Patents

Literature

38results about How to "Reduce yaw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

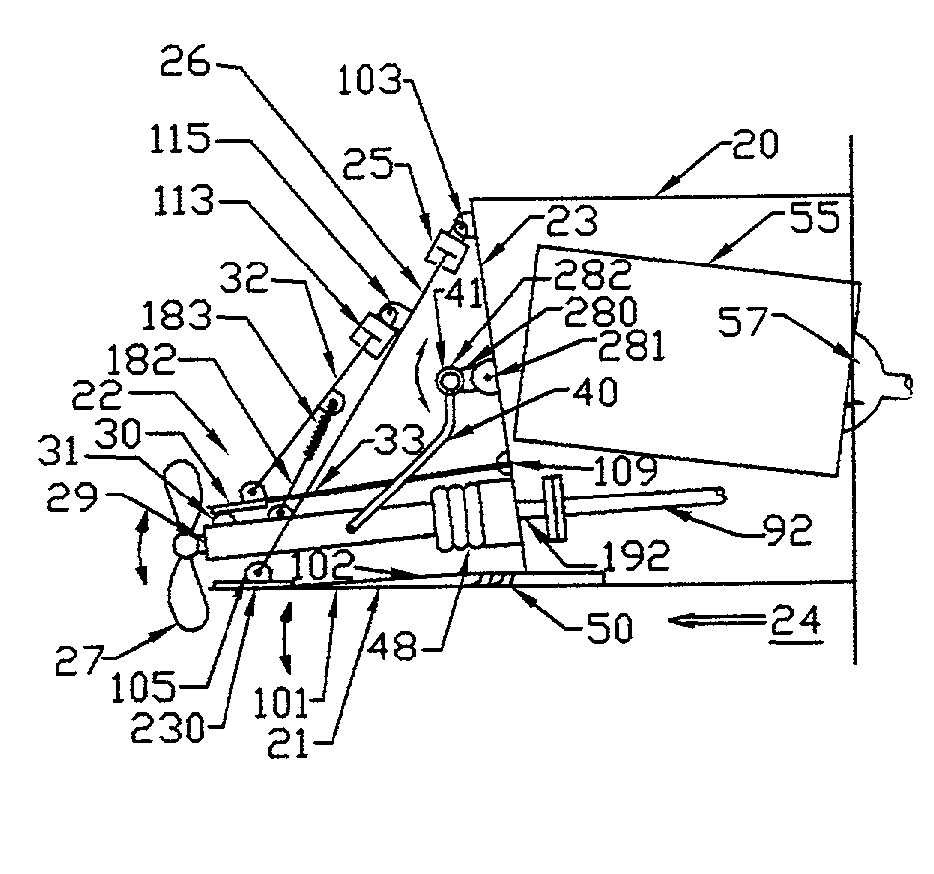

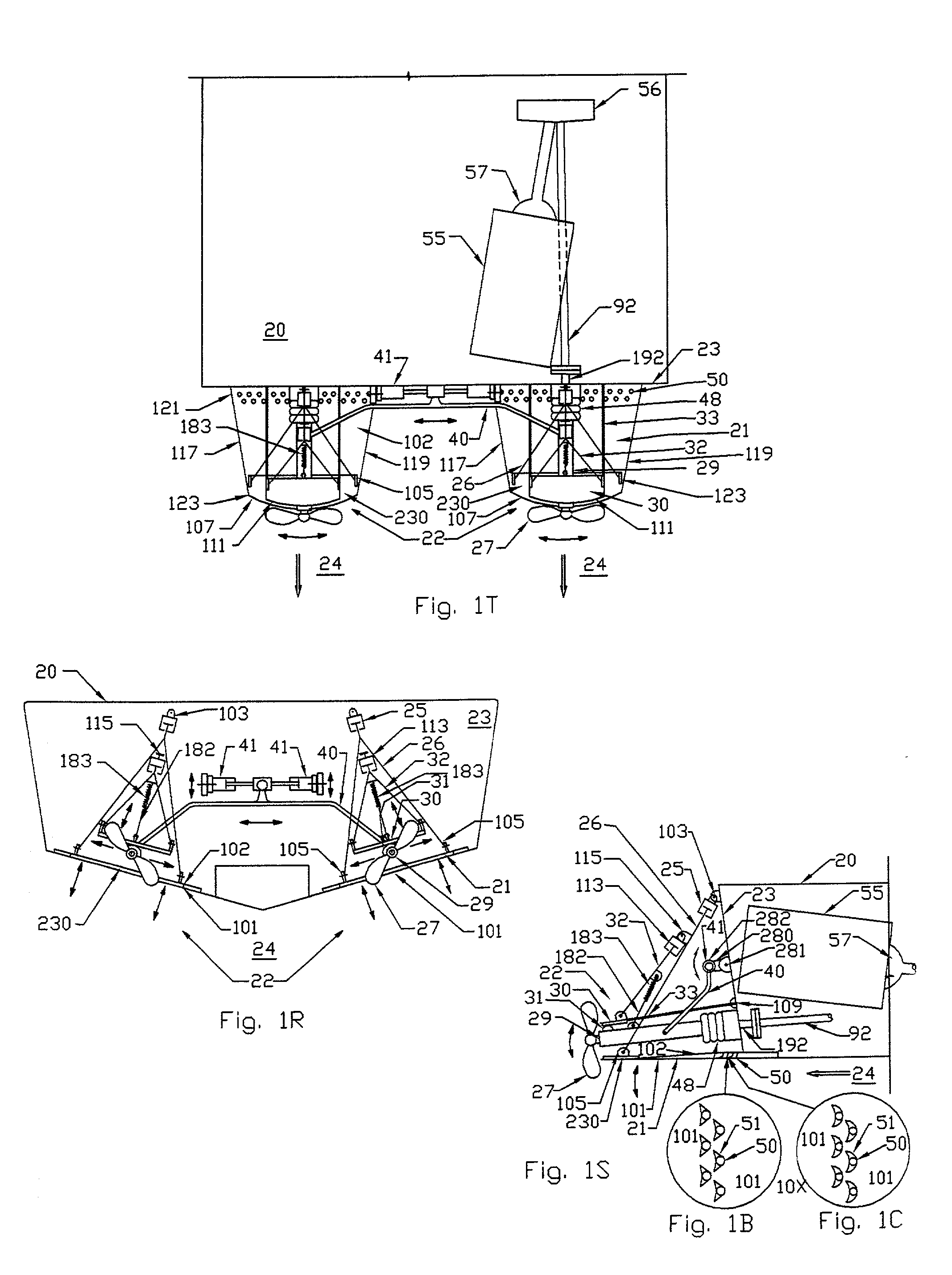

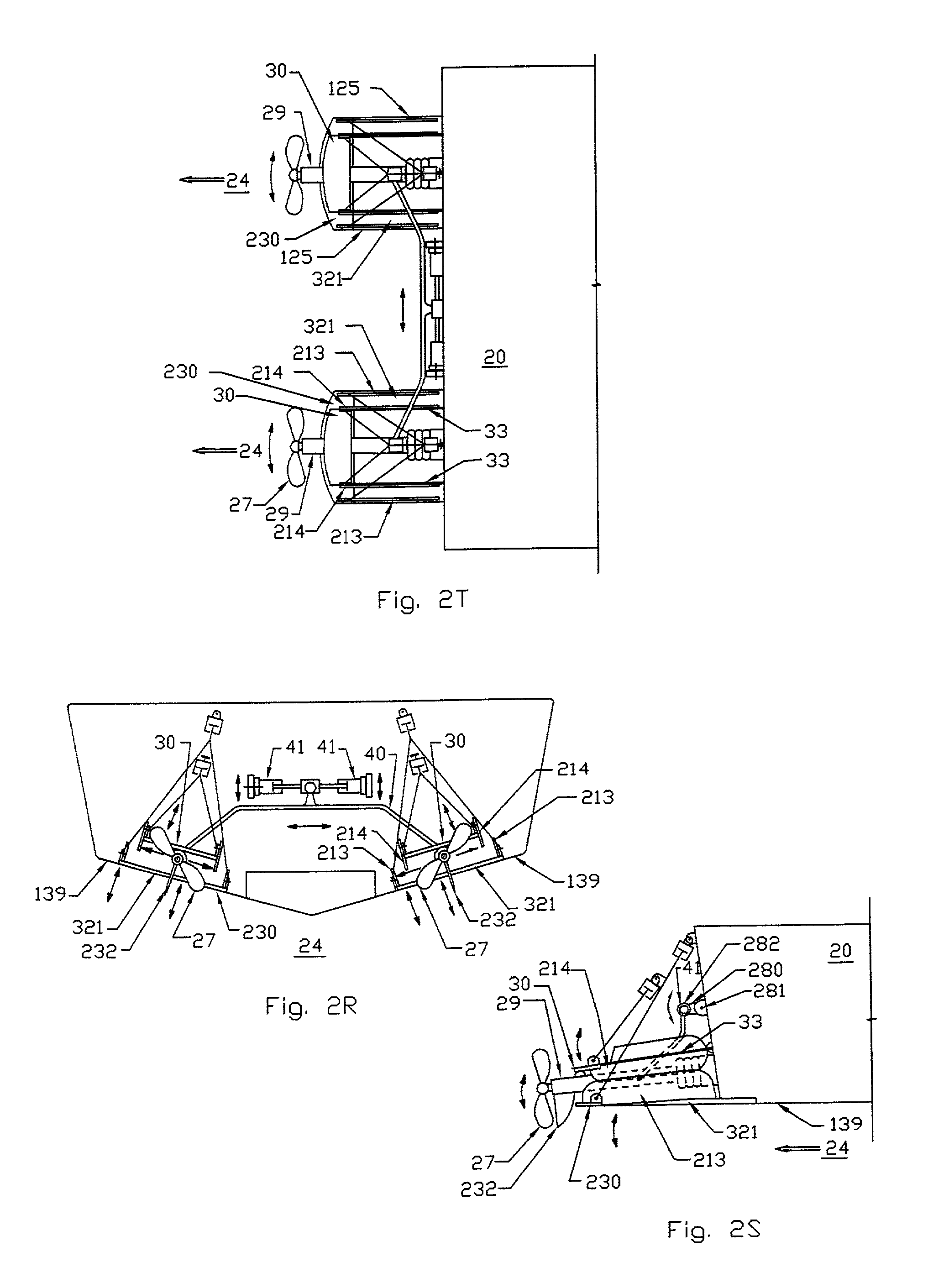

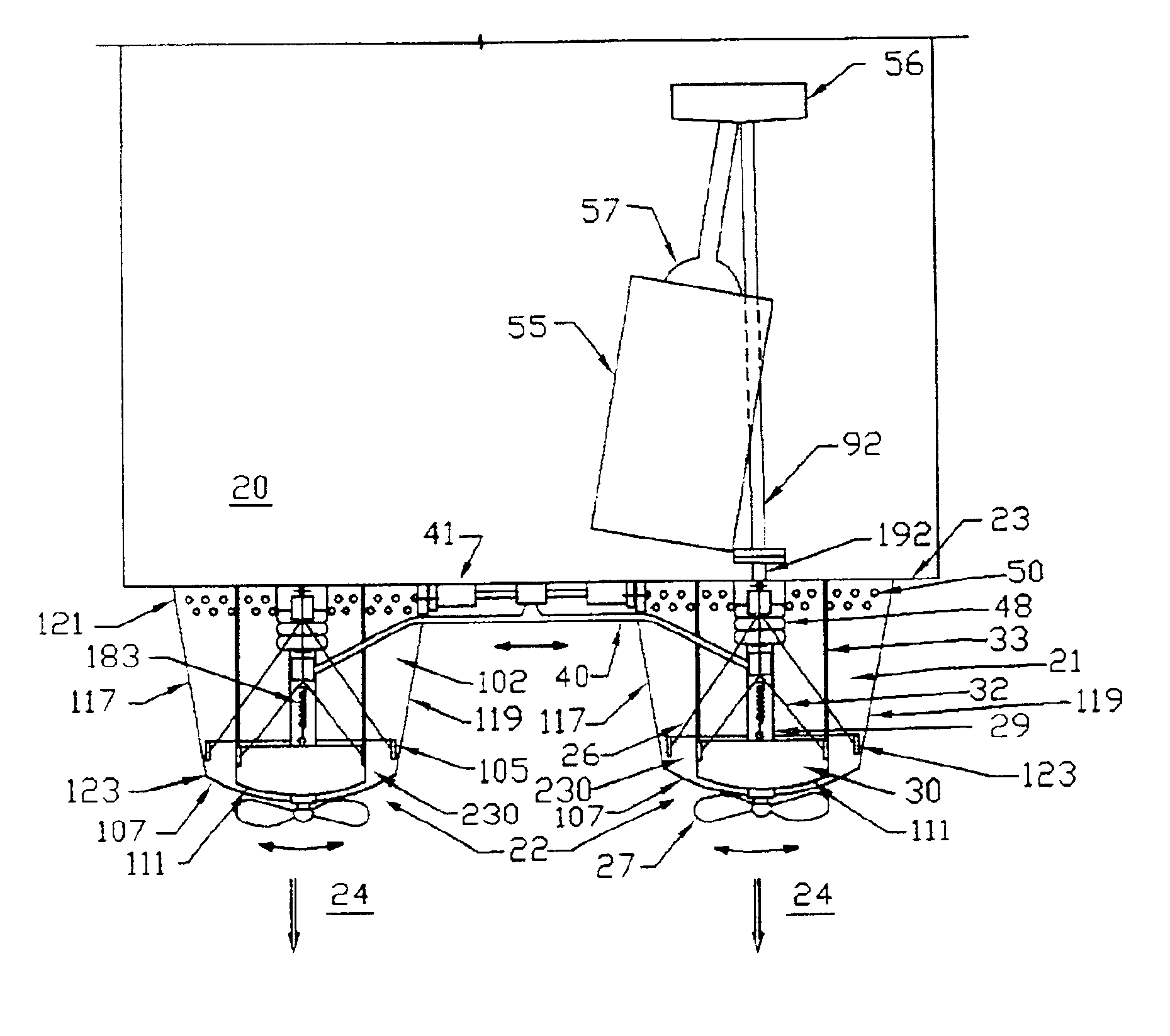

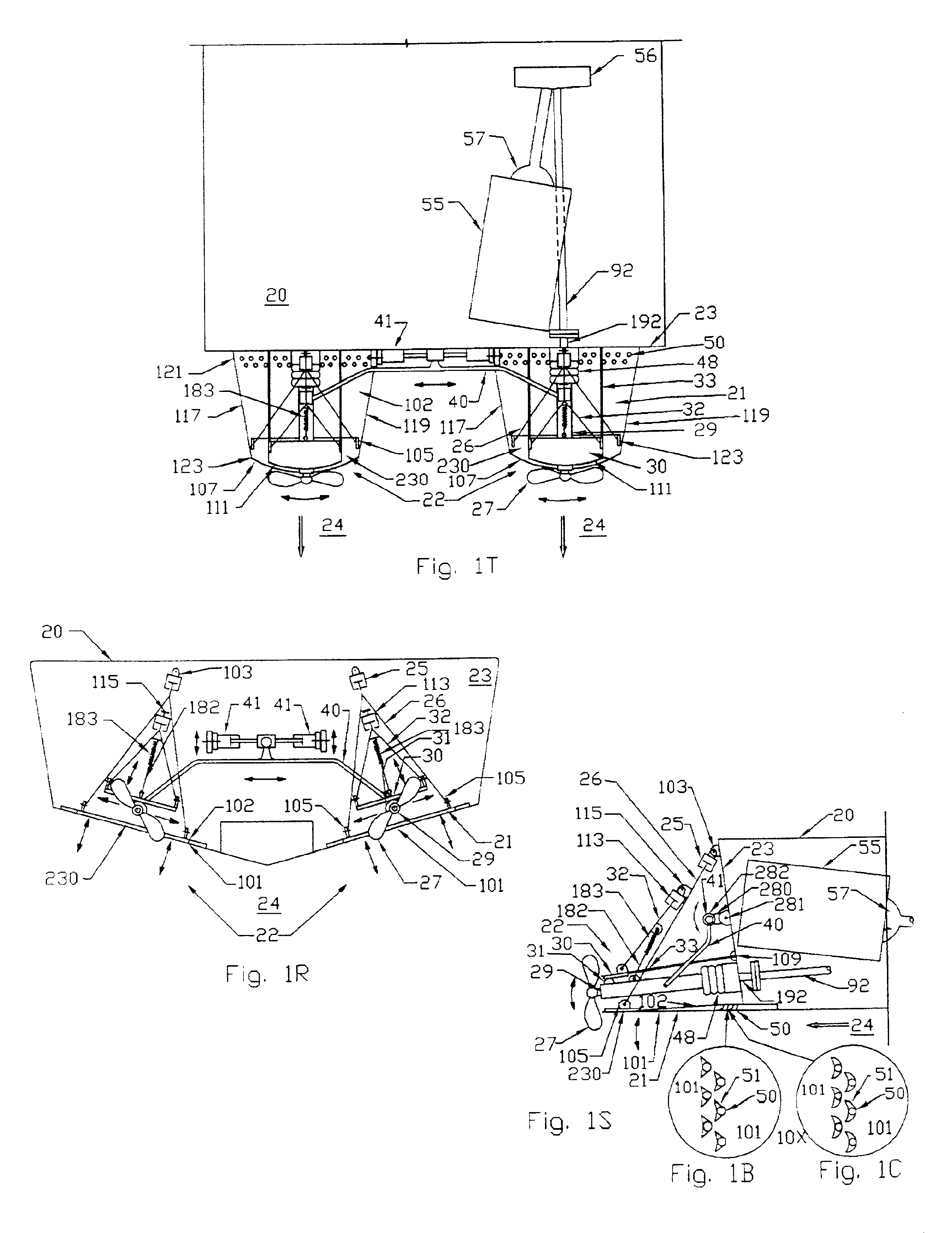

Trim tabs and surface drive propeller bite control

InactiveUS20020174818A1Reduce yawReduce decreaseRotary propellersWatercraft hull designTrim tabWater flow

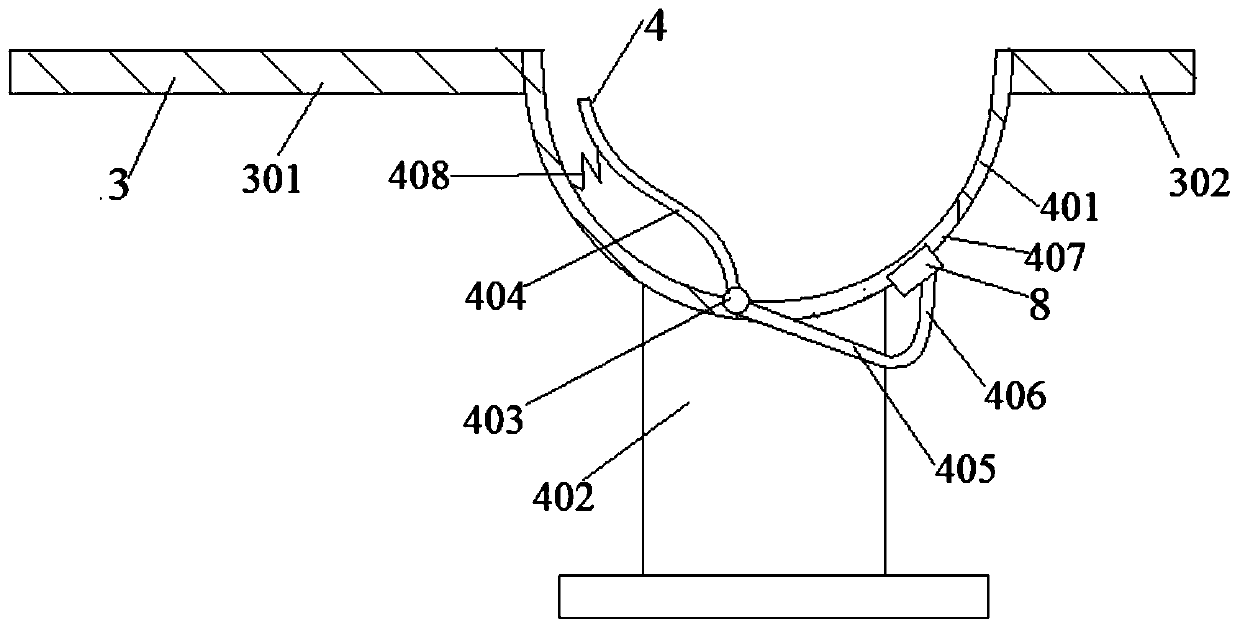

A trim tab of resilient material affixed in a cantilever fashion at the stern of a boat and of a regressive flexural stiffness such that when deflected, the undersurface of the trim tab assumes the shape of a progressive curve in the direction of water flow. A trim tab of a progressive curve which has gas or liquid ejection to the undersurface to control the boundary layer. A trim tab located under a surface drive whereby the bite of the propeller is controlled relative to the trim tab and the trim tab is controlled to optimize the boat hull.

