Spiral pressurization lock-in synchronism bone plate and application method thereof

A technology for synchronously locking and bone-synthesizing plates, applied in the direction of outer plates, fixators, and internal bone synthesis, which can solve problems such as time-consuming, labor-intensive fit, and disorderly buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

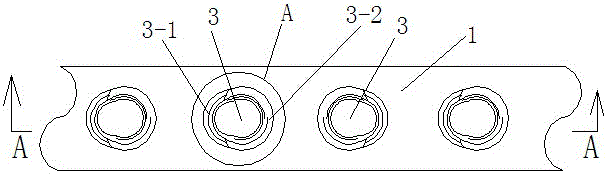

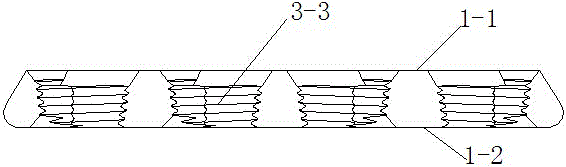

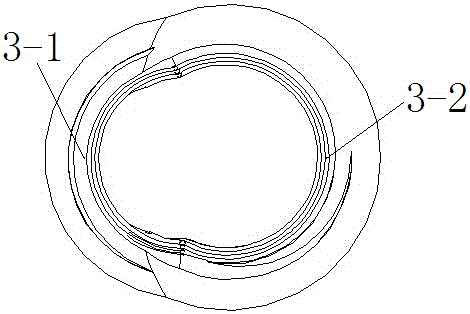

[0020] Figure 1-5 As an embodiment of the present invention, this embodiment is specifically described in conjunction with the accompanying drawings, including a bone plate body 1 and screws 2, the bone plate body 1 has a top surface 1-1 and a bottom surface 1-2 for the bone bone A group of oblong pressurized through-holes 3 arranged along the direction of its longitudinal axis are arranged on the bone plate body 1. The pressurized through-holes 3 can be straight holes or tapered holes. The pressurized through-holes 3 Connect the top surface 1-1 and the lower surface 1-2, one side of the pressurized through hole 3 is the initial end 3-1 for pressurization and the other side is the terminal end 3-2 for pressurization, the pressurized through hole 3 The upper part facing the top surface 1-1 has a groove to form a counterbore. The groove is a spherical expansion groove or a tapered groove formed by chamfering. 1 to the integral continuous thread 3-3 at the terminal end 3-2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com