Vehicle air condition controller

A vehicle air conditioner and controller technology, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., and can solve the problems of independent torque control of unfavorable gears and independent torque control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

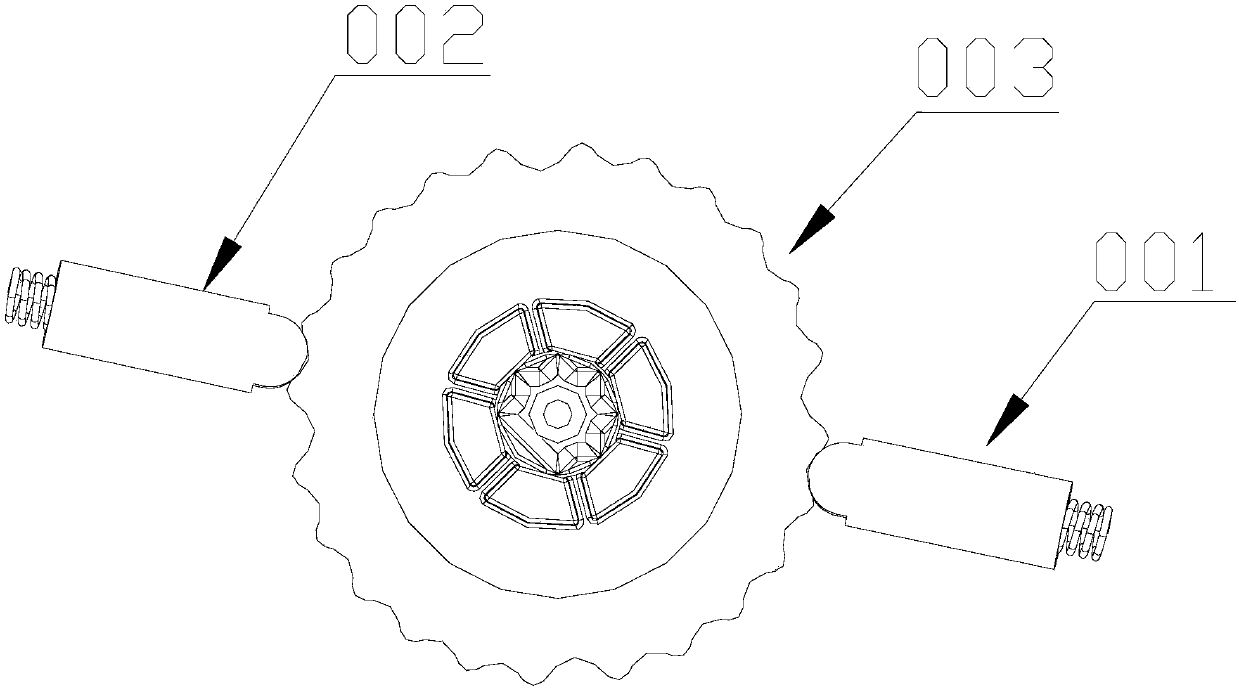

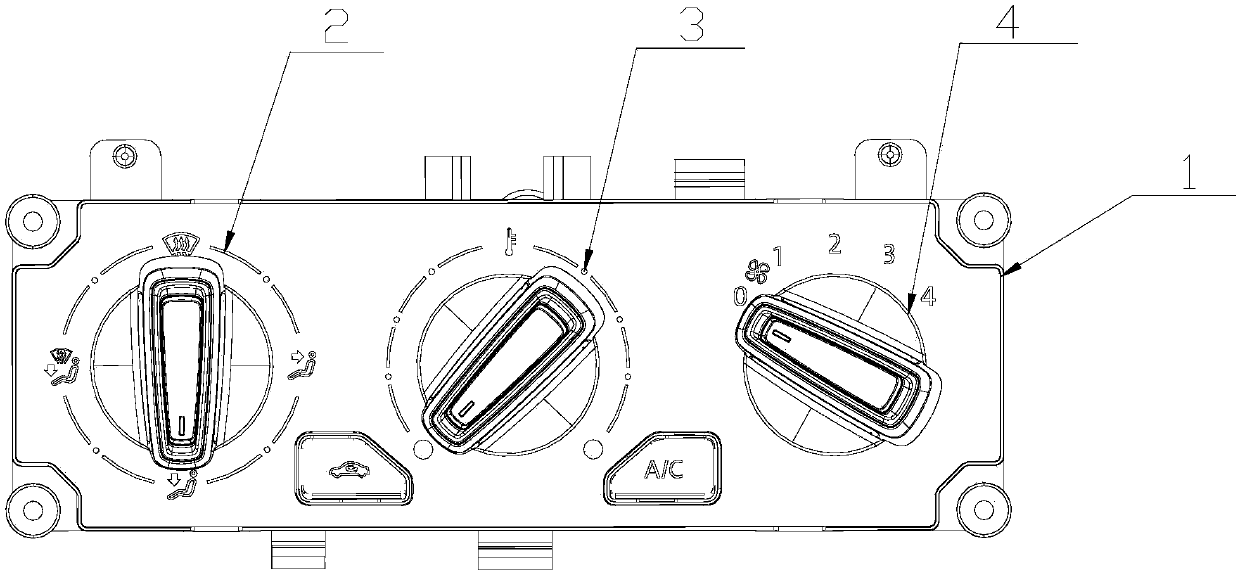

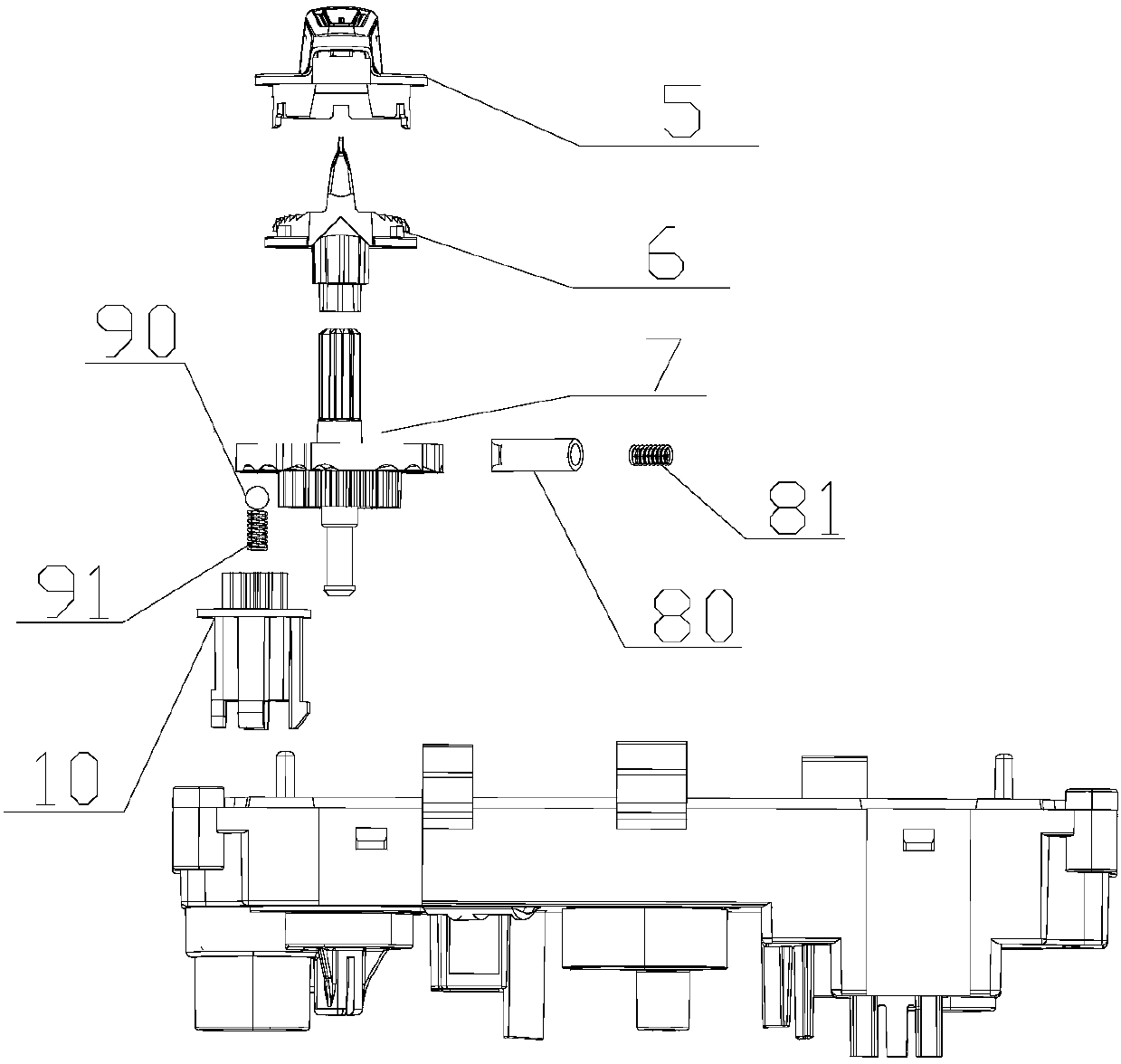

[0037] see in conjunction Figure 9 with Figure 10 , Figure 9 is a front view structural schematic diagram of the first specific embodiment of the transmission member, Figure 10 It is a schematic diagram of the isometric side structure of the first specific embodiment of the transmission member. A circuit board is installed between the light guide member 6 and the transmission member 7 , and an assembly hole is opened on the circuit board, and the transmission shaft 70 of the transmission member 7 passes through the assembly hole and is socketed with the mode knob 2 . The transmission member 7 mainly includes a transmission shaft 70 , a limiting portion 71 , a first disk portion 72 , a gear portion 73 and a connecting rod 74 , and a buckle 75 is provided at the end of the connecting portion 74 . The transmission shaft 70 is socketed with the casing part 63 through the assembly hole, and the transmission shaft 70 is provided with a first guide rib along the axial directio...

specific Embodiment approach 2

[0046] see in conjunction Figure 16 Figure 17 , Figure 16 It is a schematic structural diagram of the front view of the second specific embodiment of the transmission member, Figure 17 It is a schematic diagram of the isometric structure of the second specific embodiment of the transmission member. The transmission member 7 mainly includes a transmission shaft 70 , a limiting portion 71 , a first disk portion 72 , a second disk portion 78 , a gear portion 73 and a connecting rod 74 , and a buckle 75 is provided at the end of the connecting portion 74 . Both the first disk portion 72 and the second disk portion 78 are centered on the transmission shaft 70, and the first disk portion 72 and the second disk portion 78 have a certain thickness, and the side walls of the first disk portion 72 The outer periphery is provided with a first groove 76, and the outer periphery of the side wall of the second disk part 78 is provided with a second groove 77. The first groove 76 exte...

specific Embodiment approach 3

[0051] see in conjunction Figure 19 with Figure 20 , Figure 19 is a front view structural schematic diagram of the third specific embodiment of the transmission member, Figure 20 It is a structural schematic diagram of the isometric side rear view of the third specific embodiment of the transmission member. The transmission member 7 mainly includes a transmission shaft 70 , a limiting portion 71 , a first disk portion 72 , a second disk portion 78 , a gear portion 73 and a connecting rod 74 , and a buckle 75 is provided at the end of the connecting portion 74 . The disk surface of the first disk portion 72 is parallel to the disk surface of the second disk portion 78 and both disk surfaces are centered on the drive shaft 70, the first disk portion 72 and the second disk portion 78 are both It has a certain thickness. The disk surface of the first disk part 72 facing the rear cover 1 is the lower surface, and the lower surface of the first disk part 72 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com