A rotary dust removal device

A dust removal device and rotary technology, which is used in the manufacture of converters, waste heat treatment, lighting and heating equipment, etc., can solve the problems of complex structure of the dust removal device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

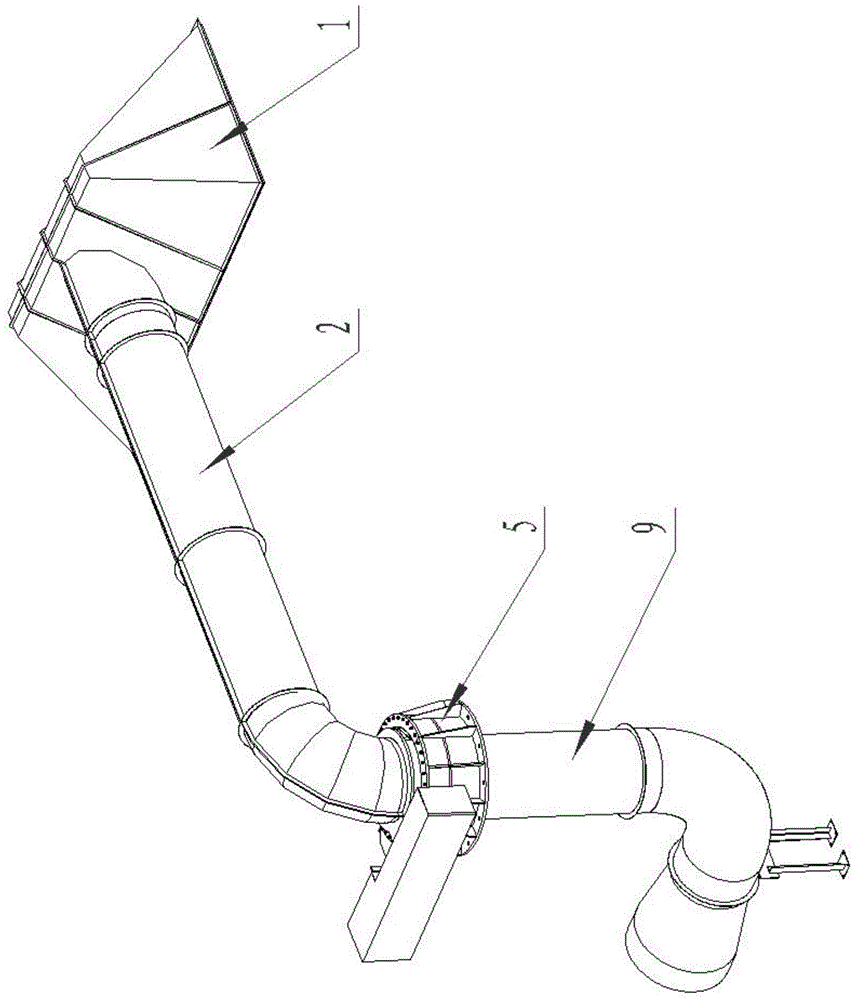

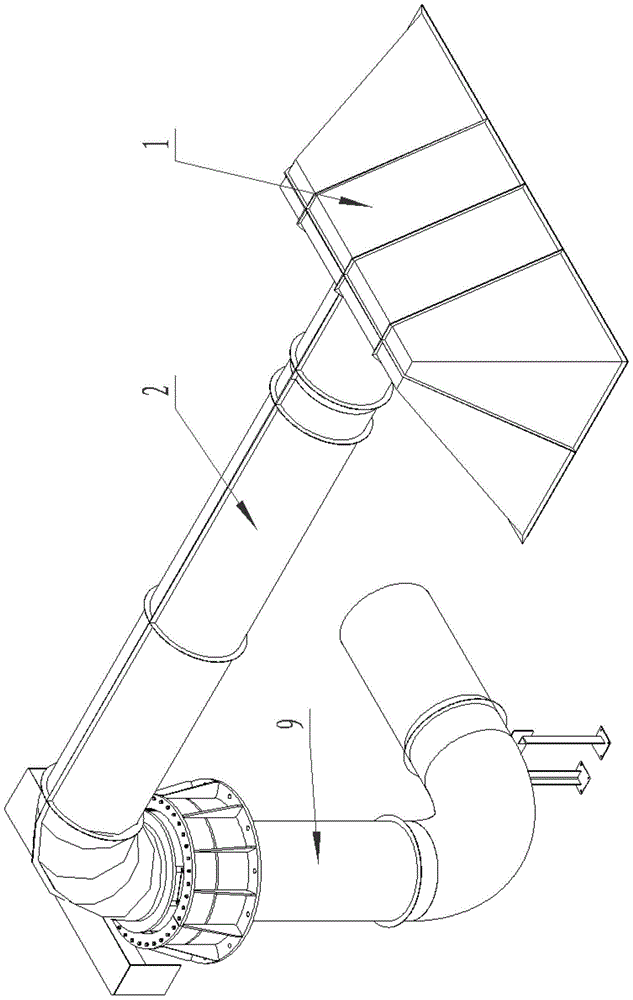

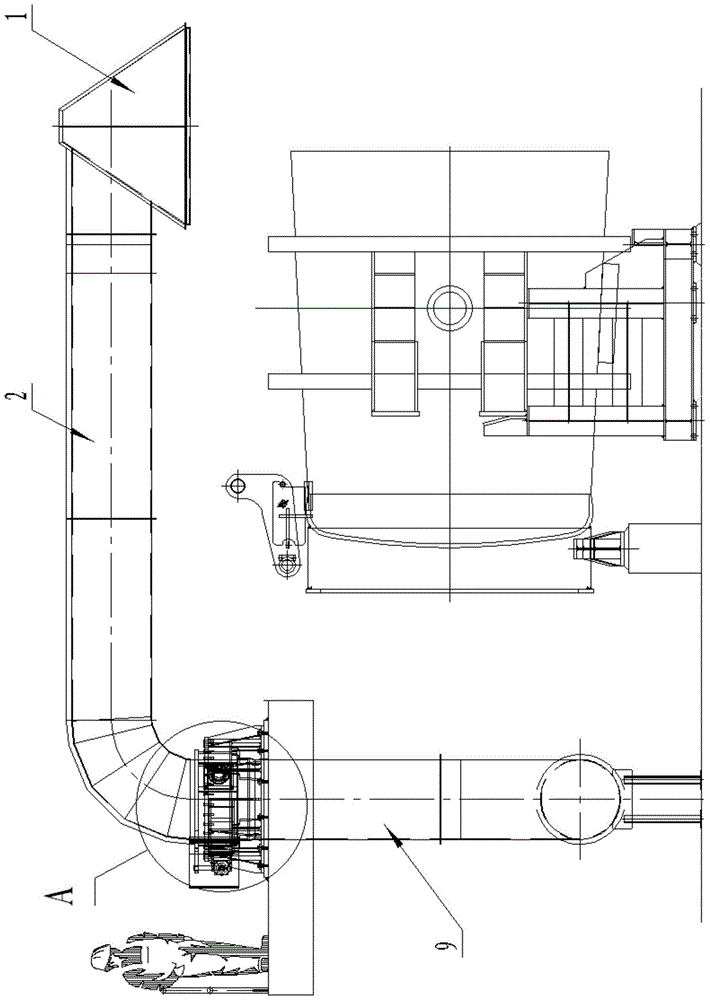

[0033] A rotary dust removal device, comprising a dust collection hood 1 and a dust suction pipe 2, the dust collection hood 1 and the dust collection pipe 2 are in communication, the rotary dust removal device also includes a drive mechanism and a guide mechanism, the drive mechanism can drive the dust suction The cover 1 and the dust suction pipe 2 rotate, and the guide mechanism can facilitate the rotation of the dust suction cover 1 and the dust suction pipe 2, and the guide mechanism is connected with the dust suction pipe 2, such as Figure 1 to Figure 3 shown.

[0034] The dust collection hood 1 has an opening and a conical cavity for gathering the high-temperature dust-laden fume emitted from scattered points. Go, due to the effect of the driving mechanism, the driving dust collection hood 1 and the dust collection pipe 2 can be flexibly rotated as required, so the rotary dust removal device has the advantages of simple structure and convenient operation. The rotary d...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, the difference is only in the specific implementation of the drive mechanism, in this embodiment, the drive mechanism includes a motor and a transmission assembly, and the transmission assembly contains a gear that can make the dust suction pipe 2 rotate For example, the outer fixed sleeve of the dust suction pipeline 2 is provided with a bull gear, and the output shaft of the motor is fixed with a pinion gear, and the rotation of the dust suction pipeline 2 driven by the motor is realized through the meshing of the pinion gear and the bull gear. Or, this transmission member contains the transmission belt that can make the dust suction pipe 2 rotate, such as the outer fixed sleeve of the dust suction pipe 2 is provided with a large gear, and the output shaft of the motor is fixed with a pinion, and the small gear and the large gear are driven by the transmission belt, thereby The rotation of the dust suction duct 2 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com