Method and device for quick treatment of boiler fan vibration failure

A fan and fault technology is applied in the field of quickly dealing with the vibration fault of the boiler fan, so as to reduce the number of starts and stops and shorten the load-limited running time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

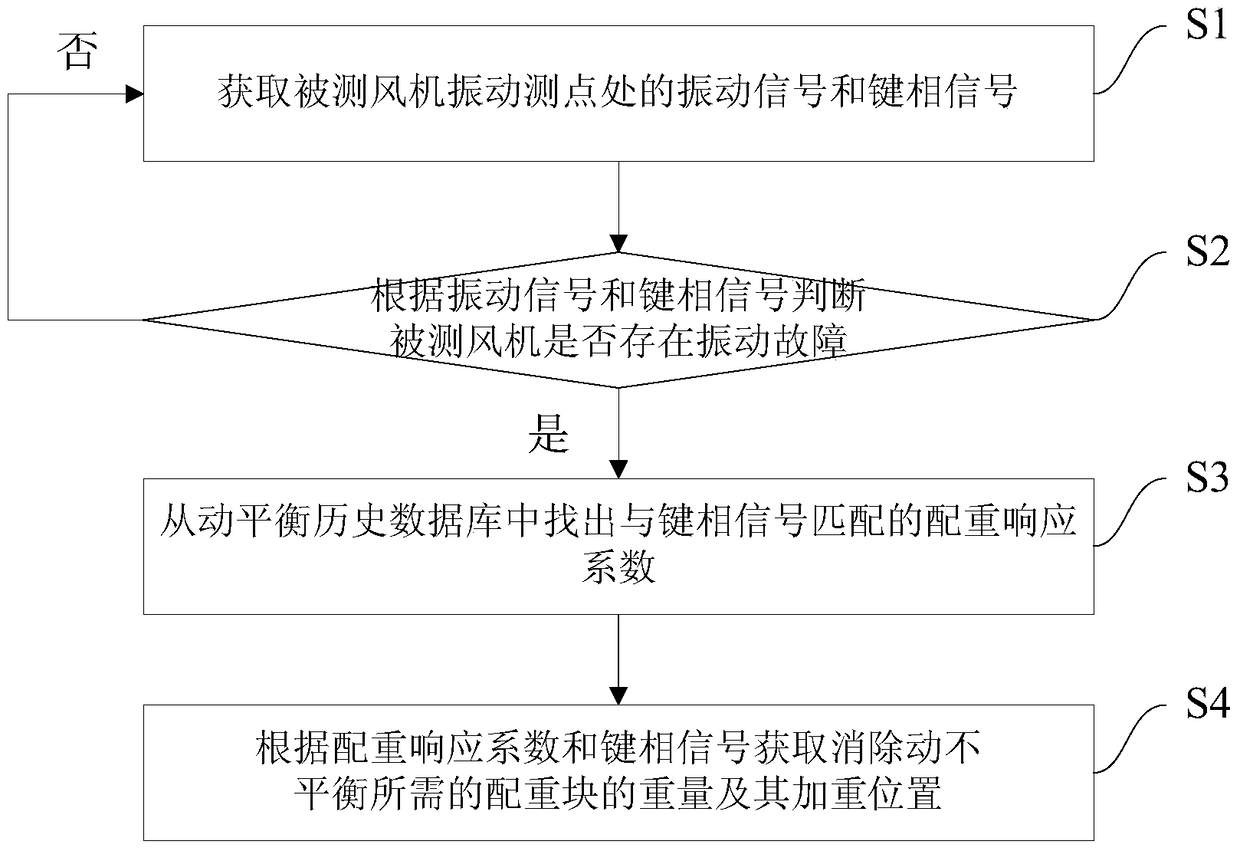

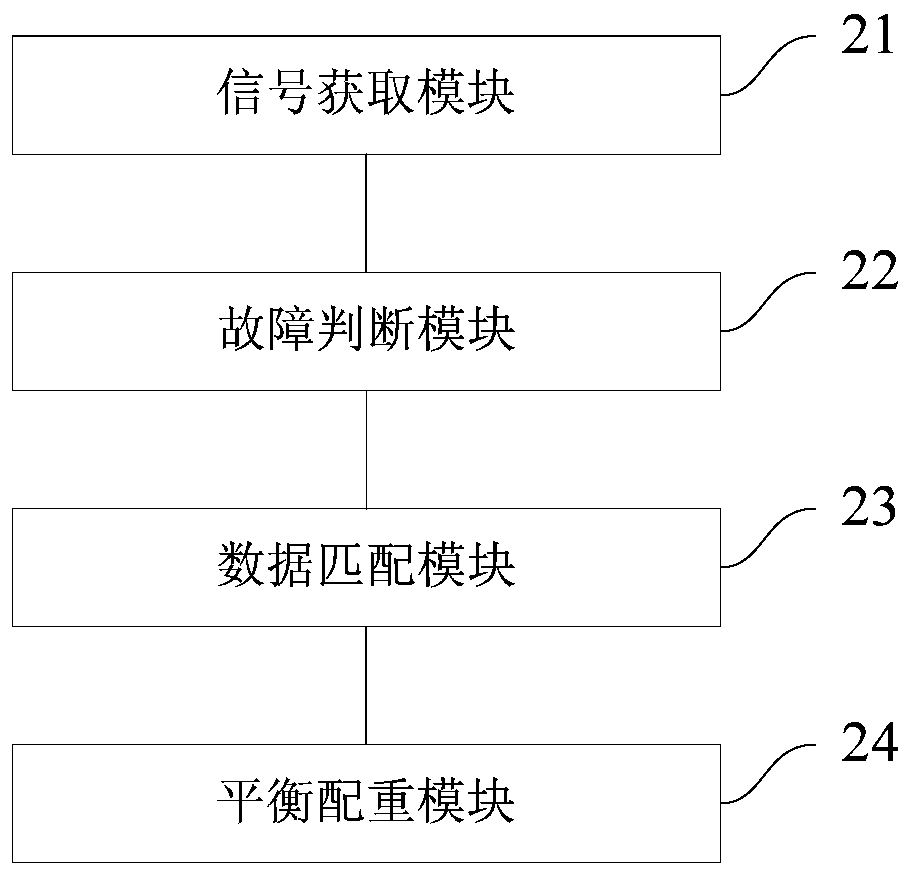

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0047] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0048] In the embodiment of the present invention, key phase grooves should be turned in advance on the fan shaft of the fan to be tested. The width of the key phase grooves is not less than 8 mm, the length is about 40 mm, and the depth is not less than 2 mm. The key phase sensor is fixedly installed at the position corresponding to the key phase slot, then the characterization method of the power frequency amplitude / phase of the abnormal vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com