Owner:VON WOLSKE JAMES P

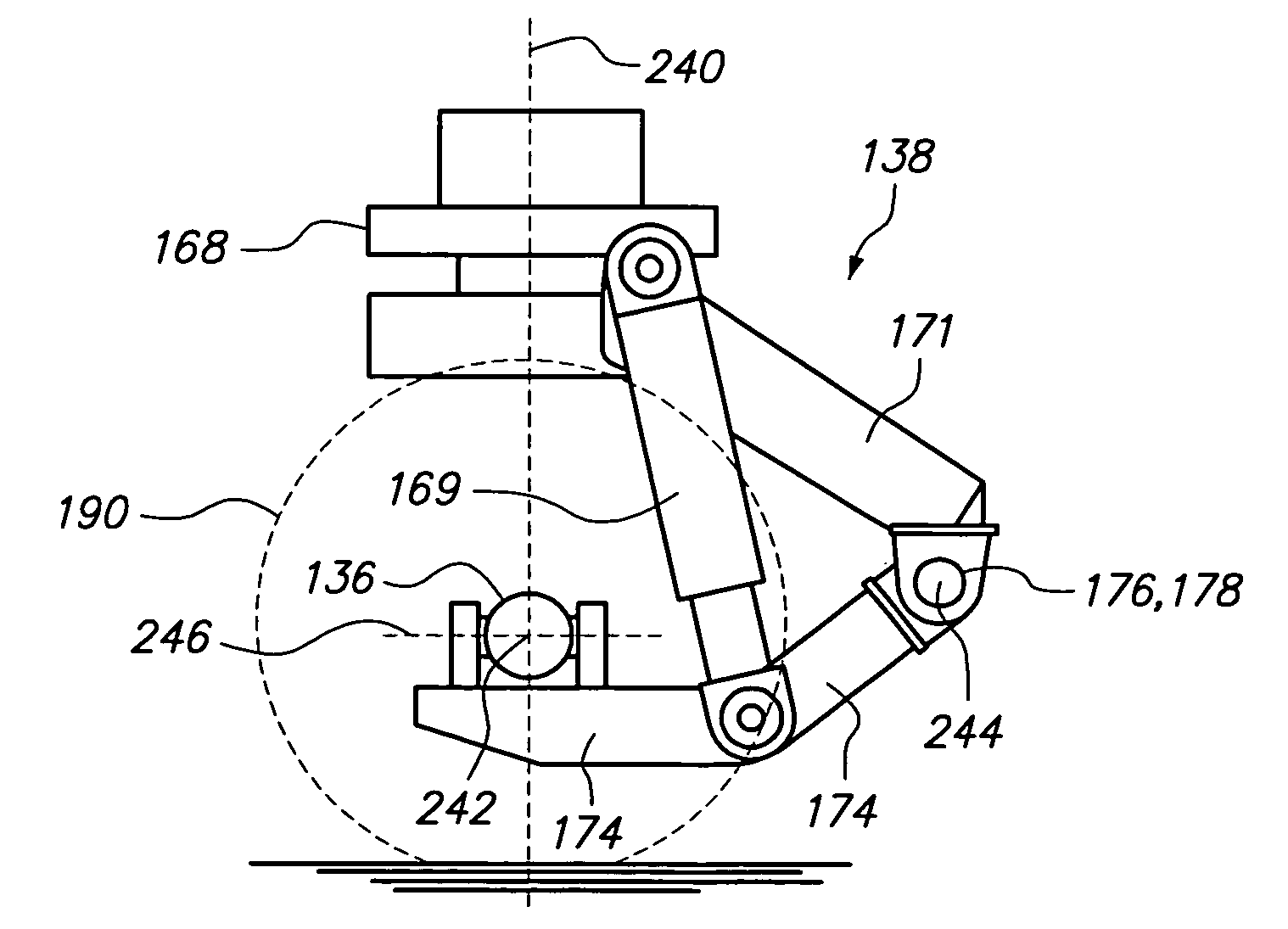

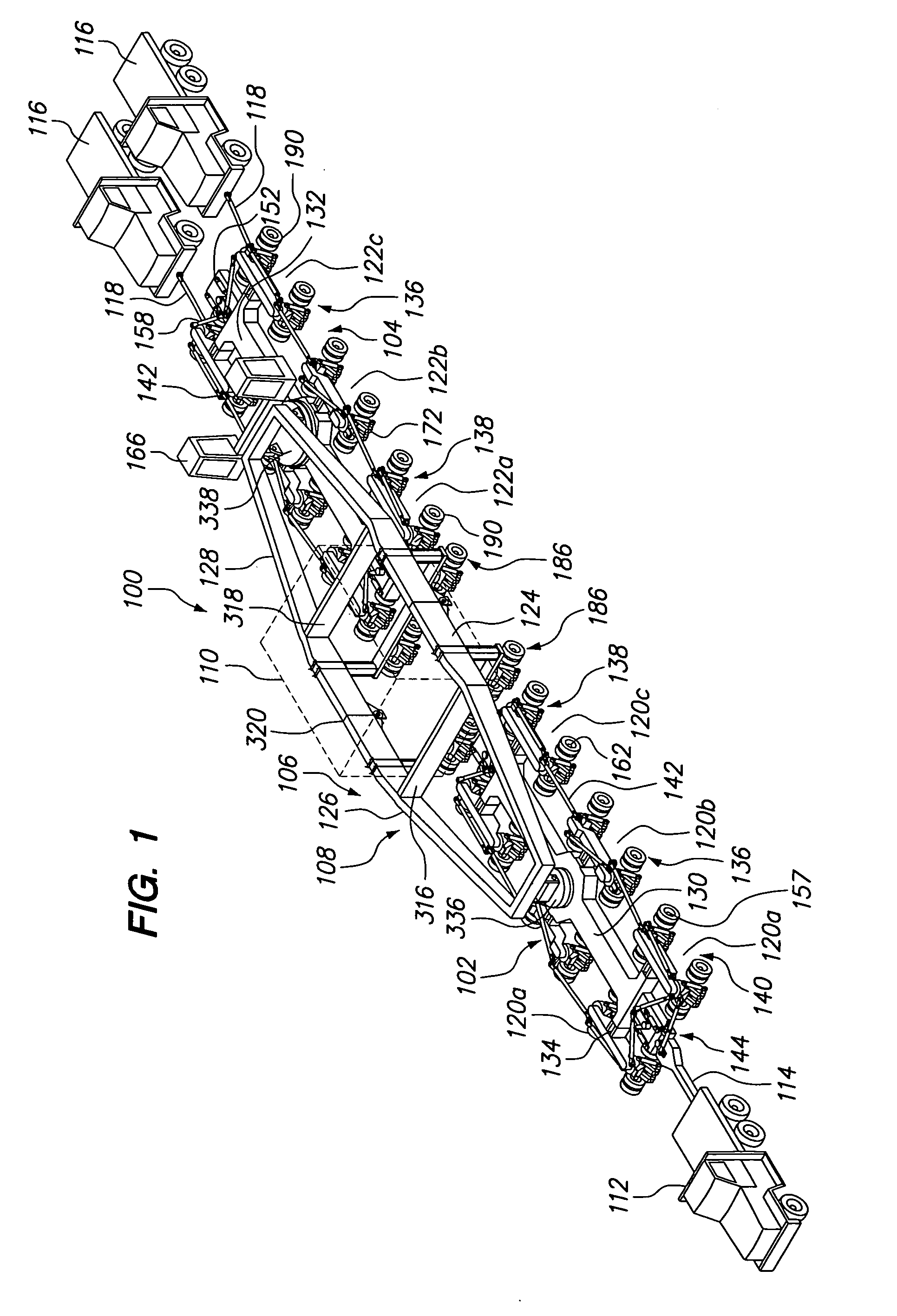

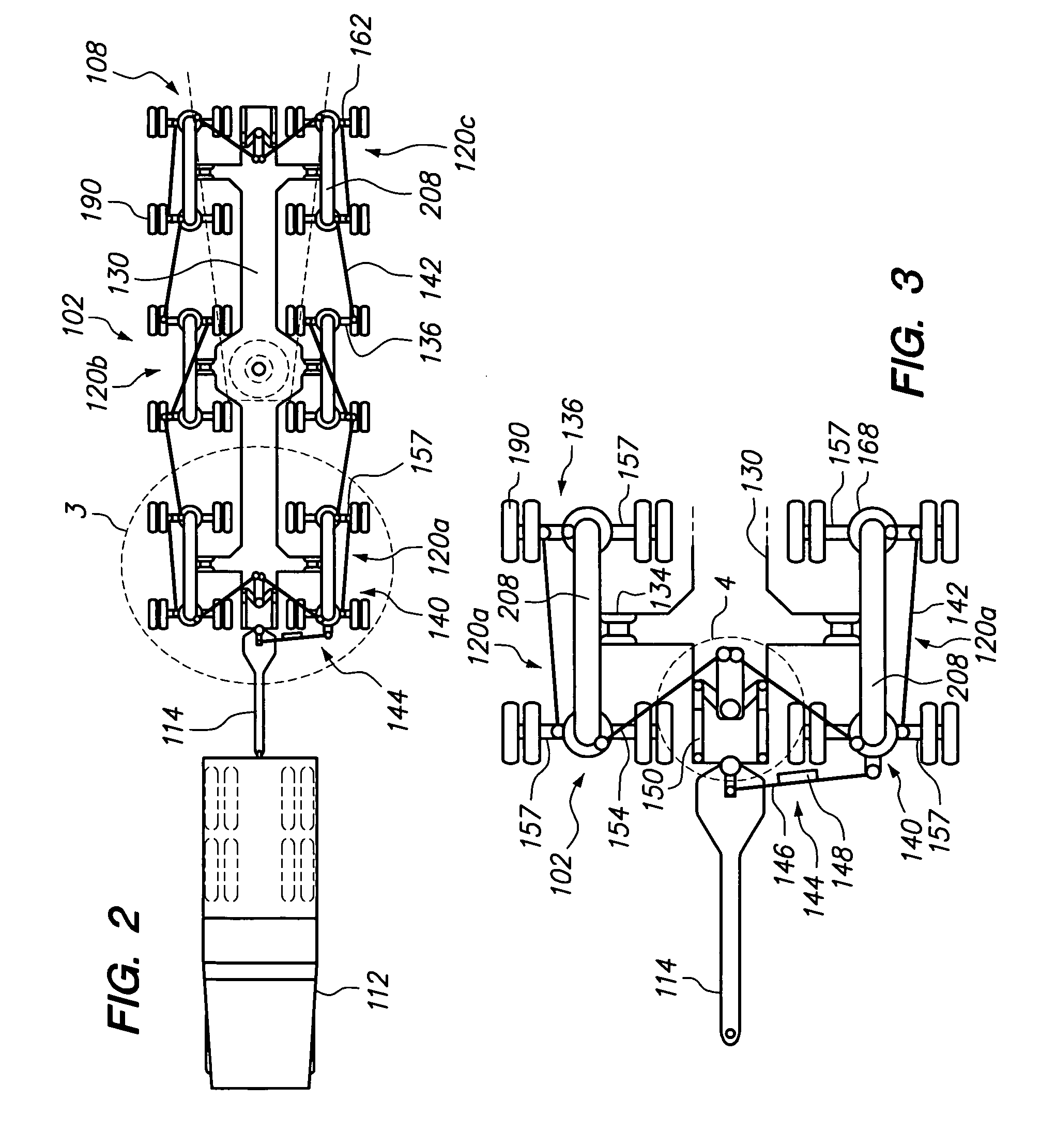

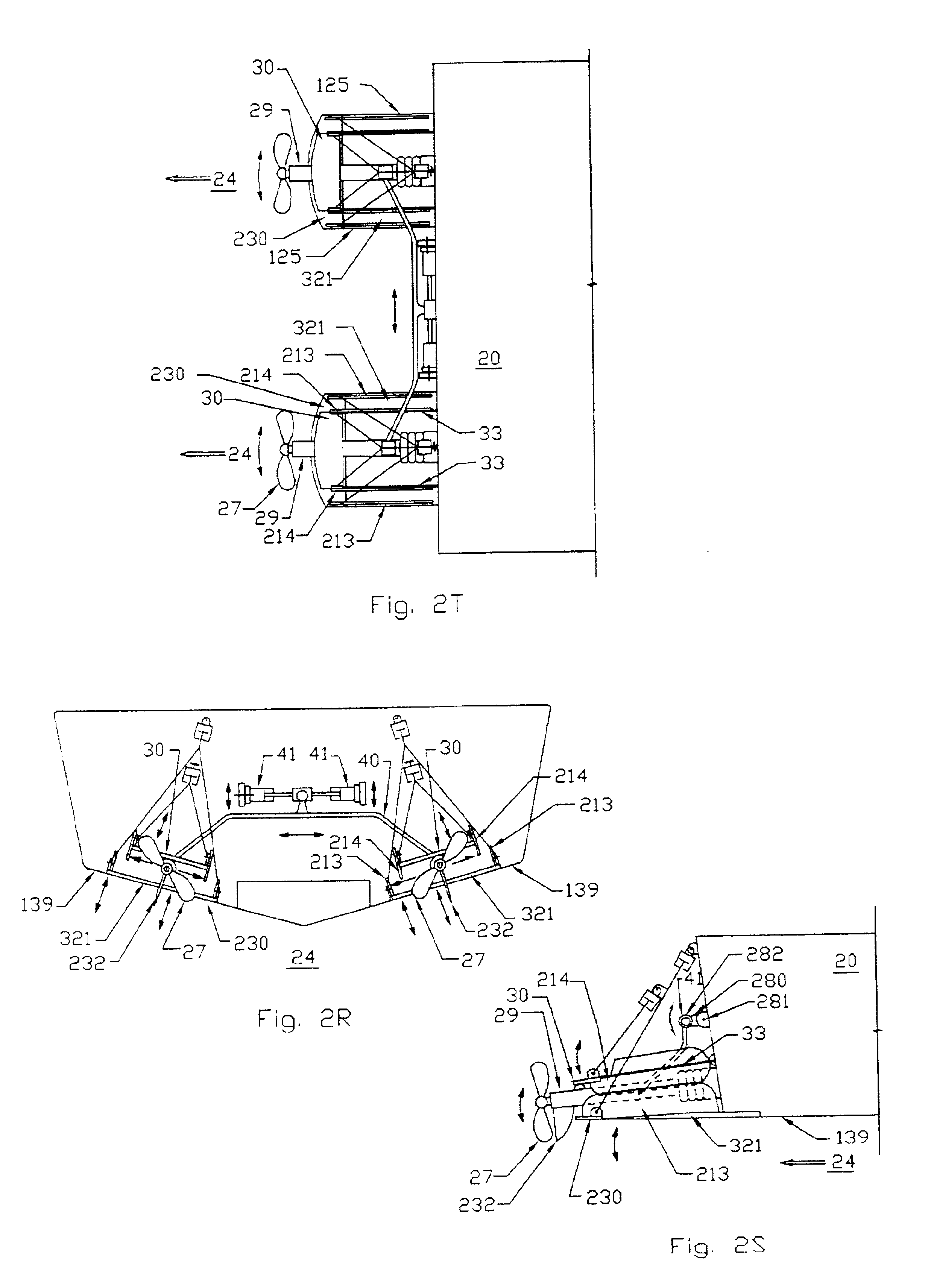

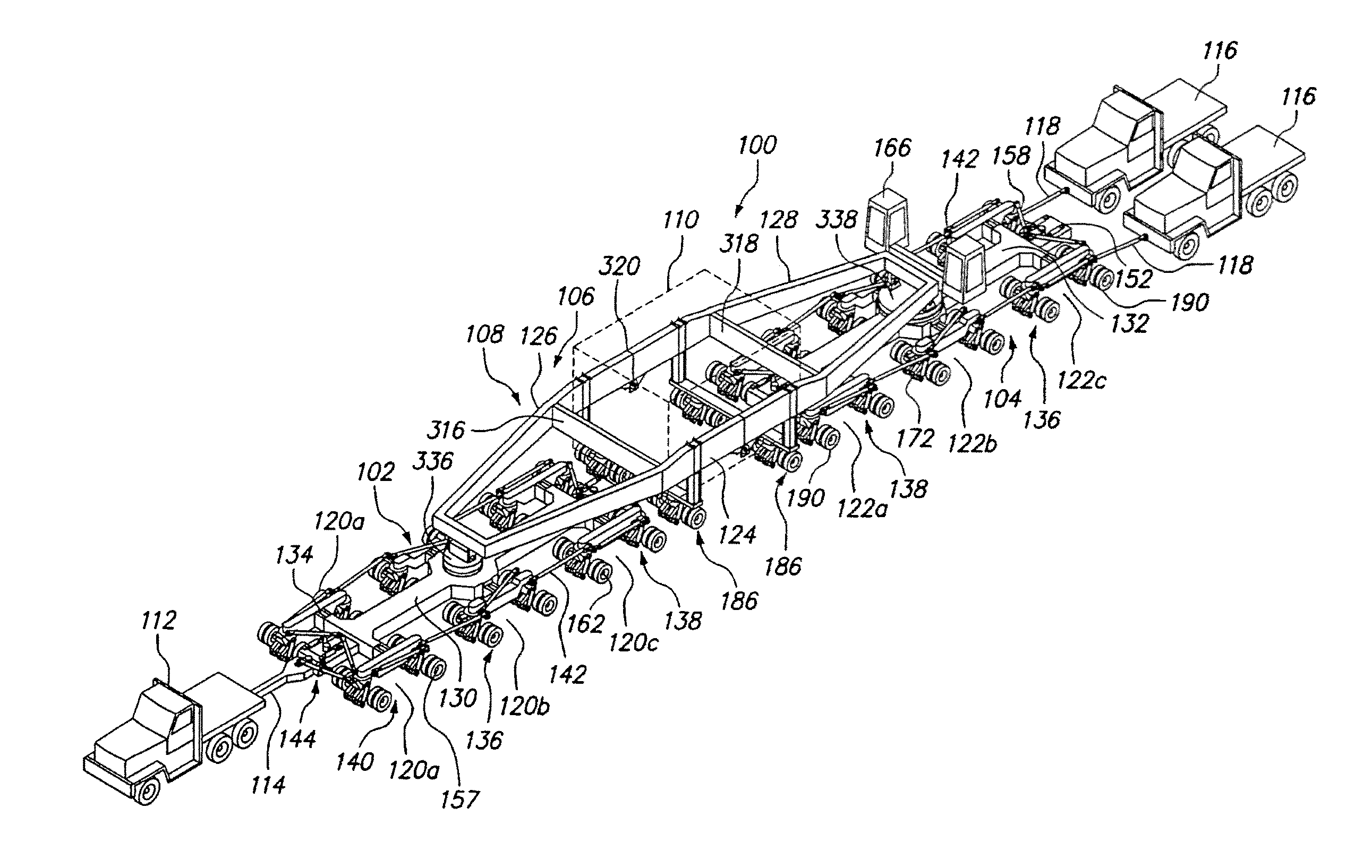

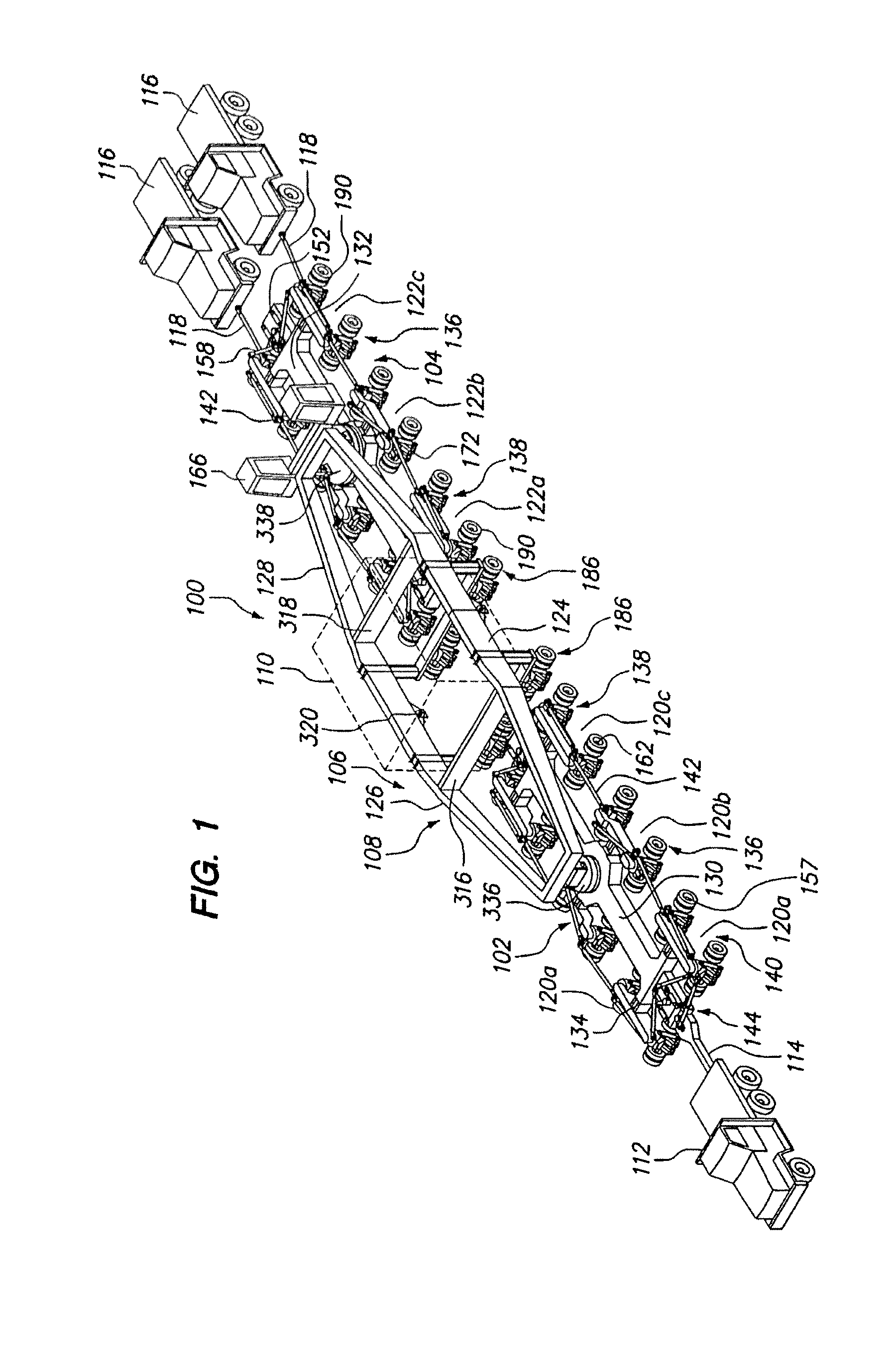

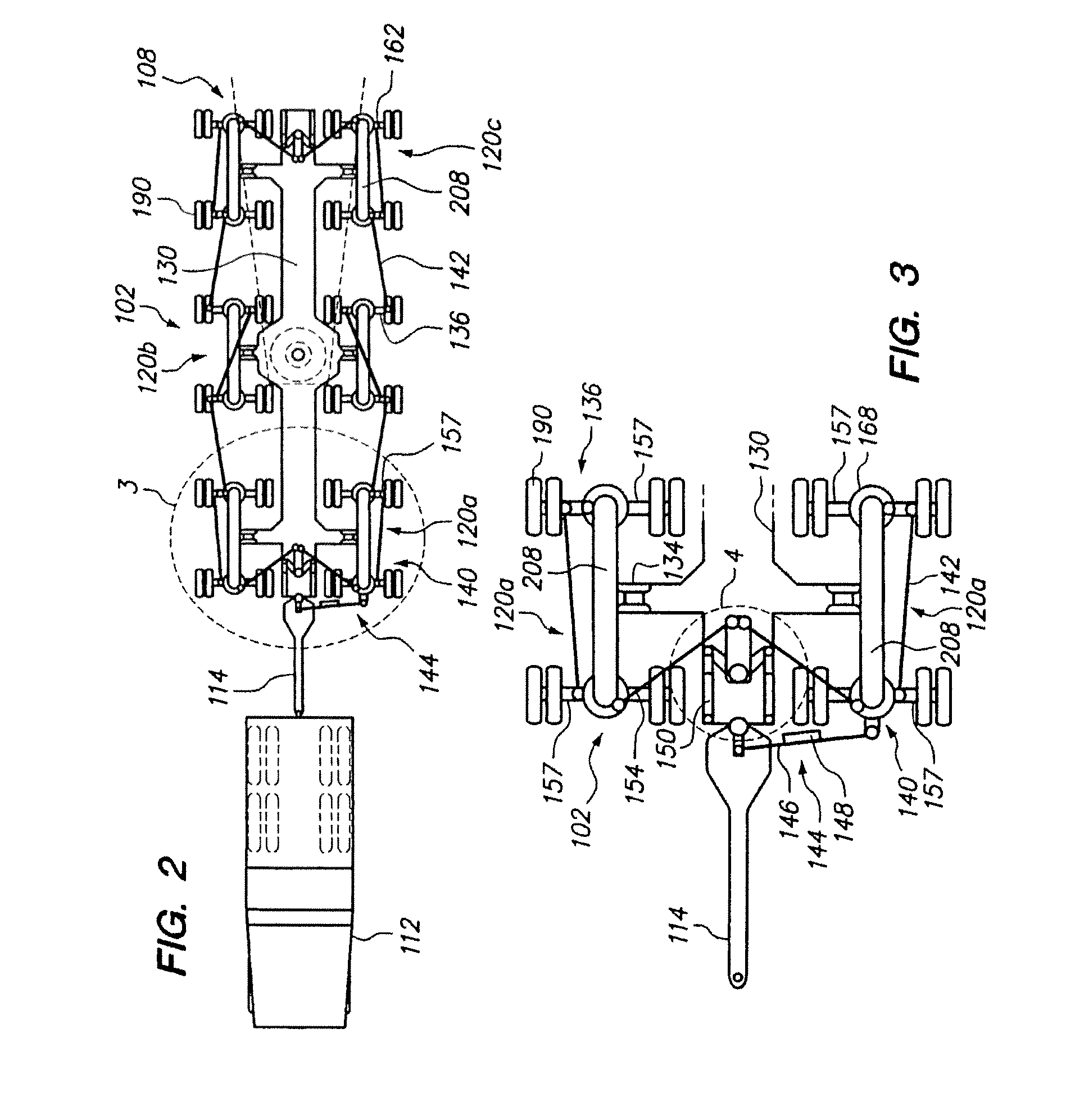

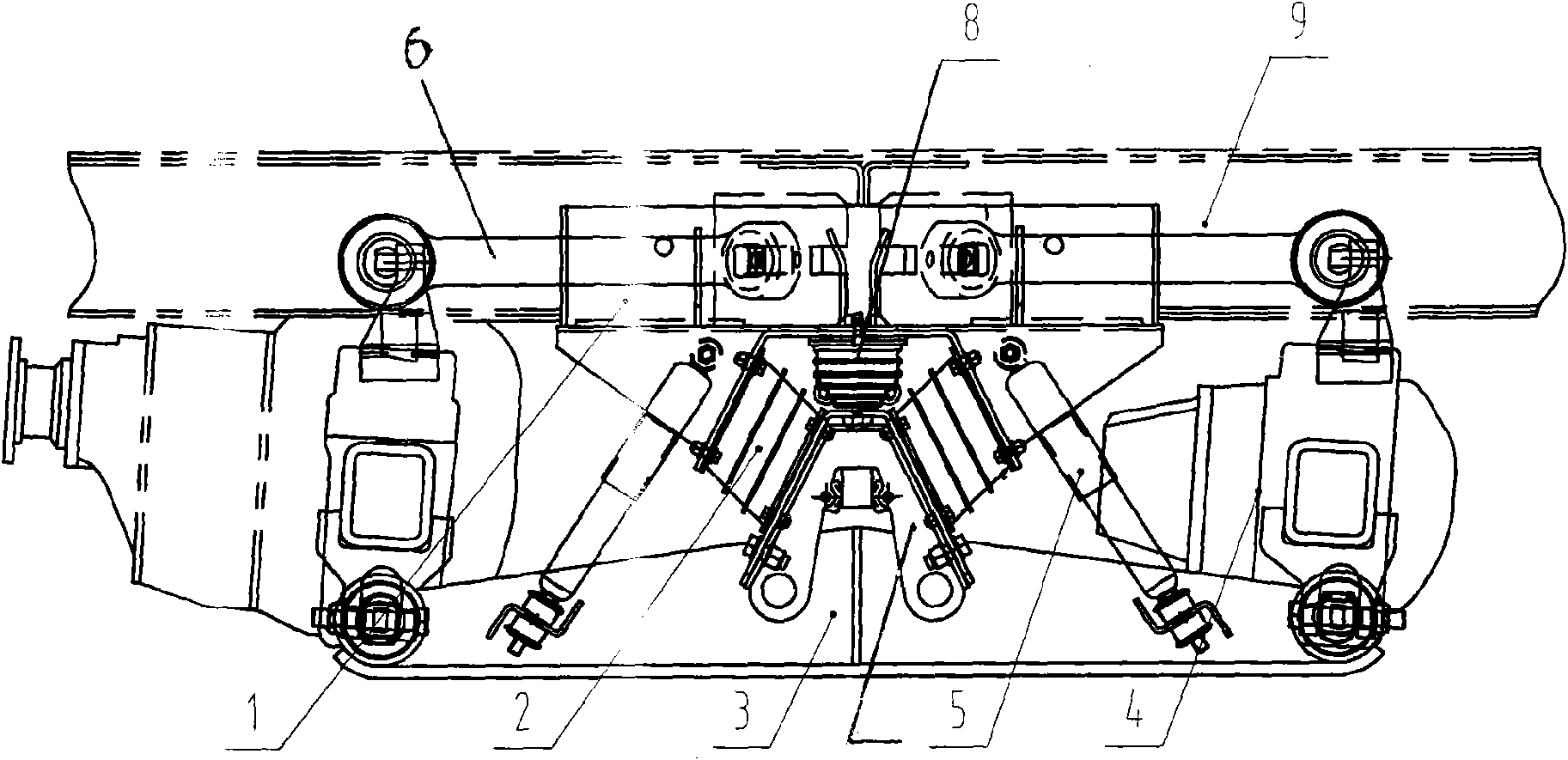

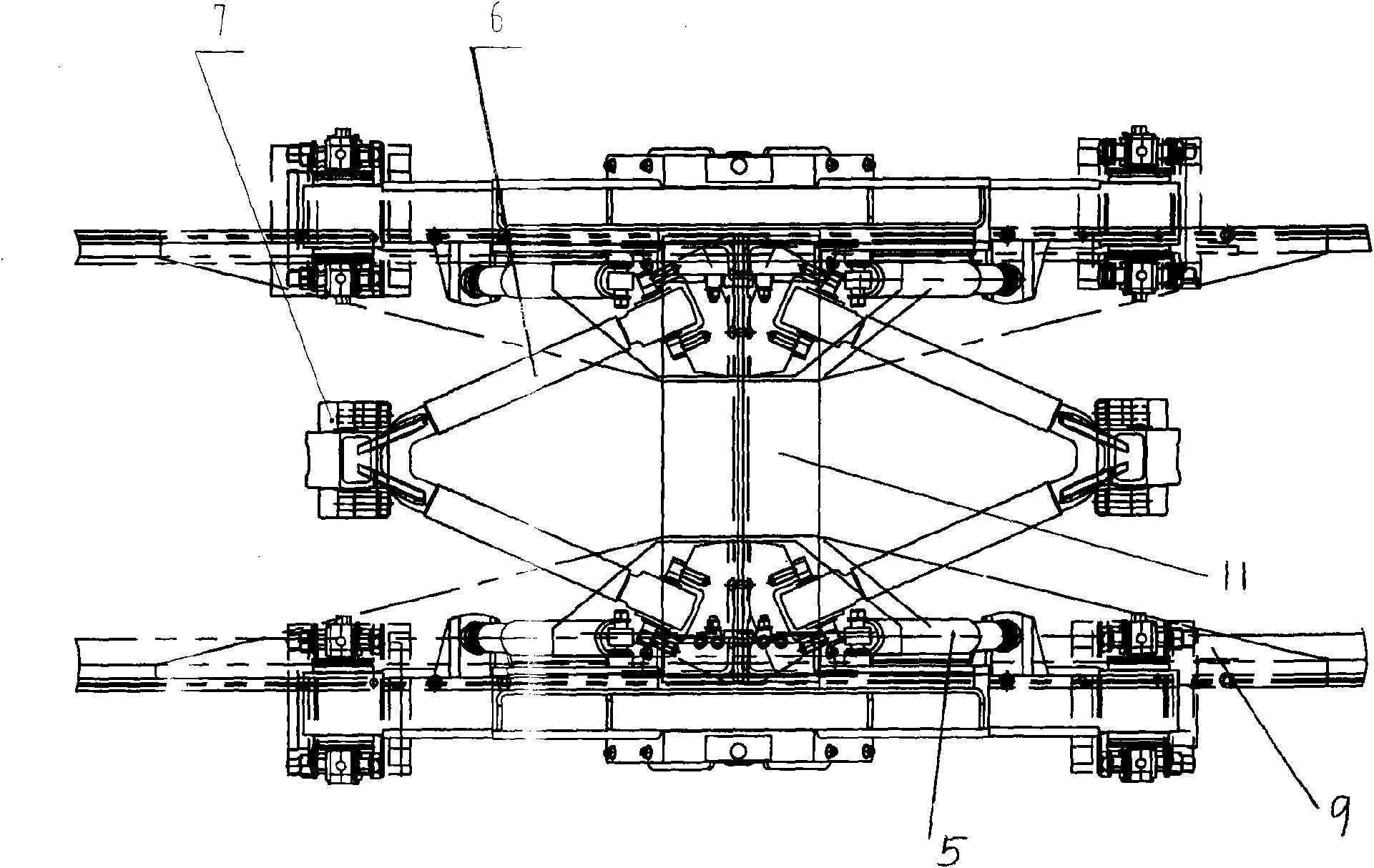

Dual lane multi-axle transport vehicle

InactiveUS20090273159A1Increase profitReducing axle yawVehicle body-frame connectionsUnderstructuresHeavy loadSteering system

A dual lane, multi-axle transport vehicle for moving heavy loads includes a forward module mounted on a plurality of axles and a rearward module mounted on a plurality of axles. The forward module is mechanically connected to the rearward module for providing a dual lane transport body. The forward module and the rearward module of the transport body each have a single central spine wherein the axles of both the forward module and the rearward module are each attached to the corresponding single central spine. The axles of both the forward module and the rearward module have an axle spacing of at least six feet. A hydraulic suspension is provided for dynamically stabilizing the axles for reducing axle yaw. An axle steering system having a plurality of steering rods controls the position of the axles of both the forward module and the rearward module.

Owner:ALPHA ONE TRANSPORTER

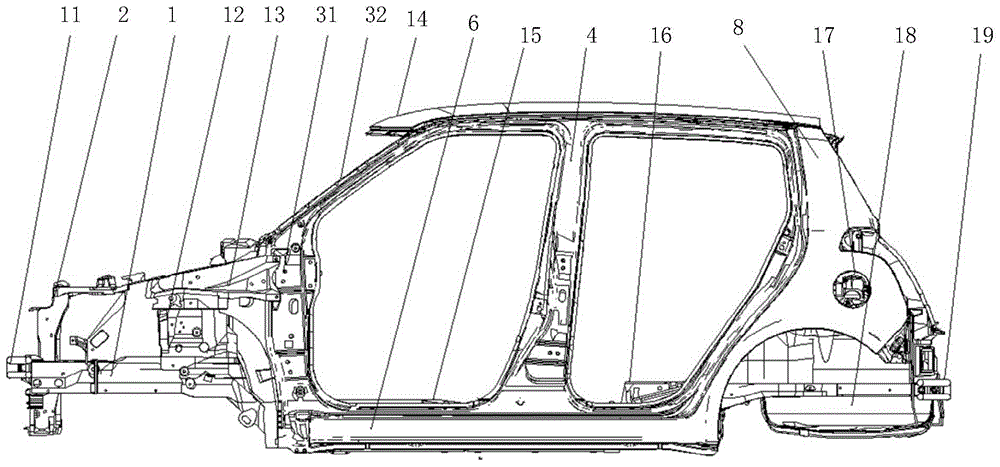

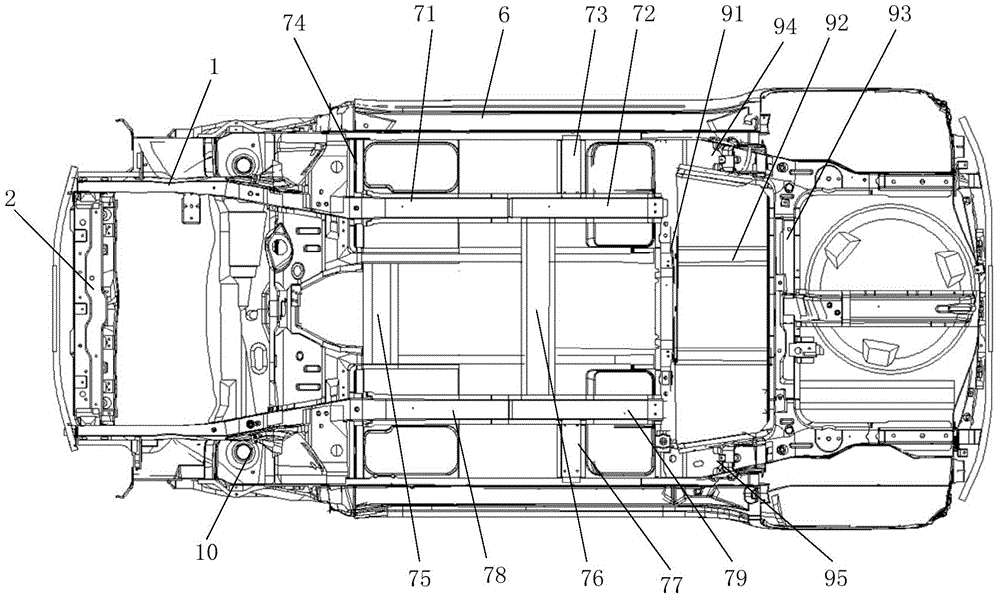

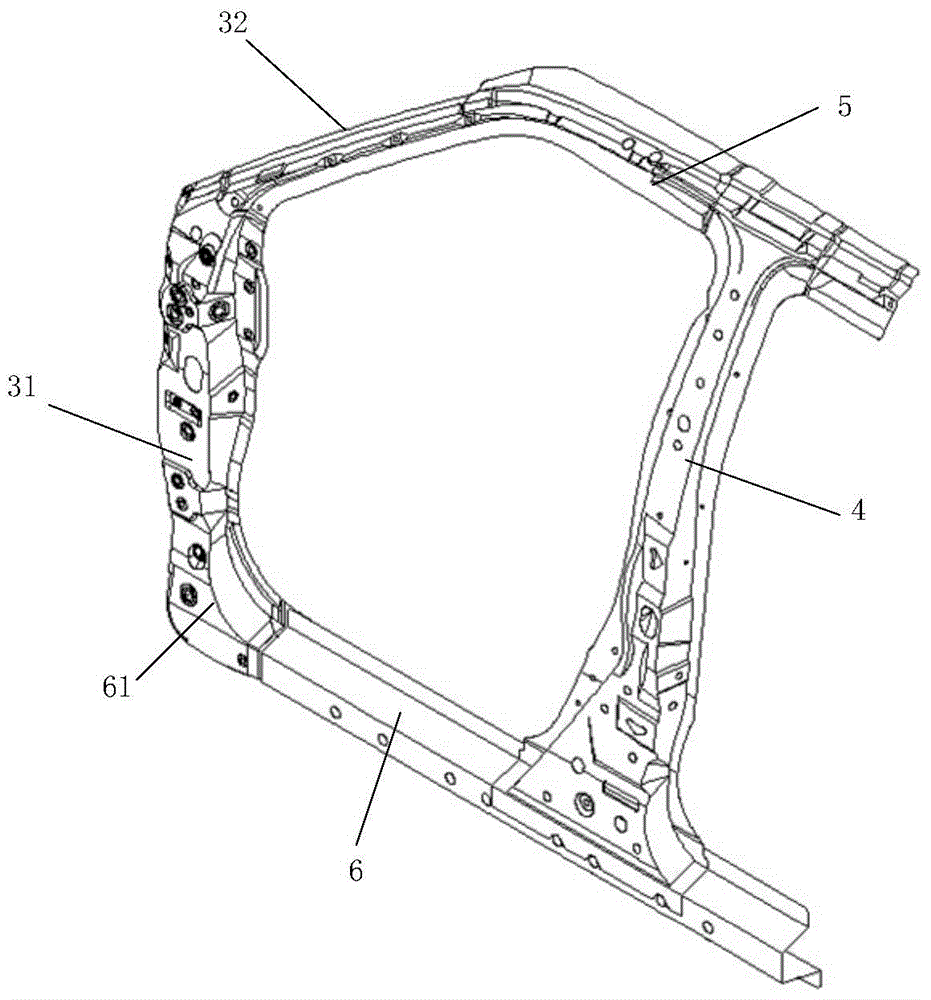

Body in white bend resistance structure and arrangement mode thereof

ActiveCN105015623AIncrease local overlapImprove bending resistanceSuperstructure subunitsMonocoque constructionsStructural engineeringEngineering

The invention provides a body in white bend resistance structure and an arrangement mode thereof. The lower end of a lower vertical plate of a column A is in overlap connection with a sill strip. The upper end of the lower vertical plate of the column A is in overlap connection with an outer plate of the column A. The outer plate of the column A is in overlap connection with an upper beam of a column B. The upper end of an outer plate of the column B is in overlap connection with the upper beam of the column B. The lower end of the outer plate of the column B is in overlap connection with the sill strip. Two to three layers of spot welding connection is formed at each overlap joint to form a closed structure. The bend resistance section of the sill strip, the bend resistance section of the vertical plate of the column A, the bend resistance section of the outer plate of the column A and the bend resistance section of the upper beam of the column B are each in a closed annular shape. Due to the fact that the bend resistance sections form the closed annular shapes and are composed of three or four sheet metal parts, the bend resistance is improved; due to extending sections at the upper and lower ends of the outer plate of the column B, the overlap connection efficiency of the upper beam and the sill strip of the column B and the outer plate of the column B is enhanced, and the bend resistance performance is improved; the transverse and longitudinal staggered closed structure has the effect of enhancing inertia torque, and the bend resistance performance is improved.

Owner:CHINA AUTOMOTIVE ENG RES INST

Trim tabs and surface drive propeller bite control

InactiveUS6823812B2Reduce yawReduce decreaseRotary propellersPropulsion power plantsTrim tabPropeller

A trim tab of resilient material affixed in a cantilever fashion at the stem of a boat and of a regressive flexural stiffness such that when deflected, the undersurface of the trim tab assumes the shape of a progressive curve in the direction of water flow. A trim tab of a progressive curve which has gas or liquid ejection to the undersurface to control the boundary layer. A trim tab located under a surface drive whereby the bite of the propeller is controlled relative to the trim tab and the trim tab is controlled to optimize the boat hull.

Owner:VON WOLSKE JAMES P

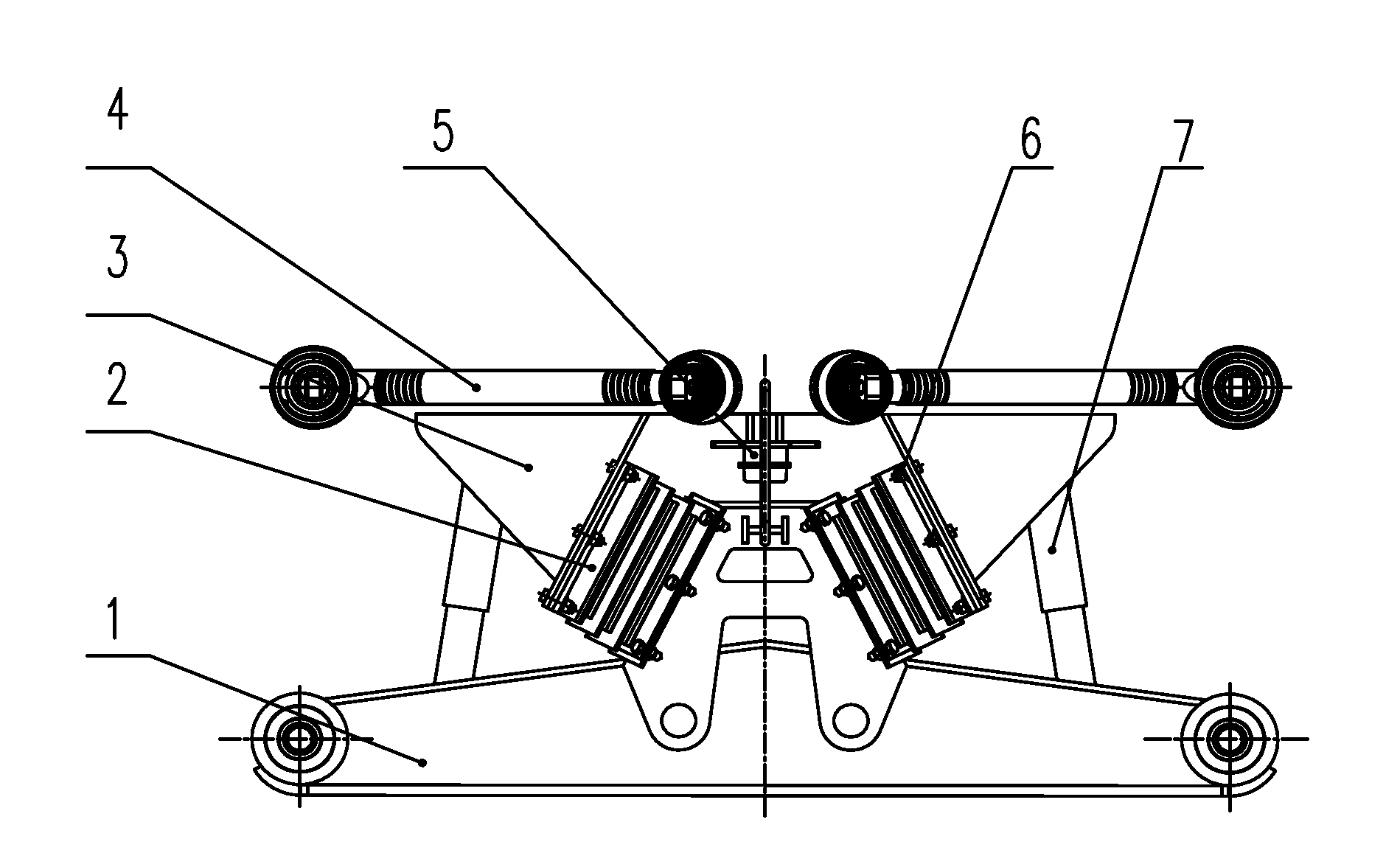

Dual lane multi-axle transport vehicle

InactiveUS8424897B1Increase profitReducing axle yawAgricultural machinesVehicle to carry long loadsSuspension (vehicle)Heavy load

A dual lane, multi-axle transport vehicle for moving heavy loads includes a forward module mounted on a plurality of axles and a rearward module mounted on a plurality of axles. The forward module is mechanically connected to the rearward module for providing a dual lane transport body. The forward module and the rearward module of the transport body each have a single central spine wherein the axles of both the forward module and the rearward module are each attached to the corresponding single central spine. The axles of both the forward module and the rearward module have an axle spacing of at least six feet. A hydraulic suspension is provided for dynamically stabilizing the axles for reducing axle yaw. An axle steering system having a plurality of steering rods controls the position of the axles of both the forward module and the rearward module.

