A roadway maintenance machine for crushing and loading in coal mines

A technology for repairing machines and roadways, which is applied in the directions of earthmoving machines/shovels, mechanically driven excavators/dredging machines, construction, etc. The transmission torque is large, the self-locking ability is good, and the effect of reducing the yaw phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

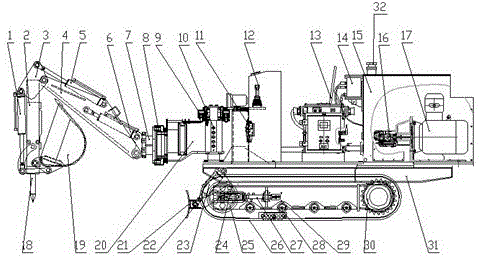

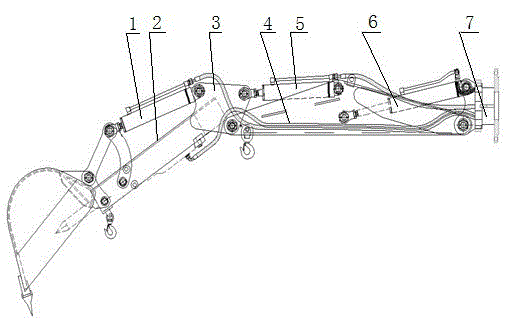

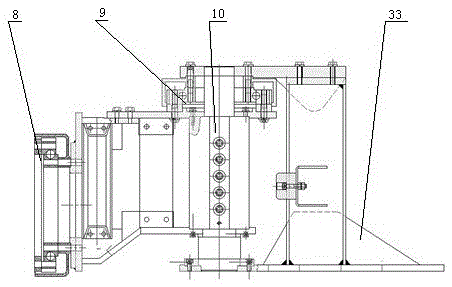

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention is a crushing and loading roadway maintenance machine for coal mines, which includes a car body part and an actuator, and the car body part includes a workbench, a driving device, a traveling device and an oil tank 15, and the driving device and the traveling device are in transmission connection. The walking device is provided with an assembled steel crawler belt 26, and in the assembled steel crawler belt 26, a guide wheel 25, a tensioning oil cylinder 27, a supporting wheel 28, and a travel motor 30 are arranged in sequence from front to back. Oil cylinder 27 is supported, and one end of tension oil cylinder 27 is connected with guide wheel, and the other end is provided with oil filling check valve 29 and is provided with bulldozer shovel device at the front portion of traveling device, and bulldozer shovel device comprises connecting rod 22 and shovel body 21, One end of connecting rod 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com