Omni-directional motion spherical robot

A spherical robot, all-round technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of limited spherical robot motion performance, limited robot motion performance, eccentric drive torque, etc., to achieve easy engineering realization, simple structure, The effect of simple mechanism principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

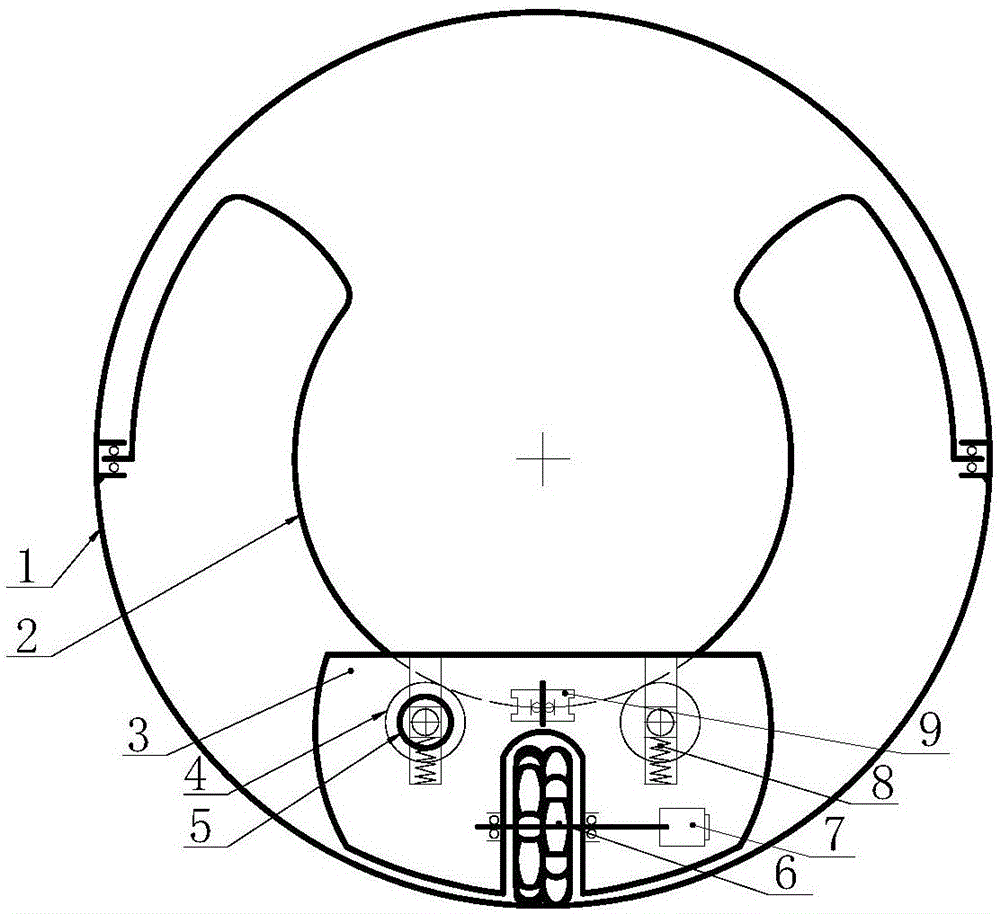

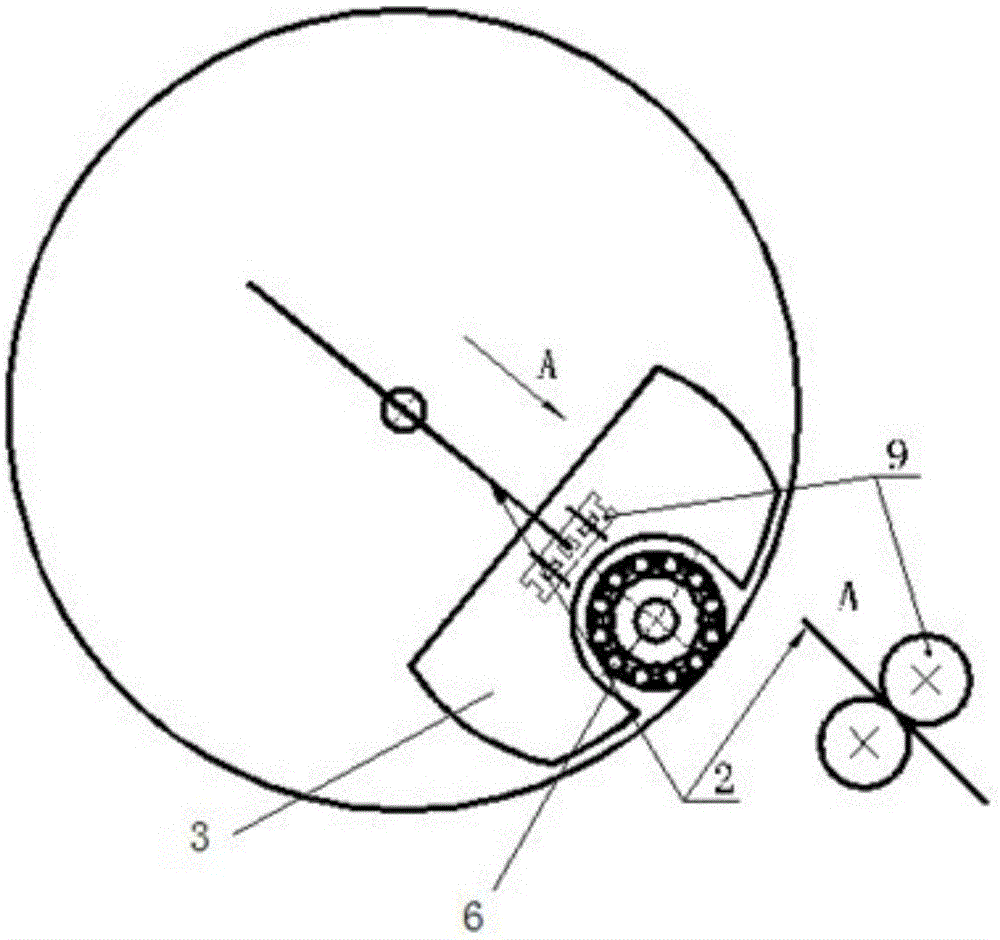

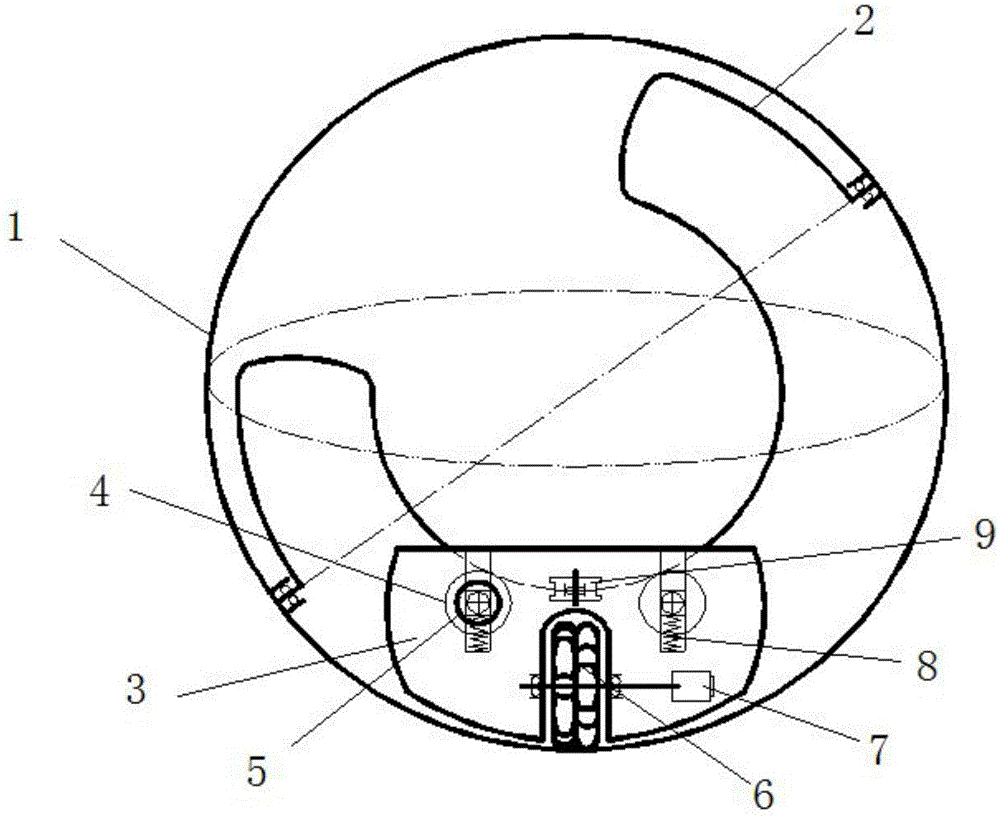

[0031] In order to solve the above-mentioned shortcoming of the prior art, the embodiment of the present invention designs a kind of omni-directional motion spherical robot, such as Figure 1 to Figure 3 As shown, it includes spherical shell 1, arc rail 2, frame 3, rail wheel 4, omnidirectional wheel 6 and guide wheel 9; arc rail 2 is set in spherical shell 1, and both ends of arc rail 2 pass through and support coaxially On the diameter of spherical shell 1; Frame 3 is located in spherical shell 1, and the top of frame 3 is supported on arc track 2 by rail wheel 4 and guide wheel 9; Omnidirectional wheel 6 is installed in the bottom of frame 3.

