116 . The slot 118 has a first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com