Cold accumulation packing bag

A packaging bag, cold storage technology, applied in packaging, transportation and packaging, bags and other directions, can solve the problems of consumers being unable to touch and use, the thickness of the cold storage plate, the free transfer of items, etc., to meet the needs of low-temperature storage and transportation, reduce heat Swap speed, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and examples.

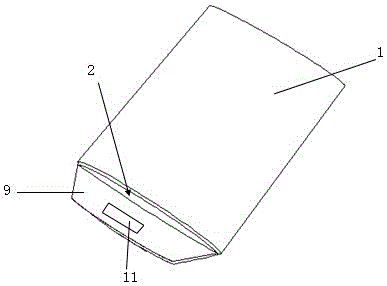

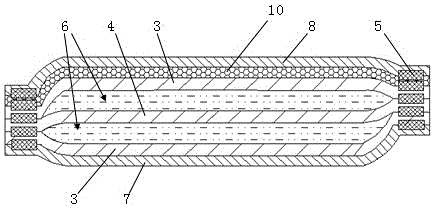

[0019] Such as Figure 1 to Figure 2 As shown, the cold storage packaging bag of the present invention includes a bag tube formed by the bag wall 1, and a storage space 2 is formed in the bag tube. and the outer wall layer 8; two cold storage layers are arranged side by side and separated from each other, each of the cold storage layers includes the outer outer membrane 3 and the inner outer membrane 4 respectively, and the heat sealing line 5 formed by hot pressing between the outer outer membrane and the inner outer membrane For welding, a plurality of liquid storage chambers 6 separated from each other and filled with cold storage agent are arranged between the heat sealing lines; the inner wall layer, outer wall layer, outer outer film and inner outer film of the edge of the bag wall are welded by heat sealing lines formed by hot pressing. A cold insulation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com