Embodiment 2

[0033] In order to solve the above-mentioned shortcoming of the prior art, the embodiment of the present invention designs a kind of omni-directional motion spherical robot, such as Figure 1 to Figure 3 As shown, it includes spherical shell 1, arc rail 2, frame 3, rail wheel 4, omnidirectional wheel 6 and guide wheel 9; arc rail 2 is set in spherical shell 1, and both ends of arc rail 2 pass through and support coaxially On the diameter of spherical shell 1; Frame 3 is located in spherical shell 1, and the top of frame 3 is supported on arc track 2 by rail wheel 4 and guide wheel 9; Omnidirectional wheel 6 is installed in the bottom of frame 3. The frame 3 also includes two rail wheels 4, two guide wheels 9, a steering motor 5, a travel motor 7 and a spring 8; the rail wheels 4 are arranged in the frame 3 along the outer circumference of the arc rail 2; the guide wheels 9 Arranged in the frame 3 on the front and rear sides of the arc rail 2; the steering motor 5 is arranged o...

Embodiment 3

[0035] In order to solve the above-mentioned shortcoming of the prior art, the embodiment of the present invention designs a kind of omni-directional motion spherical robot, such as Figure 1 to Figure 3 As shown, it includes spherical shell 1, arc rail 2, frame 3, rail wheel 4, omnidirectional wheel 6 and guide wheel 9; arc rail 2 is set in spherical shell 1, and both ends of arc rail 2 pass through and support coaxially On the diameter of spherical shell 1; Frame 3 is located in spherical shell 1, and the top of frame 3 is supported on arc track 2 by rail wheel 4 and guide wheel 9; Omnidirectional wheel 6 is installed in the bottom of frame 3. The frame 3 also includes two rail wheels 4, two guide wheels 9, a steering motor 5, a travel motor 7 and a spring 8; the rail wheels 4 are arranged in the frame 3 along the outer circumference of the arc rail 2; the guide wheels 9 Arranged in the frame 3 on the front and rear sides of the arc rail 2; the steering motor 5 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com