Cambered surface and plane sealed variable tooth wide wedge-type coupling structure and oil well pipe structure

A technology of flat sealing and oil well pipe, which is applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems that cannot meet the requirements of oil field production and use, and achieve the improvement of product quality and work efficiency, sealing performance and connection strength, The effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments.

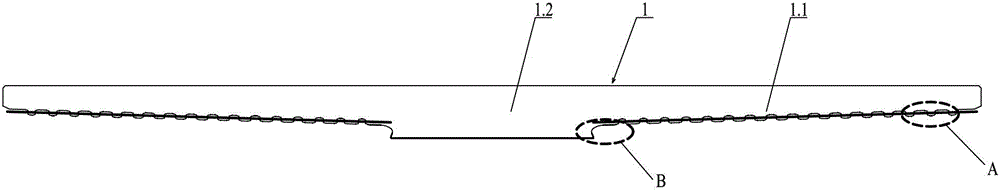

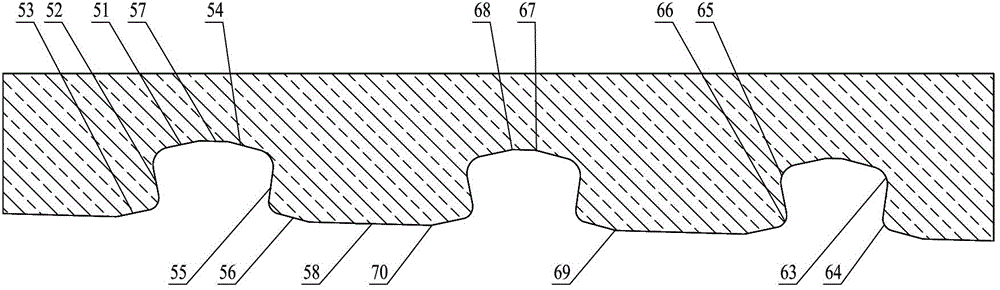

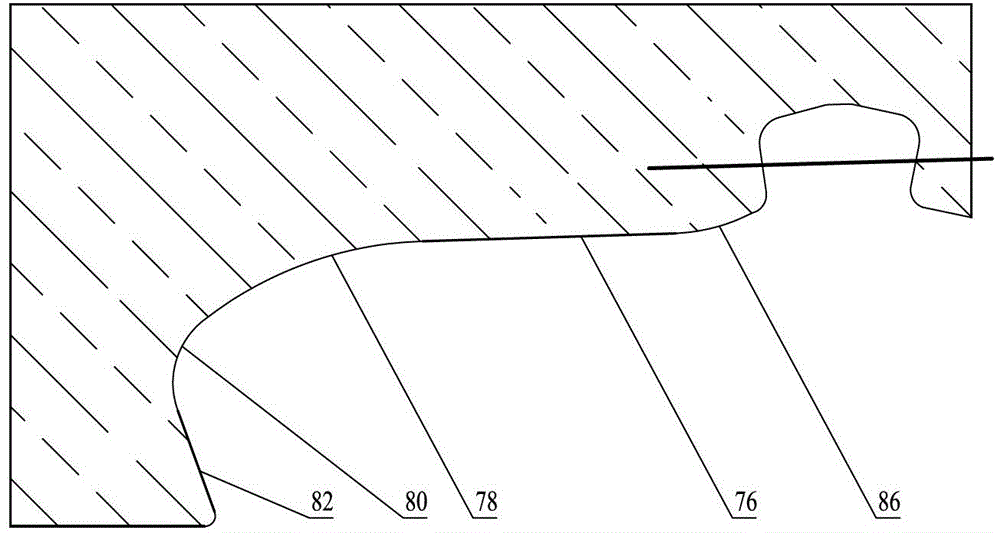

[0033] A curved and flat sealing variable-tooth width wedge coupling structure, comprising a coupling body 1. The inner walls of the two ends of the coupling body 1 are a coupling internal thread section 1.1, between the two coupling internal thread sections 1.1 A coupling shoulder 1.2 is provided; from the two ends of the coupling body 1 to the middle of the direction, the tooth width of the internal thread section 1.1 of the coupling is gradually increased, and the tooth groove of the internal thread section 1.1 of the coupling The width is gradually reduced. The difference between the width of two adjacent teeth is equal to the width of the adjacent two tooth grooves. The height of each tooth of the internal thread section 1.1 of the coupling is equal, and the taper of the internal thread section 1.1 of the coupling is 1:16 ~1:24; On the longitudinal section of the coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com