Shifting fork press fitting resetting block pneumatic tool for automotive combined switch

A combination switch and pneumatic tooling technology, applied in metal processing, manufacturing tools, vehicle parts, etc., can solve the problems of low product qualification rate and high labor intensity, and achieve the effect of improving the qualification rate, improving work efficiency and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

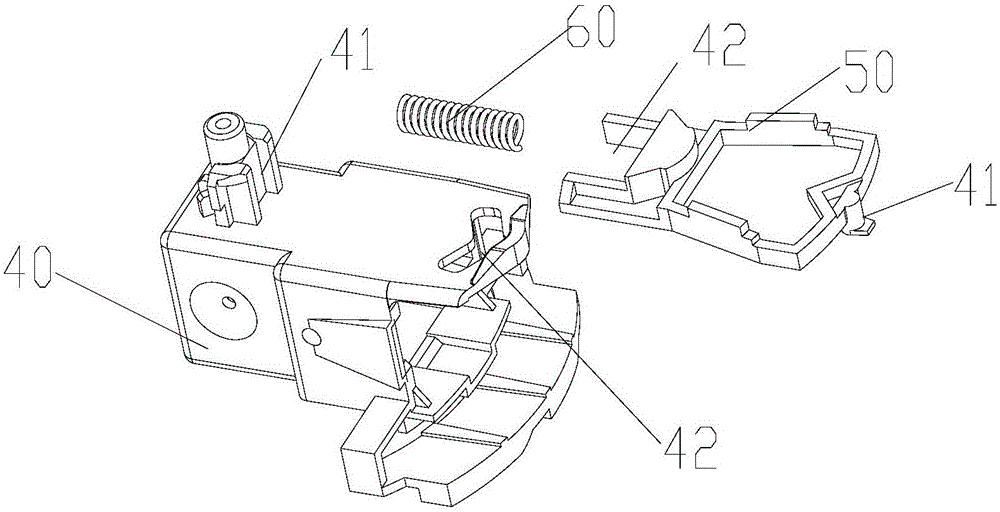

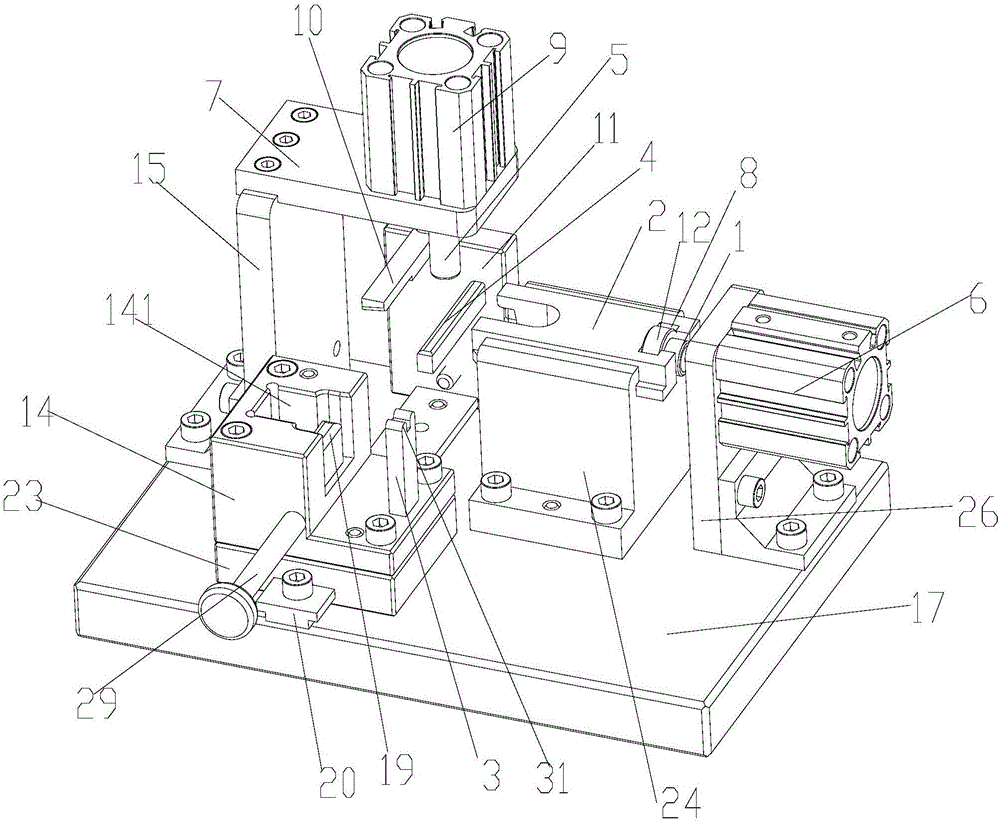

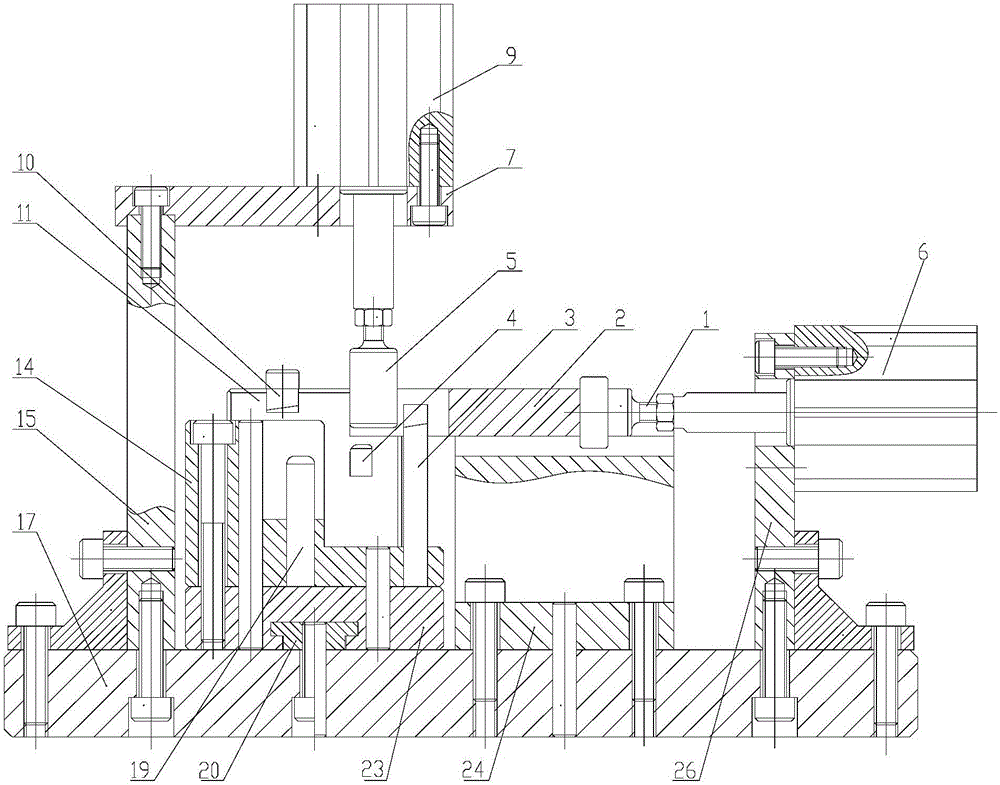

[0015] Examples such as Figures 1 to 3 As shown, a pneumatic tooling for pressing the reset block of a combination switch fork of an automobile includes a bottom plate 17 on which a positioning plate 14 for fixing the shift fork is provided, and a top block 2 and a top block for pushing out the reset block are also provided. The first cylinder 6 that controls the movement of the top block is also provided with the final shaft 5 that presses the reset block and the second cylinder 9 that controls the vertical movement of the final shaft.

[0016] Specifically, the left rear of the bottom plate 17 is fixedly provided with a vertical plate 15, and the vertical plate 15 is bolted and fixed with a horizontally arranged second cylinder fixing plate 7, on which the second cylinder fixing plate 7 is provided with the second cylinder 9, the second cylinder fixing plate 7 The two cylinders 9 are connected with a vertically downward finale shaft 5 . The right rear of the base plate 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com