Furrowing machine

A technology of trenchers and tractors, which is applied in the direction of digging/covering ditches, tillage implements, earth movers/shovels, etc. It can solve problems such as laborious, shallow and deep, and difficult to control, so as to achieve convenient operation and ensure The effect of deep consistency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

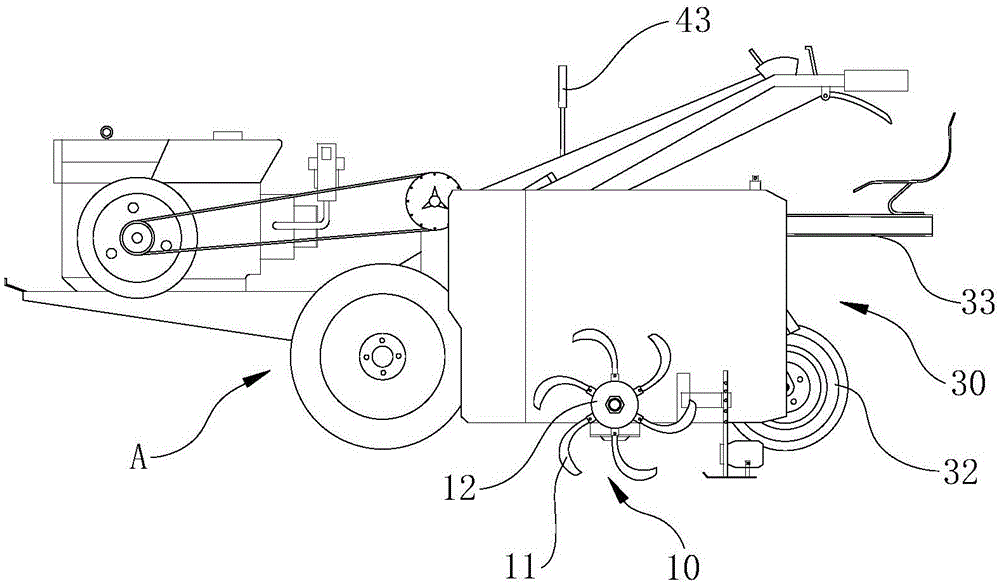

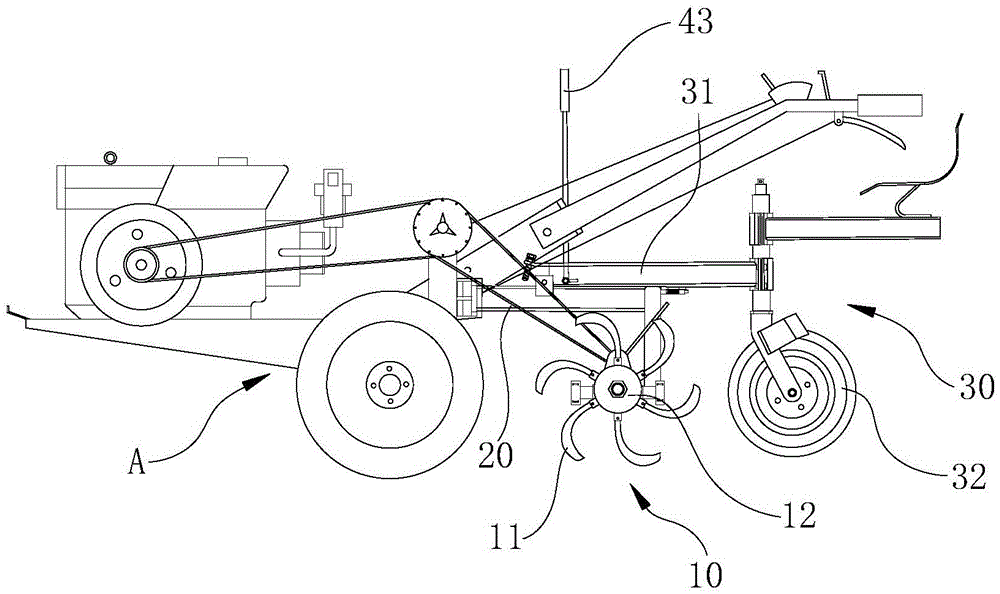

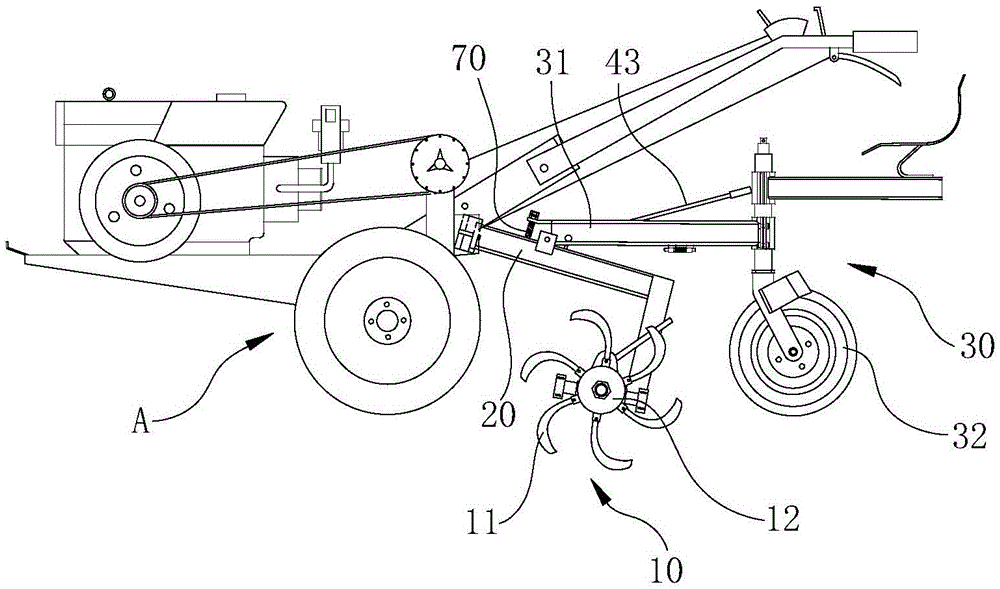

[0017] combine Figure 1 to Figure 11 , the present invention is further described:

[0018] A trencher, comprising a cutter assembly 10, the cutter assembly 10 includes a blade 11 and a cutter head seat 12 that fixes the blade 11, a drive mechanism connected to the cutter head seat 12 drives the cutter head seat 12 to rotate, and the cutter head seat 12 rotates Type is fixedly connected on the cutter assembly support 20, and the cutter assembly support 20 is connected with the tractor, and an adjustment mechanism is set between the tractor and the cutter assembly support 20, and the adjustment mechanism is used to adjust the height of the cutter head seat 12 up and down.

[0019] Utilize the adjustment mechanism arranged between the tractor A and the tool assembly bracket 20 to solve the disadvantage that the traditional trencher cannot adjust the cutter head seat 12 of the cutter assembly 10 up and down. The adjustment mechanism adjusts the cutter head seat 12 up and down T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com