An insulator truck

A technology for handling vehicles and insulators, which is applied to motor vehicles, trolleys, multi-axis trolleys, etc., can solve the problems of uneconomical and cost-effective large-size insulator handling vehicles, time-consuming and labor-intensive insulator transfer and disassembly work, and reduced power grid work efficiency. The control method is simple and flexible, the handling process is safe and convenient, and the insulators are prevented from sliding or colliding with the vehicle body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be described in detail below in conjunction with specific embodiments.

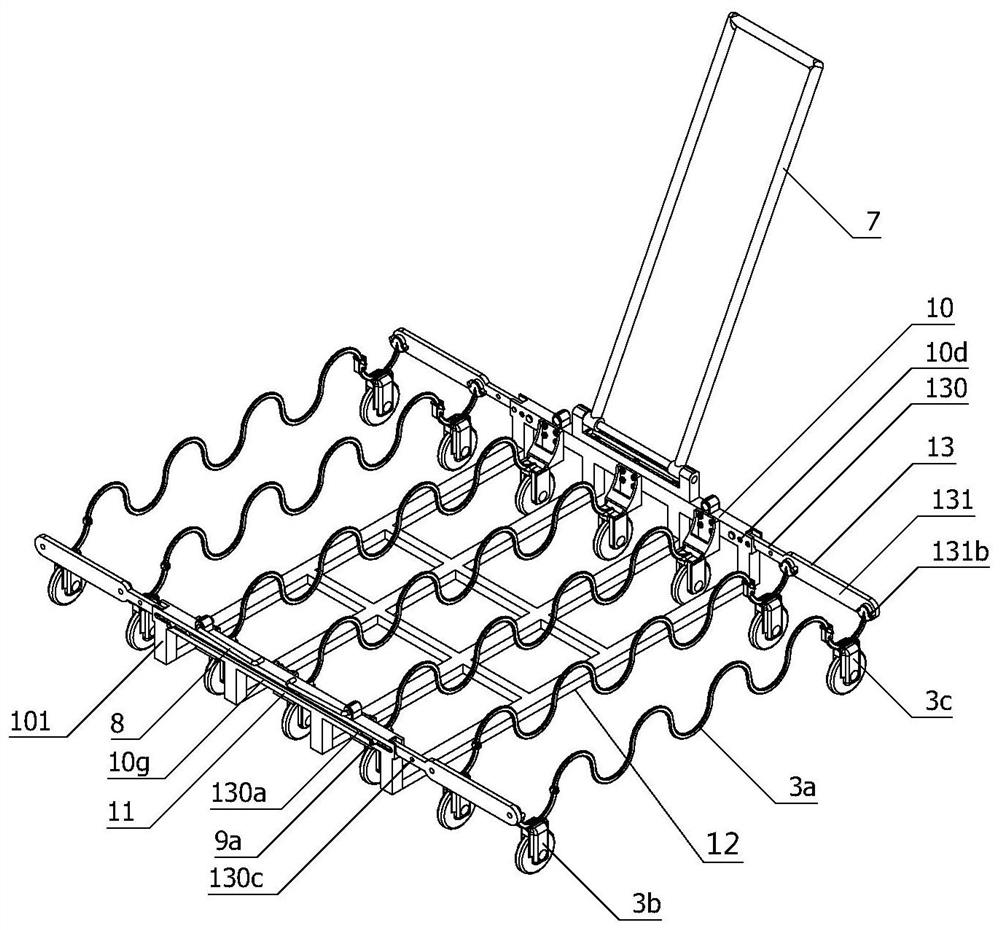

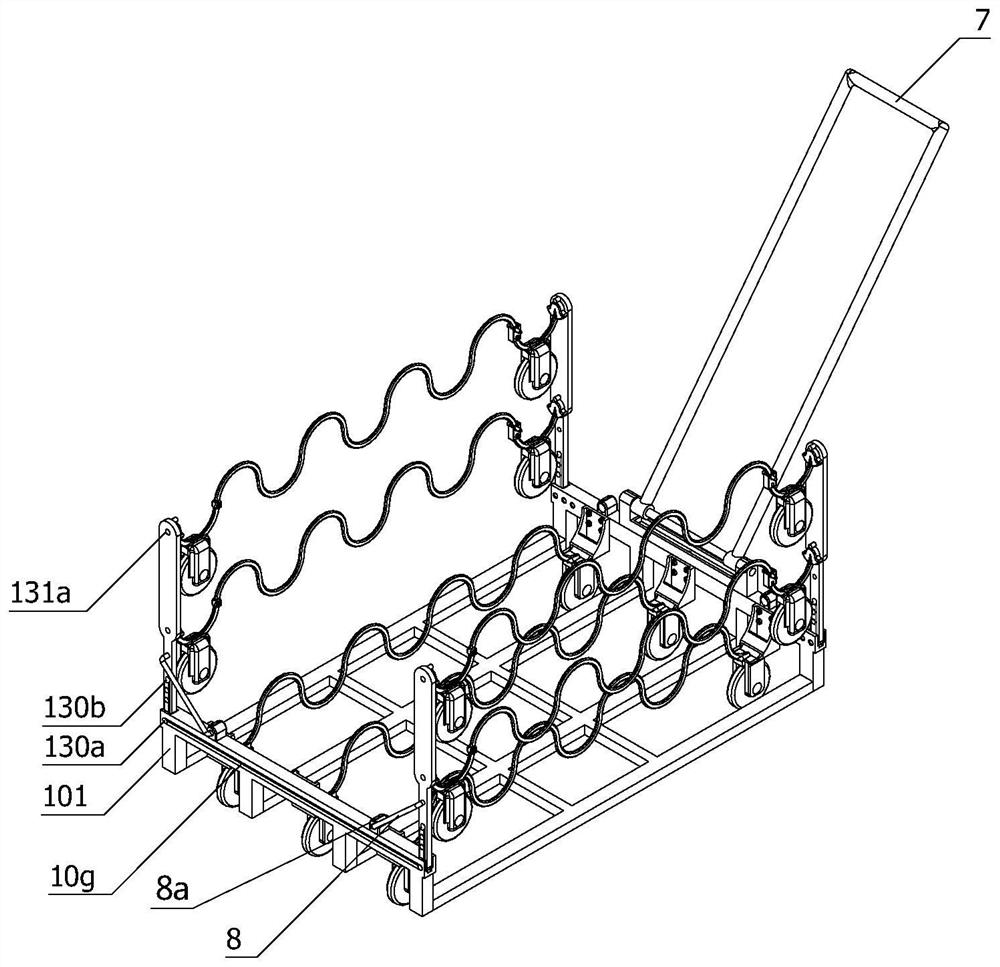

[0031] Such as figure 1 , 2 As shown, the present invention provides an insulator transport vehicle, which is mainly used to solve the problem that there is no better transport tool when large insulators and small insulators need to be transported together in the actual work process, and it is troublesome to disassemble and fix the large insulators during the transport process, and the insulators are easy to carry. Problems such as collisions

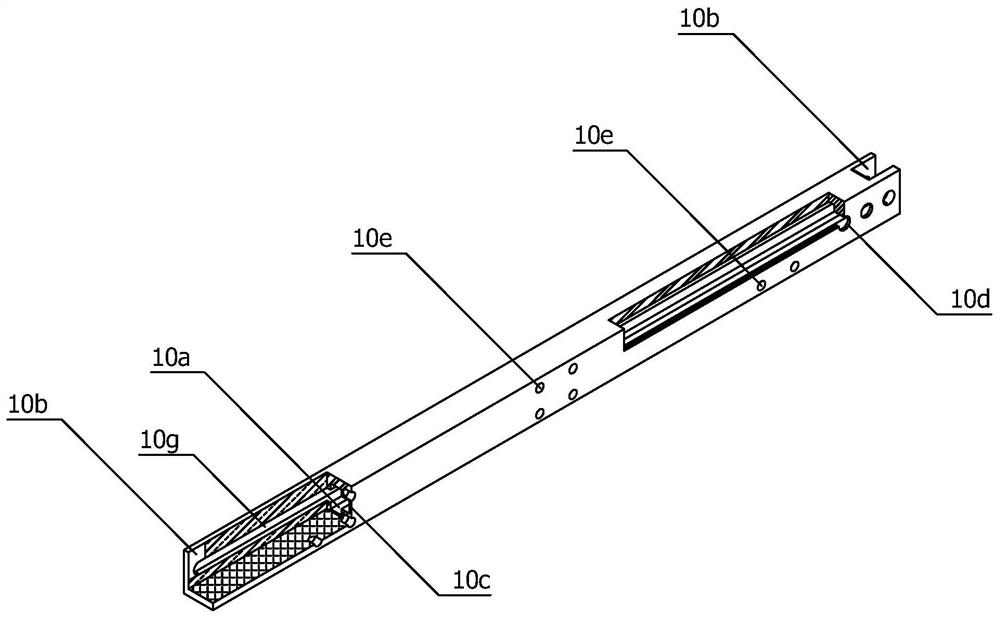

[0032] The insulator transport vehicle of the present invention includes a frame assembly for constituting the main support structure, two inner corrugated frame assemblies 2 and two outer corrugated frame assemblies 3 arranged on the frame assembly; In order to form an insulator support structure, two inner corrugated frame components 2 are located in the middle to support the main mass of the insulator, and two outer corrugated frame c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com