Apparatus and method of measuring eccentric throw of crankshaft

A technology of measuring device and eccentricity, applied in the direction of measuring device, mechanical measuring device, adopting mechanical device, etc., can solve problems such as waste, achieve the effect of saving production cost and solving difficult detection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

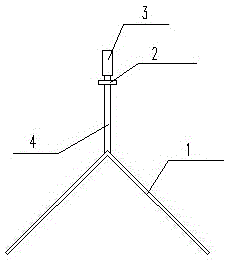

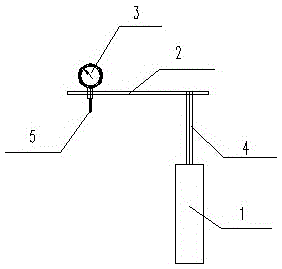

[0025] Such as figure 1 , figure 2 As shown, a crankshaft eccentricity measuring device includes a 90-degree V-shaped positioning block 1, a measuring cantilever 2, a dial indicator 3, and a connecting rod 4. The 90-degree V-shaped positioning block 1 is connected to one end of the measuring cantilever 2 through the connecting rod 4 Below, the other end of the measuring cantilever 2 is provided with a dial indicator 3, and a dial indicator contact 5 is provided under the dial indicator 3.

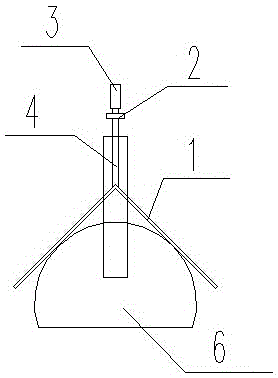

[0026] Use as figure 1 with figure 2 After the crankshaft eccentricity measuring device shown measures the eccentricity of the A-type crankshaft, when the same crankshaft eccentricity measuring device is used to measure the eccentricity of the B-type crankshaft of different crankshafts, as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the specific implementation steps are as follows: including the eccentricity measuring device, the reference block 6 of the A...

Embodiment 2)

[0033] Such as figure 1 with figure 2 As shown, a crankshaft eccentricity measuring device includes a 90-degree V-shaped positioning block 1, a measuring cantilever 2, a dial indicator 3, and a connecting rod 4. The 90-degree V-shaped positioning block 1 is connected to one end of the measuring cantilever 2 through the connecting rod 4 Below, the other end of the measuring cantilever 2 is provided with a dial indicator 3, and a dial indicator contact 5 is provided under the dial indicator 3.

[0034] Use as figure 1 with figure 2 After the crankshaft eccentricity measuring device shown measures the eccentricity of the A-type crankshaft, when the same crankshaft eccentricity measuring device is used to measure the eccentricity of the B-type crankshaft of different crankshafts, as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the specific implementation steps are as follows: including the eccentricity measuring device, the reference block 6 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com