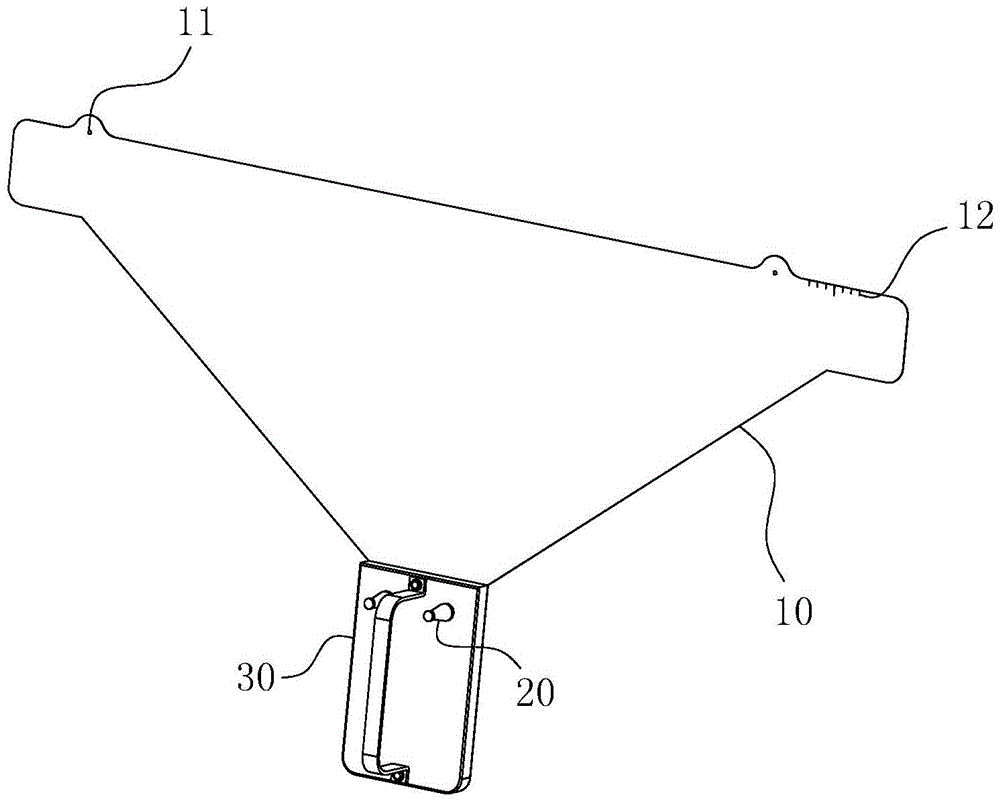

A target paper positioning device and a target paper positioning method using the device

A positioning device and target paper technology, applied in the direction of targets and attack equipment, can solve the problems of increasing the complexity of the use of target reporting devices, errors in target paper production, installation skew, etc., to achieve precise positioning requirements, ensure accuracy and speed The effect of sexiness and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

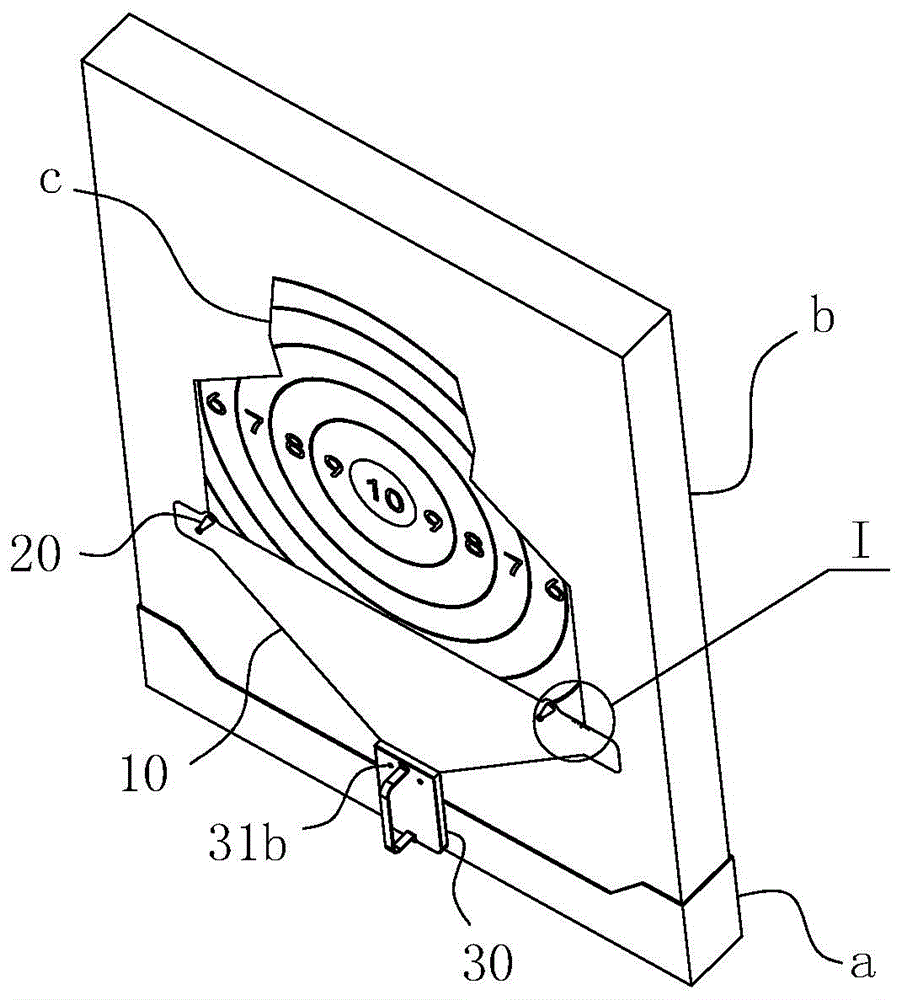

[0041] When the target paper size is smaller than the standard target paper size:

