Independent front suspension system of adjiustable front wheel positioning parameter

A positioning parameter, front suspension technology, applied in the direction of suspension, elastic suspension, transportation and packaging, etc., can solve problems such as car maintenance, adjustment work difficulties, limited adjustment range of geometric parameters, and inability to fine-tune front wheel alignment parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

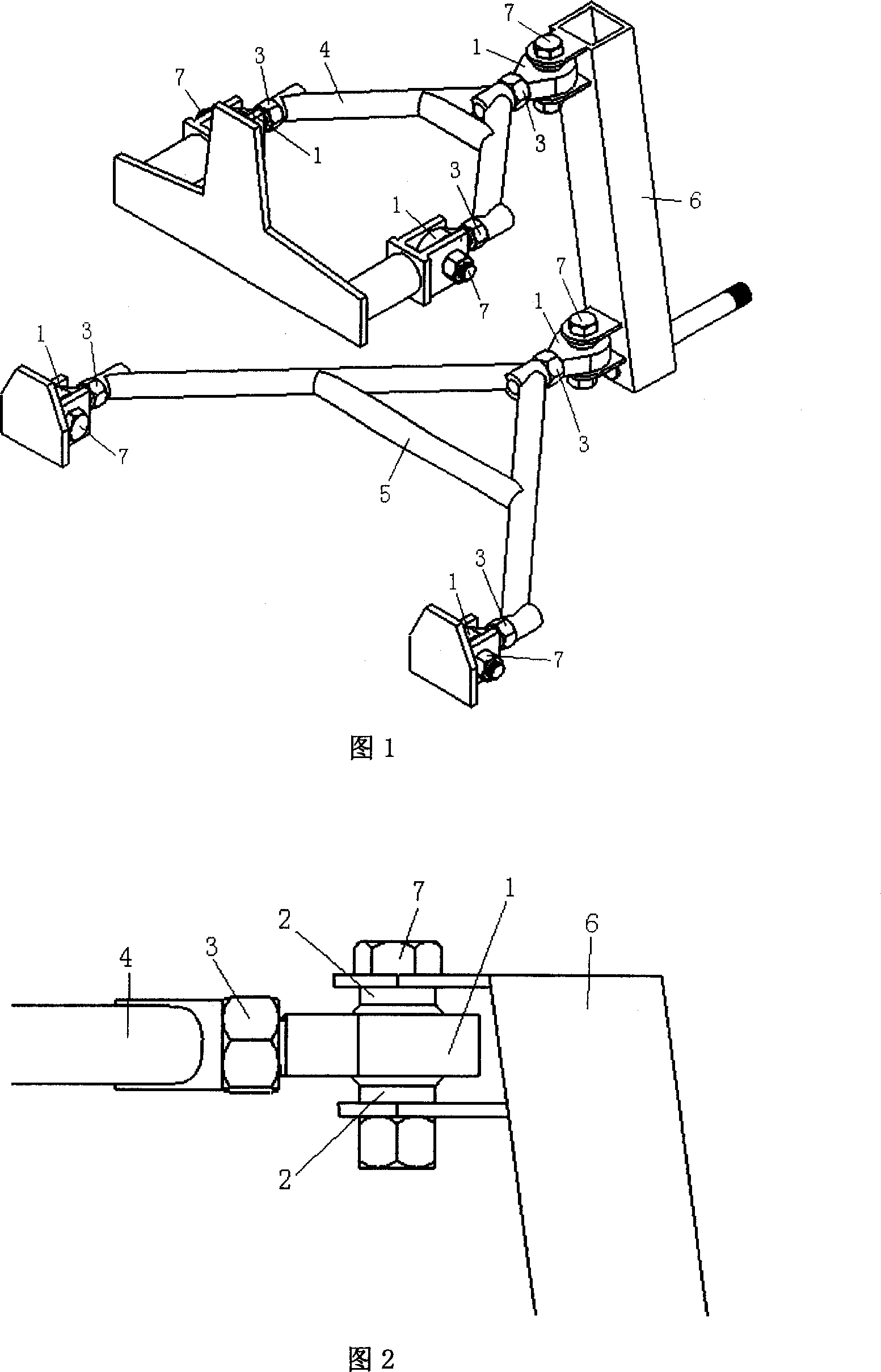

[0013] As shown in Figures 1 and 2, the present invention includes: six rod end bearings 1, bushings 2, lock nuts 3, upper cantilever 4, lower cantilever 5, steering knuckle 6, connecting bolts and nuts 7, and the lock nut 3 is located on On the threaded rod of the rod end bearing 1, six rod end bearings 1 and lock nuts 3 are respectively arranged in the three threaded holes at the two ends of the upper cantilever 4 and in the three threaded holes at the two ends of the lower cantilever 5, the threads in the threaded holes and The threaded rods on the rod end bearing 1 match, the 4 rod end bearings 1 on the side of the upper cantilever 4 and the lower cantilever 5 on the car body are connected to fix the suspension by connecting bolts and nuts 7, and the upper cantilever 4 and the lower cantilever 5 on the steering knuckle side The two rod end bearings 1 on both sides of the spherical rollers are provided with bushings 2, and the two rod end bearings 1 and bushings 2 on the knu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com