Squeeze corn thresher based on multi-row roller chain

A technology of roller chains and threshers, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems that the broken rate cannot meet the national standard, the impurity rate of corn kernels increases, and the total loss rate decreases, etc., to achieve reduction Effects of grain damage rate, reduction of crushing time, and reduction of broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

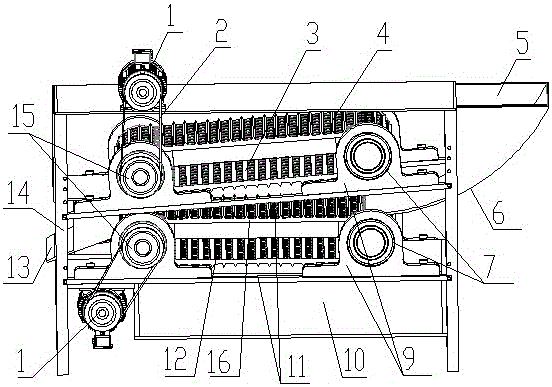

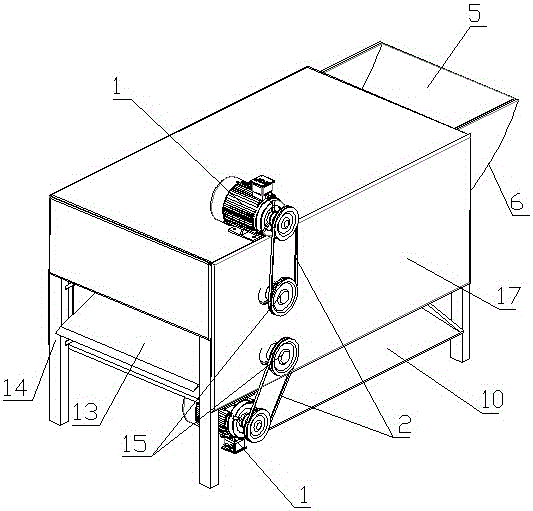

[0028] Squeeze corn thresher based on multi-row roller chain, its structure is as follows Figure 1~6 As shown, including frame 14, frame 14 outside is provided with cover plate 17, and cover plate 17 outside is arranged on belt pulley 15, and frame 14 top and bottom are respectively provided with motor 1, and motor 1 is connected with belt pulley 15 by belt 2; The two ends of the positioning rod 11 are movably connected on the frame 14 by bolts, the positioning rod 11 is provided with a plurality of bolt holes, the bearing seat 9 is connected on the positioning rod 11 by bolts, and the bearing seat 9 is provided with a bearing 7; the frame 14 There are upper and lower groups of squeezing mechanisms connected to the bearings 7. The right side of the frame 14 is provided with a feeding inlet 5, and an arc-shaped feeding baffle 6 is connected below the feeding inlet 5. The lower edge of the feeding baffle 6 It is located on the upper part of the lower rows of roller chains 16, s...

Embodiment 2

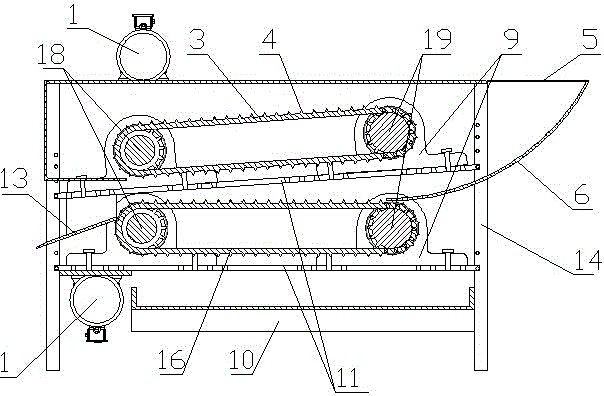

[0032] Squeeze corn thresher based on multi-row roller chain, its structure is as follows Figure 7 As shown, the difference from Embodiment 1 is that: the positioning rod 11 is provided with a plurality of bolt holes, and the bearing seat 9 is fixedly connected to the positioning rod 11 by bolts; the driving shaft 18 and the driven shaft of the upper squeezing mechanism An adjustment shaft 20 connected to the frame 14 is provided above the shafts 19, and the adjustment shaft 20 is provided with a plurality of rows of teeth matched with the multi-row roller chain along its axial direction, so that the alignment of the multi-row roller chain can be adjusted. Degree of tightness, the upper multi-row roller chain 3 meshes with the drive shaft 18, the driven shaft 19 and the adjustment shaft 20.

[0033] According to the moisture content of the ear, on the basis of ensuring the removal rate, the position of the bearing seat 9 on the positioning rod 11 and the position of the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com