Owner:FAYMONVILLE DISTRIBUTION

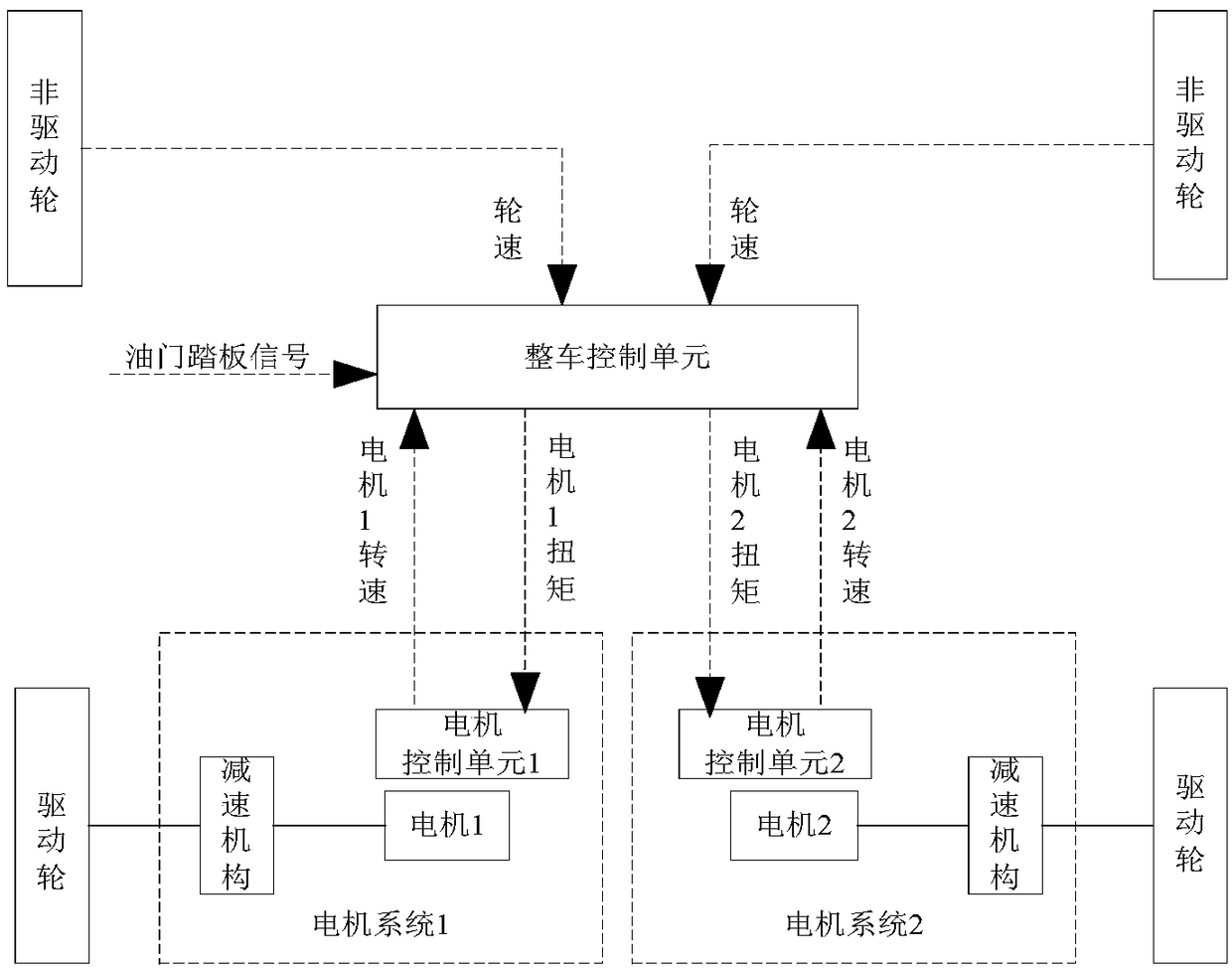

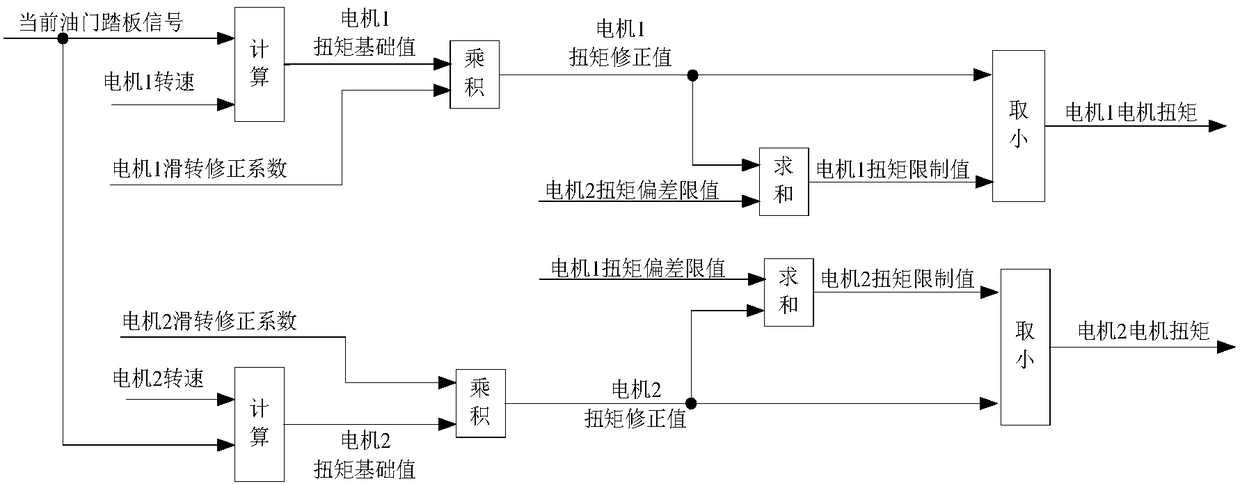

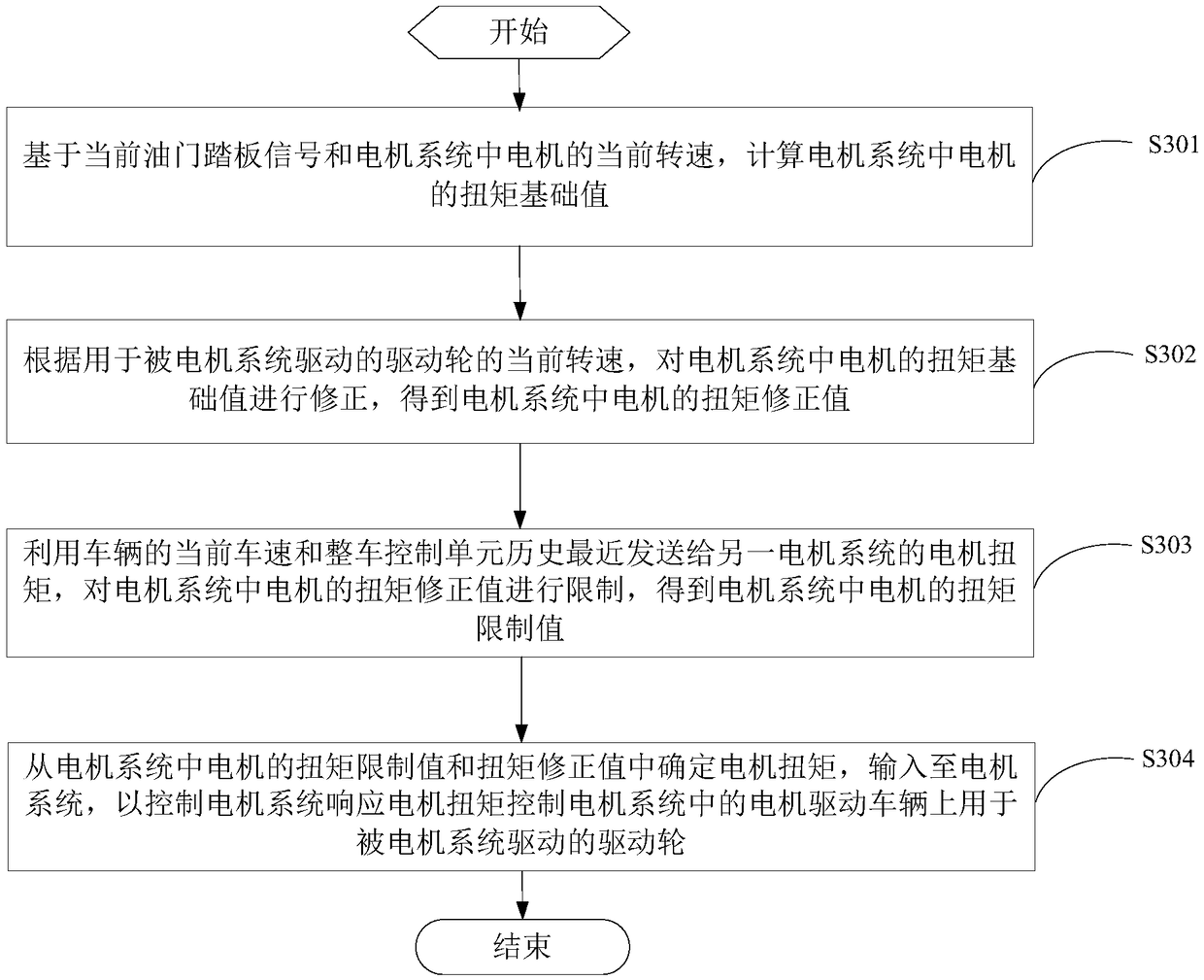

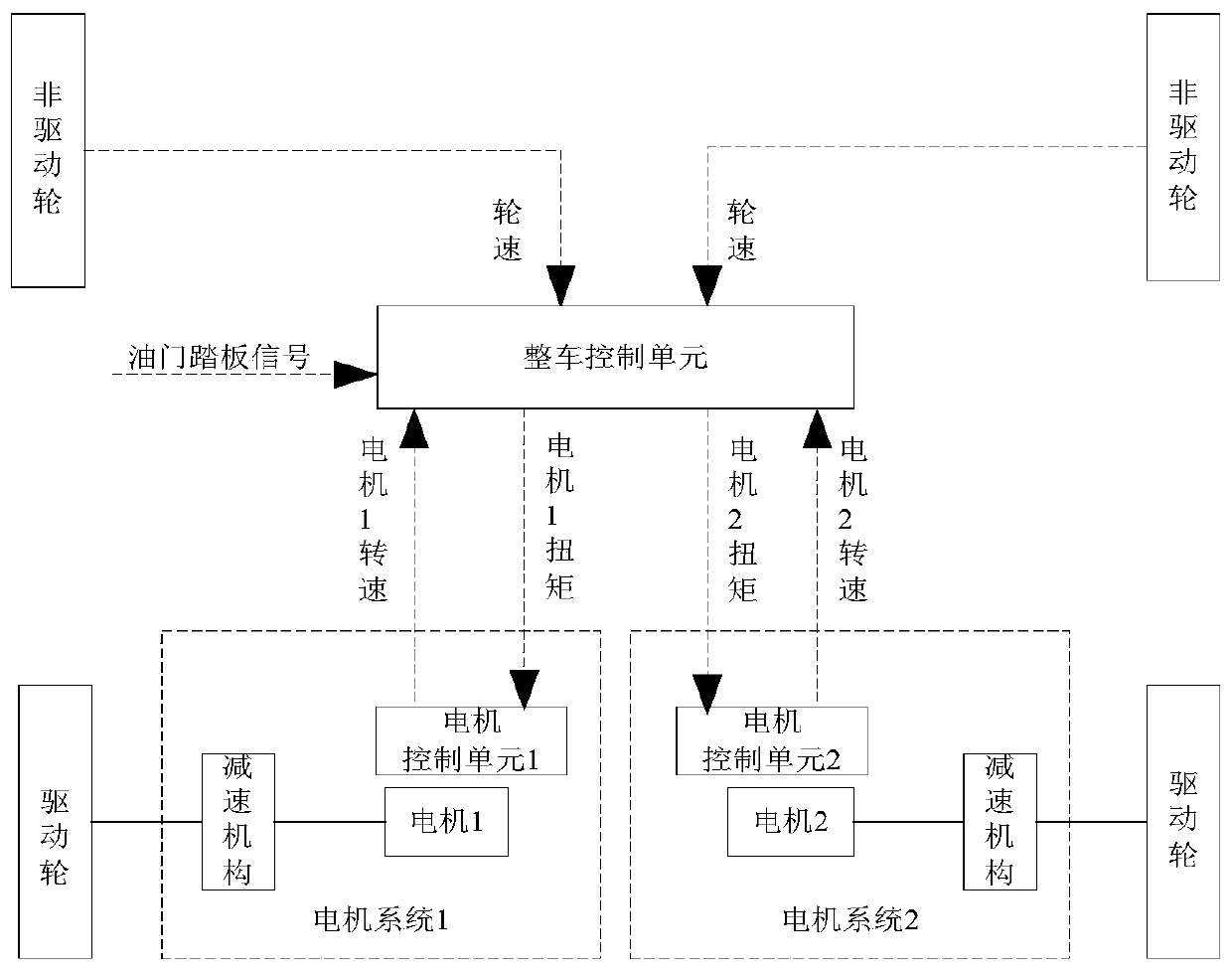

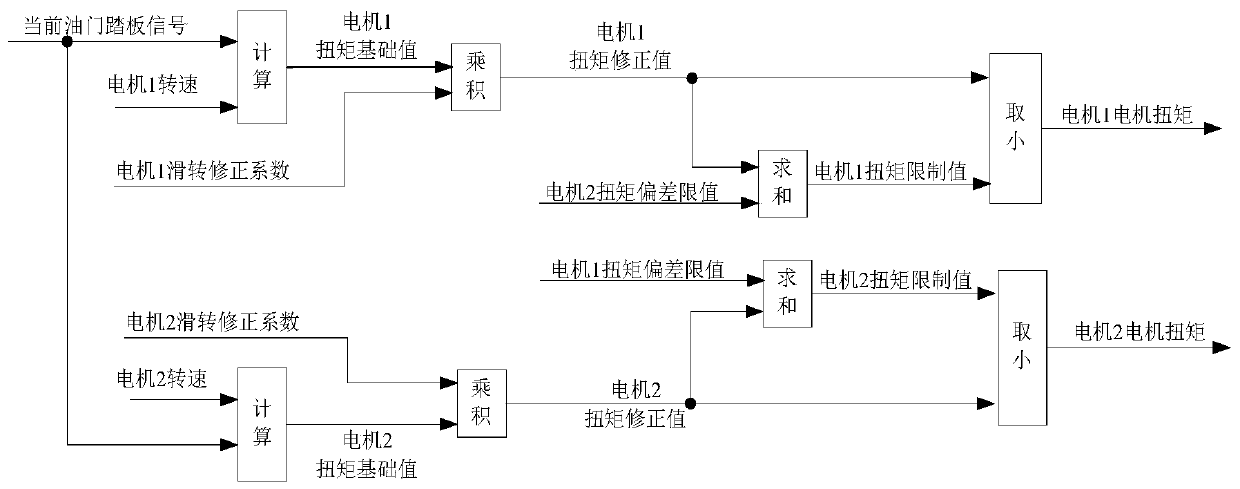

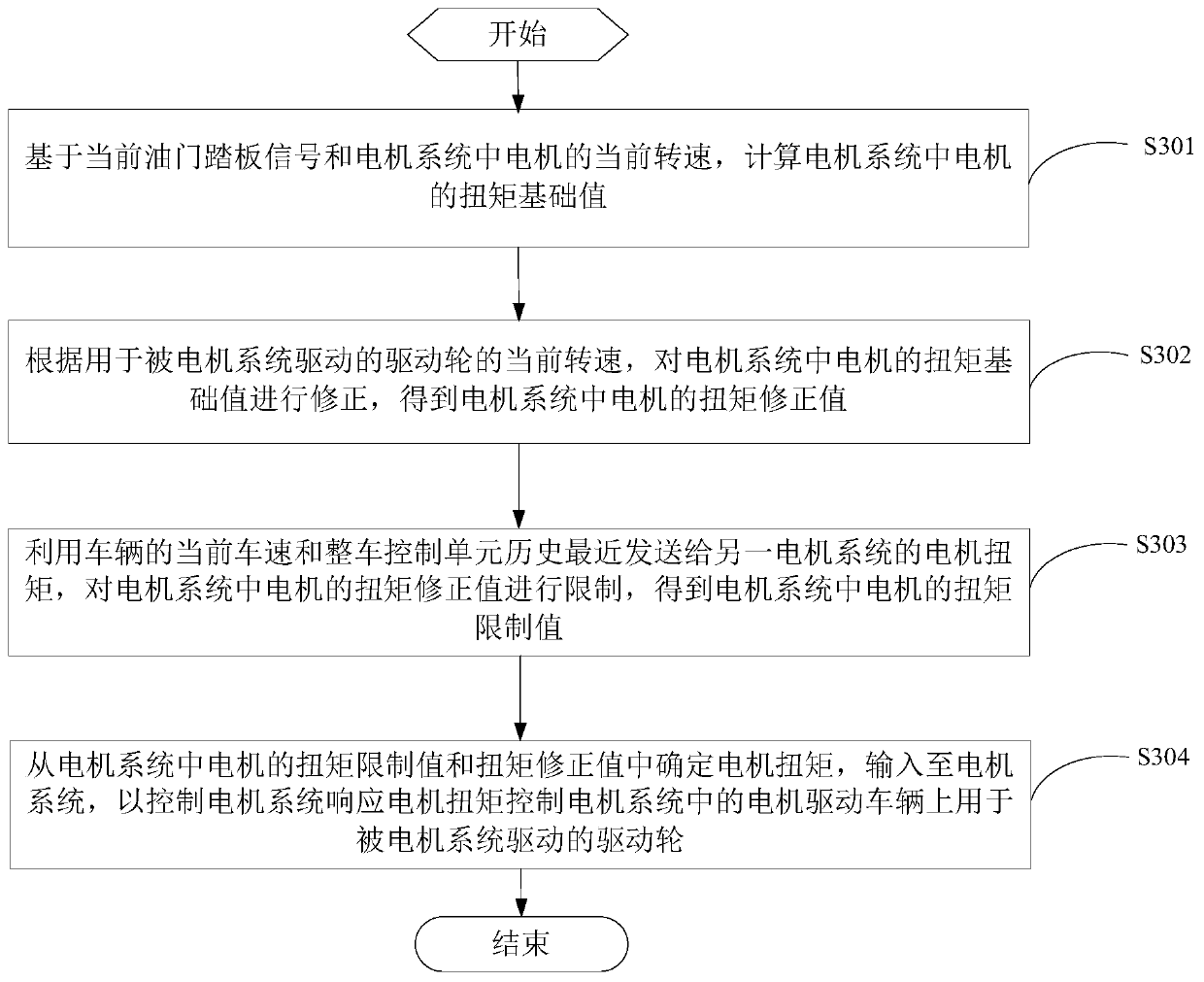

Motor torque control method and wheel rim motor distributed drive system

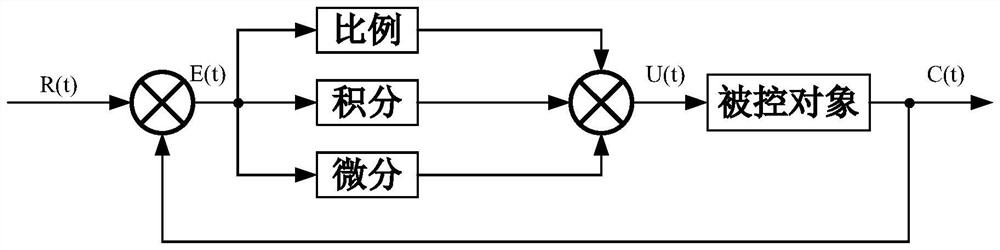

ActiveCN109353227ARealize closed-loop controlAvoid excessive slipSpeed controllerElectric devicesDrive wheelEngineering

The invention provides a motor torque control method and a wheel rim motor distributed drive system. The method is applied to a vehicle control unit in the system. The system further comprises two motor systems. The motor systems comprise motors. By means of the method, the following motor torque control process is executed to the motor systems at the same time. Based on current accelerator pedalsignals and the current rotating speeds of the motors in the motor systems, torque basic values of the motors in the motor systems are calculated; the torque basic values of the motors are corrected,and torque corrected values of the motors are obtained; the torque corrected values of the motors are limited through the current vehicle speed of a vehicle and the motor torque recently sent to the other motor system by the vehicle control unit historically, and torque limited values of the motors are obtained; the motor torque is determined from the torque limited values and the torque correctedvalues of the motors and input in the motor systems to which the motors belong, and therefore the motor systems are controlled to respond to the motor torque to control the motors in the motor systems to drive driving wheels, used for being driven by the motor systems, on the vehicle.

Owner:WEICHAI POWER CO LTD

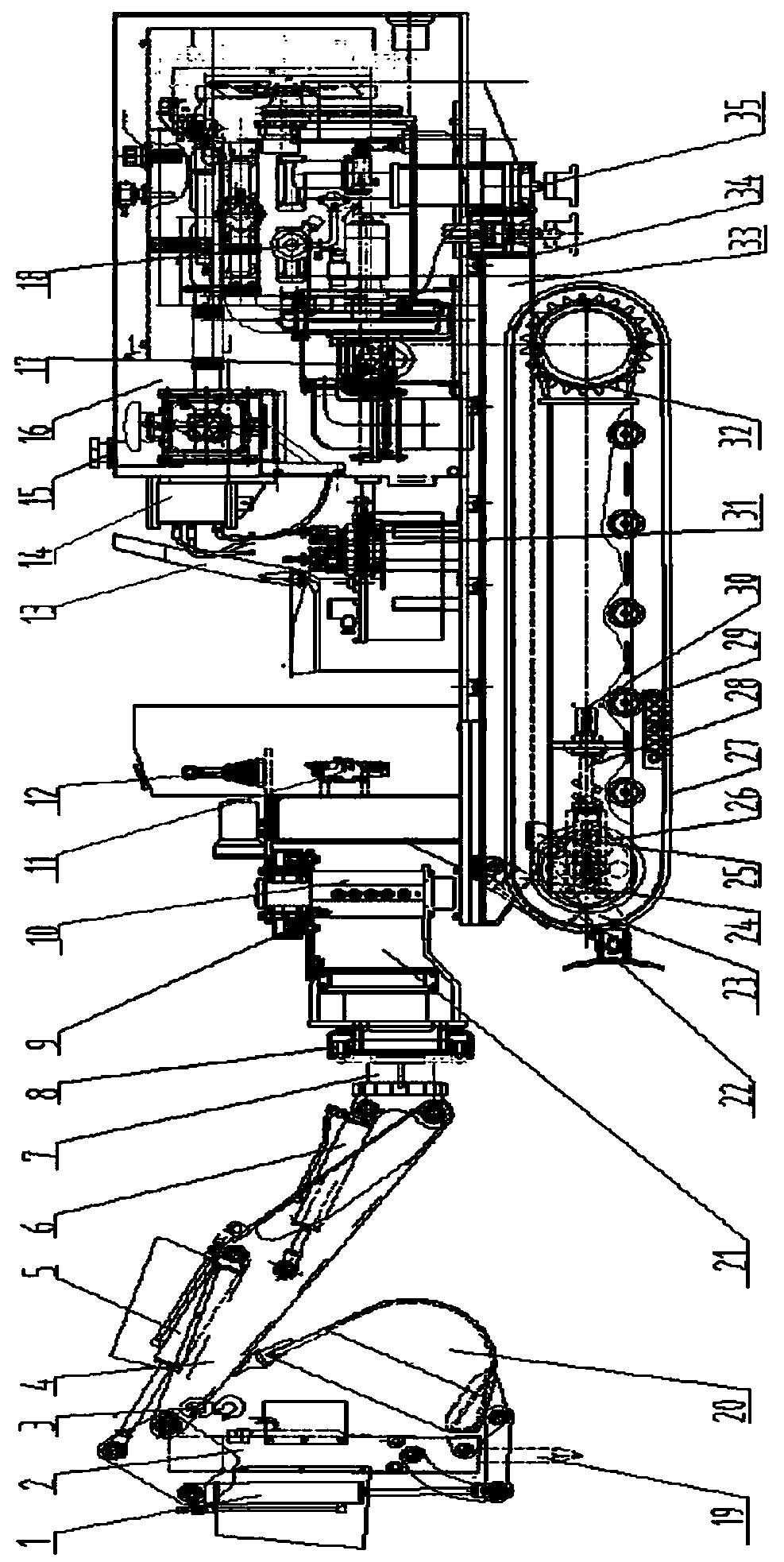

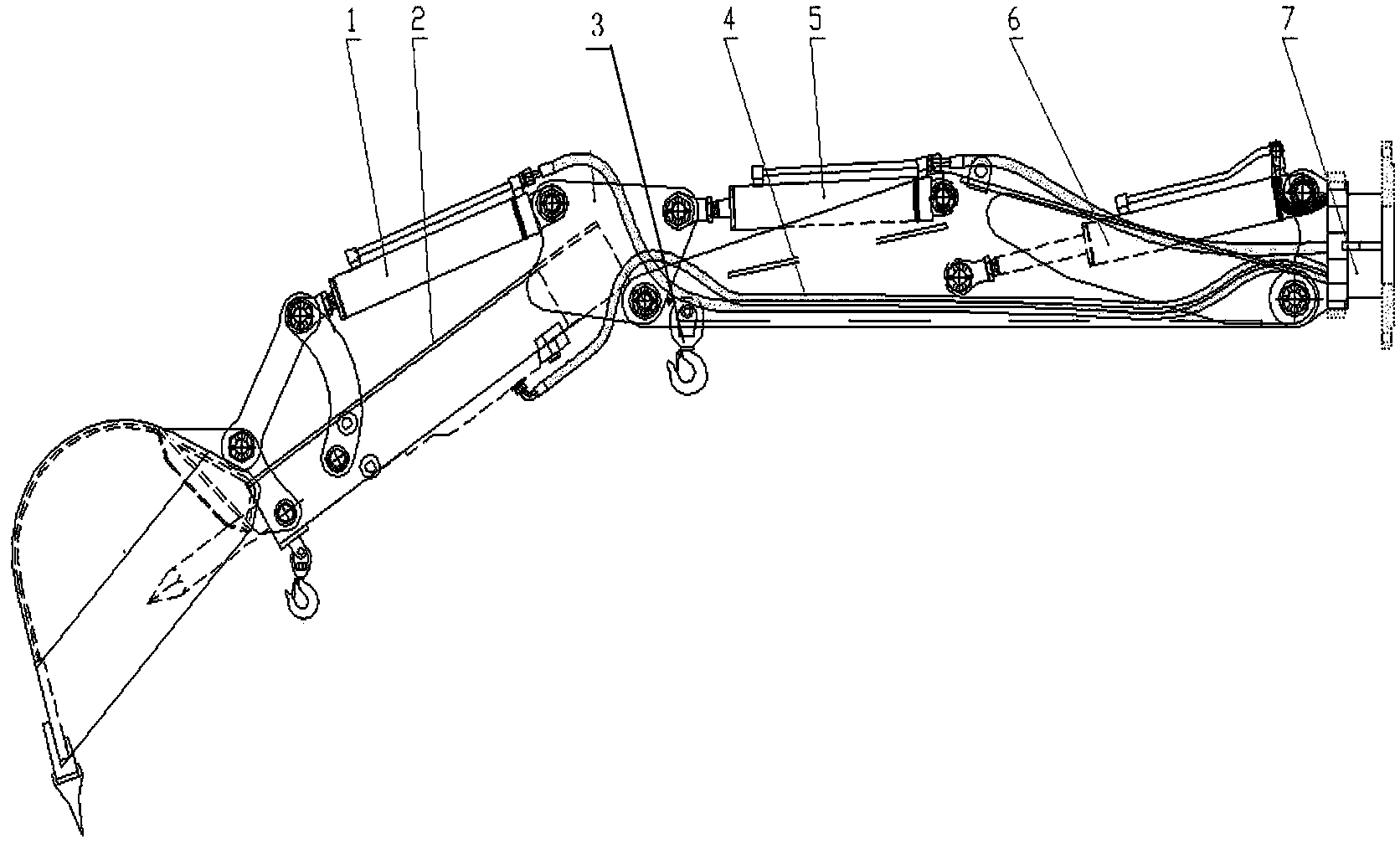

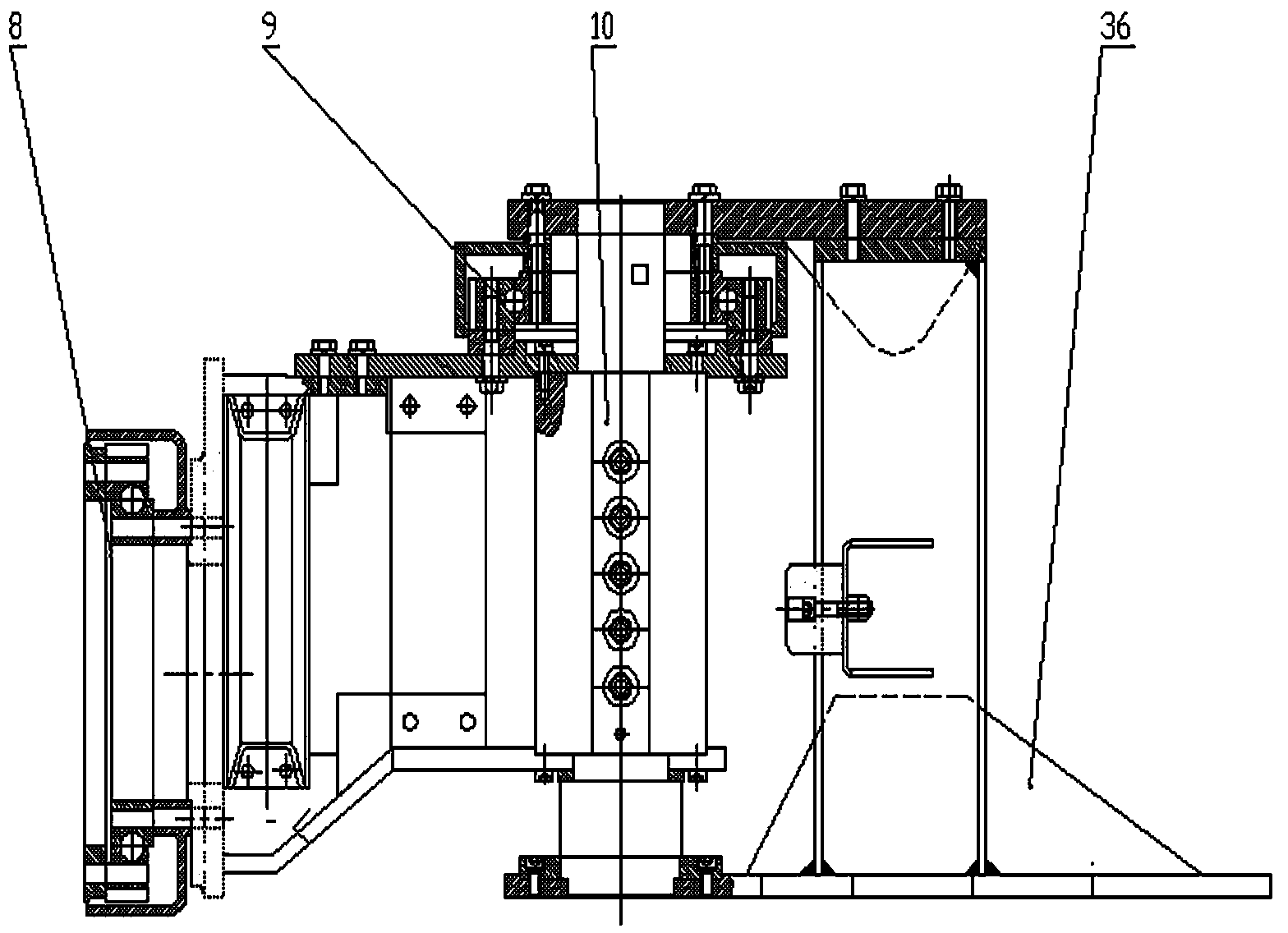

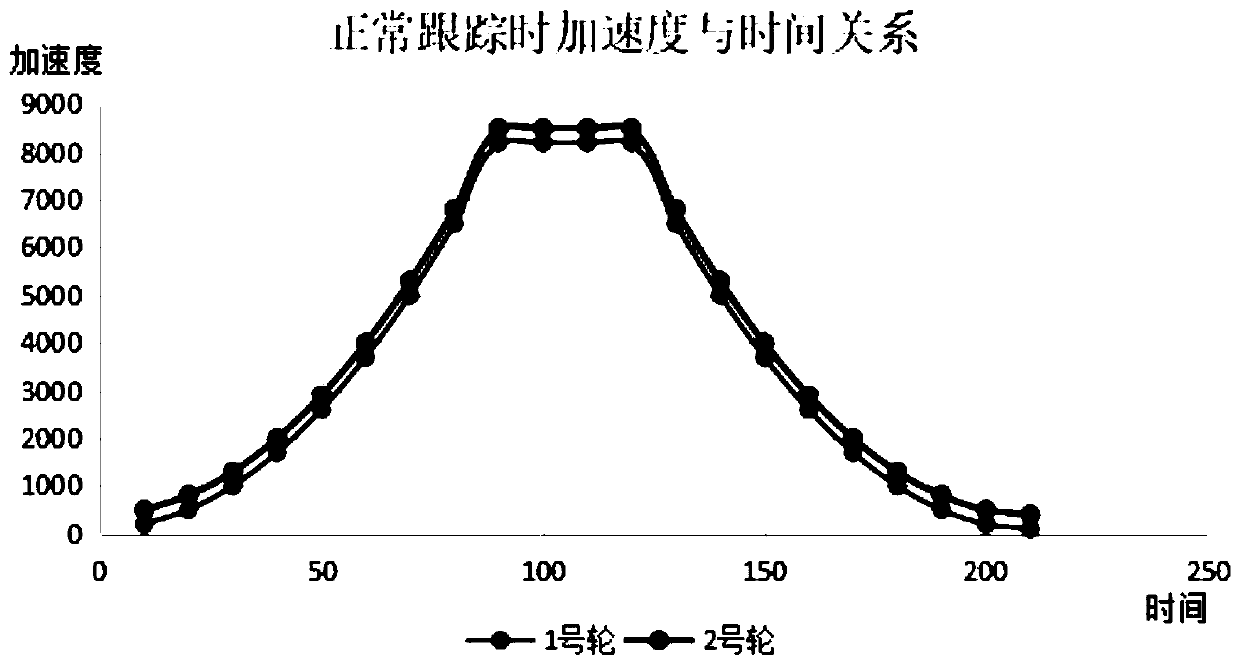

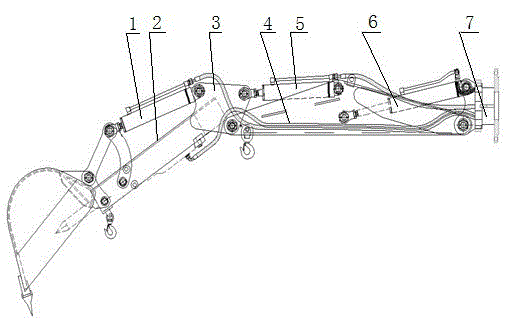

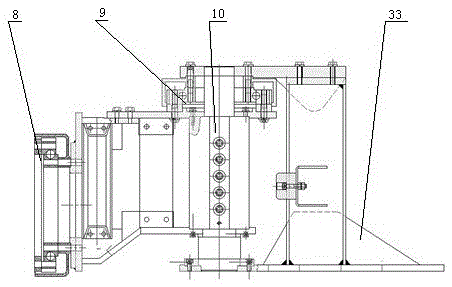

Breaking loading roadway repairing machine for coal mine

InactiveCN103669440AAchieve riseRealize the whereaboutsMechanical machines/dredgersCouplingFuel tank

The invention discloses a breaking loading roadway repairing machine. A vehicle body part comprises a worktable, a driving device, a running device, an oil tank and a supporting leg, wherein the driving device and the running device adopt a hydraulic transmission mode, the driving device is a hydraulic driving device, is arranged at the rear portion of the worktable and comprises an explosion-proof diesel engine and an oil pump, the explosion-proof diesel engine transmits the oil pump through a coupler, an input port of the oil pump and the oil tank are communicated through an oil path, and an output port of the oil pump and two sets of oil path control valves are communicated through oil paths. Liquid is supplied to the running device and each oil cylinder through the two sets of oil path control valves, the H-shaped supporting leg is arranged at the rear portion of a support of the vehicle body, and the supporting leg is matched with a supporting leg guide rail in a sliding mode.

Owner:许世东

Rubber vehicle suspension device with variable rigidity property

The invention discloses a rubber vehicle suspension device with variable rigidity property, which is characterized in that a vehicle frame is fixedly connected with a cross beam, a connection bracket is arranged on the vehicle frame, one end of a V-shaped thrusting rod is fixed on the vehicle frame and the other end thereof is fixed at the upper end of an axle through a thrusting rod pedestal, one end of a multi-layer rubber nonprismatic bumper block is fixed at the bottom end of the connection bracket, the other end thereof is suspended over the top end of a rubber spring bracket, the rubber spring bracket is fixed on a lug support by a bolt, both ends of the lug support are respectively connected with an axle pedestal which is fixed on the axle. By the above setting, the rubber vehicle suspension device with variable rigidity property has large bearing capacity, low frequency of vibration in the situation of idle load and full load, and small lateral oscillation of vehicle.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

