Two-way pipe joint and two-way pipe joint assembly

A technology for connecting pipes and components, applied in the direction of pipes/pipe joints/fittings, passing elements, hose connection devices, etc., can solve problems such as unreliable locking, hidden safety hazards and damage of tracheal connection devices and parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

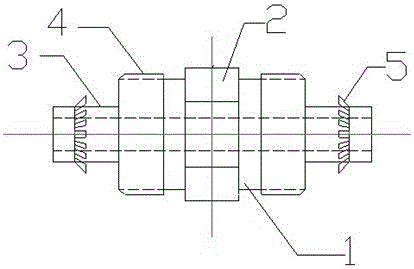

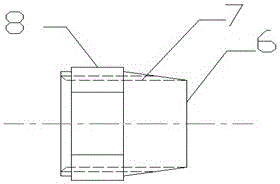

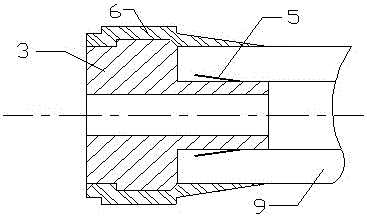

[0019] The structural diagram of an embodiment of a two-way pipe joint assembly of a pipe joint assembly is as follows Figure 1-3 As shown: it includes two-way pipe joints and two fastening nuts 6 with the same structure for locking the connecting pipes. The two ends of the main body 1 are symmetrically provided with connecting pipe sleeves 3 for socketing the connecting pipes, the connecting pipe sleeves 3 are arranged coaxially with the main body, and two connecting pipe sleeves 3 are respectively provided with a group for blocking the connecting pipes to prevent The shedding elastic barbed steel sheet 5 is fixed on the connecting pipe sleeve 3 along the circumference and in the direction inclined to the center of the connecting pipe two-way joint main body 1, and the middle of the two-way pipe joint main body 1 is provided with a main body The outer hexagonal fastener 2, the two sides of the main body outer hexagonal fastener 2 are symmetrically provided with two external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com