Double hook upending maintaining device and method

An equipment and double hook technology, applied in mechanical equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as cumbersome operation, and achieve the effect of improving work efficiency, reducing labor intensity and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

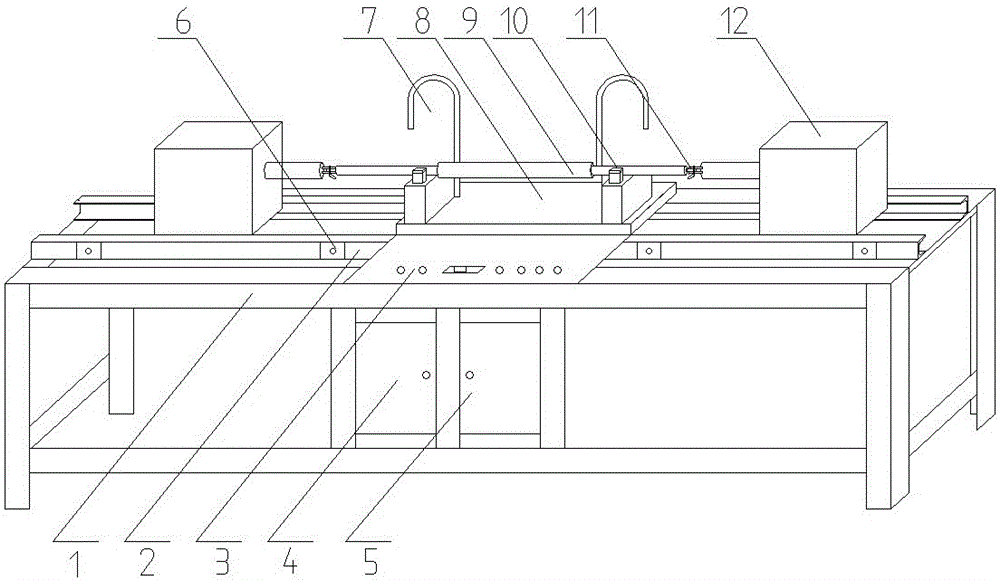

[0022] The present invention includes a frame, an operating table 1 arranged on the frame, a guide rail 2 longitudinally arranged on the operating table 1, two traveling trolleys 12 arranged on the guiding rail 2 and capable of moving relative to each other, and used to limit the traveling carts 12. The travel switch 6, the fixed platform 8 arranged above the guide rail 2, the cleaning system 10 and the refueling system 7 arranged on the fixed platform 8, the rotating motor arranged in the walking trolley 12, and the universal connection connected to the output end of the rotating motor Connector 11, a control circuit connected to the walking trolley 12, the rotating motor, the cleaning system 10 and the refueling system 7 for controlling the longitudinal movement of the walking trolley 12, controlling the rotation of the motor, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com