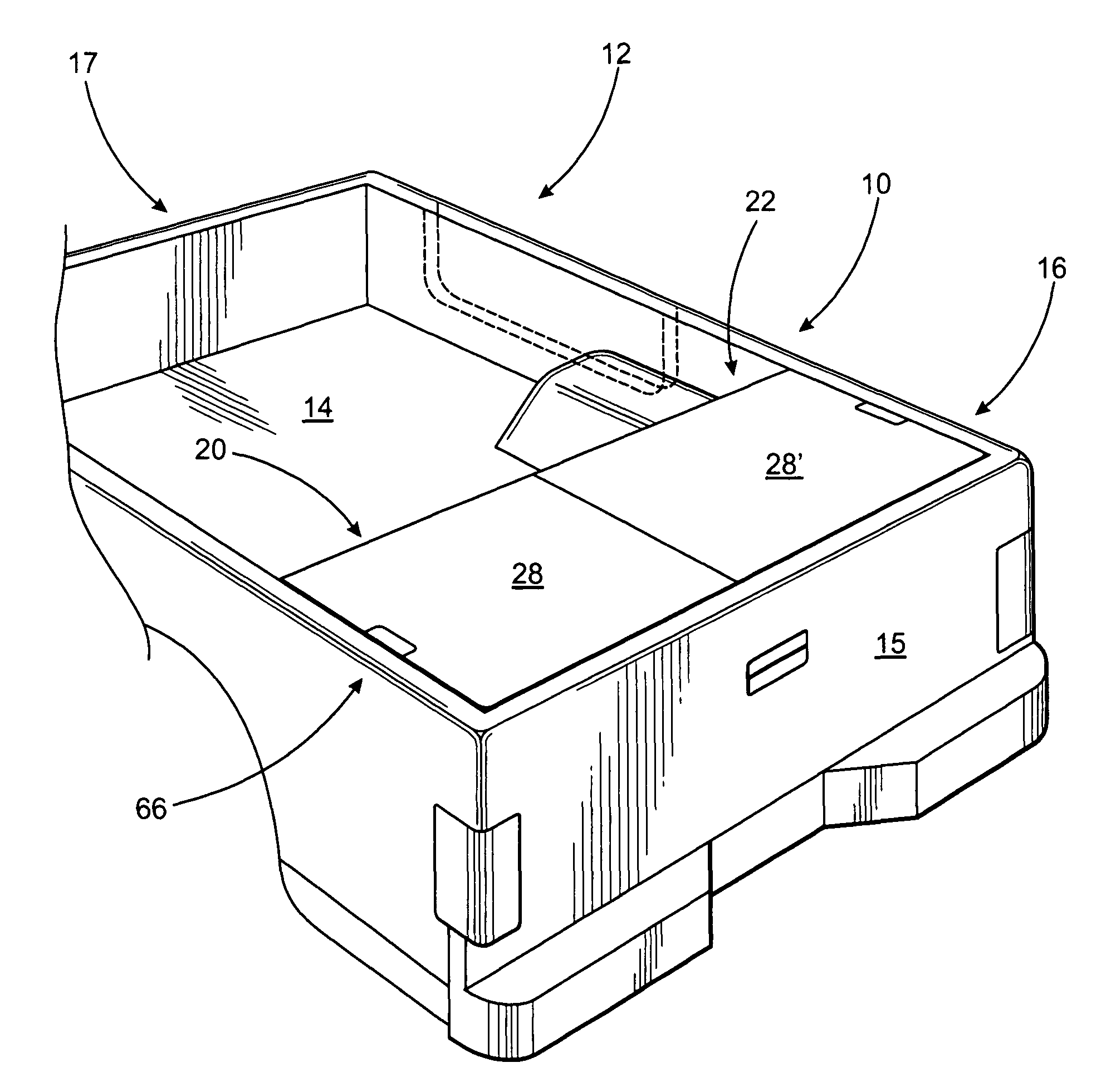

Airflow deflector assembly

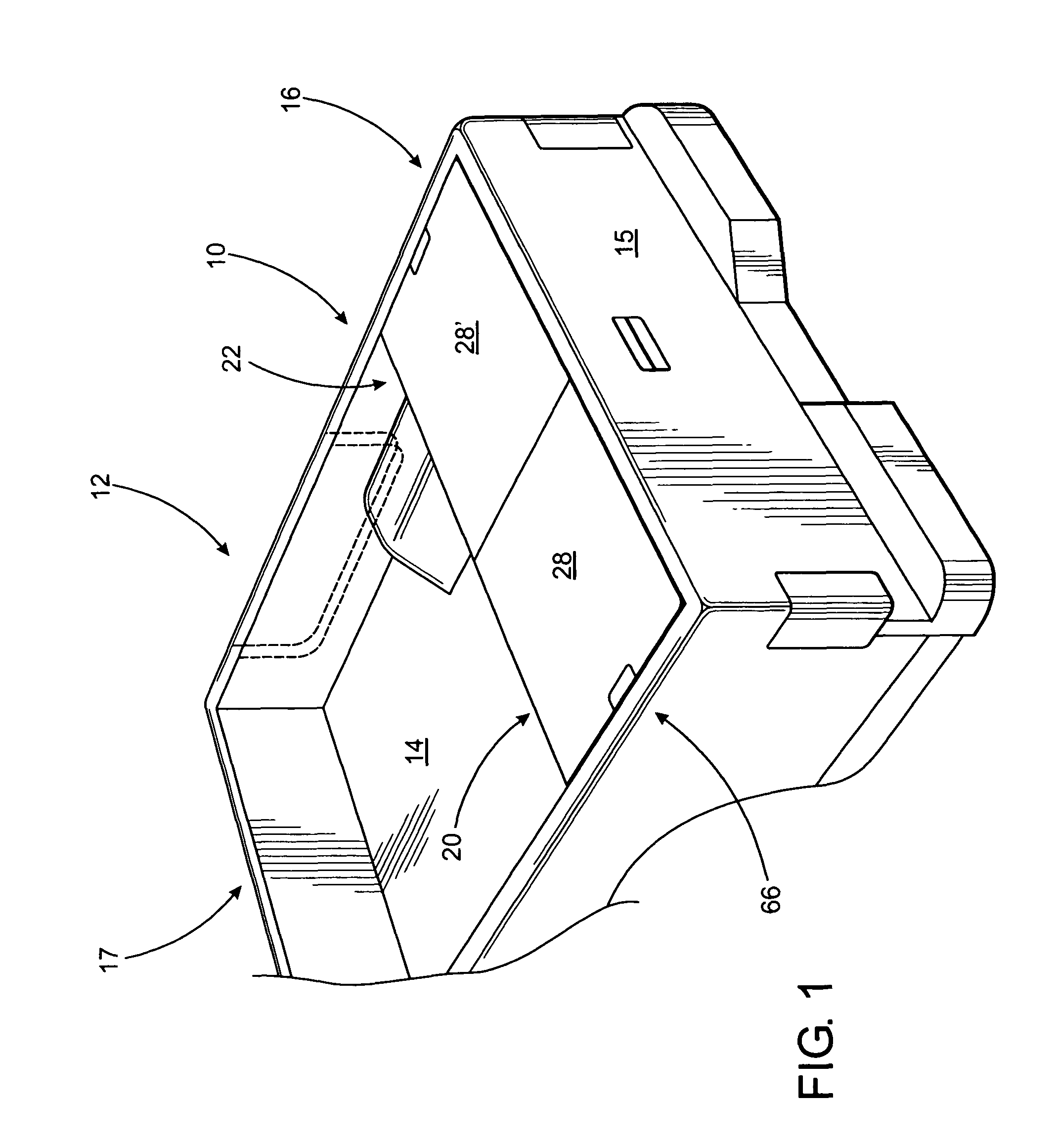

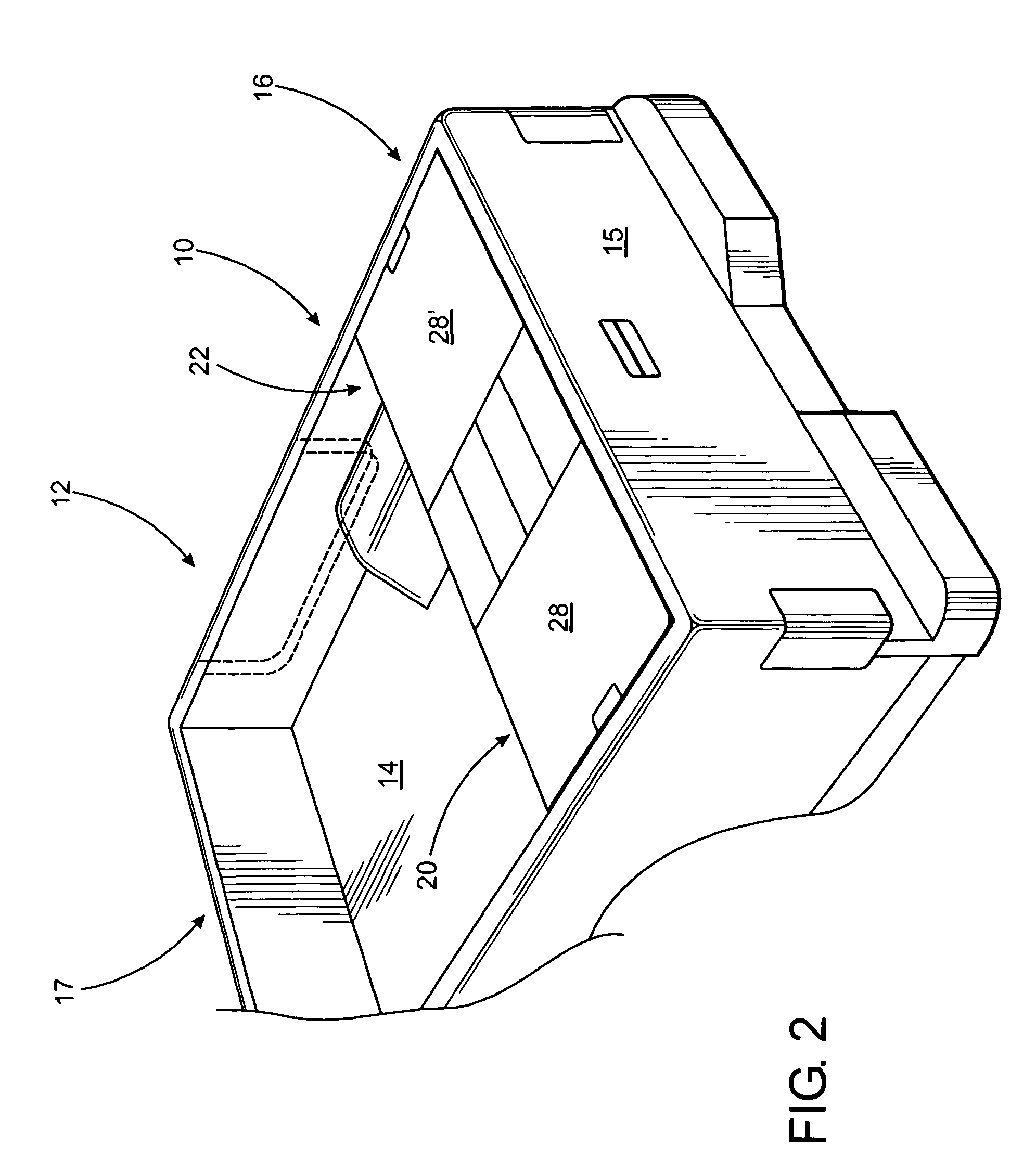

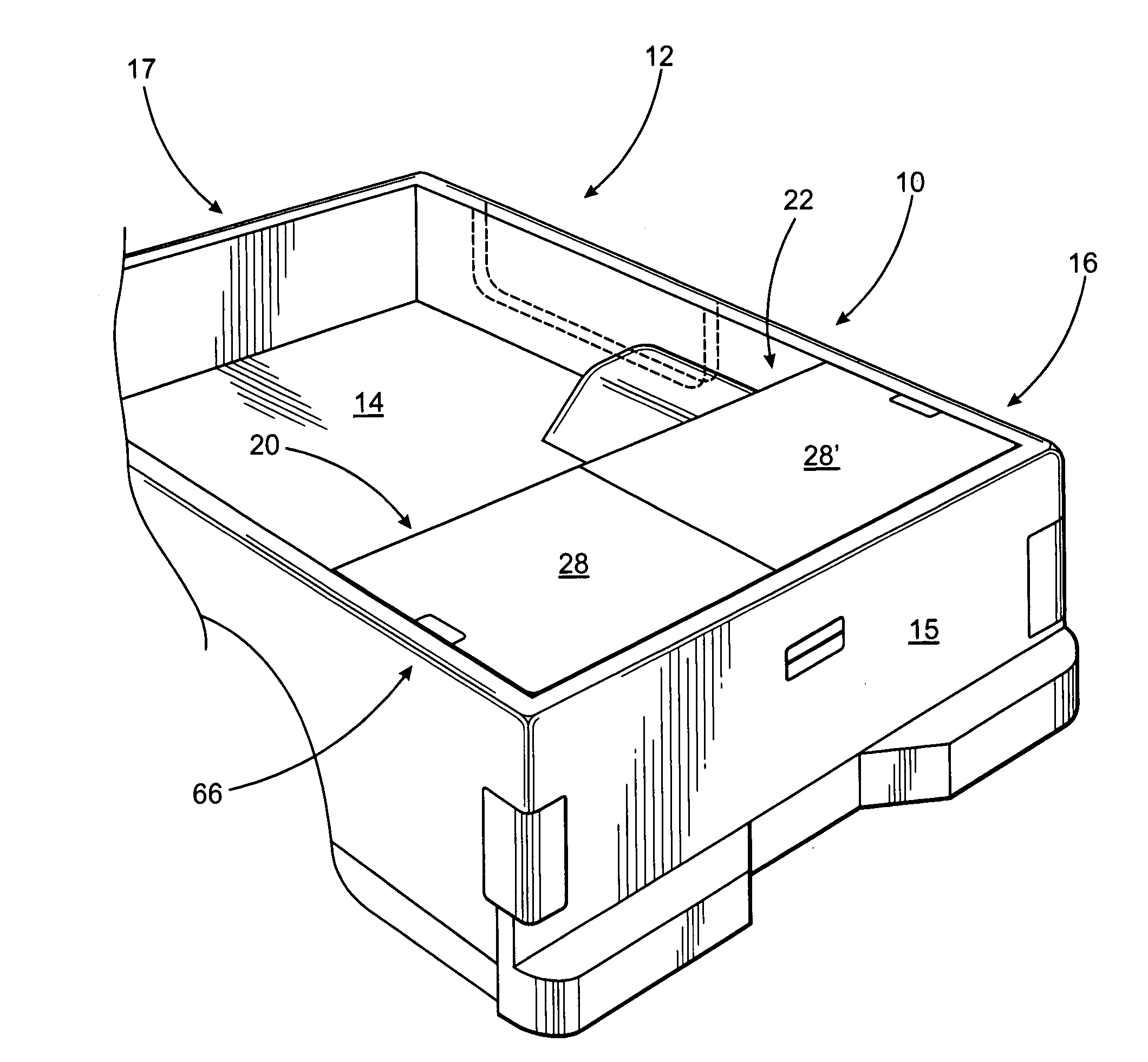

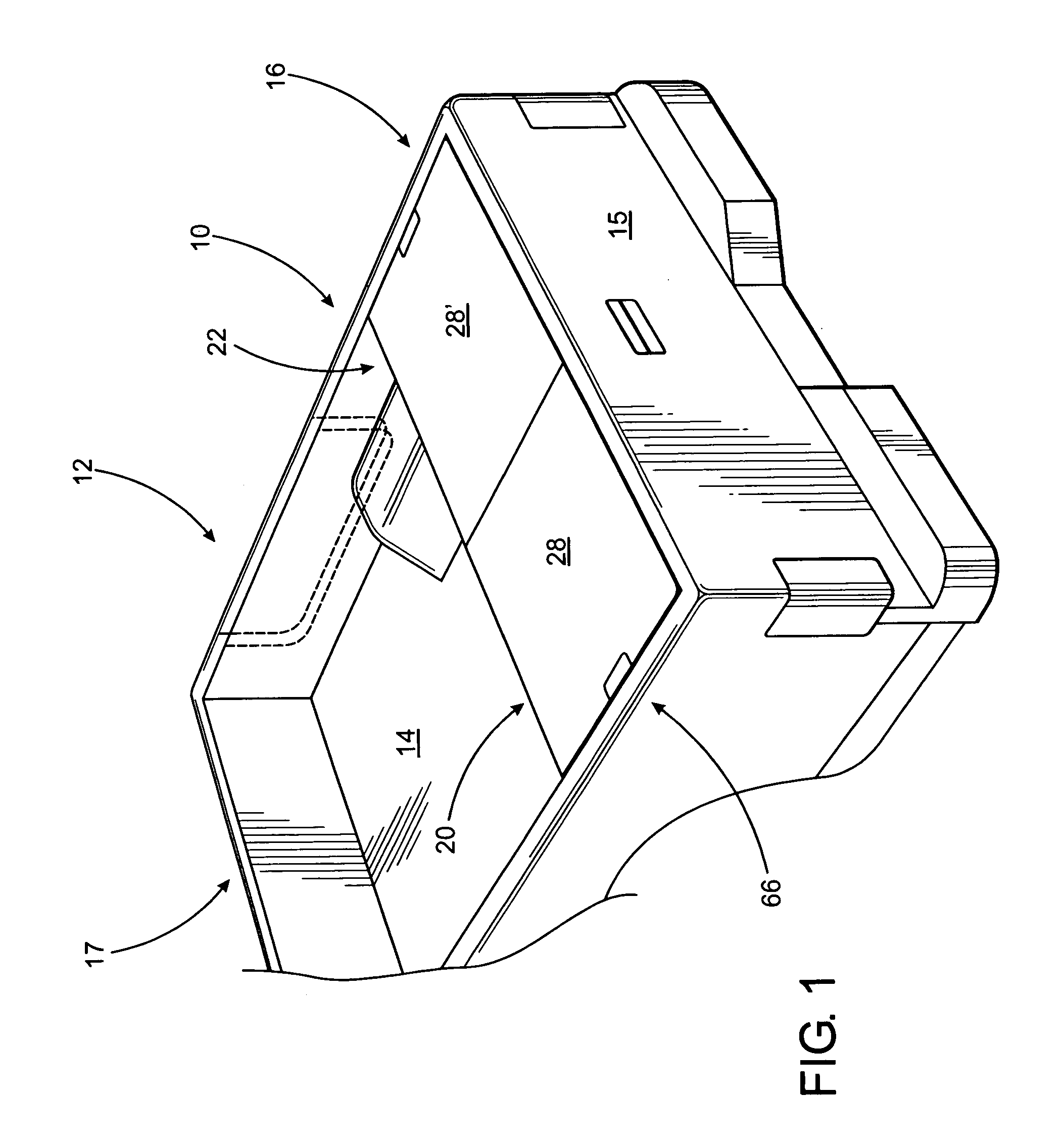

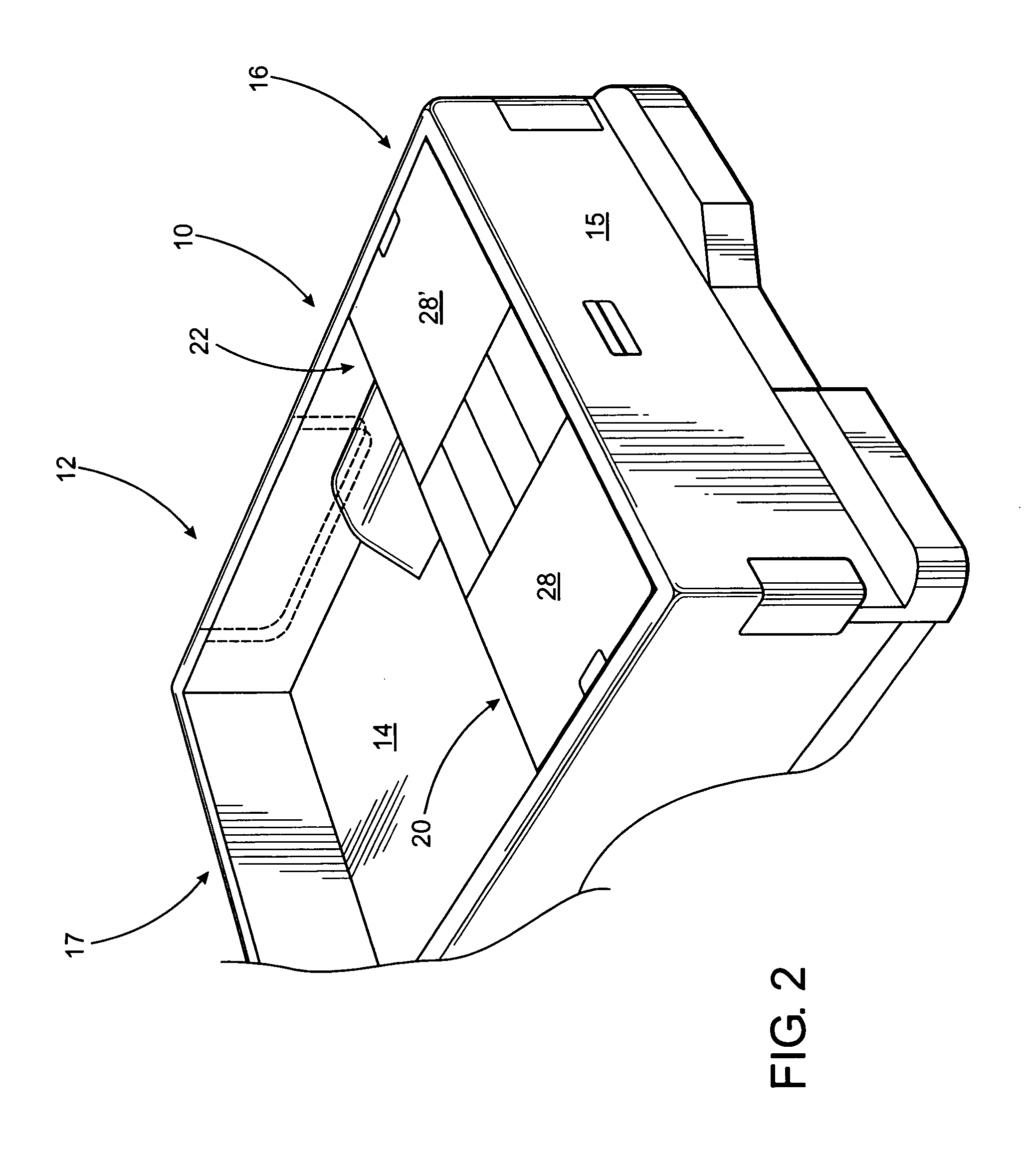

InactiveUS7878576B1Great tractionImprove fuel efficiencyVehicle seatsWindowsInterconnectionEngineering

An airflow deflector assembly for an open bed truck or like vehicle including a plurality of preferably two cover sections each having a base and an attachment assembly cooperatively disposed and structured to adjustably interconnect the two cover sections facilitating their selective positioning into any one of a plurality of operative orientations. The selected operative orientation corresponds to the width of the trailing end of the open bed of the vehicle so as to so as to establish a substantially continuous air deflecting surface over the trailing end and thereby increasing the aerodynamics of the vehicle. The cooperative structuring of the attachment assemblies facilitate an adjustable sliding interconnection there between such that the bases of each cover section may be reciprocally positioned toward and away from one another to assume the preferred operative orientation corresponding to the width of the truck bed.

Owner:EMBLER SUSAN +2

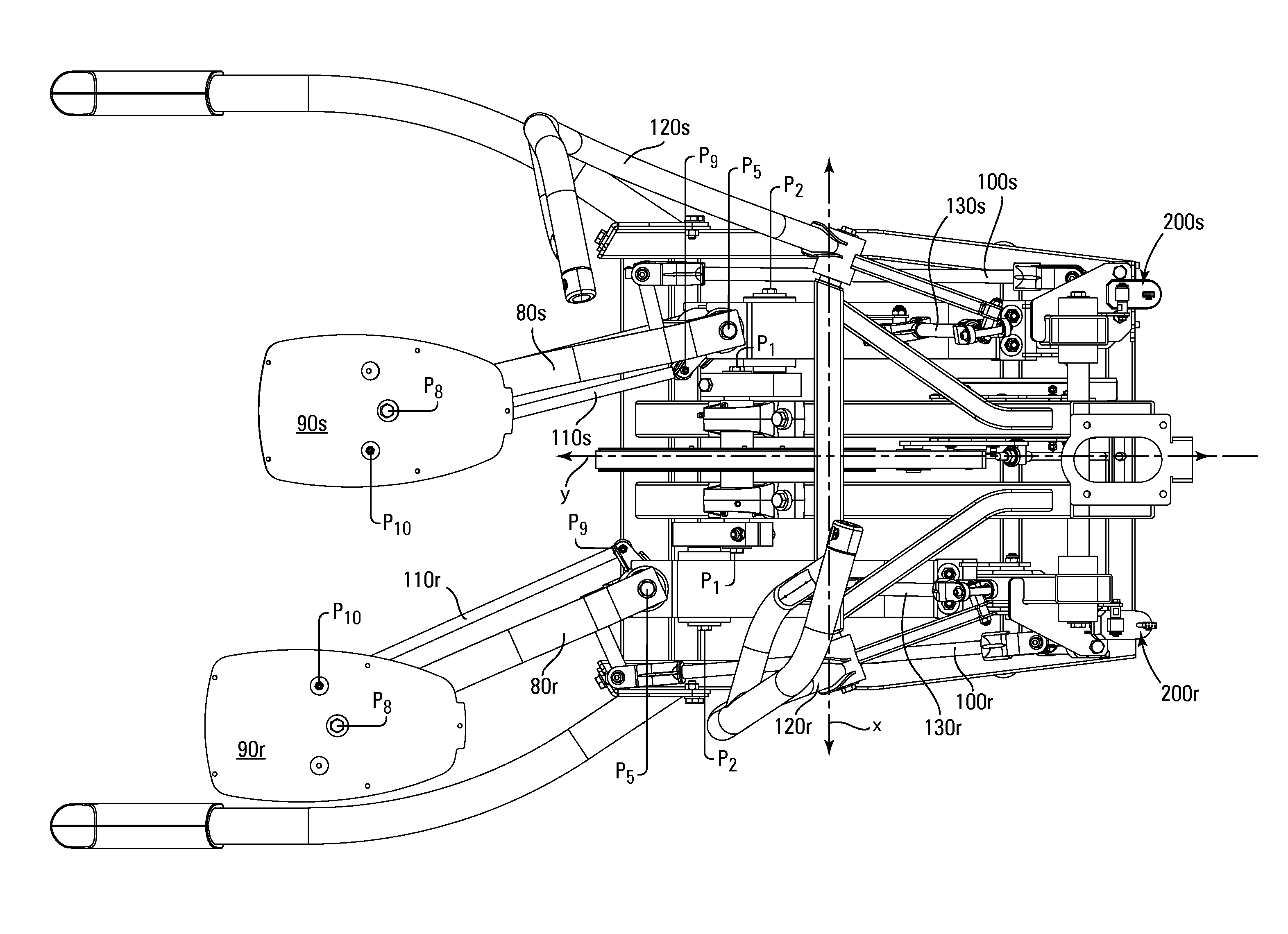

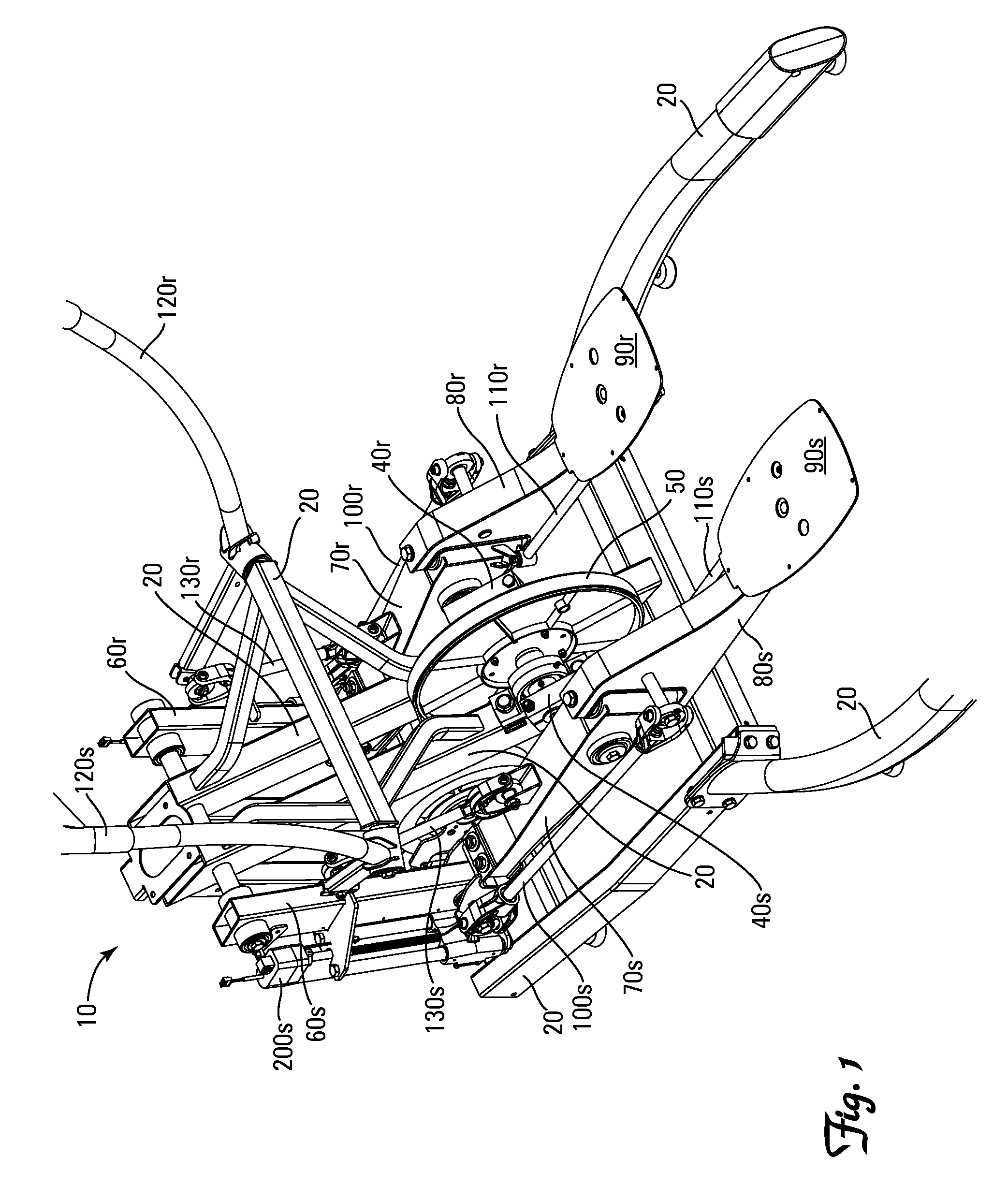

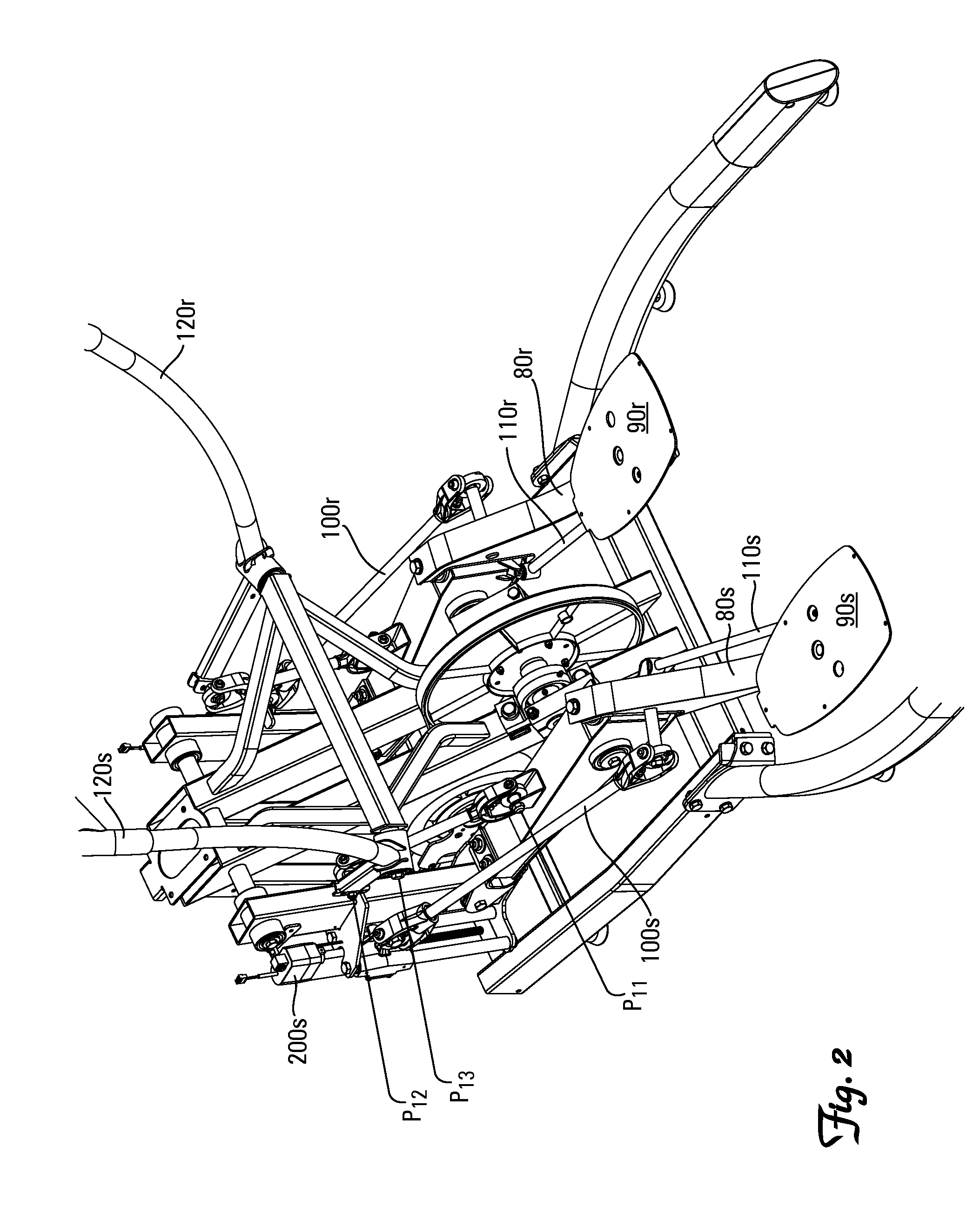

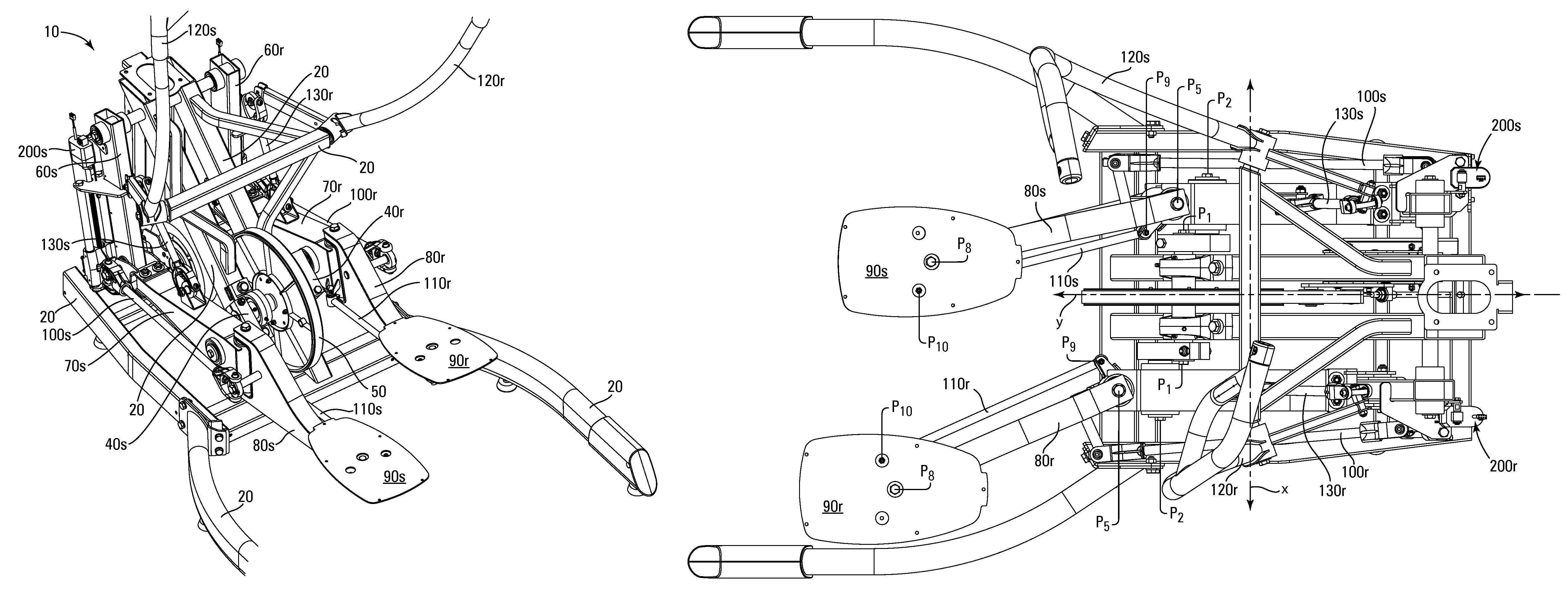

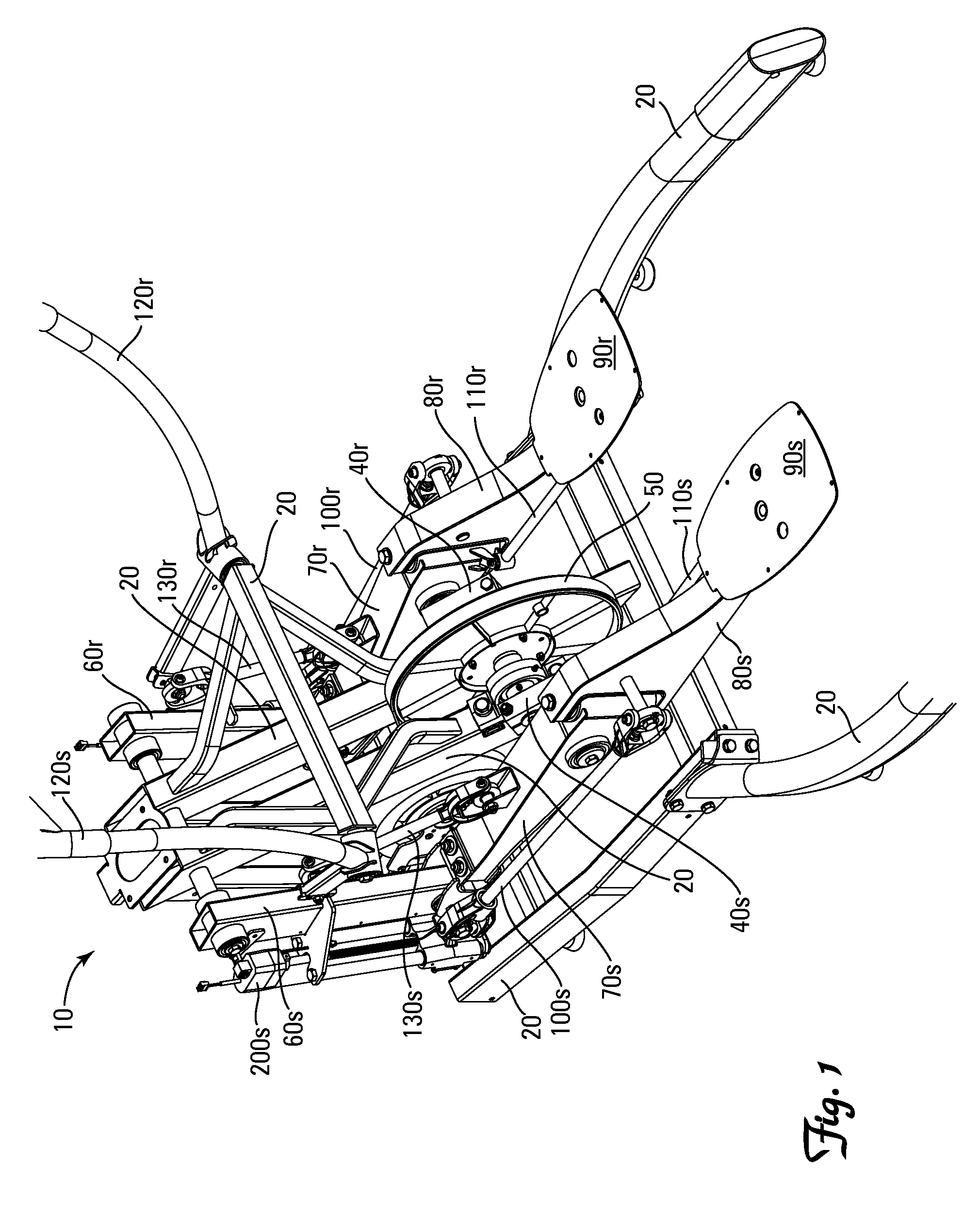

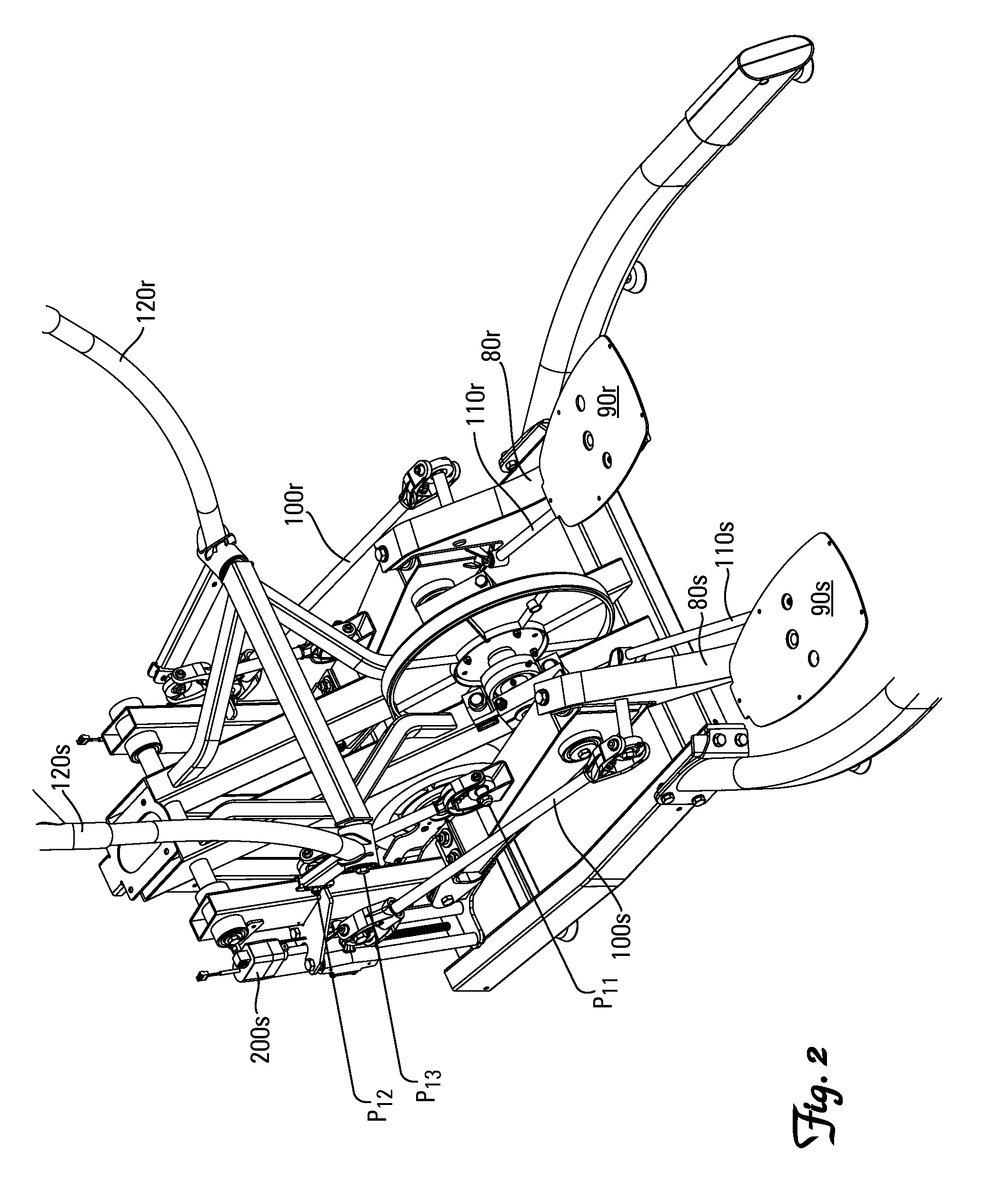

Lateral glide elliptical exercise machine with yaw control

ActiveUS20160089562A1Reduce yawMuscle exercising devicesMovement coordination devicesEllipseFoot supports

A lateral glide stationary elliptical exercise device (10) with foot support platform (90) yaw control. Yaw control is achieved by a four bar dual rocker linkage yaw control mechanism that includes (i) a foot link (70) with a pair of laterally offset first (p5) and second (p9) connection points constrained to move through generally elliptical paths within parasagittal planes, (ii) a glide link (80) pivotably connected at a first end to the first connection point (p5), (iii) a drawbar (100) pivotably connected at a first end to the second connection point (p9), and (iv) a foot support platform (90) pivotably connected proximate a second end of the glide link (80) and proximate a second end of the drawbar (100).

