Motor torque control method and wheel rim motor distributed drive system

A technology of motor torque and wheel-side motor, which is applied in the direction of control drive, electric vehicle, control device, etc., can solve problems such as body yaw, problems, affecting driving safety, etc., to avoid excessive slippage, reduce tire wear, The effect of improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

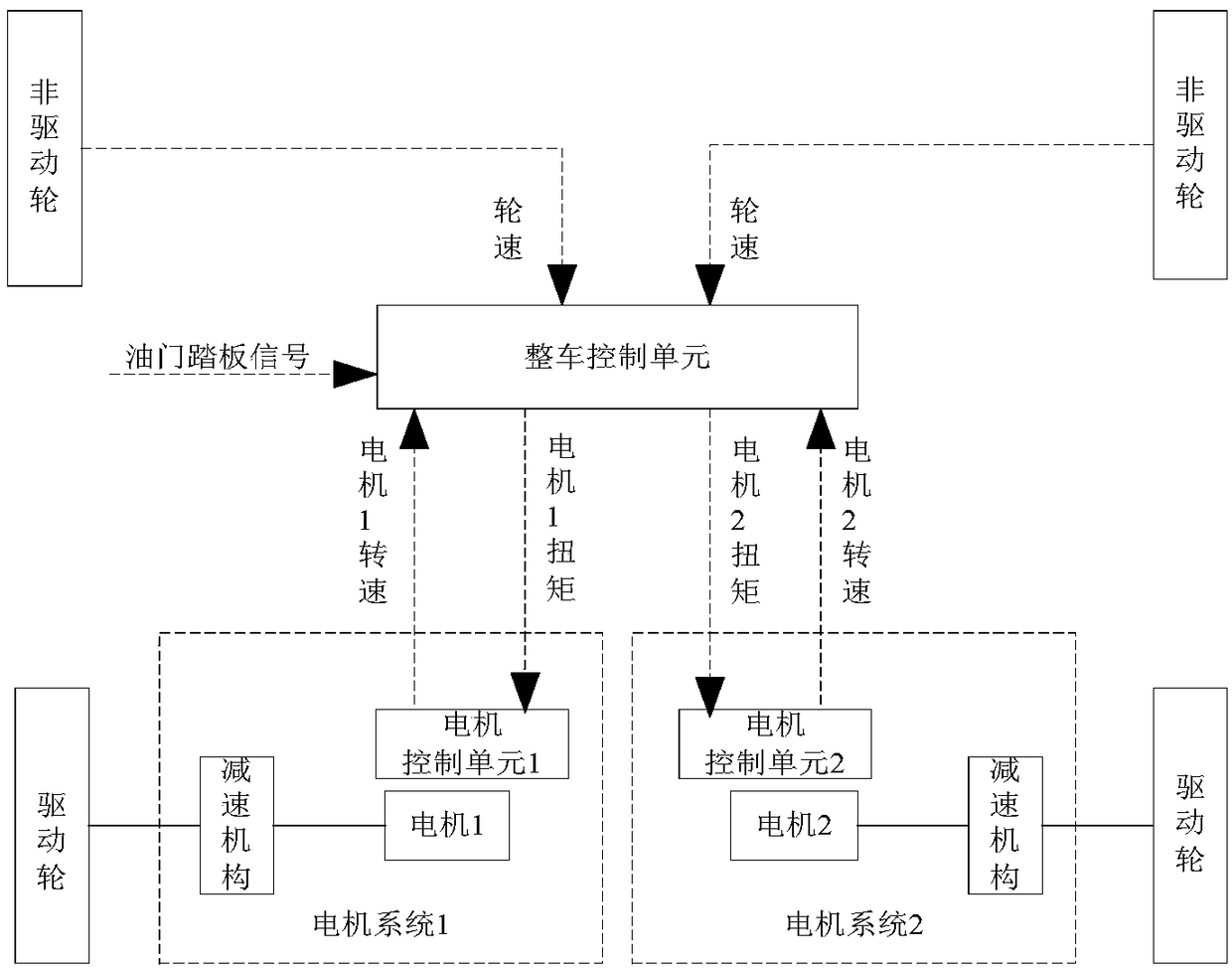

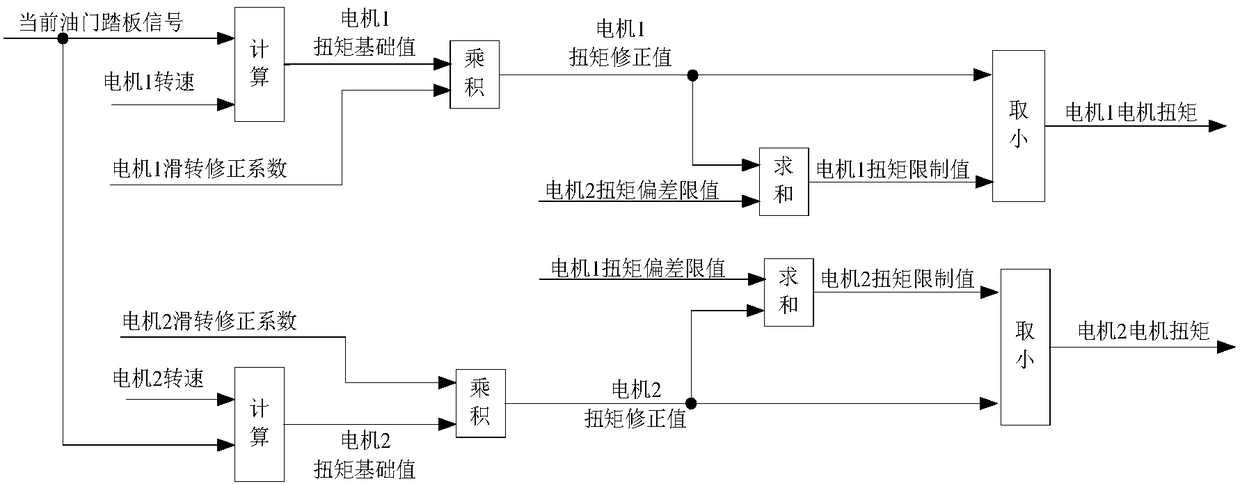

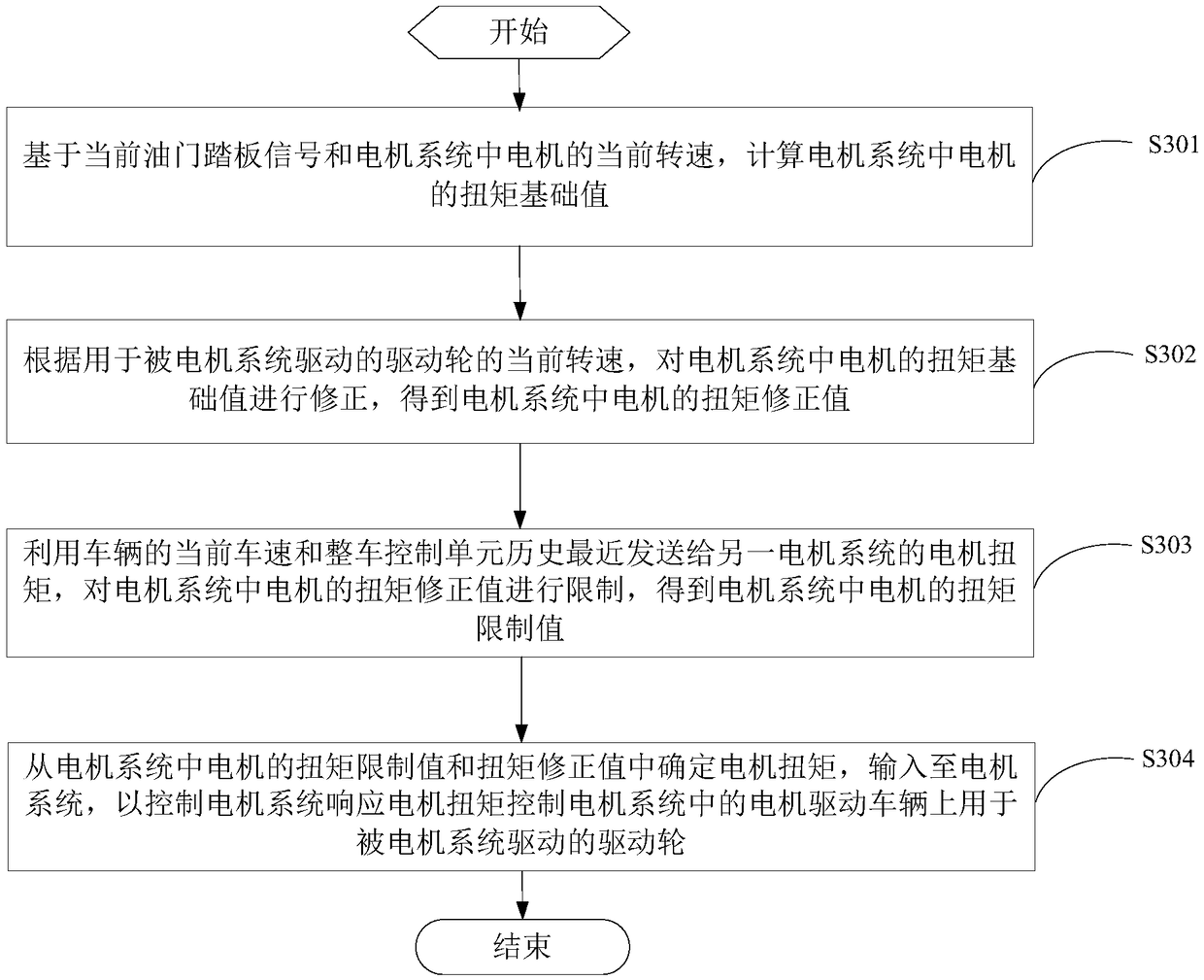

[0047] An embodiment of the present application provides a motor torque control method to simultaneously control the torque of motors in two motor systems in a wheel-side motor distributed drive system. In order to facilitate the understanding of the motor torque control method provided in the embodiment of the present application, a distributed drive system for wheel-side motors provided in the embodiment of the present application is firstly introduced in detail.

[0048] figure 1 It is a schematic structural diagram of a distributed drive system for in-wheel motors provided in an embodiment of the present application.

[0049] like figure 1 As shown, the wheel-side motor distributed drive system includes: a vehicle control unit, a motor system 1 and a motor system 2; the motor system 1 includes a motor 1, and the motor system 2 includes a motor 2, and the motor 1 and the motor 2 are used to drive the vehicle different drive wheels.

[0050] In this embodiment of the appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com