Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., and can solve the problem of insufficient improvement in handling stability and durability of pneumatic tires, and carcass cords. The problem of not being able to fully utilize the characteristics of the cord, etc., to achieve the effect of excellent handling stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0047] Examples 1-3, Conventional Examples 1-6

[0048] As test tires, five tires were produced for each of the examples and each of the comparative examples, each of which had a tire size of 225 / 50R1692V, and were mounted on JATMA standard rims to obtain test tires.

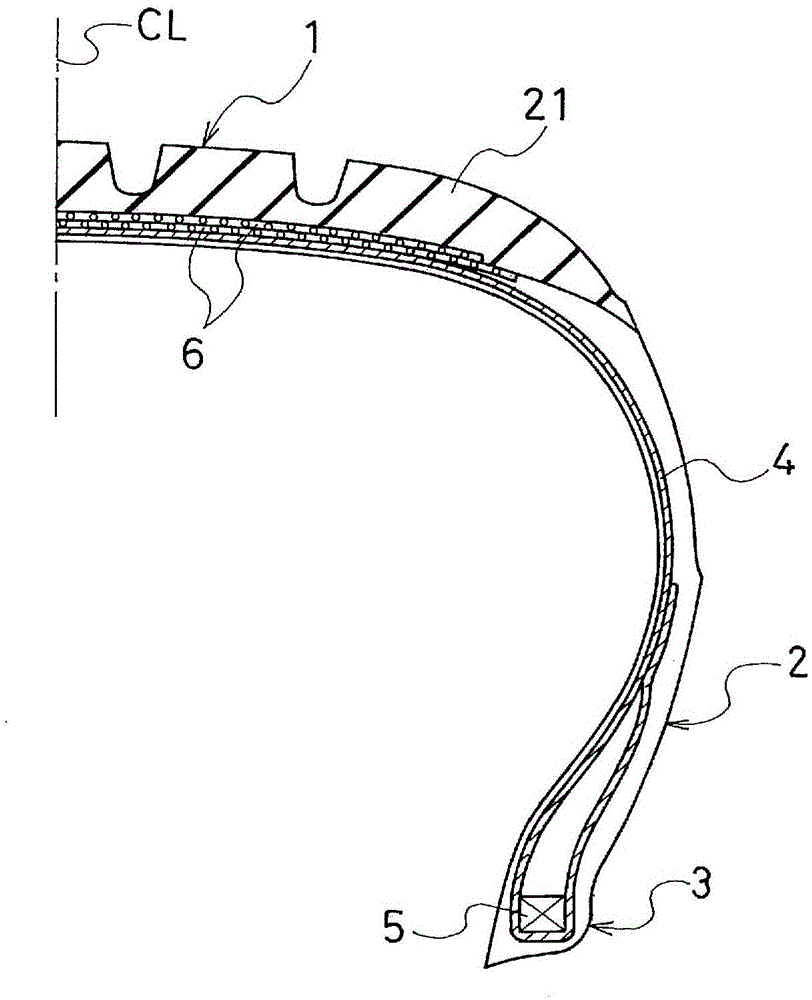

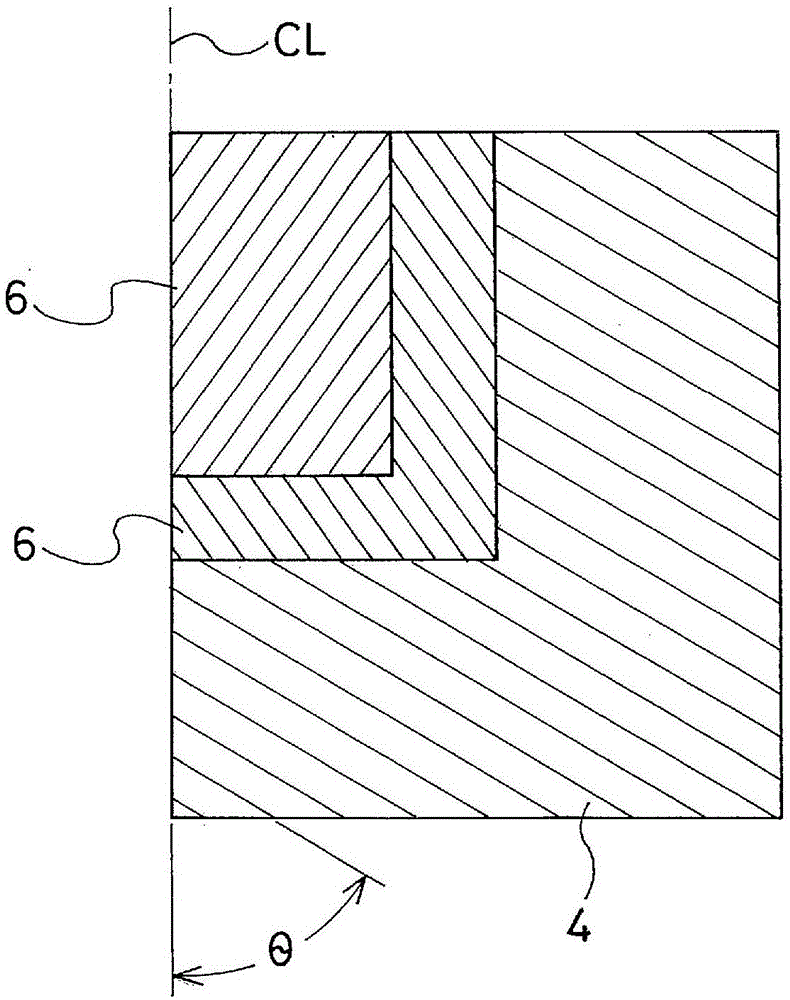

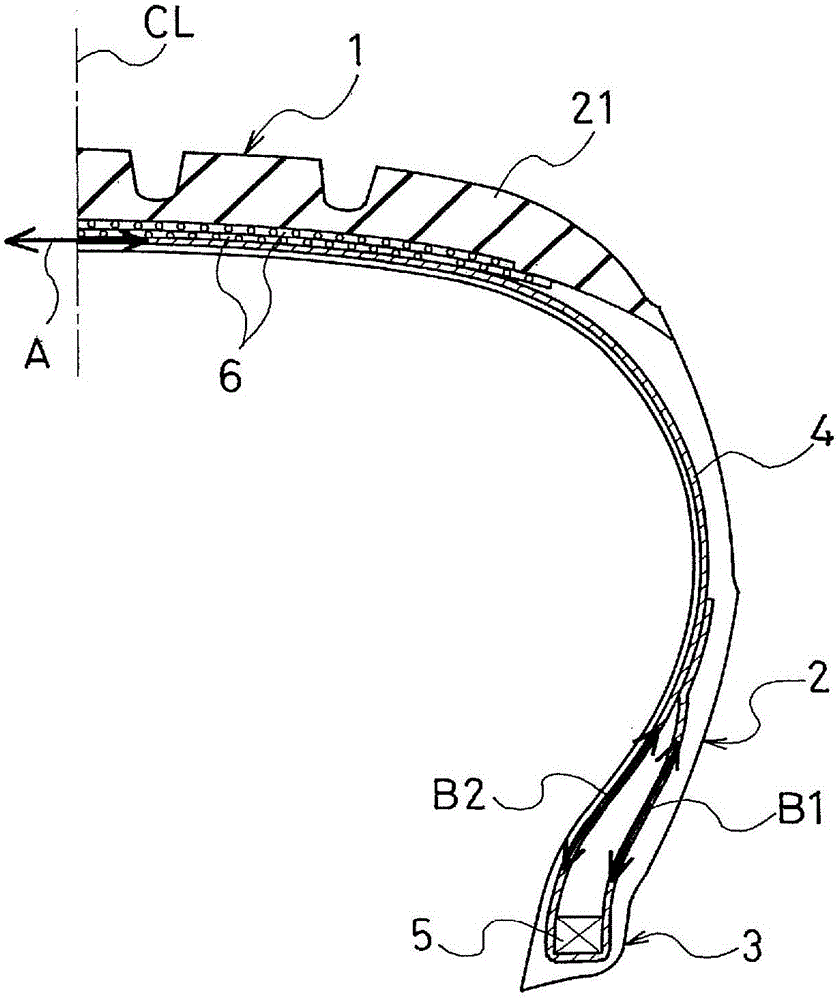

[0049] The specifications of the carcass structure of each pneumatic radial tire of each example and each comparative example are as described in Table 1. In terms of carcass structure, it is described as the conventional method is figure 1 construction shown.

[0050] For each test tire, the handling stability, ride comfort performance, load durability performance, and tire weight were measured and evaluated by the test evaluation methods described in the following (B) to (D), and the evaluation results are shown in Table 1. .

[0051] In addition, the method for obtaining the difference in intermediate elongation at 2.0 cN / dtex between the center portion and the side portion of the carcass cord used in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com