Owner:OCTANE FITNESS

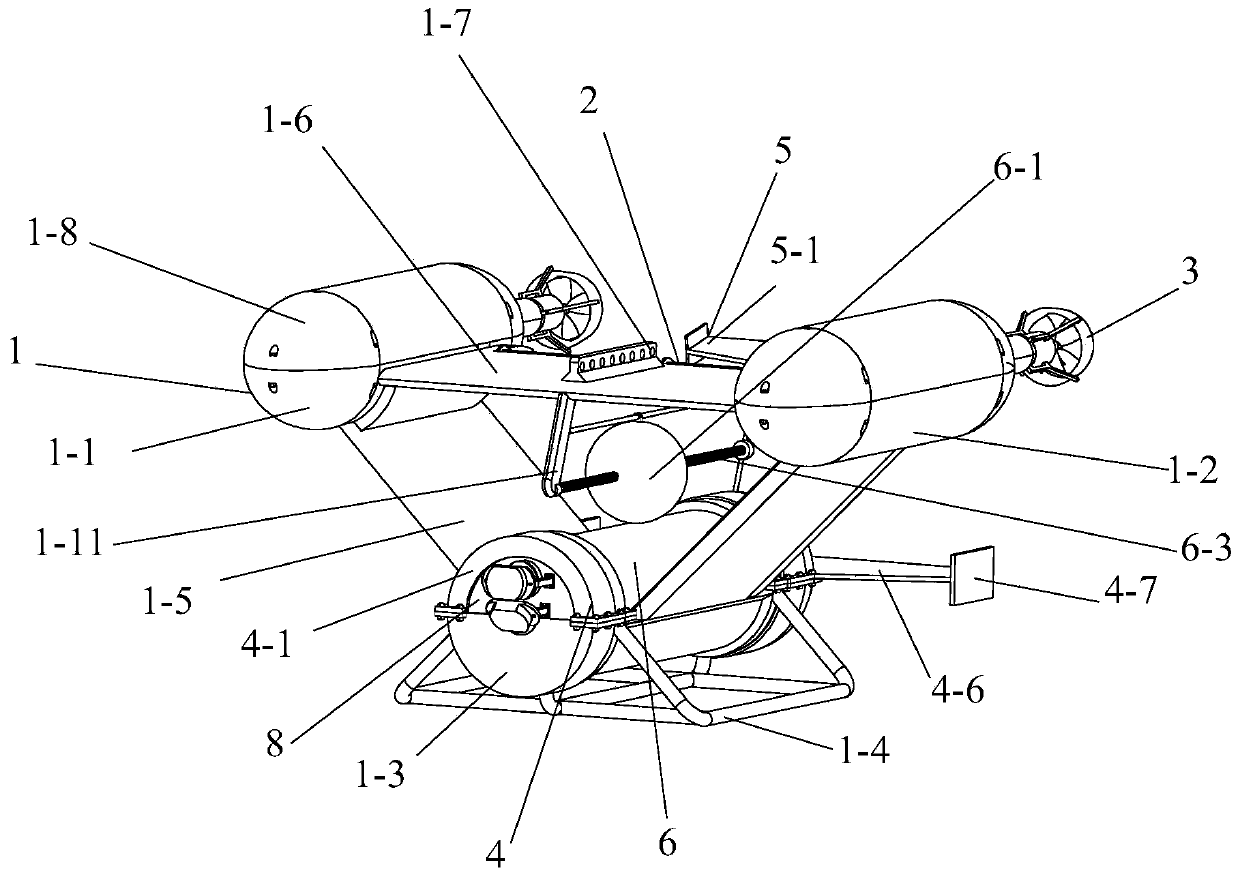

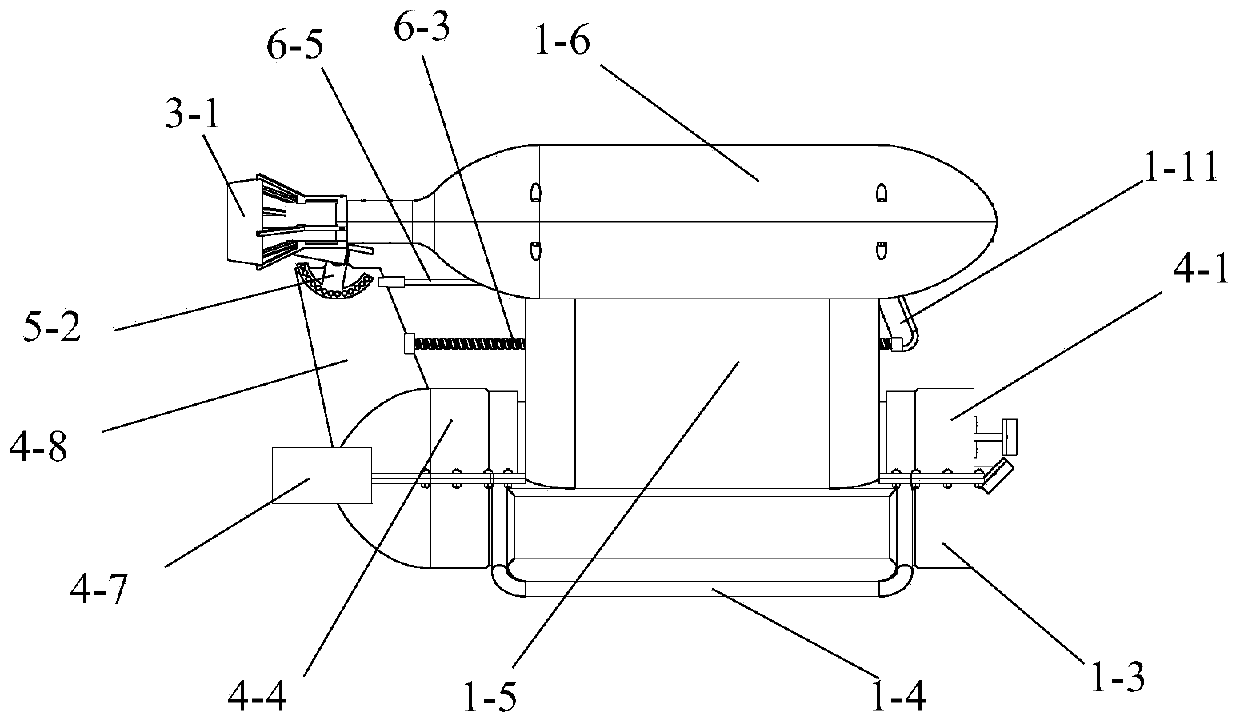

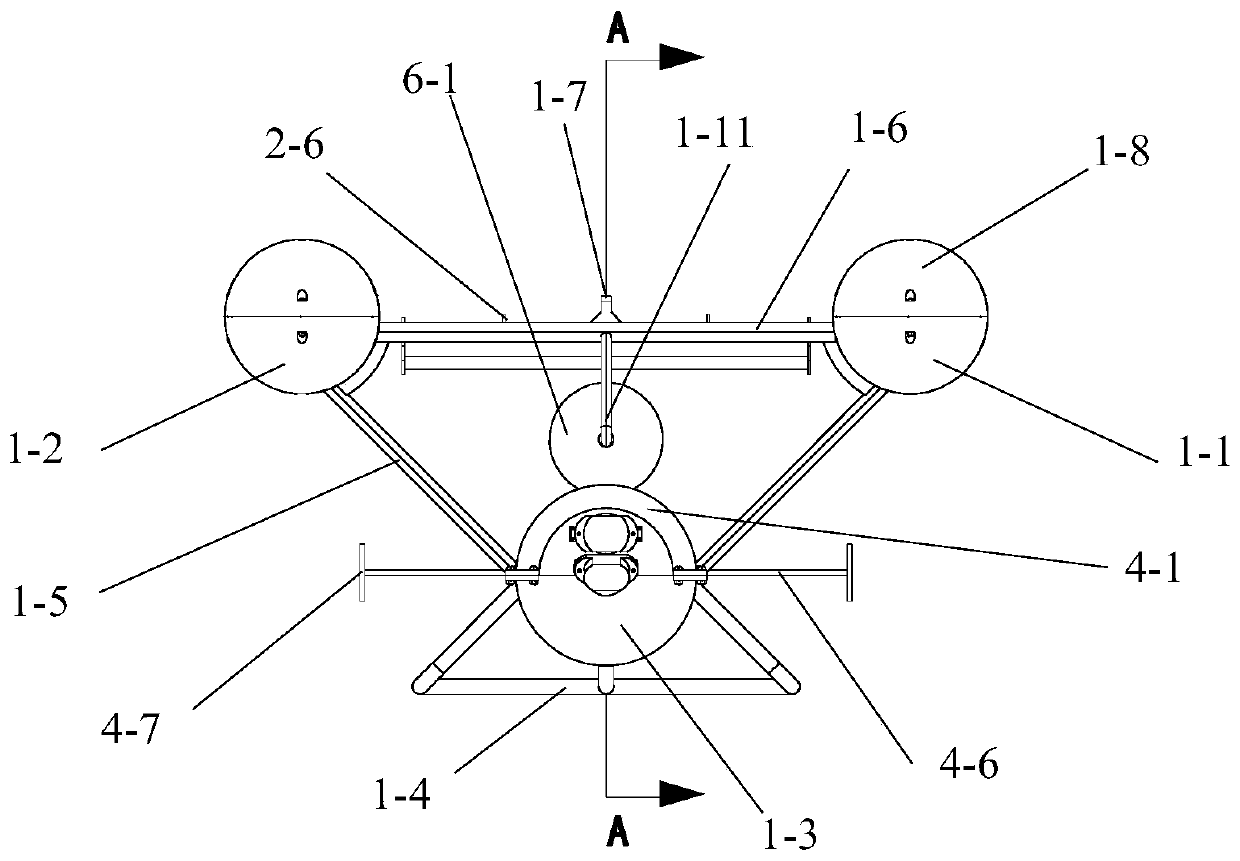

Autonomous stable multi-degree-of-freedom motion controllable pod type underwater towed body

ActiveCN110435858ALower center of gravityStable center of gravityUnderwater vesselsUnderwater equipmentUnderwaterControl system

The invention discloses an autonomous stable multi-degree-of-freedom motion controllable pod type underwater towed body which comprises a main body, a heave control mechanism, a bow turning control mechanism, an instrument pod fixing mechanism, a wing type trim control mechanism, a float type trim control mechanism, a transverse tilt control system and an instrument pod; the left heave control cabin and the right heave control cabin of the main body are of columnar cavity structures, and are arranged on the left side and the right side of the upper end of the main body at intervals; the left heave control cabin and the right heave control cabin are respectively connected with an instrument pod base through two inclined struts, and the left heave control cabin and the right heave control cabin are rigidly connected through a horizontal strut; the middle rear part of the horizontal strut is cut off to form a gap; and the heave control hydrofoil of the heave control mechanism is of a wing-shaped structure arranged in the gap at the rear part of the horizontal strut. The autonomous stable multi-degree-of-freedom motion controllable pod type underwater towed body has the advantages of independent stability, controllable multi-degree-of-freedom motion, good course stability, flexible heave control and the like.

Owner:SOUTH CHINA UNIV OF TECH

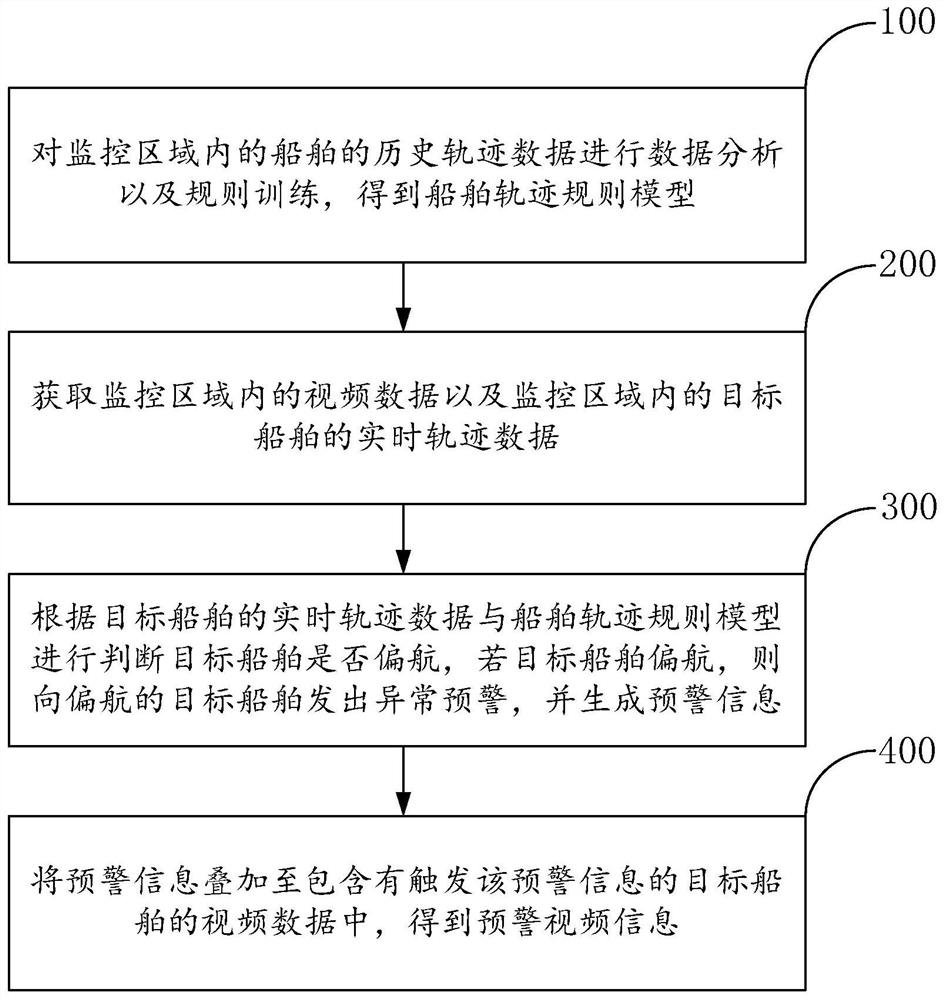

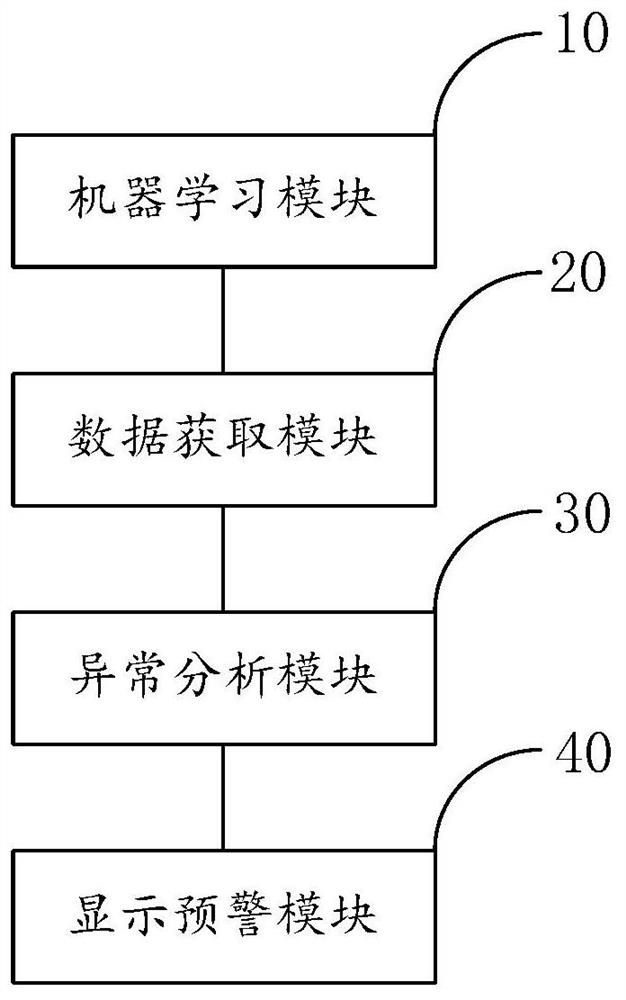

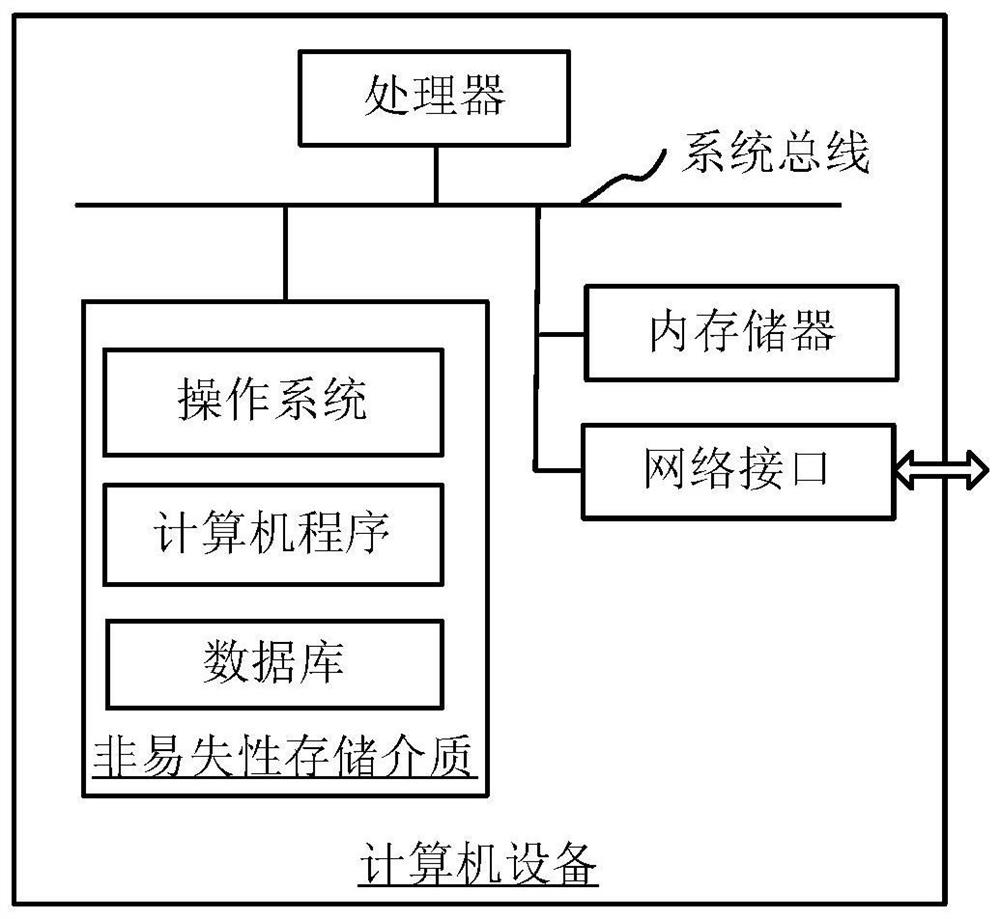

Photoelectric linkage-based ship monitoring method, system and equipment and storage medium

InactiveCN113393707AReduce yawEase of Playback ForensicsImage enhancementImage analysisSimulationMonitoring methods

The invention relates to a photoelectric linkage-based ship monitoring method, system and equipment and a storage medium, and the main points of the technical scheme are that the method comprises the steps: carrying out data analysis and rule training on the historical trajectory data of a ship in a monitoring region, and obtaining a ship trajectory rule model; obtaining video data in the monitoring area and real-time trajectory data of a target ship in the monitoring area; according to the real-time trajectory data of the target ship and the ship trajectory rule model, judging whether the target ship yaws, if yes, sending abnormal early warning to the yawing target ship, and generating early warning information; and superposing the early warning information to video data containing a target ship triggering the early warning information to obtain early warning video information. The method has the effects of monitoring the dynamic state of the ship in real time, controlling the destination of the ship and performing early warning on the abnormal ship.

Owner:广州嘉航通信科技有限公司

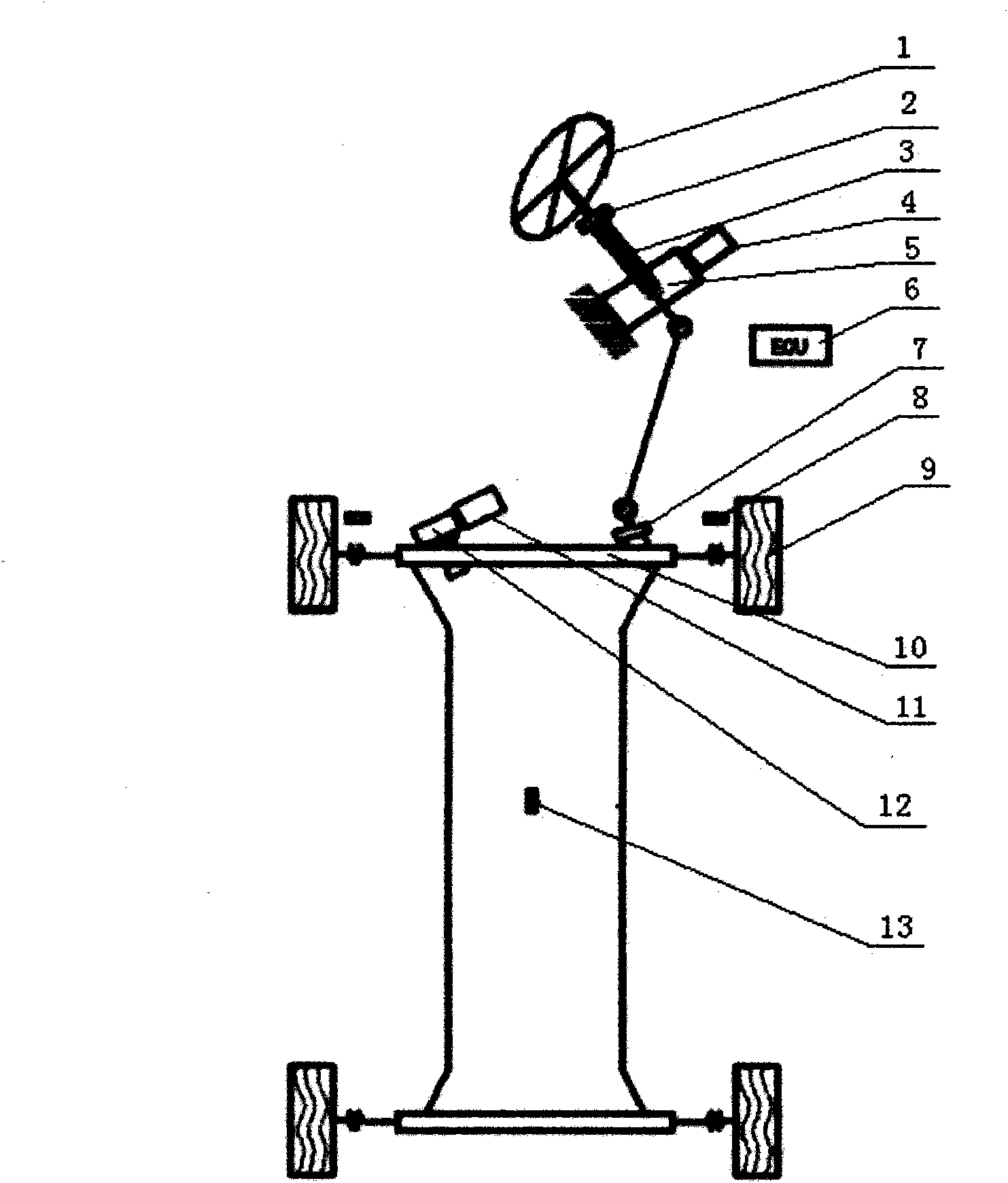

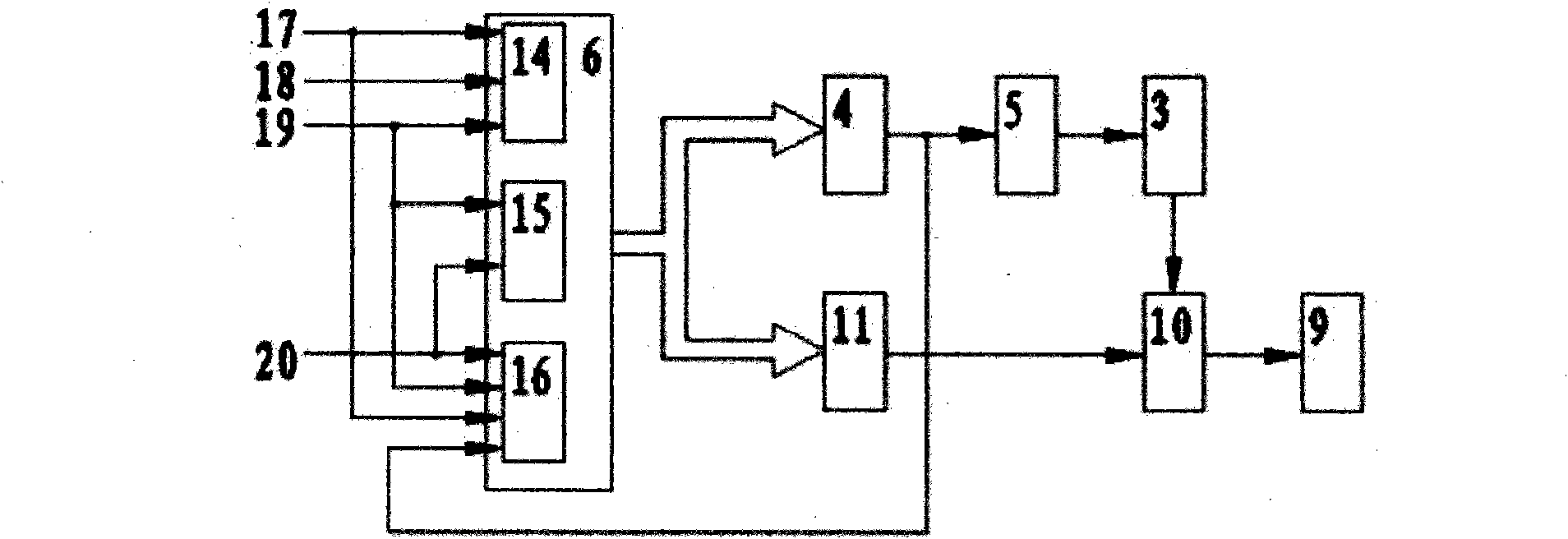

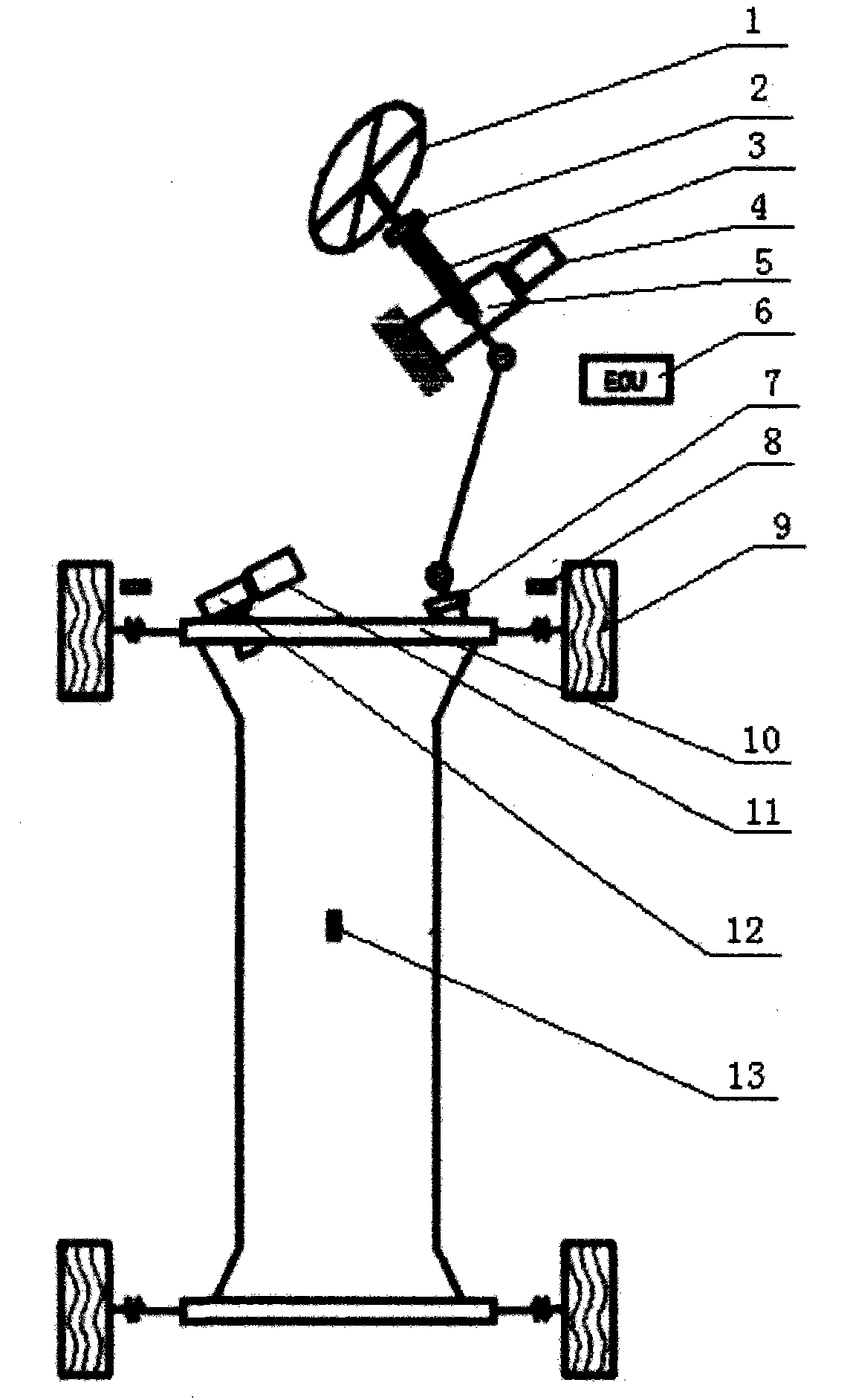

Active electric power steering system capable of changing steering system transmission ratio

InactiveCN101898583AGuaranteed stabilityGuaranteed to drive in a straight lineSteering linkagesAutomatic steering controlElectric power steeringGyroscope

The invention discloses an active electric power steering system capable of changing a steering system transmission ratio, which comprises a steering wheel, a steering column, a steering angle sensor, a torque sensor, a worm gear speed reducer, an assisted motor, a gear rack steering gear, an infinitely variable transmission, a steering angle speed ratio adjustment motor which drives the infinitely variable transmission, a wheel speed sensor, a gyroscope and a steering system controller. The gear ratio control adjustment motor realizes the continuous and smoothly infinite variation of steering transmission ratios at different vehicle speeds, and also can perform steering angle compensation; and in the steering transition of a vehicle, negative steering adjustment is actively performed, and in the steering process, the adjustment motor and the assisted motor perform flexible control and compensate for each other, thereby perfectly combining steering flexibility, convenience and operation stability and improving maneuvering performance and security performance.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

Lateral glide elliptical exercise machine with yaw control

ActiveUS9364707B2Reduce yawMuscle exercising devicesMovement coordination devicesClassical mechanicsFoot supports

A lateral glide stationary elliptical exercise device (10) with foot support platform (90) yaw control. Yaw control is achieved by a four bar dual rocker linkage yaw control mechanism that includes (i) a foot link (70) with a pair of laterally offset first (p5) and second (p9) connection points constrained to move through generally elliptical paths within parasagittal planes, (ii) a glide link (80) pivotably connected at a first end to the first connection point (p5), (iii) a drawbar (100) pivotably connected at a first end to the second connection point (p9), and (iv) a foot support platform (90) pivotably connected proximate a second end of the glide link (80) and proximate a second end of the drawbar (100).

