Rubber vehicle suspension device with variable rigidity property

A suspension device and variable stiffness technology, applied in the field of rubber suspension for commercial vehicles, can solve the problems of no stiffness change, vehicle yaw, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

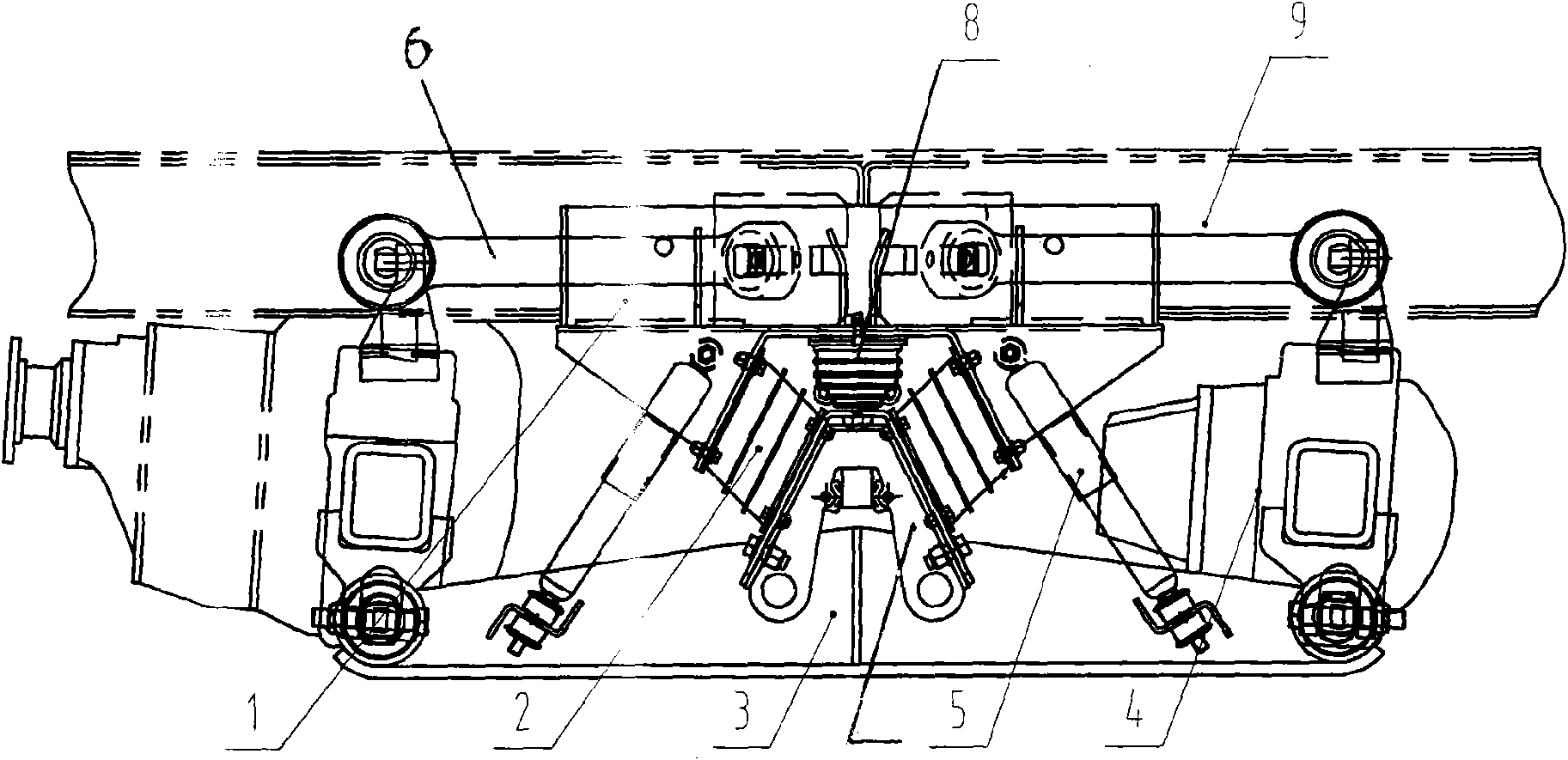

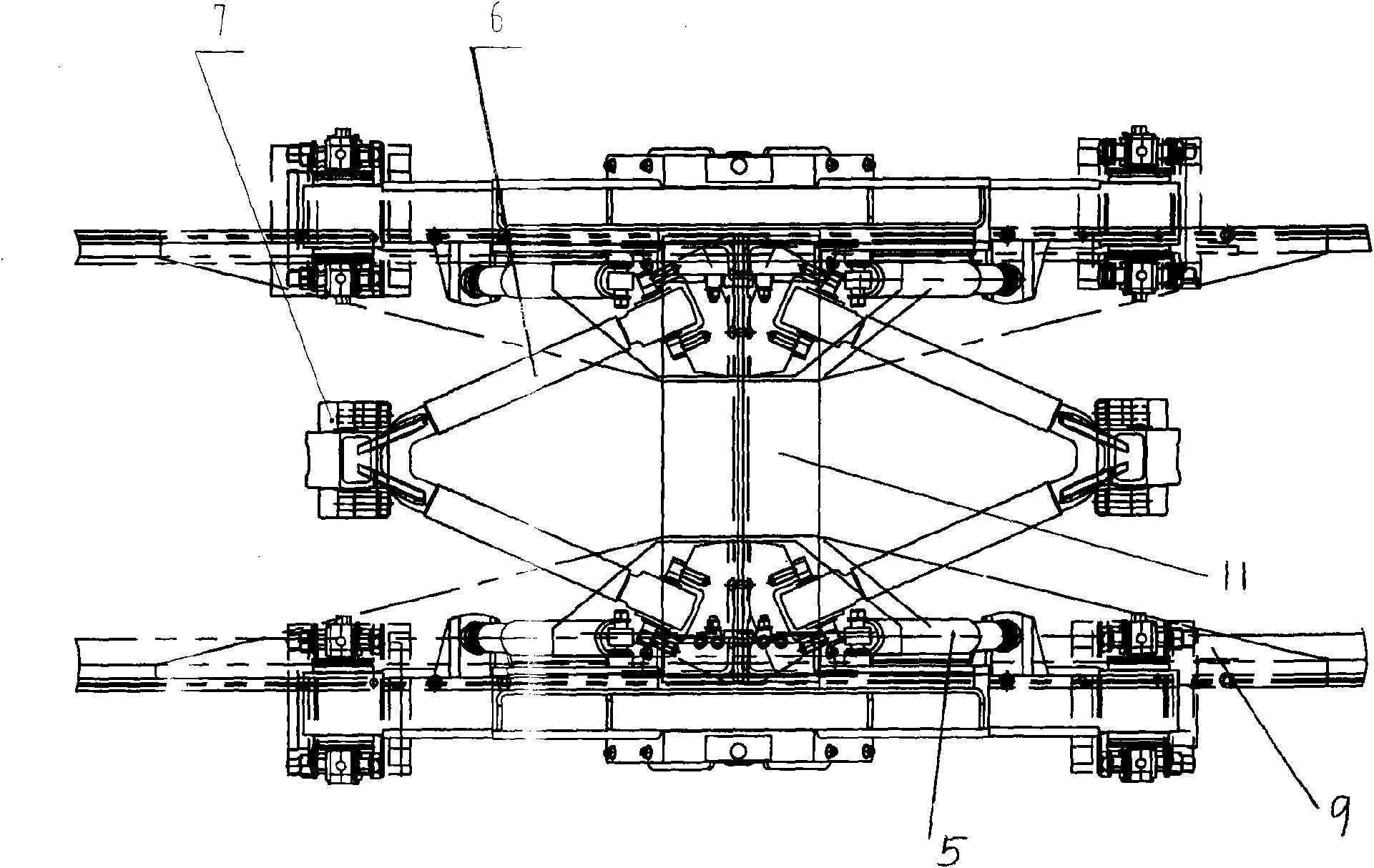

[0010] Such as figure 1 , 2 As shown, the vehicle frame 9 of the present invention is fixedly connected with the crossbeam 10, and the vehicle frame 9 is provided with a connecting bracket 1, and one end of the V-shaped thrust rod 6 is fixed on the vehicle frame 9, and the other end is fixed on the vehicle frame through the thrust rod support 7. On the upper end of the bridge 4, one end of the multi-layer rubber variable-section buffer block 8 is fixed on the bottom end of the connecting bracket 1, and the other end is suspended on the top of the rubber spring bracket 11. One end of the rubber spring 2 is fixed to the connecting bracket 1, and the other end is connected to the rubber spring The bracket 11 is connected, and the rubber spring bracket 11 is fixed on the bracket 3 by bolts. fixed, and the other end is connected with bracket 3 by bolts. Two sets of the V-shaped thrust rods 6 are arranged symmetrically, two sets of the rubber springs 2 are arranged symmetrically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com