A woven bag multi-station automatic processing machine

A fully automatic, woven bag technology, applied in bag making operations, paper/cardboard containers, packaging, etc., can solve the problems of low degree of automation, insufficient smooth movement, poor quality of woven bags, etc., saving time and benefiting mechanical structure. Design, reduce the effect of hot stamping and stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

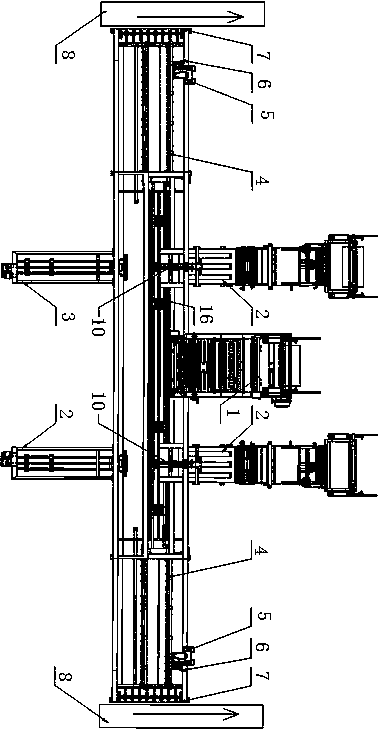

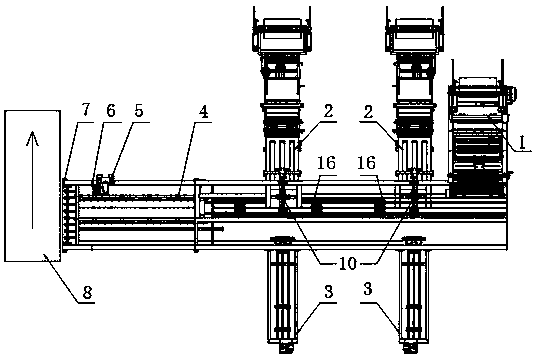

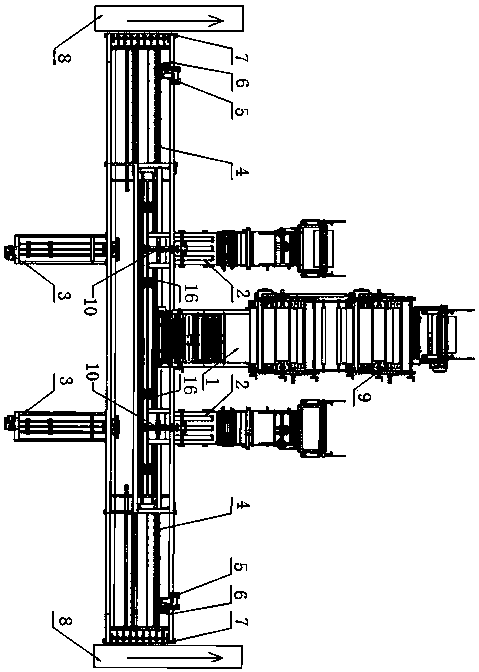

[0029] Embodiment one: with reference to attached figure 1 , 3 A woven bag double-station automatic processing integrated machine shown in -11 includes an outer bag cutting machine 1, an inner film making machine 2 and an inner film pulling machine 3, and two sets of the outer bag cutting machine 1 are arranged on the same side Described inner membrane machine 2, two described inner membrane machines 2 are respectively arranged on the both sides of described outer bag cutting machine 1, and the front of each described inner membrane machine 2 is also all connected with conveyor 4, sewing machine 5. Thread cutting device 6, bag stacking device 7 and output conveyor 84, all horizontally connect bag removing mechanism 16 between the output end of each said inner film making machine 2 and said outer bag cutting machine 1, and each The output end of the inner membrane machine 2 is correspondingly connected with the inner membrane machine 3 on the same straight line as the inner me...

Embodiment 2

[0043] Embodiment 2: The difference from Embodiment 1 is that two inner film-making machines 2 are arranged on the same side of the outer bag cutting machine 1, and a conveyor is connected in front of the two inner film-making machines 2 in the same direction. Machine 4, sewing machine 5, thread cutting device 6, bag stacking device 7 and output conveyor 8, that is, a single outer bag cutting machine 1 cuts the bag and then transports the bag in the same direction to supply 2 inner film making machines 2 sets of inner bags , and then through a sewing machine to sew the bottom of the bag, cut the thread, and fold the bag to transport.

[0044] Its principle is: because the speed of outer bag cutting machine 1 and sewing machine 5 is relatively fast, about 40 pieces per minute, while the bagging machine has many actions and slow speed, so utilize one outer bag cutting machine 1 and two bag removing mechanisms 16 , 2 sets of inner film making machines 2, 2 inner film pulling mach...

Embodiment 3

[0046] Embodiment 3: Different from Embodiment 1, a printing machine 9 is also set on the outer bag cutting machine 1; the printing machine 9 is set between the deviation correction mechanism 12 and the conveying mechanism 13. The all-in-one machine can only use printed woven bag rolls, printing and bag making are divided into two processes, and the degree of automation is not high;

[0047] Its principle is: put the roll of ordinary woven fabric or composite woven fabric on the tension unwinding mechanism 11, and pass through the printing machine 9 (the printing machine can be vertical or horizontal, double-color or multi-color, available in the market) can be optional), so that the unprinted woven cloth can be placed on the tension unwinding mechanism 11, after printing by the printing machine 9, the outer bag is cut off by the cutter part of the outer bag cutting machine 1 and then left Convey the outer bag to the right to the 10 stations of the bag opening device to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com