Owner:OCTANE FITNESS

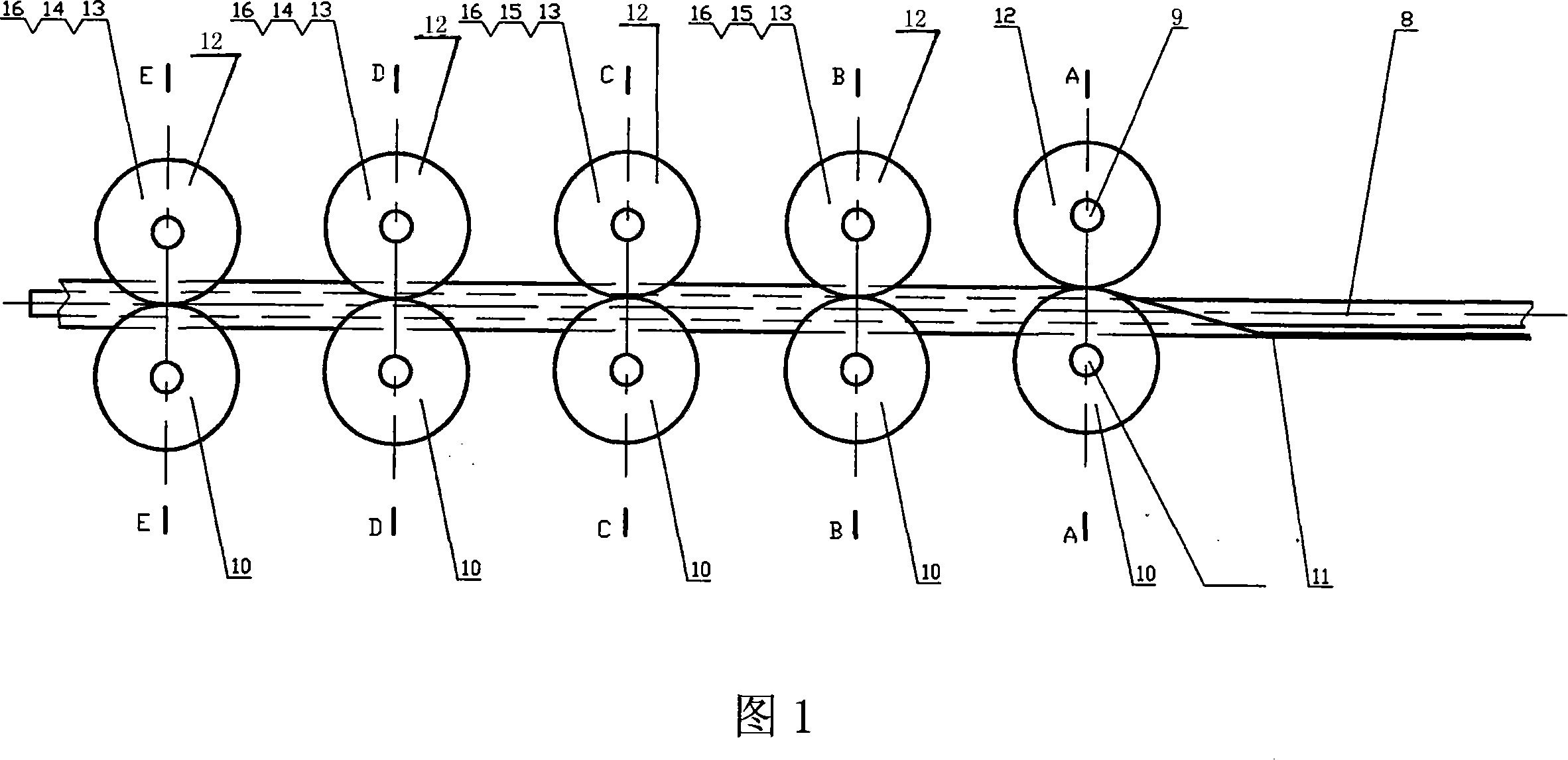

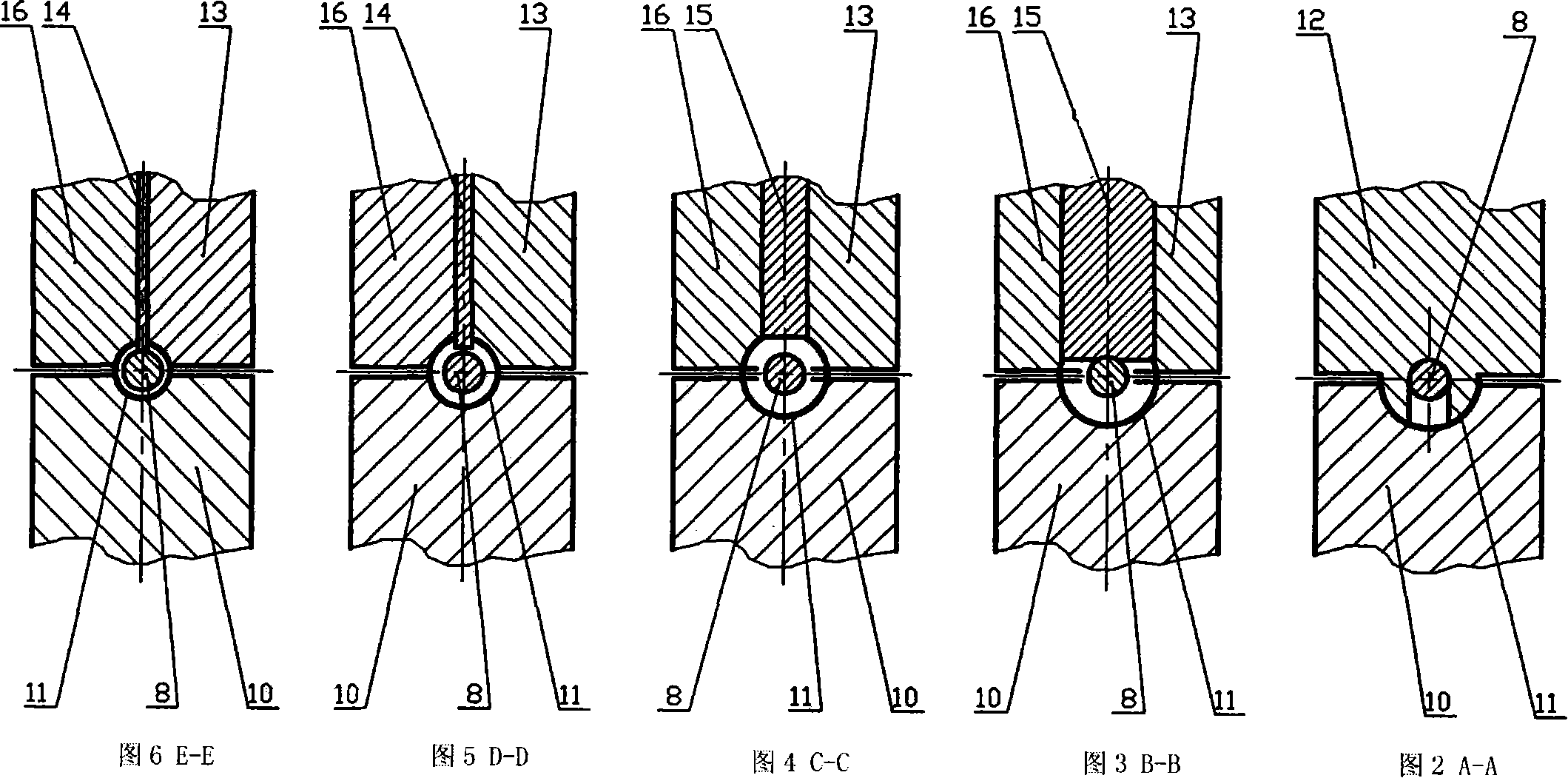

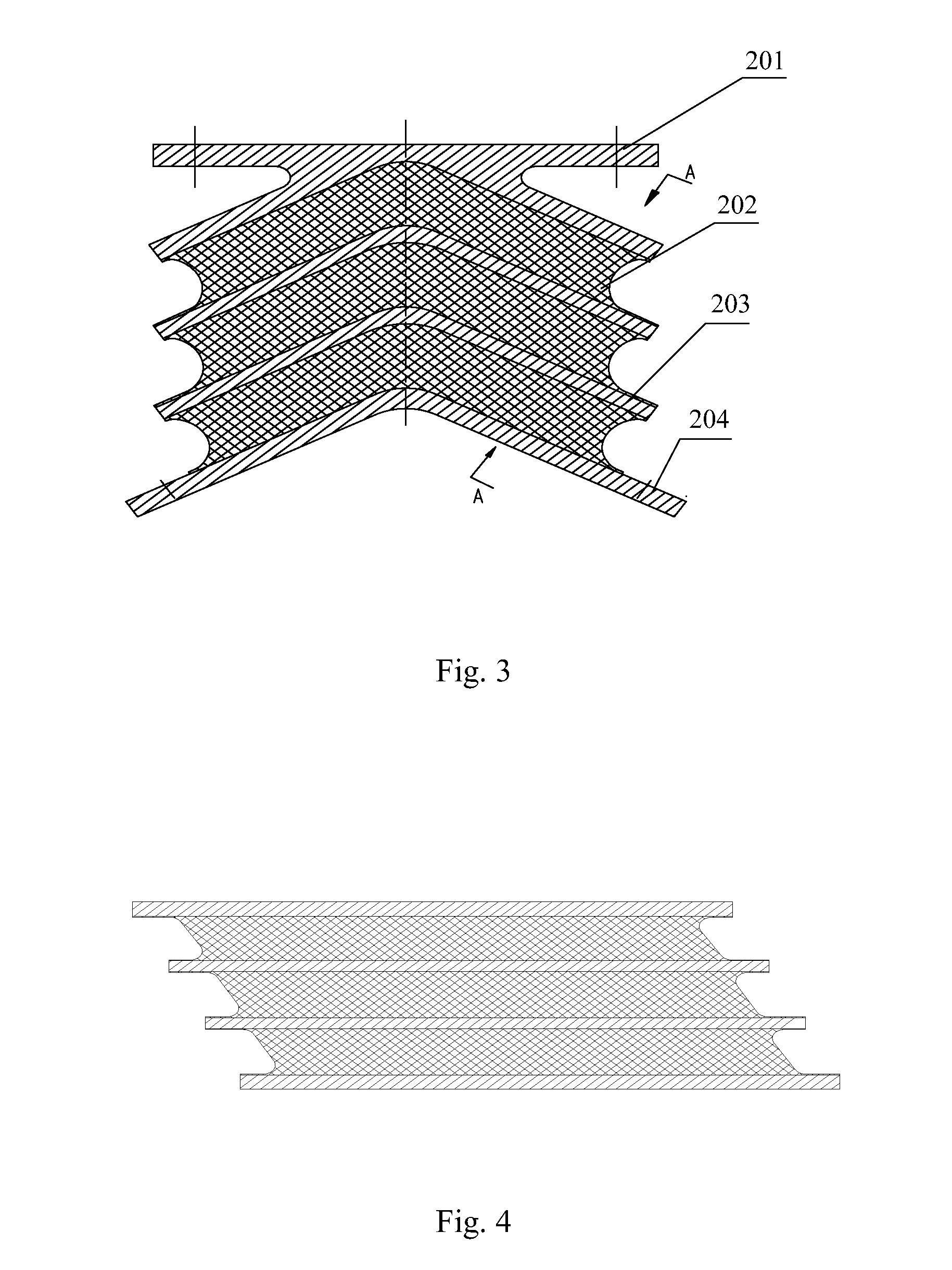

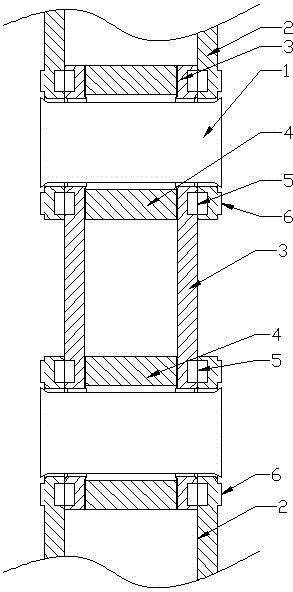

Coiled pipe forming roller assembly

InactiveCN101121185AMeet the technical requirements of weldingReduce yawStress concentrationSEMI-CIRCLE

The present invention relates to a wrapping pipe welder in particular to a coiled pipe forming roller battery; the invention consists of multilevel a plurality of pairs of upper and lower shaping rollers installed on upper and lower roller output shafts of the wrapping pipe welder. The material input end is the primary level and the output end is the last level; all rollers are arranged according to this sequence and kept on the same central line; the cavity of every pair of upper and lower shaping rollers is reduced and limited level by level and the cavity of the rollers at the last level reaches the set size. In the process that the belting is shaped into a semi-circle one and reduced into a vertical seam-type coiled pipe by being reduced and limited level by level, the cavity of every pair of shaping rollers makes the belting form a smooth arc without hard angle for transition and the phenomenon of local stress concentration will not happen; and then the belting is wrapped on the wrapping pipe welder by an aluminum core rod to be welded; the welding line is stable without oscillation and the welding quality is high with little welding error.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

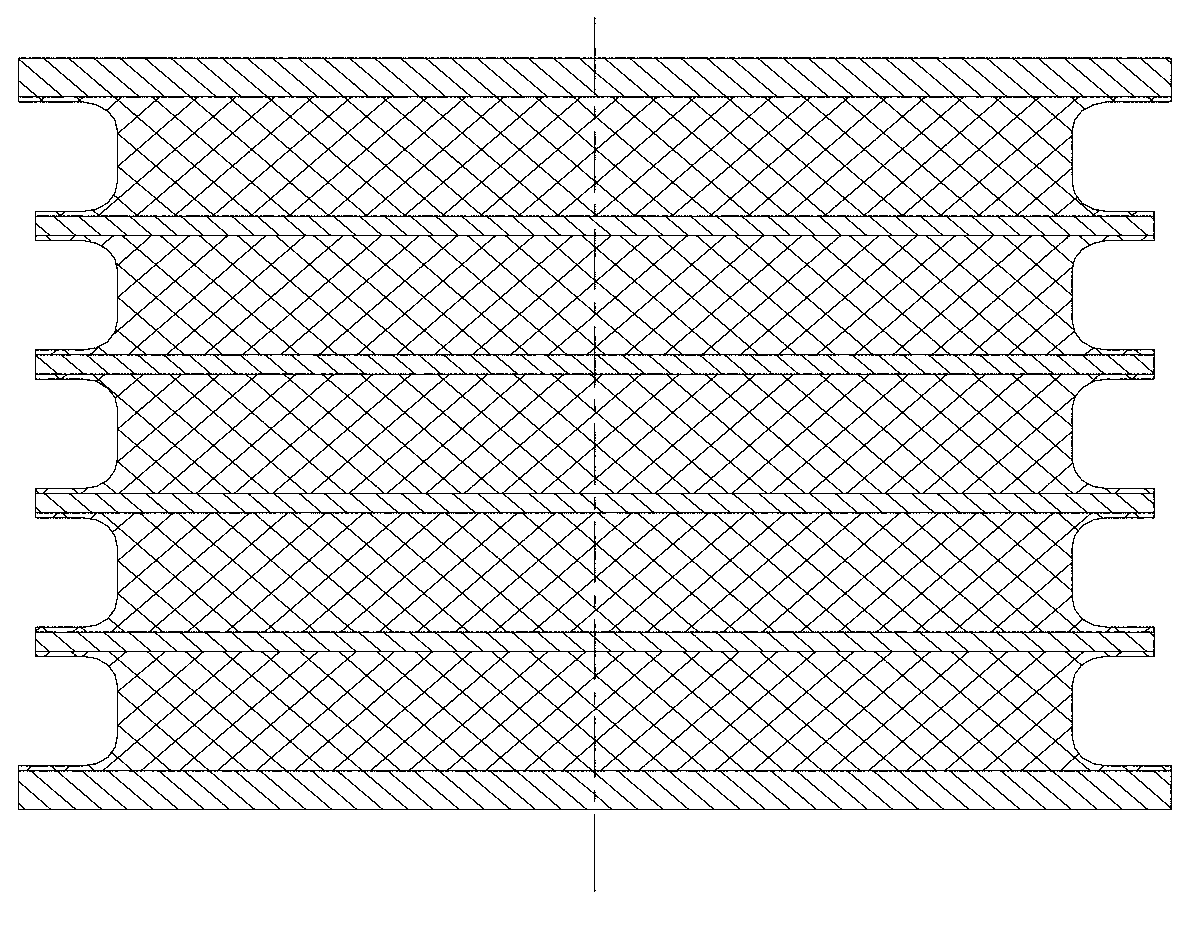

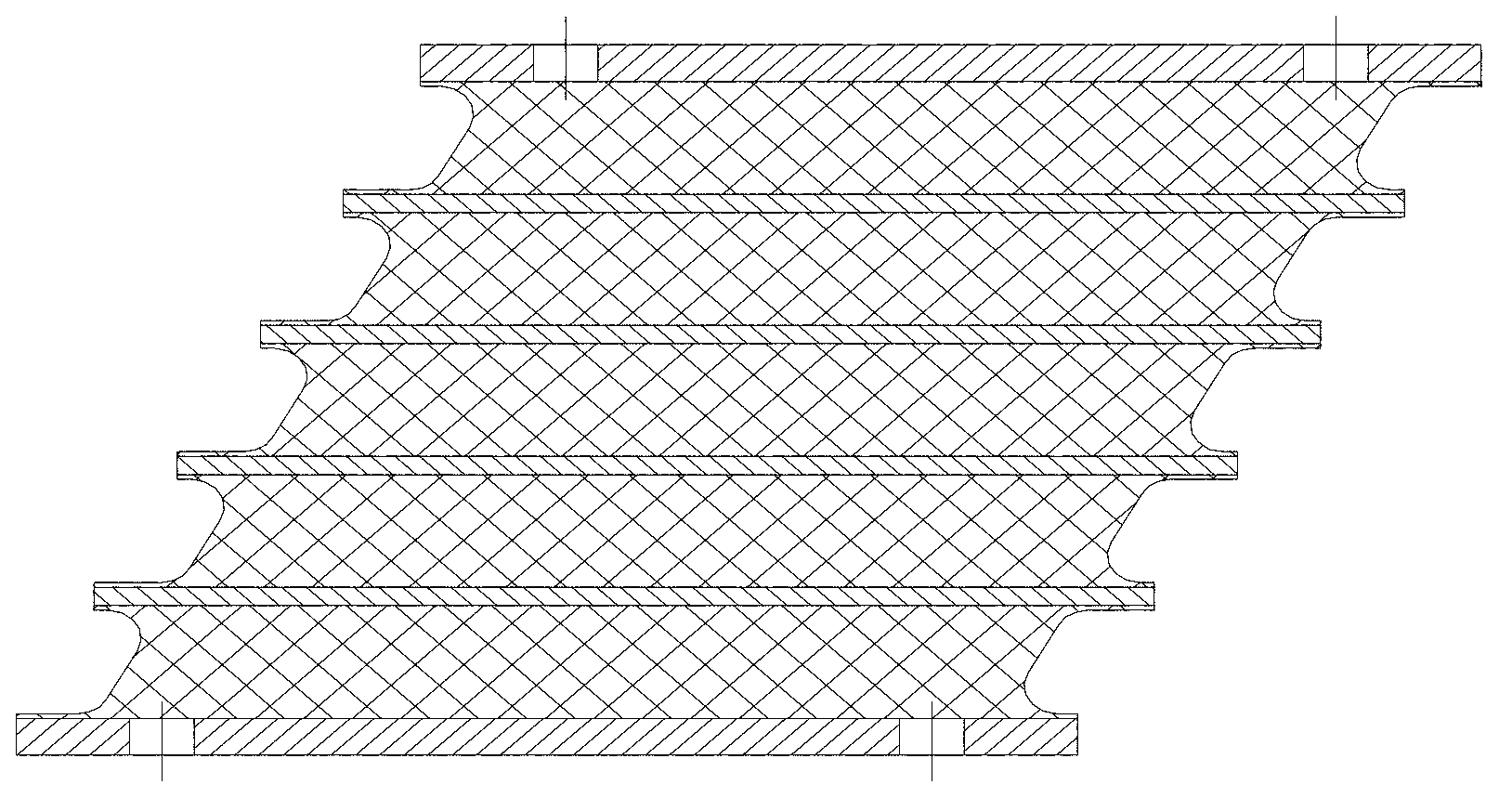

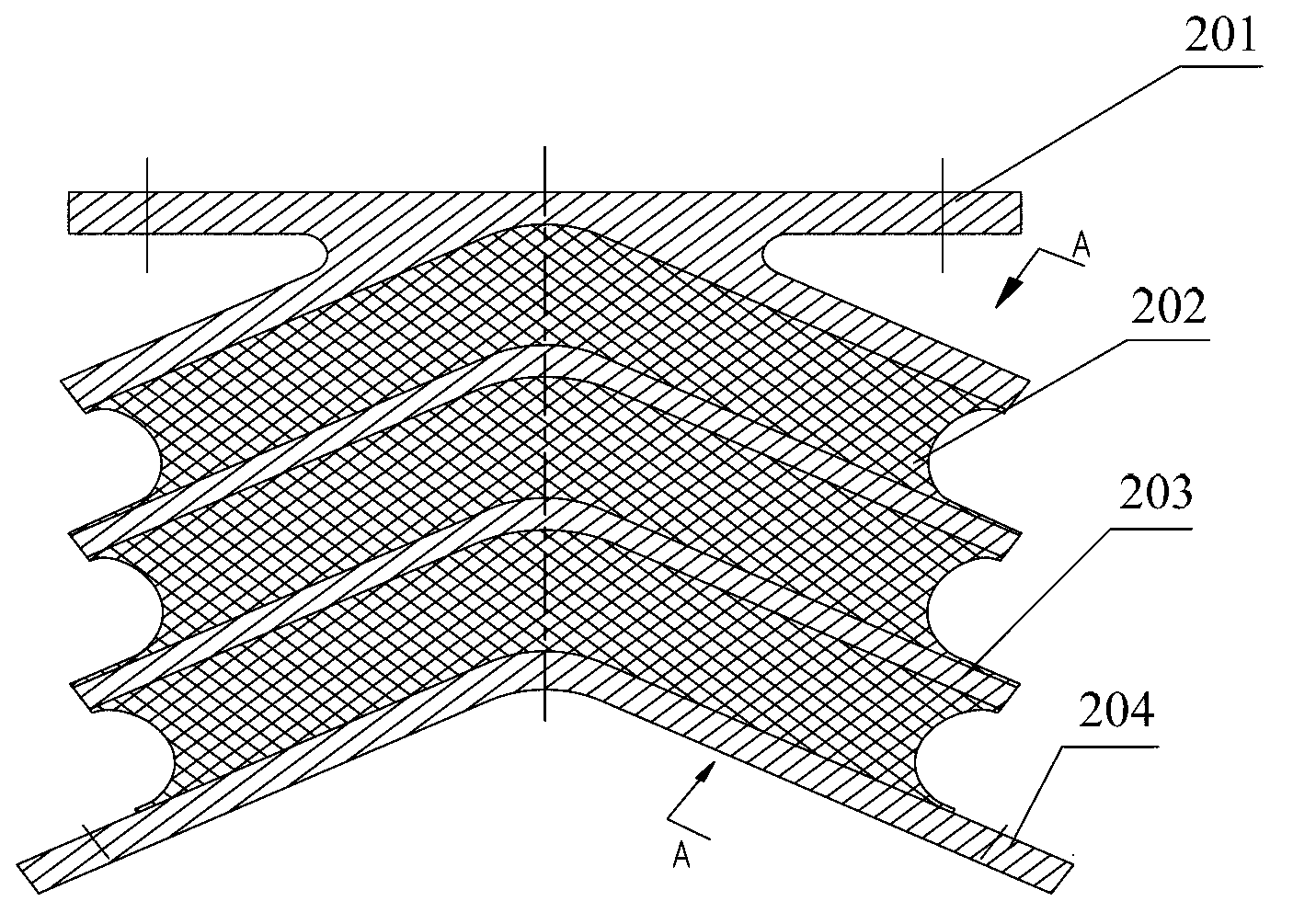

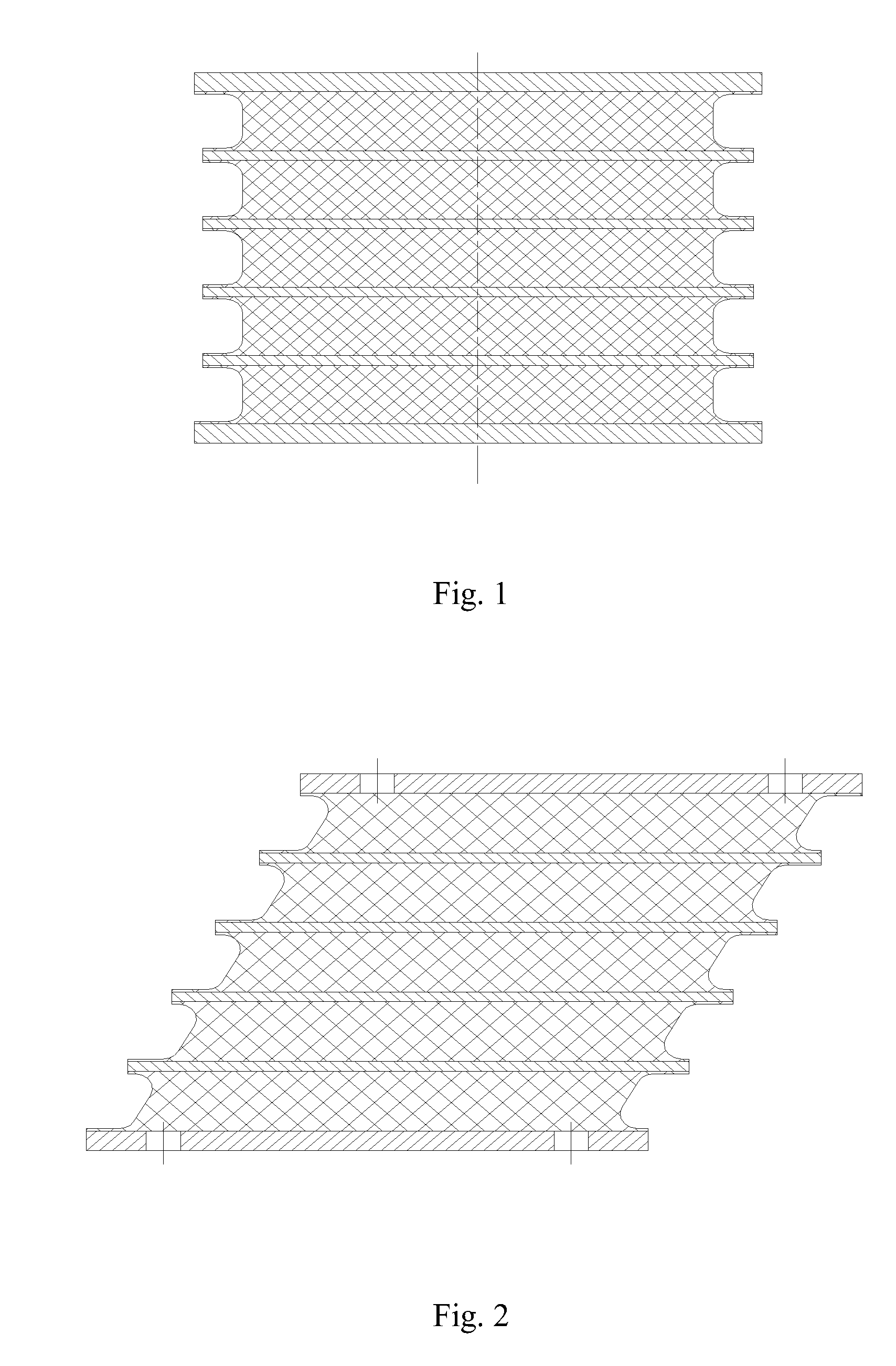

Rubber spring, rubber suspension system and cargo truck

InactiveCN103244590AImprove lateral stabilityExtended service lifeResilient suspensionsVehicle springsTransverse forceEngineering

The invention discloses a rubber spring. The rubber spring comprises a first mounting plate, a second mounting plate, and multiple rubber layers, wherein the first mounting plate is provided with a first V-shaped plate with an opening angle greater than 90 degrees; the second mounting plate is provided with a second V-shaped plate with the opening angle greater than 90 degrees; the multiple rubber layers are arranged between the first V-shaped plate and the second V-shaped plate; each two adjacent rubber layers are separated by an intermediate plate; the intermediate plate is a V-shaped plate with the opening angle greater than 90 degrees; and the opening directions of the first V-shaped plate, the second mounting plate and the intermediate plate are the same. The rubber spring has a certain transverse stiffness while enabling a suspension to satisfy the requirements for lengthways and vertical bearing capabilities; the transverse stiffness can be up to 3-15 kN / mm through the adjustment of the hardness of a sizing material of a rubber layer 202; when a vehicle turns a corner or runs on a concave-convex road surface, the rubber spring can bear a very great transverse force to reduce yaw of the vehicle and improve transverse stability of the whole vehicle. The invention also discloses a rubber suspension system and a cargo truck.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

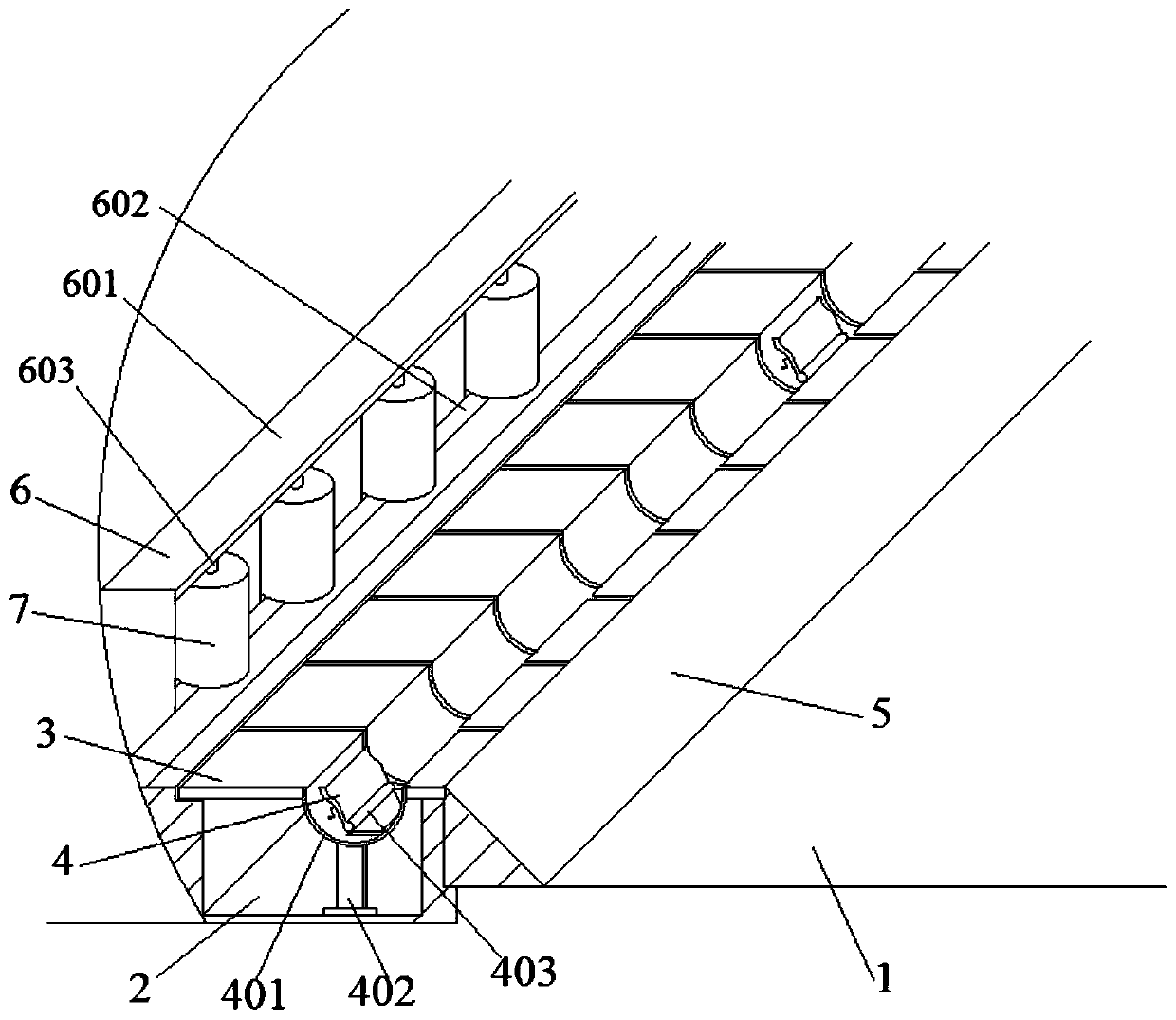

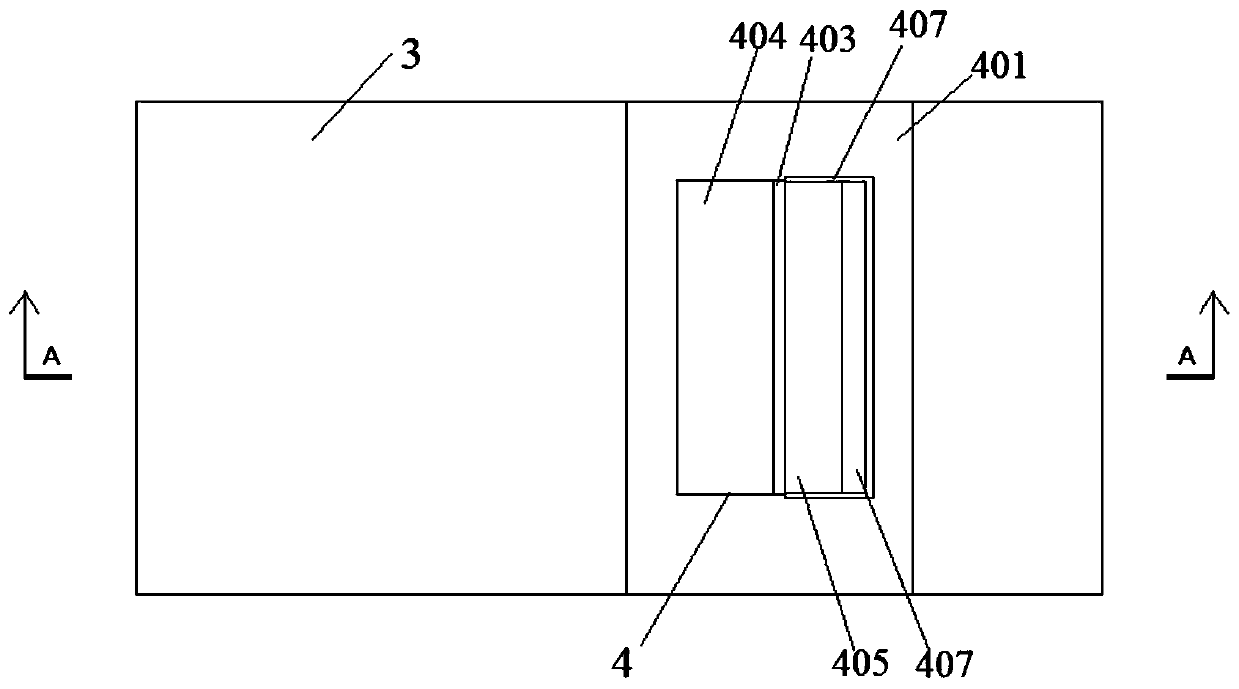

Expressway tunnel traveling safeguard device

ActiveCN109736232AAvoid yawAvoid the situationClimate change adaptationTraffic signalsRolloverRoad surface

The invention discloses an expressway tunnel traveling safeguard device. The expressway tunnel traveling safeguard device comprises deceleration guiding devices arranged at intervals on the cover plates of cable ducts in the two sides of the inner pavement of an expressway tunnel. Each deceleration guiding device comprises through grooves formed in the wheel guiding surfaces of the cover plates, arotary shaft is installed on the edge of one side of the through grooves, a pressing plate and a rotary plate are arranged on the rotary shaft, wherein the pressing plate is located on the inner sideof the wheel guiding surface, and a first spring is arranged between the pressing plate and the wheel guiding surface; one end of the rotary plate penetrates through the through grooves and is located under the through grooves, and a decelerator is connected to the end of the rotary plate through a bending part; when the first spring is pressed because the pressing plate is under pressing force,the rotary plate rotates around the rotary shaft and drives the decelerator to move to the upper part of the through grooves; and guiding cylinders are arranged on the side, on the inner walls of thetunnel, of each cable duct. According to the expressway tunnel traveling safeguard device, automobile wheels can be decelerated, driving directions are further corrected, so that wheels on one side ofthe vehicle is at last stopped on the wheel guiding surfaces of the cover plates and the occurrence of conditions such as automobile yawing and rollover caused by losing control of the wheels is avoided.

Owner:山西省交通建设工程质量检测中心(有限公司)

Airflow deflector assembly

InactiveUS7566093B1Easy to participateEasy to manufactureVehicle seatsWindowsEngineeringInterconnection

An airflow deflector assembly for an open bed truck or like vehicle including a plurality of preferably two cover sections each having a base and an attachment assembly cooperatively disposed and structured to adjustably interconnect the two cover sections facilitating their selective positioning into any one of a plurality of operative orientations. The selected operative orientation corresponds to the width of the trailing end of the open bed of the vehicle so as to so as to establish a substantially continuous air deflecting surface over the trailing end and thereby increasing the aerodynamics of the vehicle. The cooperative structuring of the attachment assemblies facilitate an adjustable sliding interconnection there between such that the bases of each cover section may be reciprocally positioned toward and away from one another to assume the preferred operative orientation corresponding to the width of the truck bed.

Owner:EMBLER SUSAN +2

Rubber spring, rubber suspension system and truck

InactiveUS20140346750A1Improve carrying capacityReduce probabilityResilient suspensionsVehicle springsEngineeringTruck

The present application provides a rubber spring, including a first mounting plate and a second mounting plate, the first mounting plate having a first V-shaped plate with an opening angle larger than 90°, and the second mounting plate having a second V-shaped plate with an opening angle larger than 90°; and a plurality of rubber layers arranged between the first V-shaped plate and the second V-shaped plate, wherein each two adjacent rubber layers are separated by an intermediate plate, the intermediate plate is a V-shaped plate with an opening angle larger than 90°, and openings of the first V-shaped plate, the second mounting plate and the intermediate plate are facing the same direction. The present application further provides a rubber suspension system and a truck.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

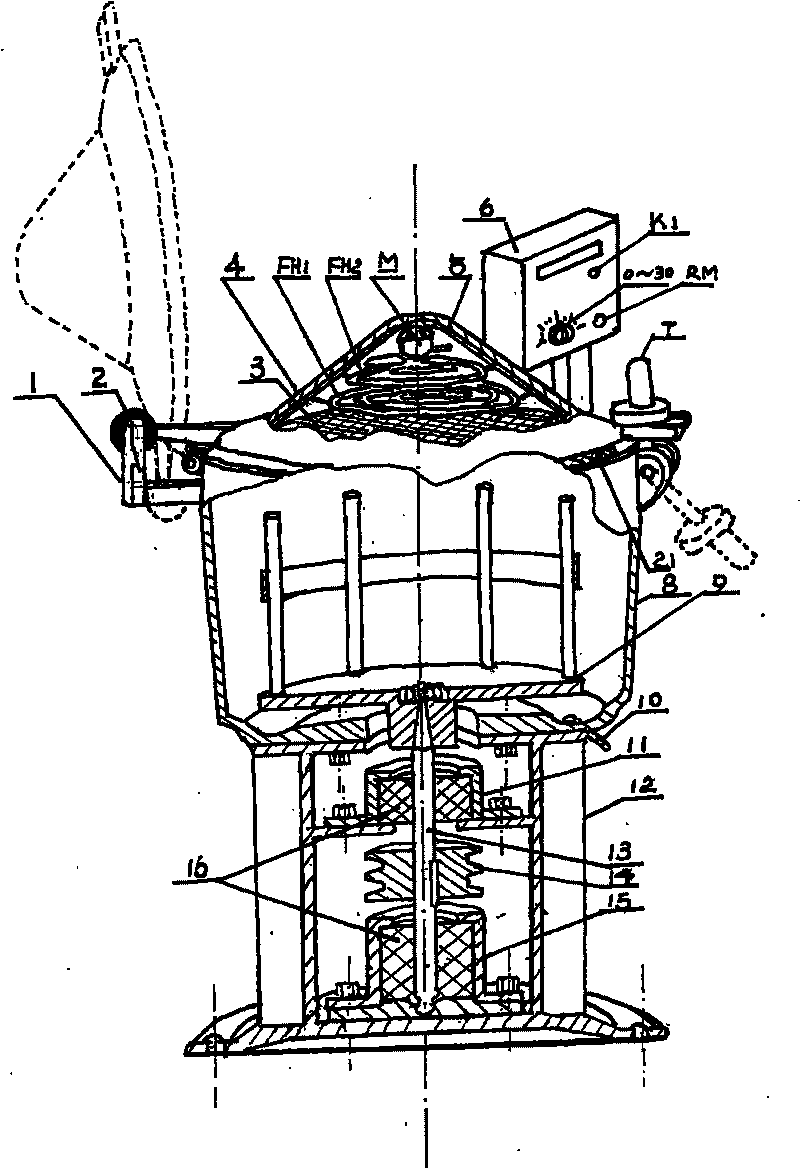

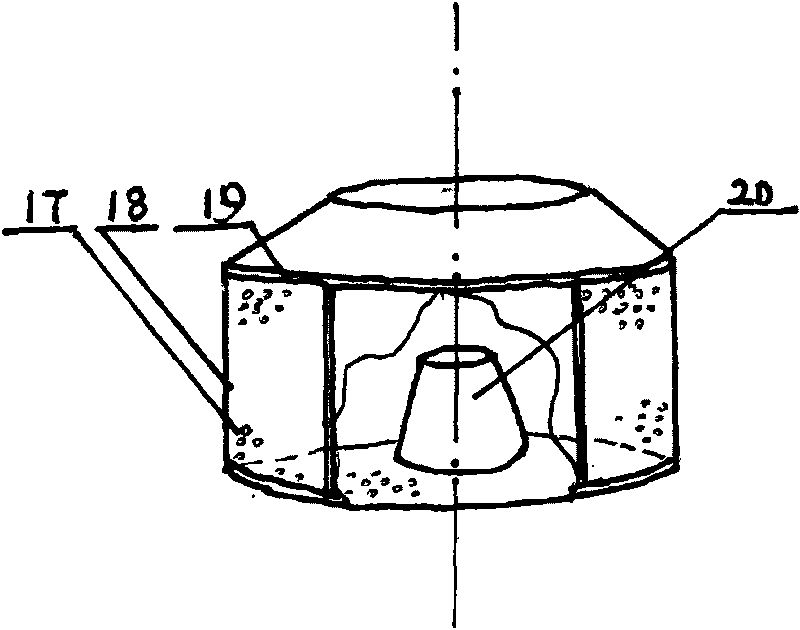

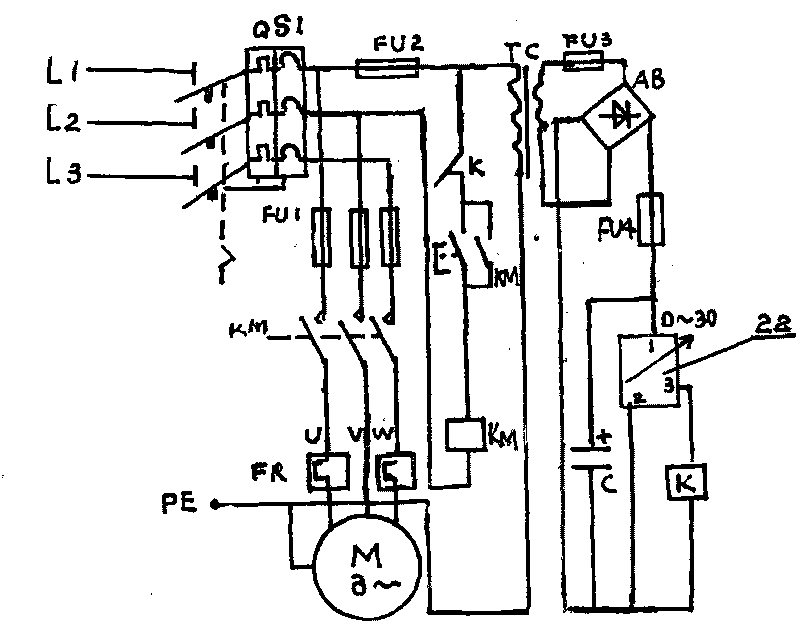

Energy-saving durable dewatering and drying centrifuge

InactiveCN101762140AShorten the lengthReduce yawDrying using combination processesProduction lineRubber ring

The invention discloses an energy-saving durable dewatering and drying centrifuge, which is used for dewatering and drying electronic components in an electroplating production line after washing. A main shaft (13) in the middle of a lower support (12) of the centrifuge uses a high-carbon rubber ring (16) in an upper stabilized seat (11) and a lower stabilized seat (15) as a bearing bush; the main shaft passes through an upper seat dewatering dryer (8) to be connected and fixed with a stainless steel disk (9) of a basket (18) for accommodating stainless steel parts; a far-infrared taper reflector (5) quick heater is arranged below a centrifuge cover (4); the heater is supplied with power by the connecting and disconnecting of the contacts in a reed pipe (1); the reed pipe is controlled by a permanent magnet (2) arranged at the rotary position of the centrifuge cover; the fact that the centrifuge cover is closed means that electrification heating is performed, and the fact that the centrifuge cover is open means outrage and heating termination; a timer (22) is arranged according to the quantity and complexity degree of parts; and the centrifuge is shut down automatically after dewatering and drying of parts.

