Connecting structure capable of being rapidly mounted and dismounted

A connecting mechanism and fast technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of inability to adapt to small spaces, slow installation process, time-consuming and laborious installation and disassembly, and achieve good anti-loosening effect, fast and convenient disassembly, and complex production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

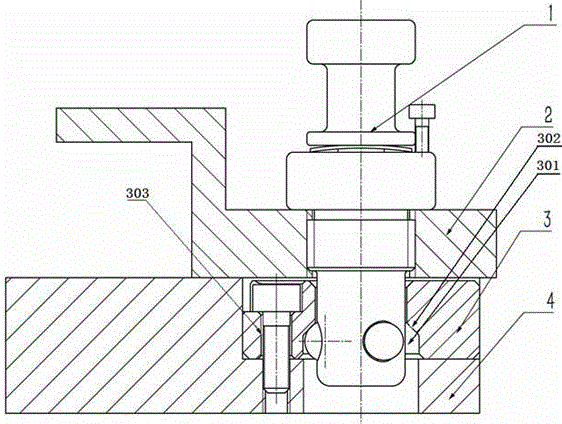

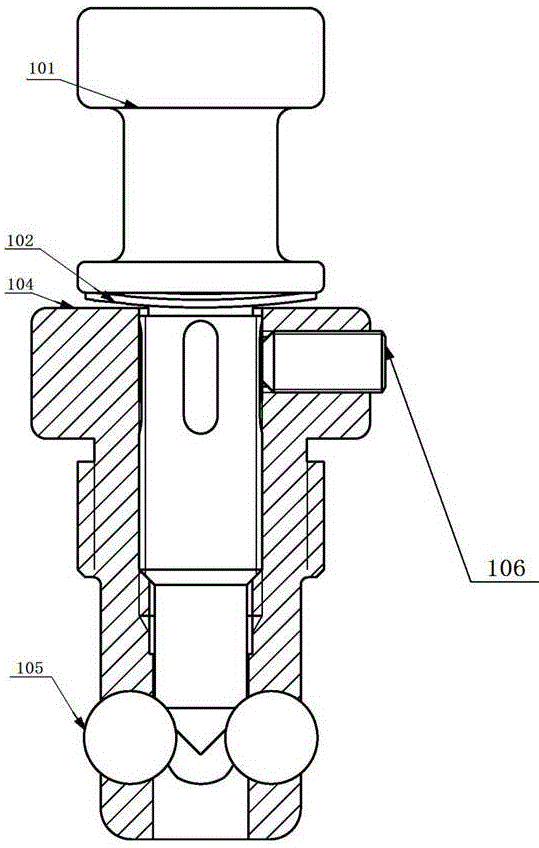

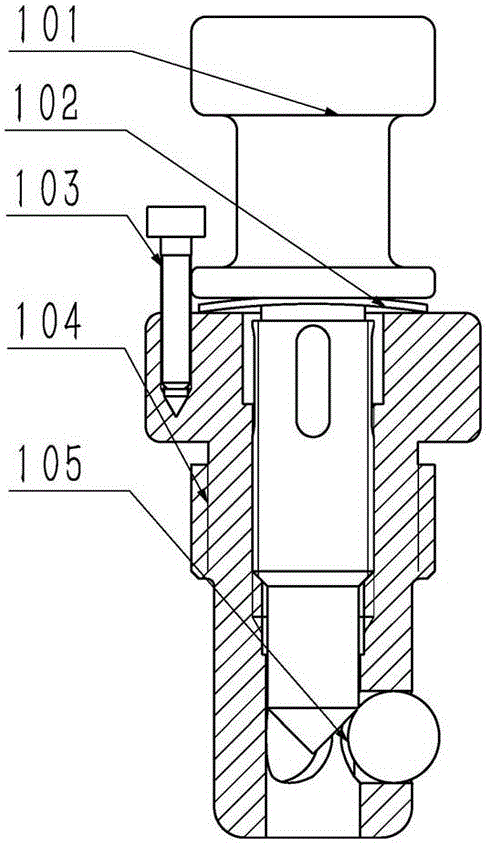

[0033] like figure 1 As shown, a connection mechanism that can be quickly installed and disassembled, including a locking pin 1 and a locking block 3, such as figure 2 and image 3 As shown, the locking pin 1 includes a pin shaft 101 and a pin sleeve 104 threaded on the lower part of the pin shaft 101. There are a number of through holes e evenly distributed around the axis below the bottom of the shaft. A steel ball 105 that can move freely but will not fall out is provided in each through hole e. The locking block 3 is provided with a connecting hole and a container. Cavity 301, the connecting hole is located on the top surface of the locking block 3 and its bottom communicates with the top of the cavity 301, the top surface of the cavity 301 is a tapered surface 302; during installation, the pin sleeve 104 and the locking block 3 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com