glass cutting tool

A technology of glass cutting and knives, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as obstructing sight, waste, and affecting the working environment, so as to be beneficial to environmental protection, save resources, avoid waste and environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

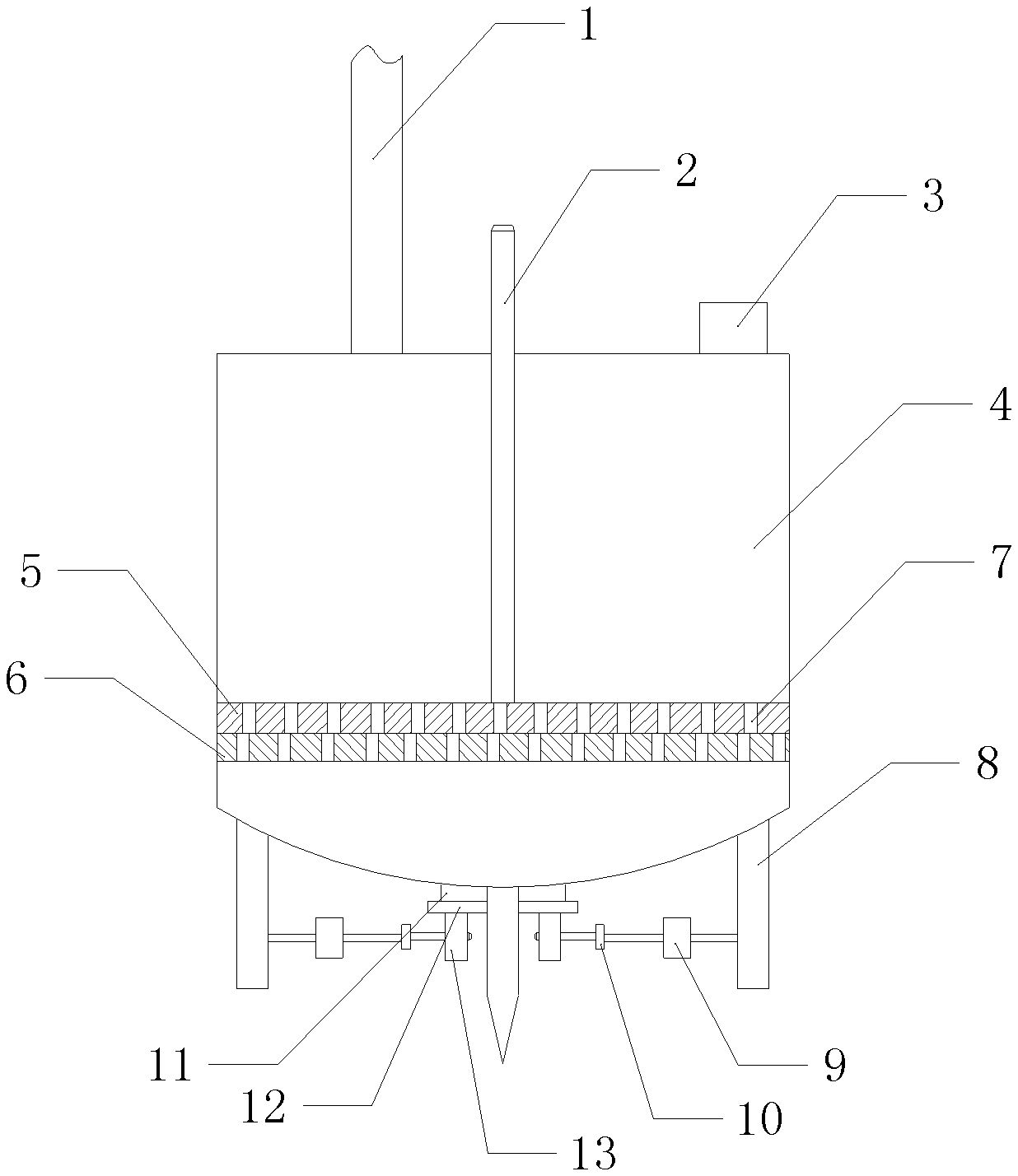

[0017] Among them: bracket 1, rotating shaft 2, oil injection pipe 3, oil box 4, upper oil baffle 5, lower oil baffle 6, oil hole 7, infrared sensor 8, PLC controller 9, motor 10, oil outlet pipe 11, rack 12. Gear 13.

[0018] Such as figure 1 As shown, the glass cutting tool of the present invention includes a bracket 1, an oil box 4 and a blade arranged sequentially from top to bottom, the upper end of the oil box 4 is provided with an oil filling pipe 3, and the lower end surface of the oil box 4 is a downwardly concave arc surface, The cross section of the oil box 4 is circular, the support 1 is welded to the eccentric place of the oil box 4 top, and the blade is welded to the center of the oil box 4 bottom.

[0019] The oil box 4 is horizontally provided with an upper oil baffle plate 5 and a lower oil baffle plate 6 with a circular cross section, and a group of oil holes 7 are arranged on the upper oil baffle plate 5 and the lower oil baffle plate 6, and the lower oil b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com