Owner:成都崇安科技有限公司

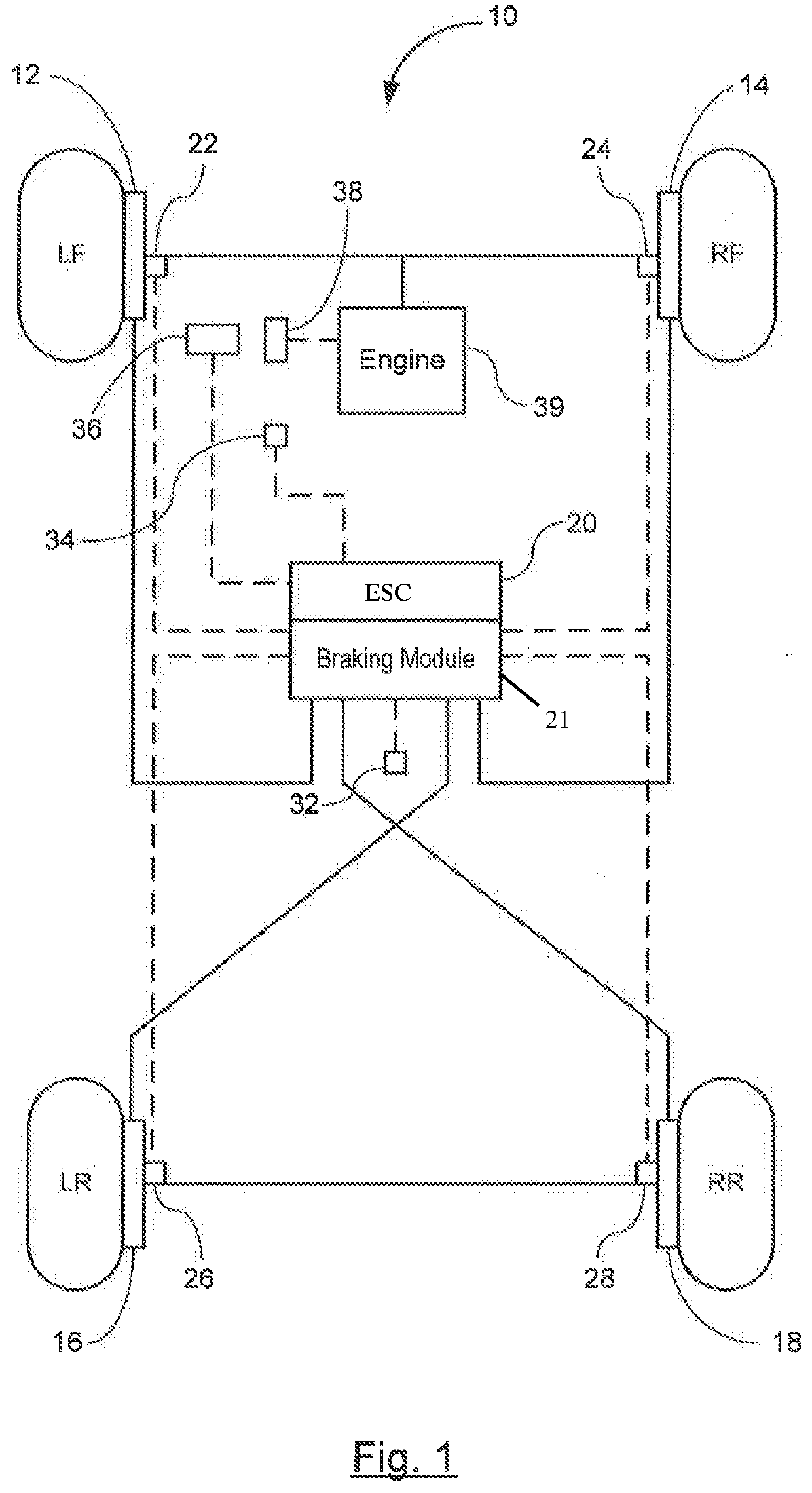

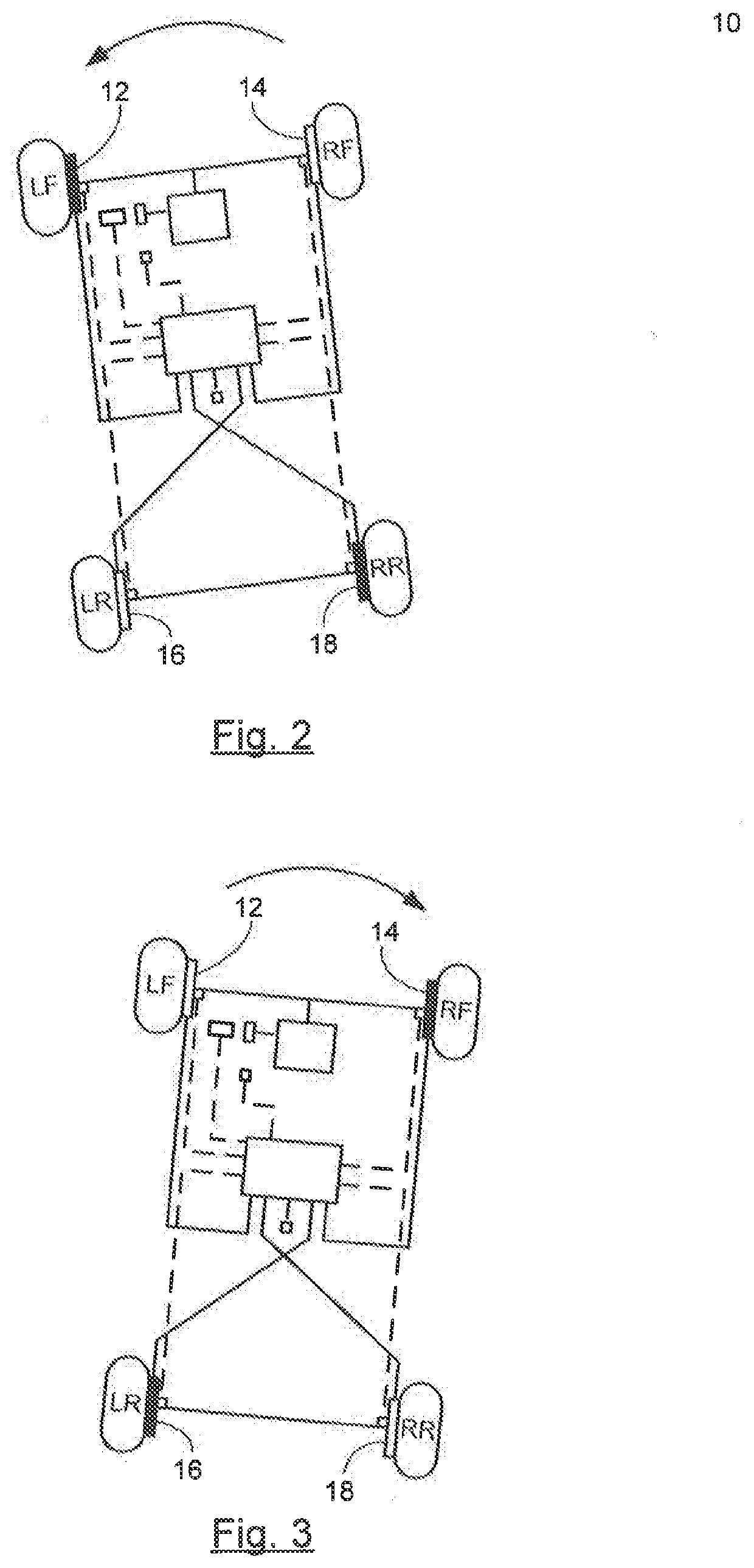

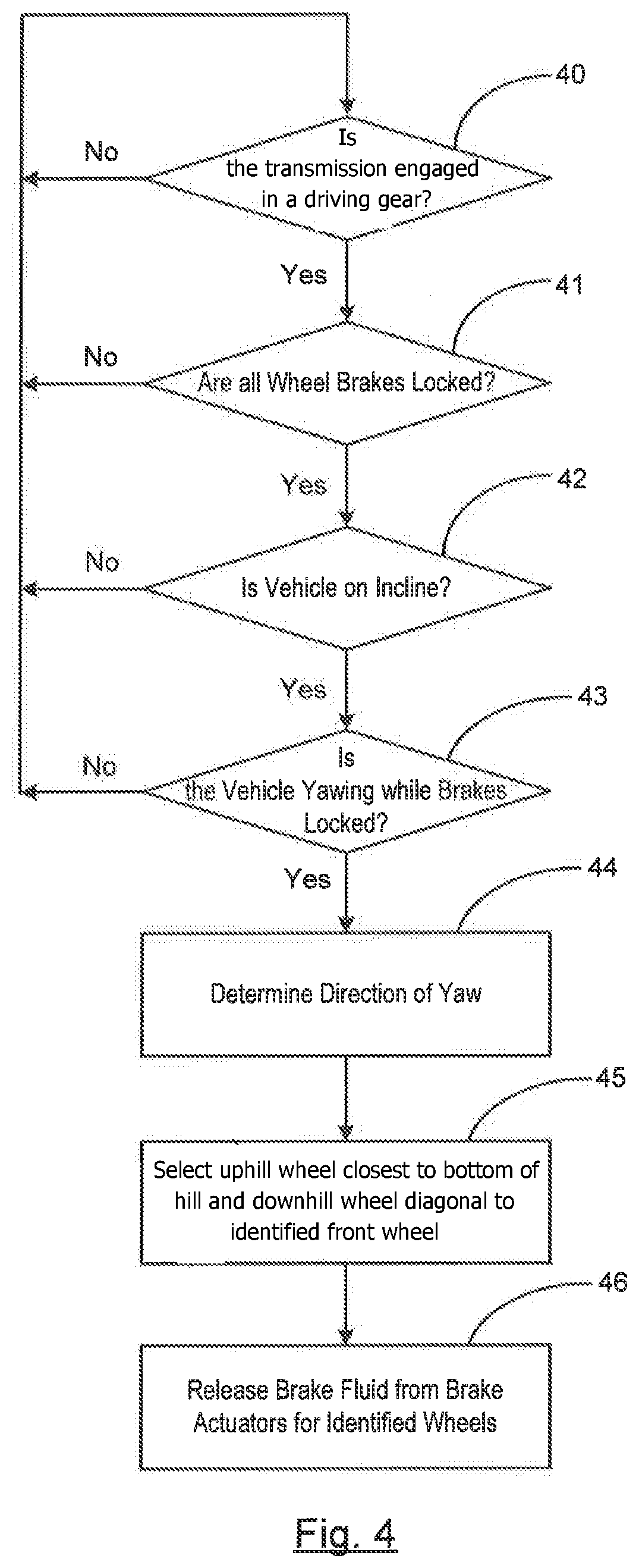

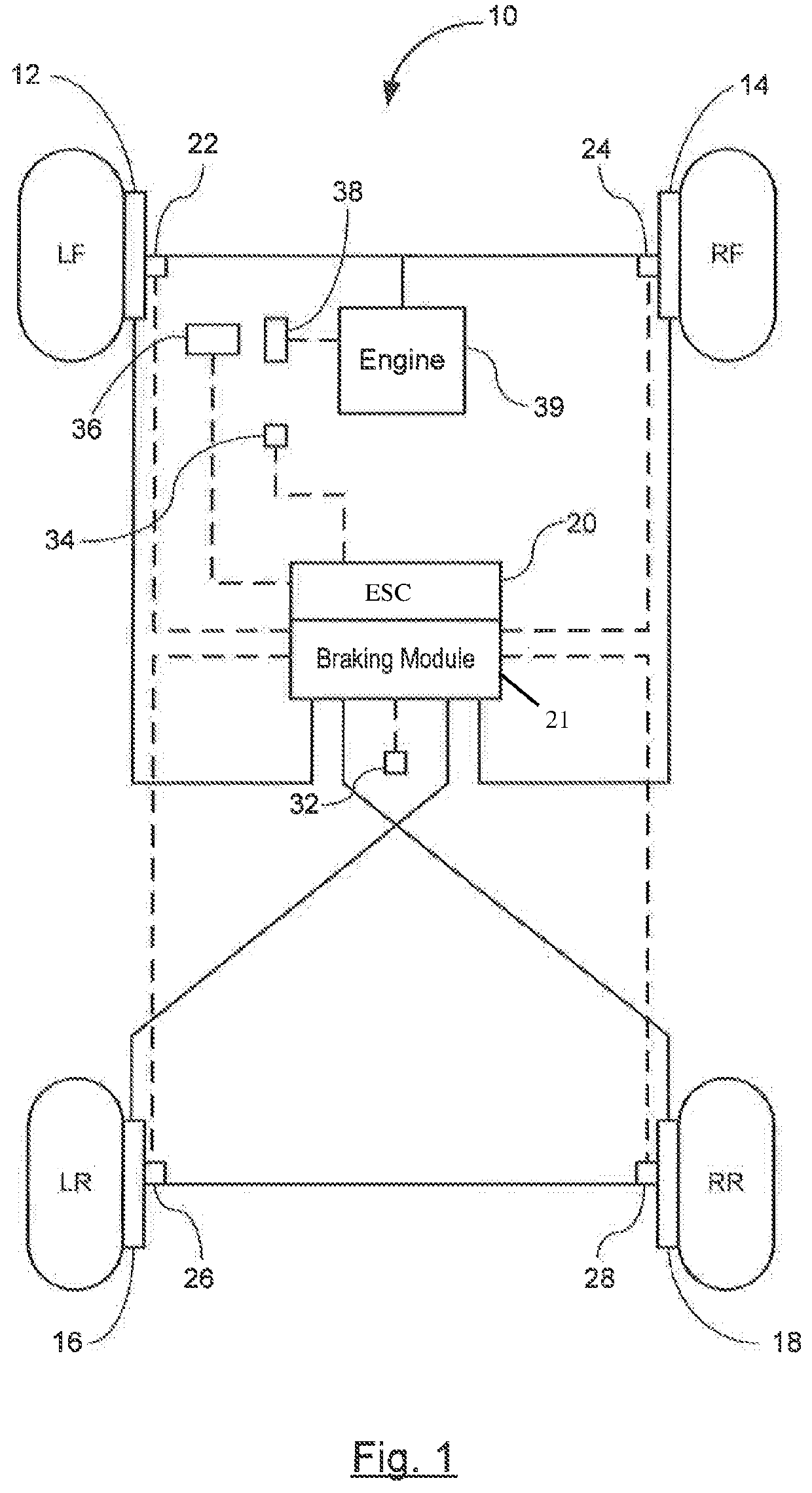

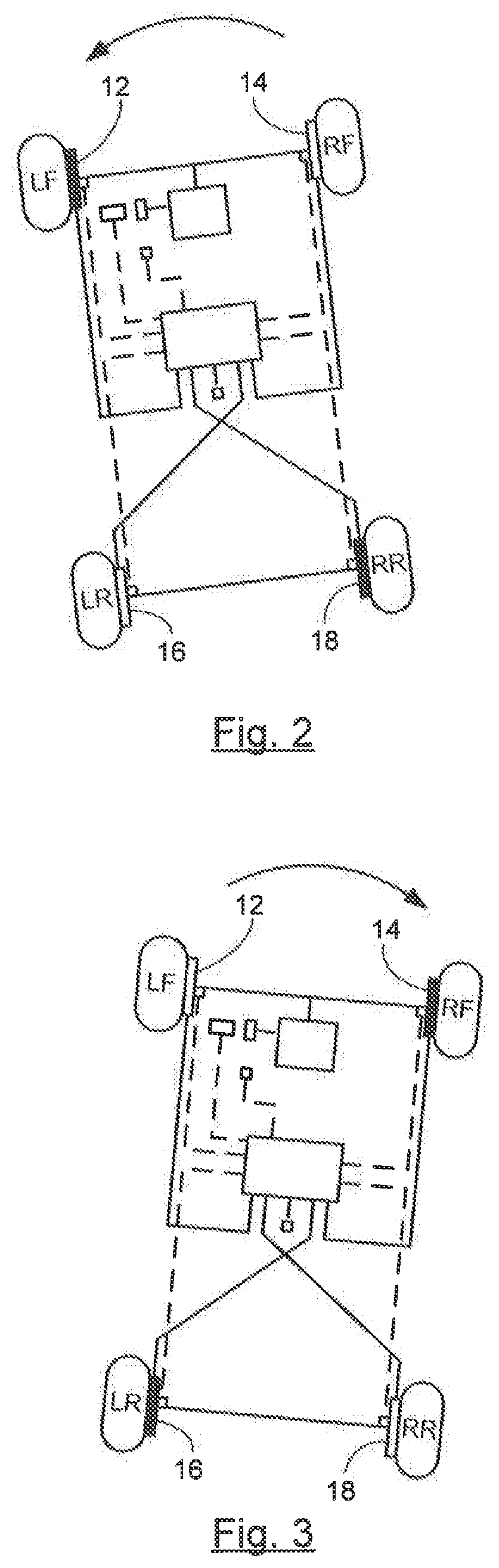

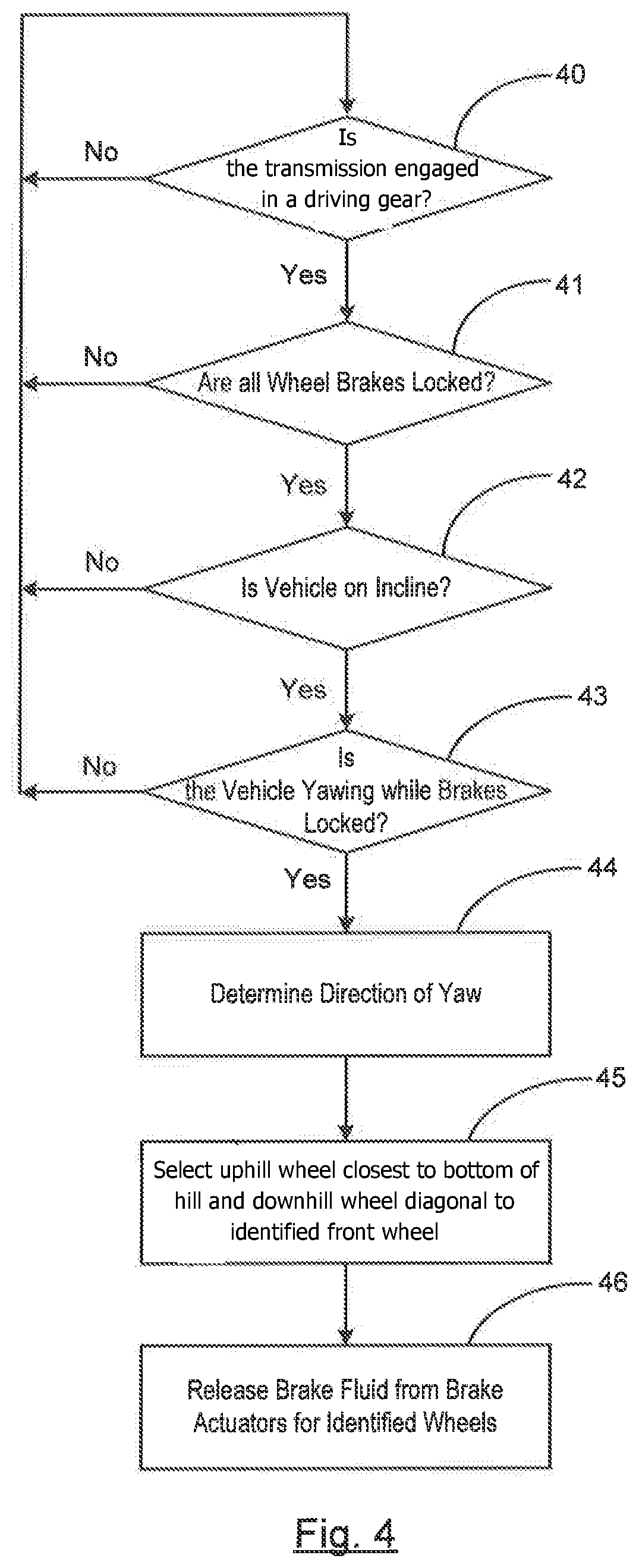

Standstill management yaw mitigation on low mu grades

ActiveUS20200361432A1Reduce vehicle yawReducing yaw conditionBraking systemsControl systemControl cell

A stability control system of a vehicle utilizing an electronic control unit that detects a yaw condition while each of the wheel brakes are actuated by EBCM and the wheel speeds are zero. An electronic control unit includes an electronic braking control module that controls actuation and de-actuation of vehicle brakes on an inclined surface. A yaw condition is identified while all vehicle brakes are actuated on the inclined surface and each wheel speed is zero. The electronic control unit identifies which uphill wheel is leading a direction of the yaw and identifies a wheel of an opposing axle diagonal to the identified uphill wheel. The electronic control unit in cooperation with the electronic braking control module de-actuates the vehicle brakes of the identified uphill wheel and diagonal wheel to increase a side friction to the identified diagonal wheels to reduce further yawing of the vehicle.

Owner:ZF ACTIVE SAFETY US INC

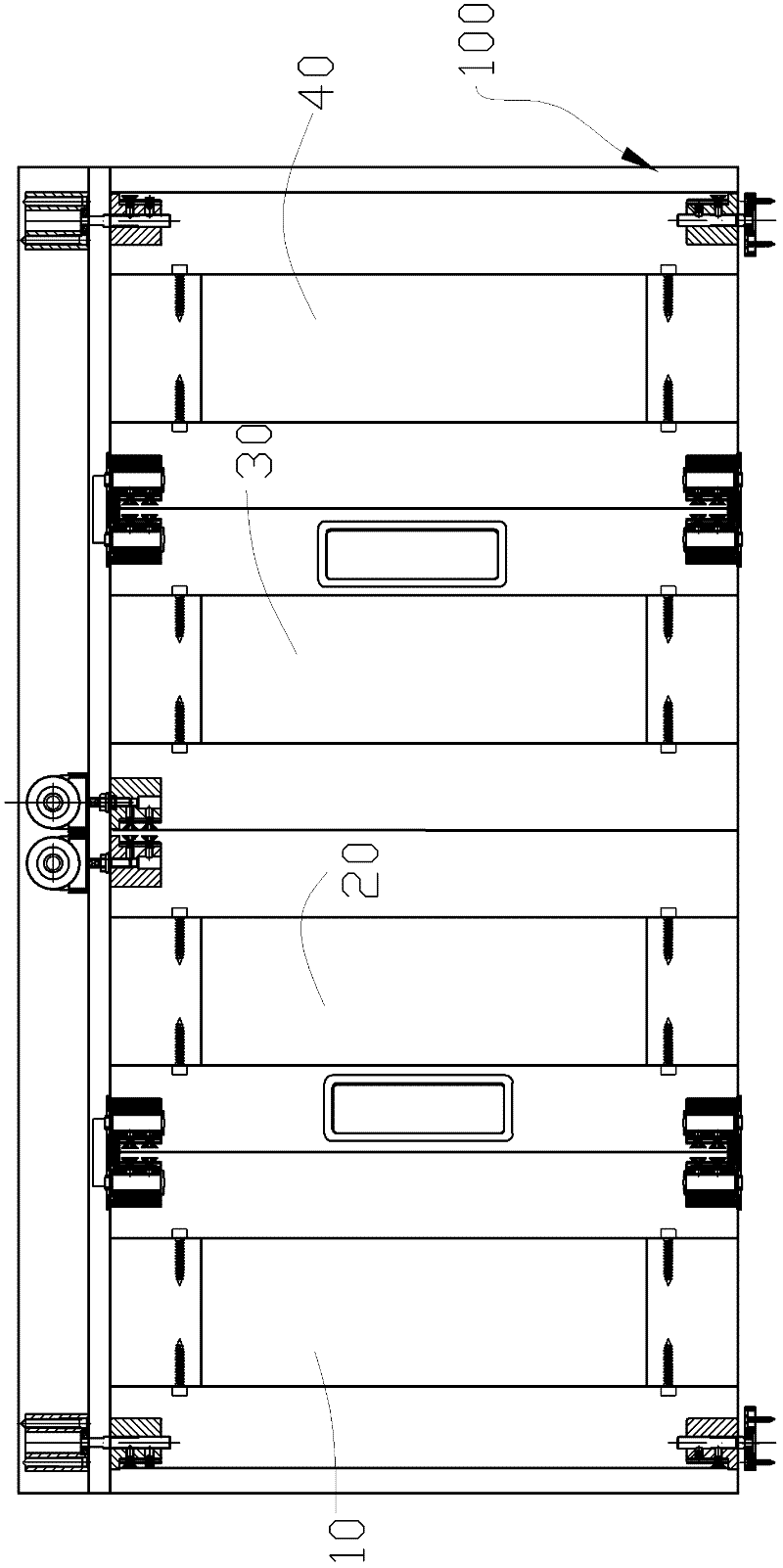

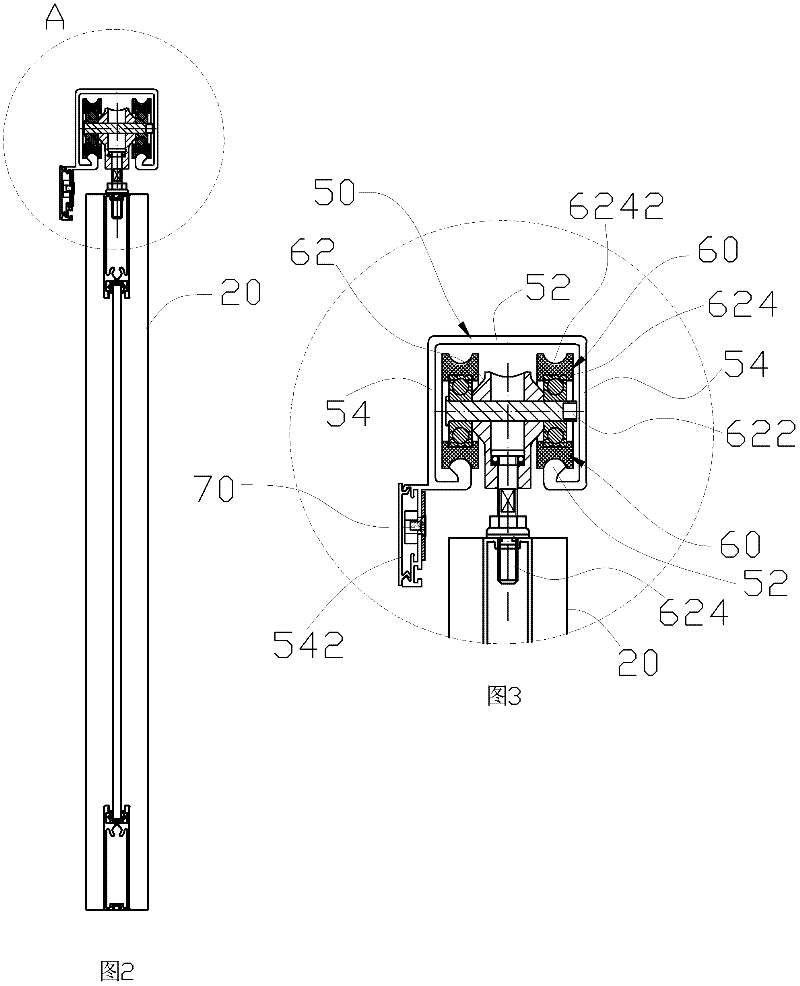

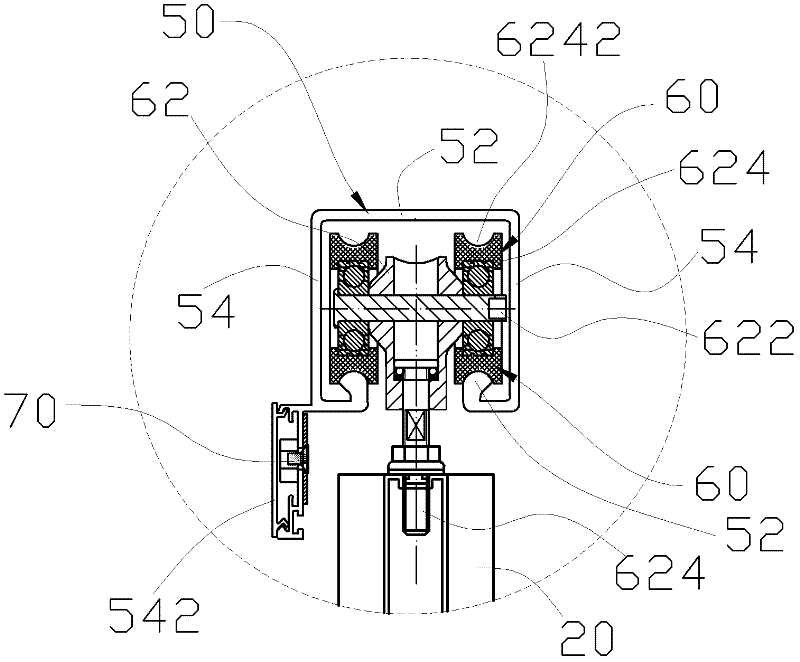

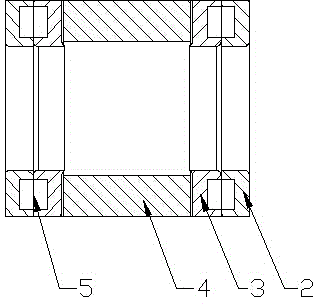

Hanging wheel device on top part of door body

InactiveCN102561866AReduce jumpingReduce yawWing suspension devicesEngineeringMechanical engineering

The invention discloses a hanging wheel device on a top part of a door body. The hanging wheel device comprises a door leaf, a hanging wheel component and a holding groove, wherein the hanging wheel component is installed on a top part of the door leaf and the holding groove is matched with the hanging wheel component. The hanging wheel component comprises a wheel frame, a horizontal shaft and a pair of guide wheels, wherein the horizontal shaft is installed on the wheel frame and the two guide wheels are installed at two ends of the horizontal shaft respectively. The circumferential surface of each guide wheel is indented to form an arc-shaped groove. The holding groove comprises a pair of arc-shaped guide ways. The hanging wheel component is held in the holding groove and the arc-shaped groove of each guide wheel is matched with the arc-shaped guide rail of the holding groove mutually. According to the hanging wheel device on a top part of a door body, the phenomenon of door leaf jumping and swinging is avoided, therefore, the whole hanging wheel runs more stably, so that the service life of the door is greatly prolonged, the lower guide way adopted by the industry is avoided and the product cost is lowered.

Owner:广东顶固集创家居股份有限公司

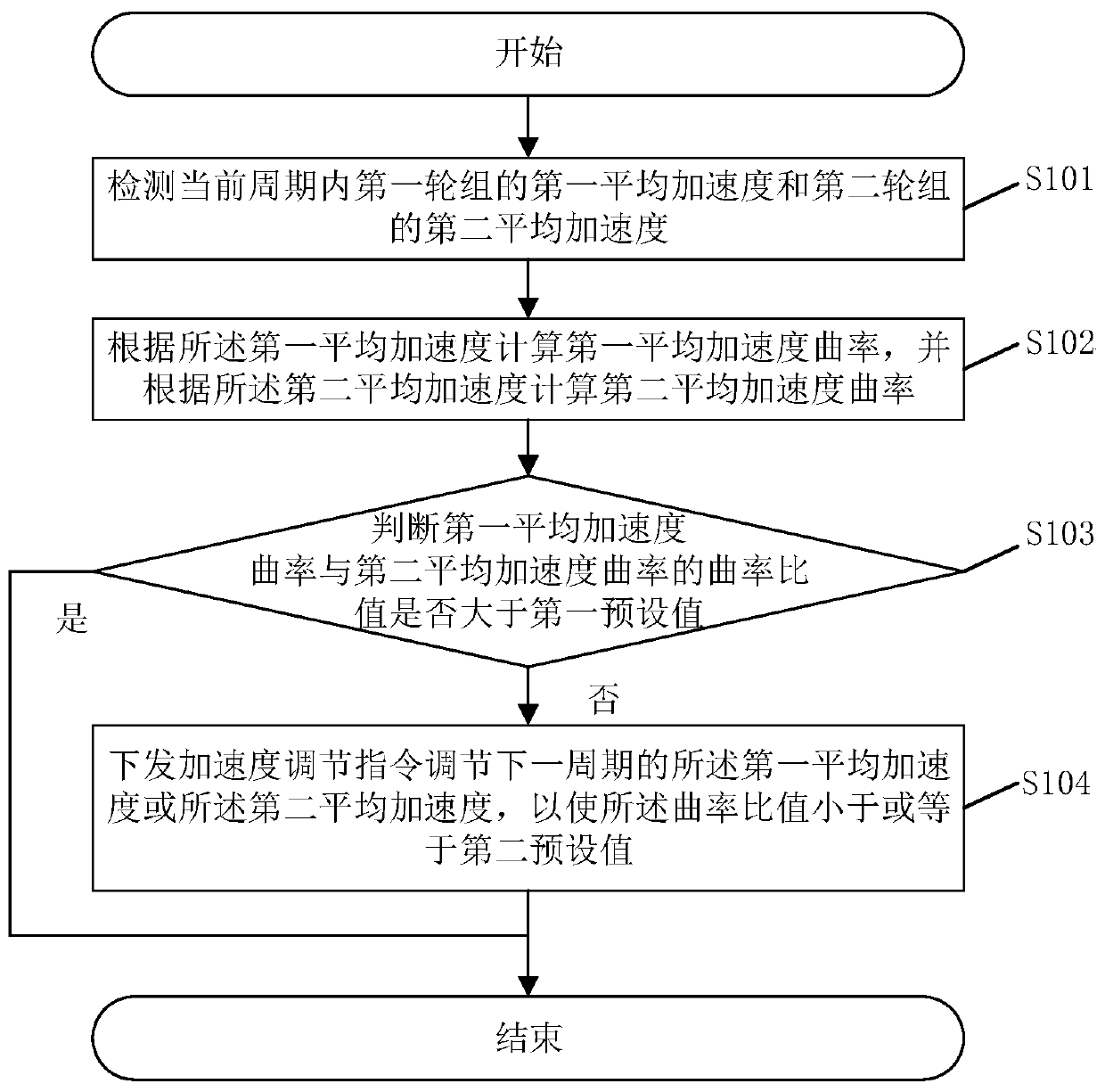

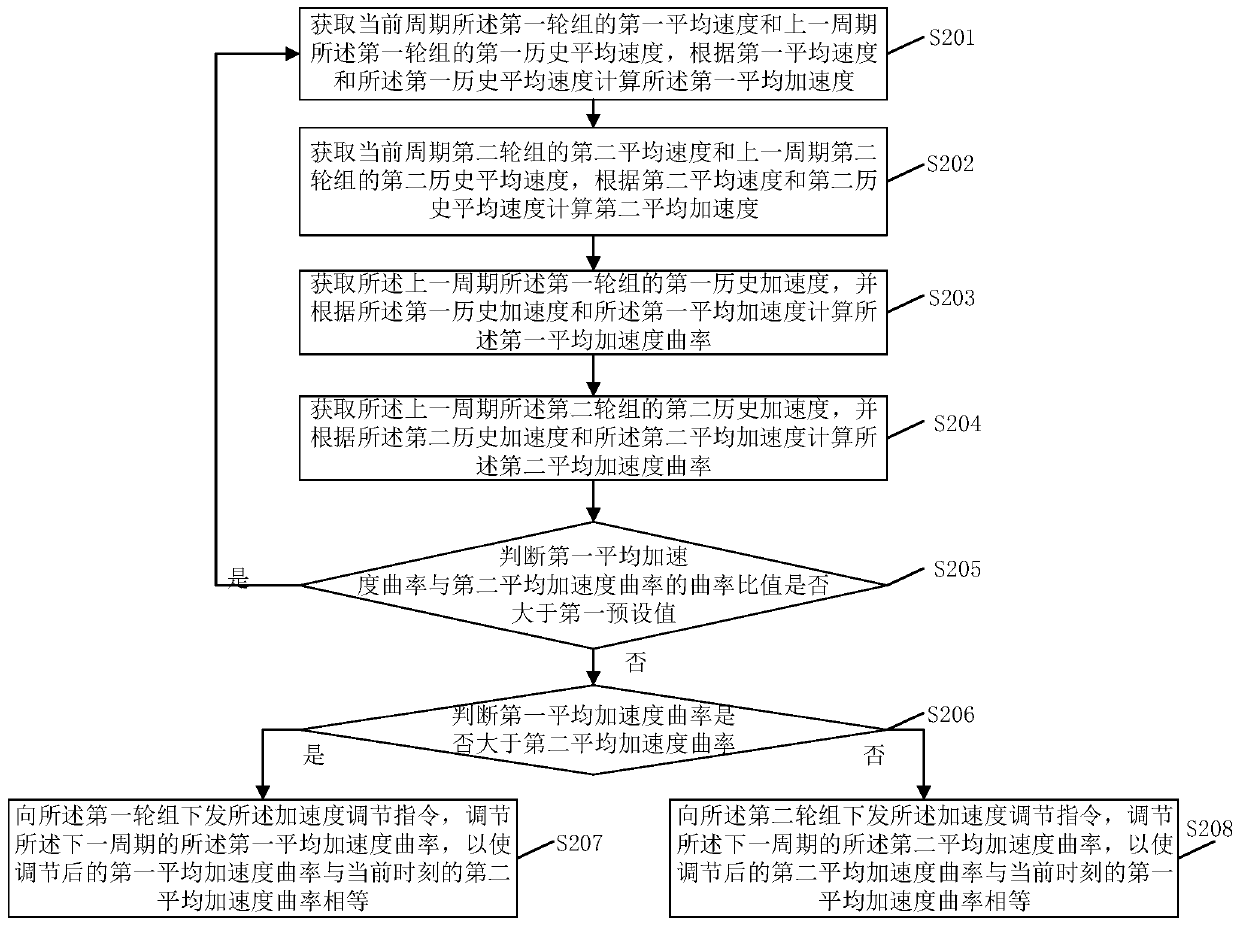

A dual-drive vehicle acceleration change curvature synchronization method, system and related device

The invention discloses a double-drive vehicle acceleration variation curvature synchronization method. The double-drive vehicle acceleration variation curvature synchronization method comprises the steps of detecting a first average acceleration of a first wheel set and a second average acceleration of a second wheel set in a current period; calculating a first average acceleration curvature according to the first average acceleration and calculating a second average acceleration curvature according to the second average acceleration; judging whether the curvature ratio between the first average acceleration curvature and the second average acceleration curvature is larger than a first preset value or not; and if the curvature ratio between the first average acceleration curvature and thesecond average acceleration curvature is larger than the first preset value, issuing an acceleration adjusting instruction to adjust the first average acceleration or the second average accelerationof the next period to make the curvature ratio be less than or equal to a second preset value. According to the double-drive vehicle acceleration variation curvature synchronization method, the problem that vehicle yawing or driver error-reporting caused by mechanical structure of the vehicle can be solved. The invention further discloses a double-drive vehicle acceleration variation curvature synchronization system, a computer readable storage medium and a driver of the double-drive vehicle; and the double-drive vehicle acceleration variation curvature synchronization system, the computer readable storage medium and the driver of the double-drive vehicle have the above advantageous effects.

Owner:ZHEJIANG GUOZI ROBOT TECH

A roadway maintenance machine for crushing and loading in coal mines

ActiveCN102936905BSafe and convenient handlingSmall transmission clearanceMechanical machines/dredgersCouplingFuel tank

Owner:TAIZHOU XINGDONG COAL MINING MACHINERY +1

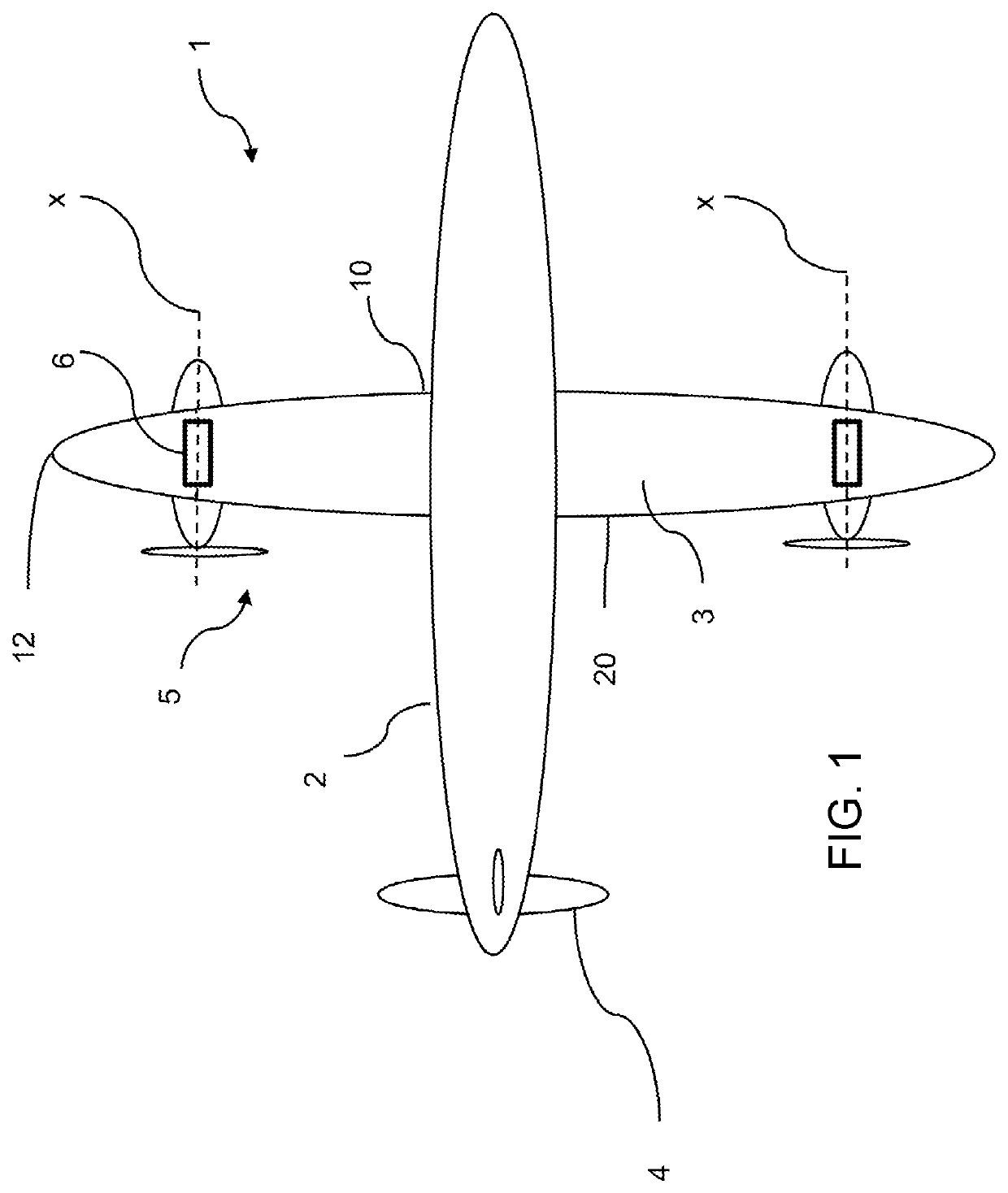

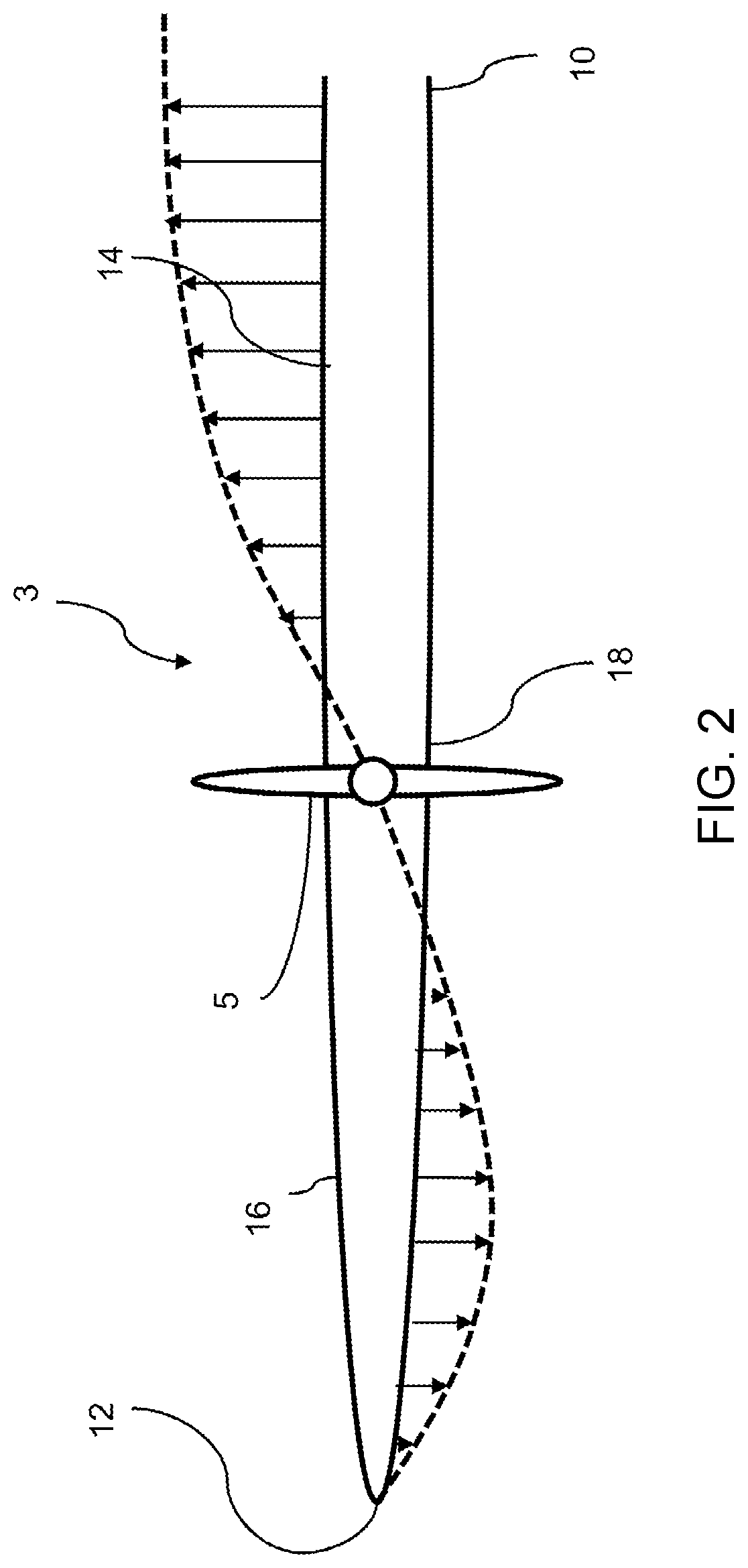

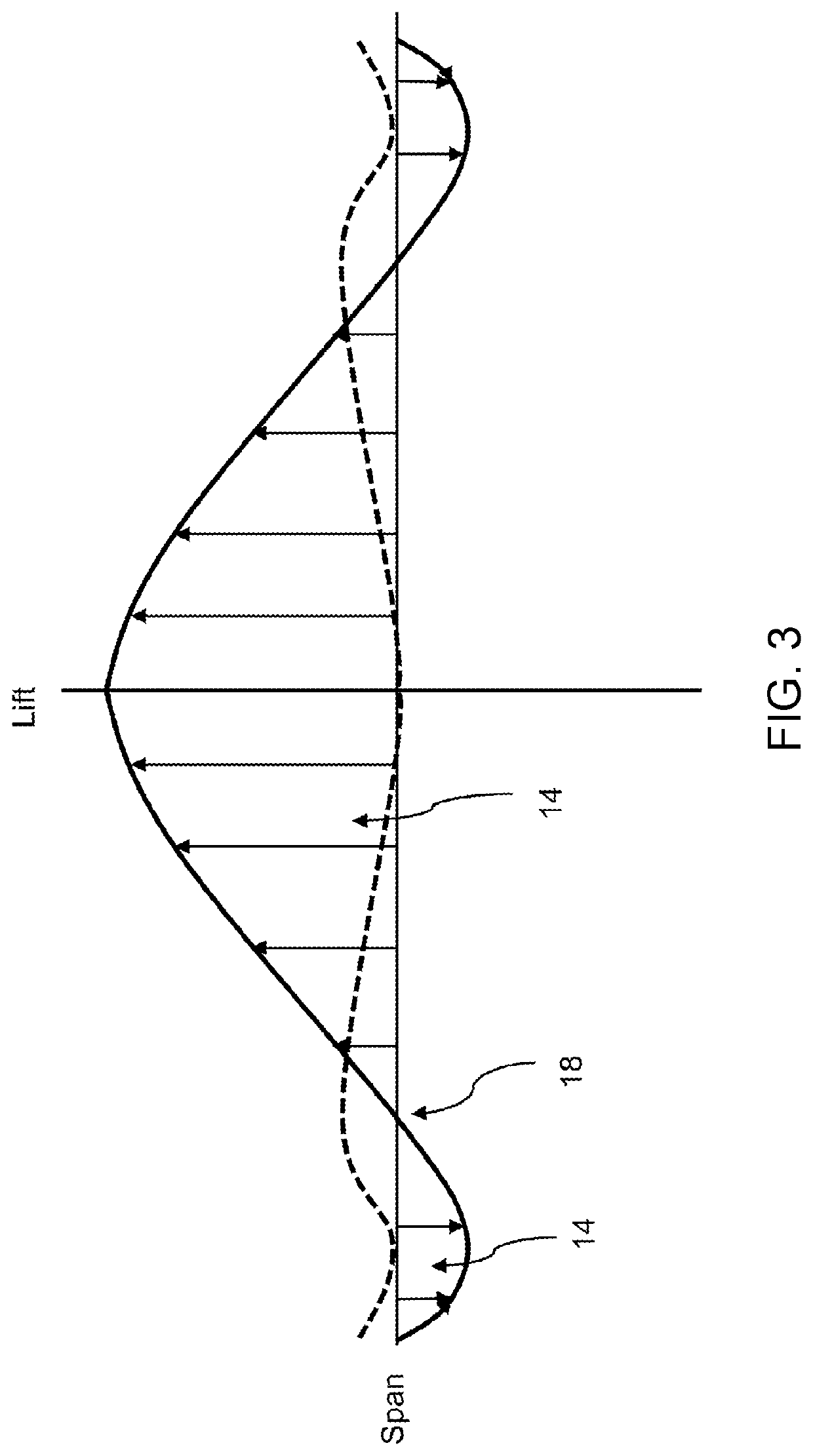

Wing integrated propulsion system

ActiveUS20210387715A1Reduced advance ratioReduce resistancePropellersWing shapesRotational axisFlight vehicle

An aircraft comprising a wing having a spanwise lift distribution extending from a root to a tip, the lift distribution defining an inboard region defining a positive lift contribution, an outboard region defining a negative lift contribution, and an intermediate region defining a neutral lift contribution, the neutral region being spaced from the tip and from the root. A propulsion system is provided, comprising a wing mounted propulsor. The wing mounted propulsor has a rotational axis (x) positioned substantially at a span of the wing where a value of δLift / δSpan is at a maximum for the span of the wing, and may be located at the intermediate region along the span of the wing.

Owner:ROLLS ROYCE PLC

A motor torque control method and a wheel-side motor distributed drive system

ActiveCN109353227BRealize closed-loop controlAvoid excessive slipSpeed controllerElectric devicesDrive wheelElectric machinery

The invention provides a motor torque control method and a wheel rim motor distributed drive system. The method is applied to a vehicle control unit in the system. The system further comprises two motor systems. The motor systems comprise motors. By means of the method, the following motor torque control process is executed to the motor systems at the same time. Based on current accelerator pedalsignals and the current rotating speeds of the motors in the motor systems, torque basic values of the motors in the motor systems are calculated; the torque basic values of the motors are corrected,and torque corrected values of the motors are obtained; the torque corrected values of the motors are limited through the current vehicle speed of a vehicle and the motor torque recently sent to the other motor system by the vehicle control unit historically, and torque limited values of the motors are obtained; the motor torque is determined from the torque limited values and the torque correctedvalues of the motors and input in the motor systems to which the motors belong, and therefore the motor systems are controlled to respond to the motor torque to control the motors in the motor systems to drive driving wheels, used for being driven by the motor systems, on the vehicle.

Owner:WEICHAI POWER CO LTD

Standstill management yaw mitigation on low mu grades

ActiveUS11173885B2Reduce amount of acceleration and speedReduce the vehicle yawBraking systemsControl systemControl cell

A stability control system of a vehicle utilizing an electronic control unit that detects a yaw condition while each of the wheel brakes are actuated by EBCM and the wheel speeds are zero. An electronic control unit includes an electronic braking control module that controls actuation and de-actuation of vehicle brakes on an inclined surface. A yaw condition is identified while all vehicle brakes are actuated on the inclined surface and each wheel speed is zero. The electronic control unit identifies which uphill wheel is leading a direction of the yaw and identifies a wheel of an opposing axle diagonal to the identified uphill wheel. The electronic control unit in cooperation with the electronic braking control module de-actuates the vehicle brakes of the identified uphill wheel and diagonal wheel to increase a side friction to the identified diagonal wheels to reduce further yawing of the vehicle.

Owner:ZF ACTIVE SAFETY US INC

Precise transmission chain

The invention relates to a precise transmission chain. The precise transmission chain comprises an inner link and an outer link; the outer link comprises two outer link pieces, two lateral ends of the outer link pieces are provided with press-fitting holes A, the inner link comprises two inner link pieces, and two lateral ends of the inner link pieces are provided with press-fitting holes B; the positions, corresponding to the press-fitting holes B, of the two inner link pieces are provided with annular cushion blocks; an arc-shaped cavity corresponding to the annular shapes of the cushion blocks are formed between the inner link pieces and the outer link pieces, the direction of an arc opening faces towards the longitudinal middle portions of the inner link pieces or the outer link pieces, and the arc-shaped cavity is internally provided with an arc-shaped elastic piece to achieve the support of the inner link pieces and the outer link pieces. By means of spring pieces which are arranged on the edges of the link pieces, the deflection degree of the chain is lowered, and therefore the transmission precision of the chain is improved.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

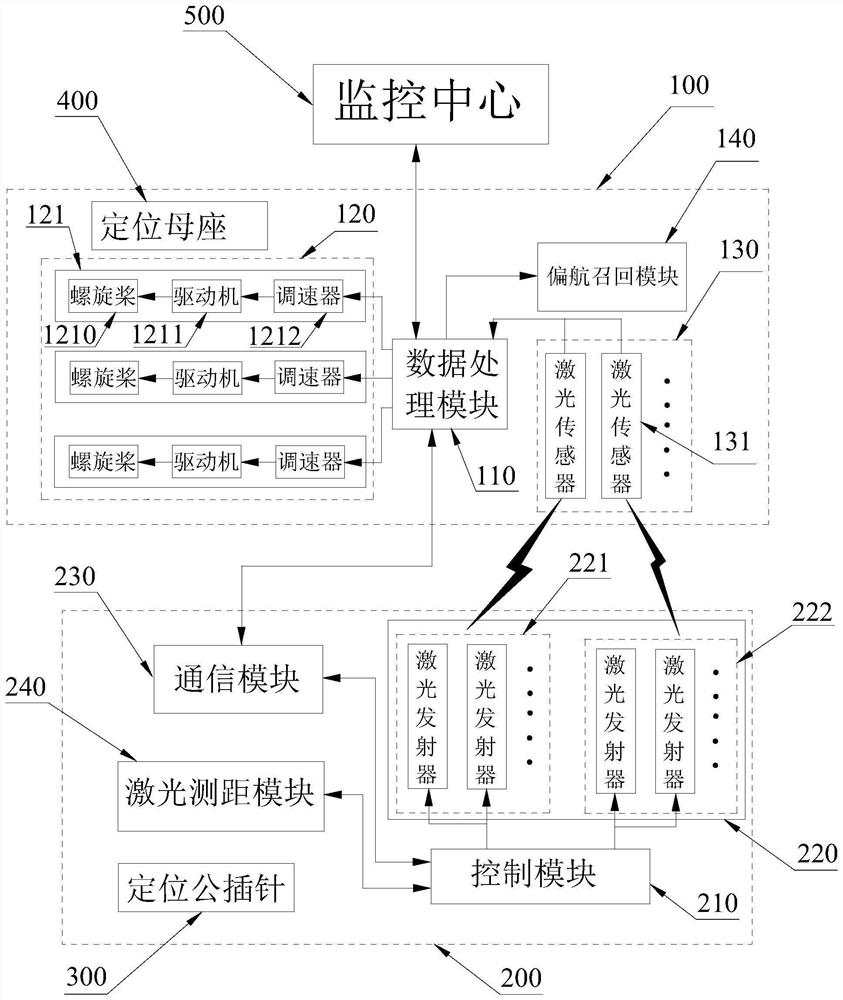

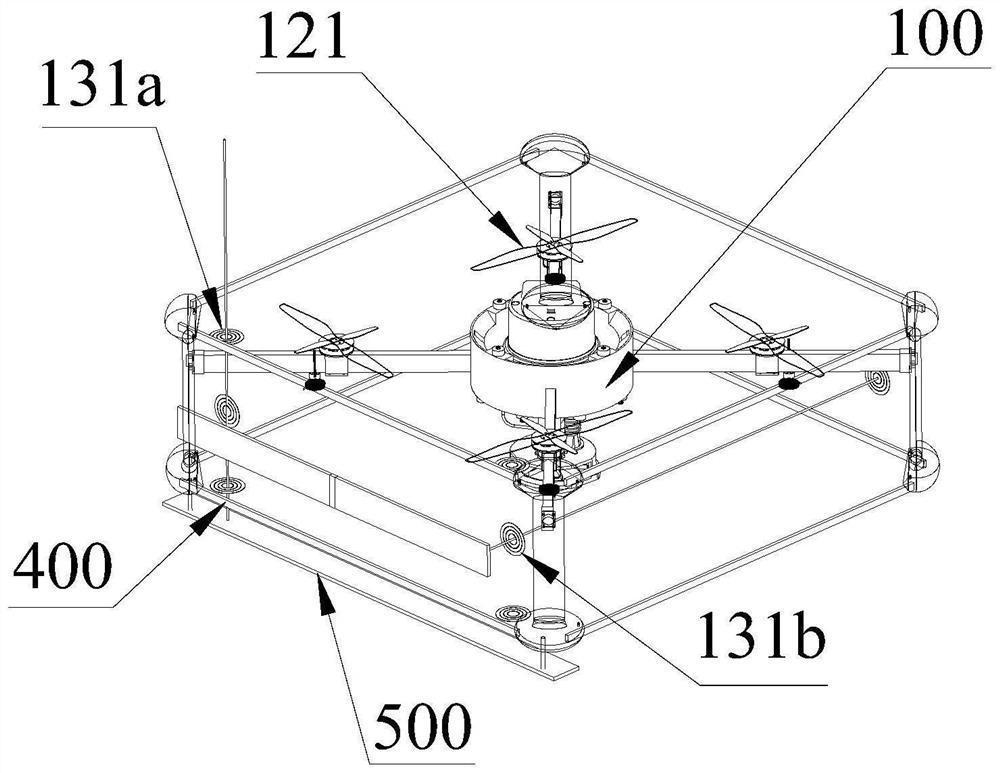

Unmanned aerial vehicle flight system of millimeter-precision laser virtual cableway

PendingCN114706423AReduce Yaw ProblemsReduce the probability of losing control and crashingPosition/course control in three dimensionsFlight vehicleEngineering

The invention relates to the technical field of flight rail transit, in particular to an unmanned aerial vehicle flight system of a millimeter-precision laser virtual cableway. The system comprises an aircraft and a virtual cableway device, wherein the aircraft comprises a data processing module, and a power module and a laser sensing module which are in electric signal connection with the data processing module; the virtual cableway device comprises a control module, and a cableway laser emission module and a communication module which are in electric signal connection with the control module, the cableway laser emission module is used for emitting virtual cableway laser, and the communication module is used for adjusting signal intercommunication with the data processing module; after the virtual cableway device emits the virtual cableway laser, the aircraft identifies the virtual cableway laser and slides along the virtual cableway laser, and meanwhile, the sliding posture of the aircraft is further adjusted through the communication module, so that the aircraft can be restrained to slide along the virtual cableway laser at millimeter-level precision, and the aircraft is prevented from yawing and sliding along the virtual cableway laser. The flight route precision of the aircraft can be effectively improved, and the probability that the aircraft is out of control and falls is reduced.

Owner:安徽阿拉丁航空航天有限公司

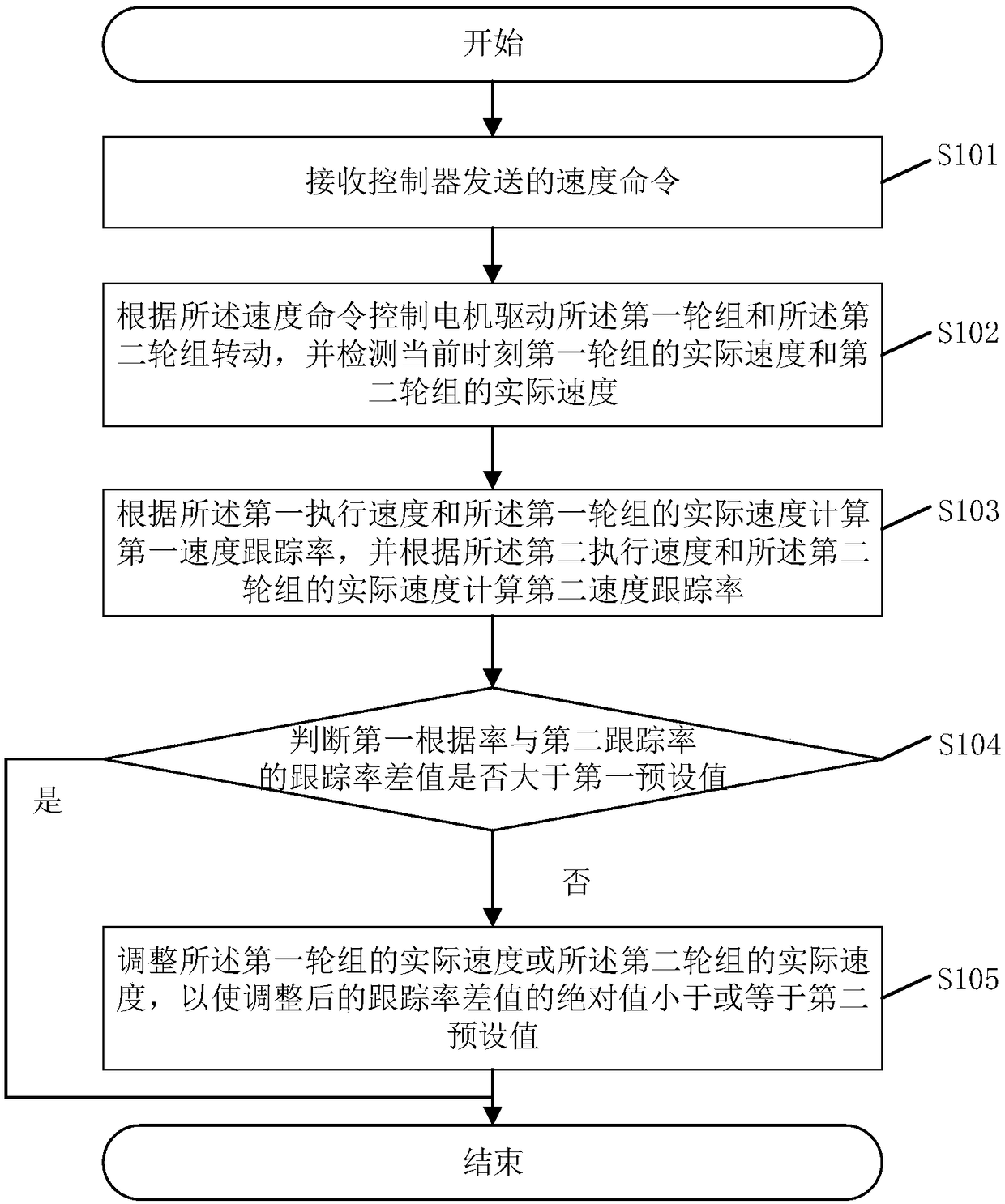

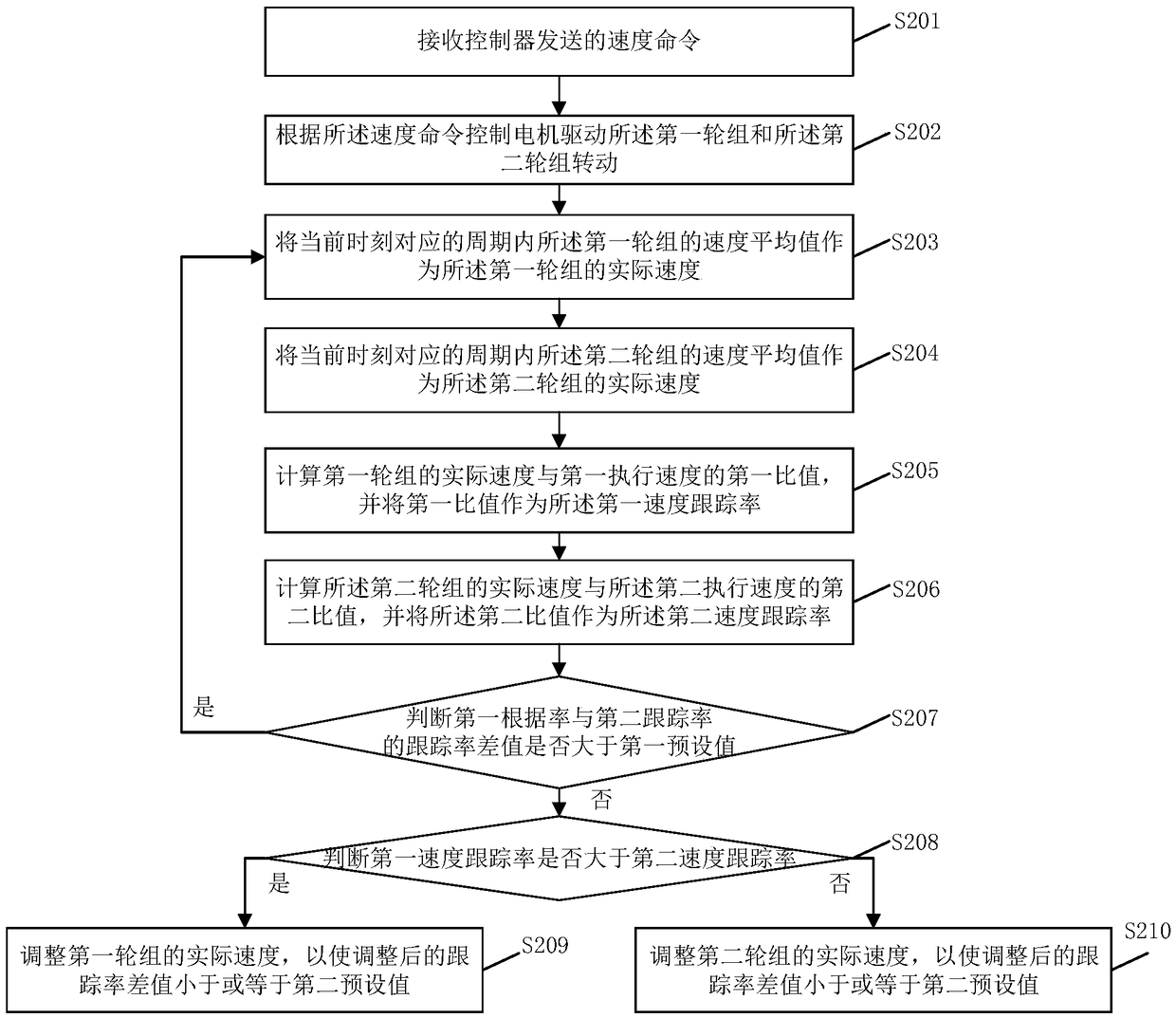

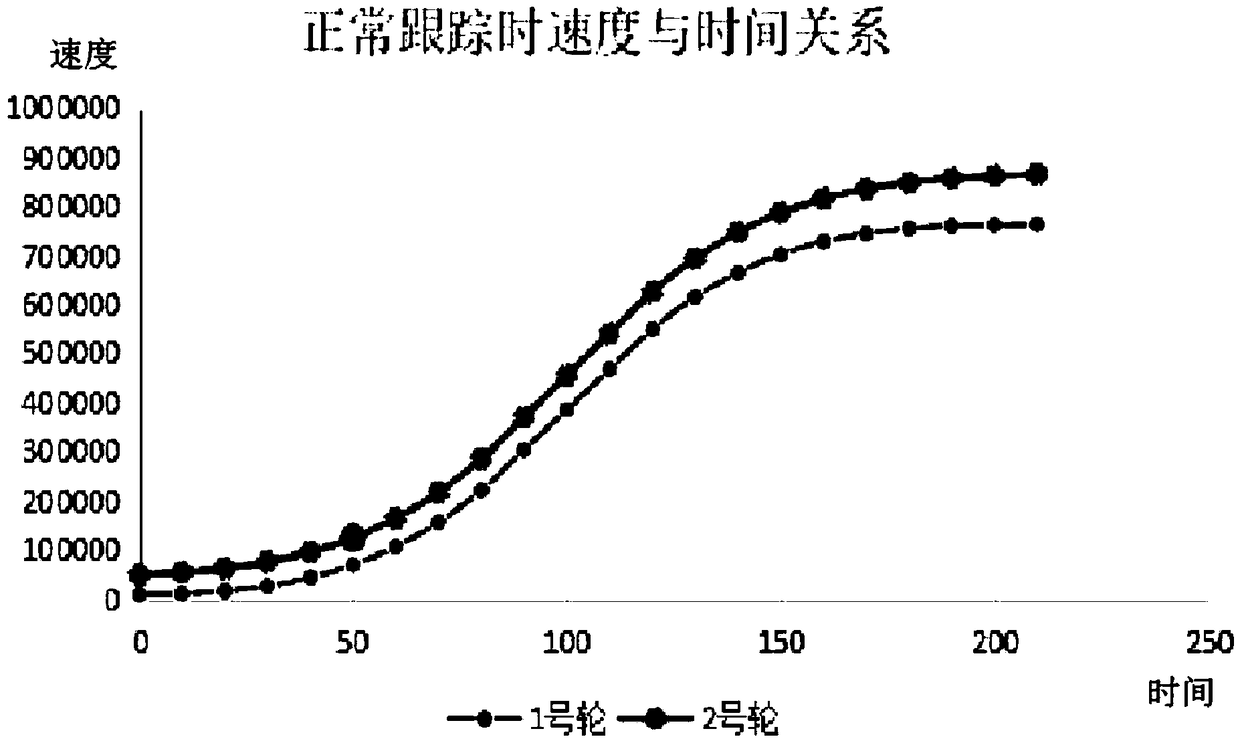

Method and system for synchronizing speed change curvatures of dual-drive vehicle, and related component

ActiveCN108776740AReduce yawReduce yaw rateDesign optimisation/simulationSpecial data processing applicationsTime differenceComputer science

The invention discloses a method for synchronizing speed change curvatures of a dual-drive vehicle. The method for synchronizing the speed change curvatures of the dual-drive vehicle comprises the steps of receiving a speed command sent by a controller; detecting actual speeds of a first wheel set and a second wheel set at a current moment; calculating a first speed tracking rate according to a first execution speed and the actual speed of the first wheel set, and calculating a second speed tracking rate according to a second execution speed and the actual speed of the second wheel set; judging whether a tracking rate difference value between the first tracking rate and the second tracking rate is greater than a first preset value; and if so, adjusting the actual speed of the first wheel set or the actual speed of the second wheel set. With the method, a time difference between the first wheel set and the second wheel set that reach a target speed in a control command can be reduced and the probability of vehicle yawing is reduced. The invention further discloses a system for synchronizing the speed change curvatures of the dual-drive vehicle, a computer-readable storage medium anda driver of the dual-drive vehicle. The system for synchronizing the speed change curvatures of the dual-drive vehicle, the computer-readable storage medium and the driver of the dual-drive vehicle have the abovementioned beneficial effects.

Owner:ZHEJIANG GUOZI ROBOT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com