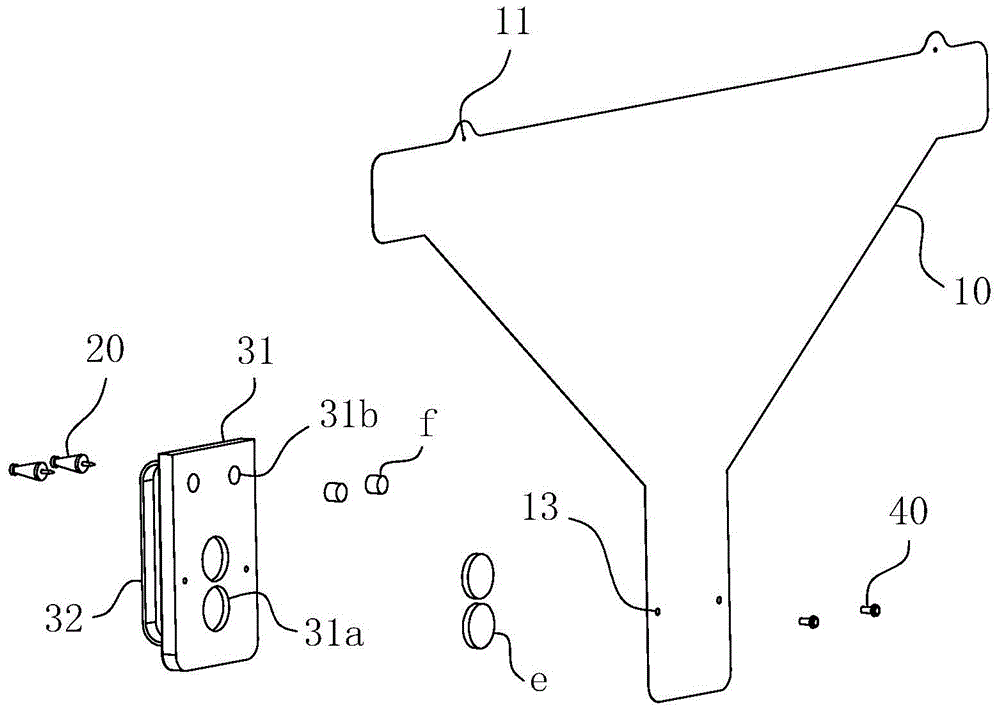

[0042] 1) Align the positioning point on the positioning target with the pin hole on the target surface of the target frame to realize the two-point positioning of the positioning target based on the target surface of the target frame;

[0043] 2) Take out the target paper, align the lower edge of the target paper with the upper edge of the positioning target plate, and ensure that one corner of the target paper is just in one of the positioning holes; use the plunger to align one side of the target paper Insert the positioning hole at the corner end and fix it, and continue to insert the inserting rod to fix another positioning hole on the target paper;

[0044] 3) Preliminarily paste and fix the target paper;

[0045] 4) According to the possible size difference of the target paper, after aligning and fixing the upper edge of the positioning target plate along the lower line of the target pa...

Embodiment 2

[0048] When the target paper is the standard target paper size:

[0049] 1) Align the positioning point on the positioning target with the pin hole on the target surface of the target frame to realize the two-point positioning of the positioning target based on the target surface of the target frame;

[0050] 2) Take out the target paper, align the lower edge of the target paper with the upper edge of the positioning target plate, and ensure that one corner of the target paper is just in one of the positioning holes; use the plunger to align one side of the target paper Insert the positioning hole at the corner end and fix it, and continue to insert the inserting rod to fix another positioning hole on the target paper;

[0051] 3) Preliminarily paste and fix the target paper;

[0052] 4) Read the deviation of the scale line on the positioning target based on the zero point of the scale, and find that the zero point of the scale on the positioning target is completely aligned ...

Embodiment 3

[0055] When the target paper size is larger than the standard target paper size:

[0056] 1) Align the positioning point on the positioning target with the pin hole on the target surface of the target frame to realize the two-point positioning of the positioning target based on the target surface of the target frame;

[0057] 2) Take out the target paper, align the lower edge of the target paper with the upper edge of the positioning target plate, and ensure that one corner of the target paper is just in one of the positioning holes; use the plunger to align one side of the target paper Insert the positioning hole at the corner end and fix it, and continue to insert the inserting rod to fix another positioning hole on the target paper;

[0058] 3) Preliminarily paste and fix the target paper;

[0059] 4) According to the possible size difference of the target paper, after aligning and fixing the upper edge of the positioning target plate along the lower line of the target pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com