Roller cutter with improved sealing

A technology of hob and retainer, which is applied in drilling equipment, earthwork drilling, drill bits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The characteristics and advantages of the present invention can be better understood by reading the following detailed description in conjunction with the accompanying drawings. In the accompanying drawings, similar reference numerals indicate similar components, and in the accompanying drawings:

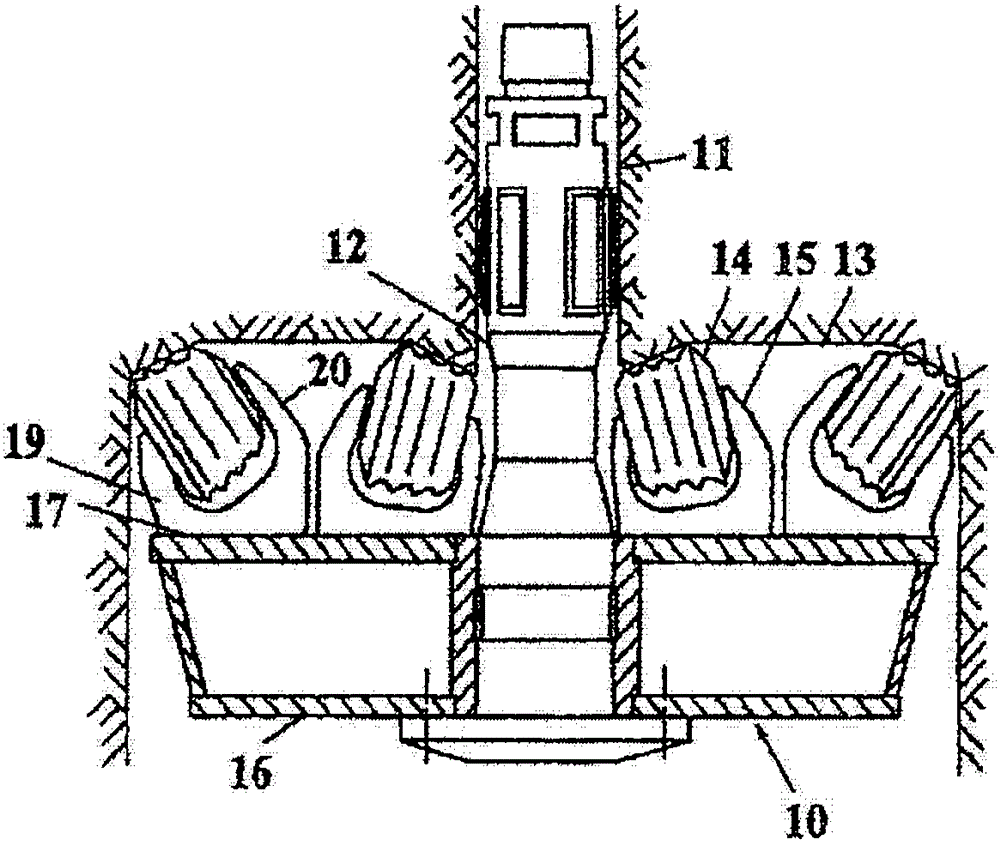

[0012] figure 1 Shows how the pilot hole 11 is drilled. The pilot hole is drilled between the upper ore bed and the lower ore bed using the existing method. The upper and lower ore beds are not shown in the figure. The pilot hole is drilled by the drill bit 10. Into. The drill bit 10 is connected to a driving rod 12, by means of the driving rod 12, the drill bit rotates and presses against the annular surface 13 around the pilot hole 11. The surface 13 thus defines the surface of the earth formation.

[0013] The present invention relates generally to formation drilling, but mainly to raise hole drilling. When drilling a raise hole, first drill a certain distance between the upp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap