Patents

Literature

37results about How to "Realize the whereabouts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

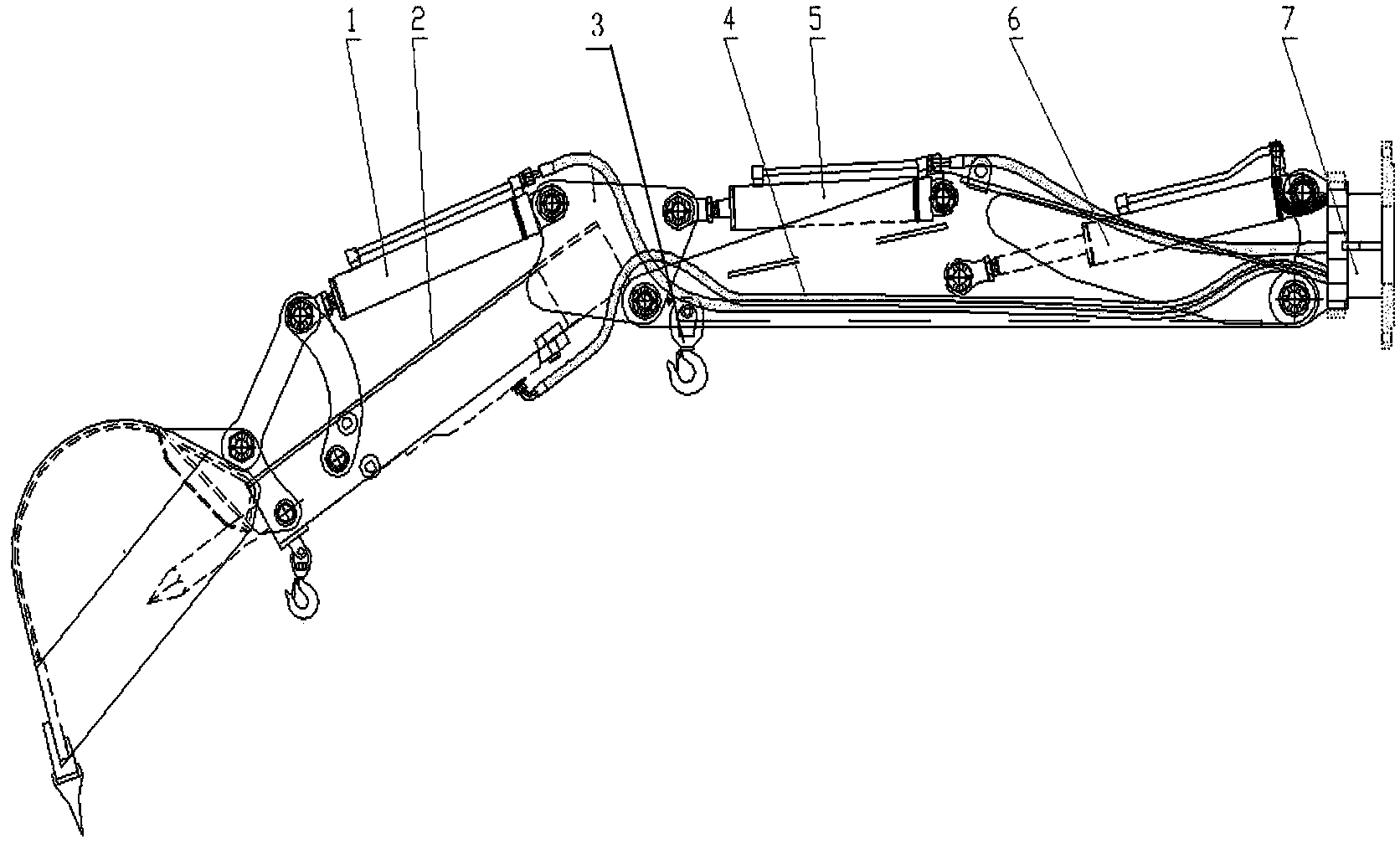

Multifunction downhole bottom ripping machine

InactiveCN101392651AAdaptableAchieve riseUnderground miningMechanical machines/dredgersEngineeringControl valves

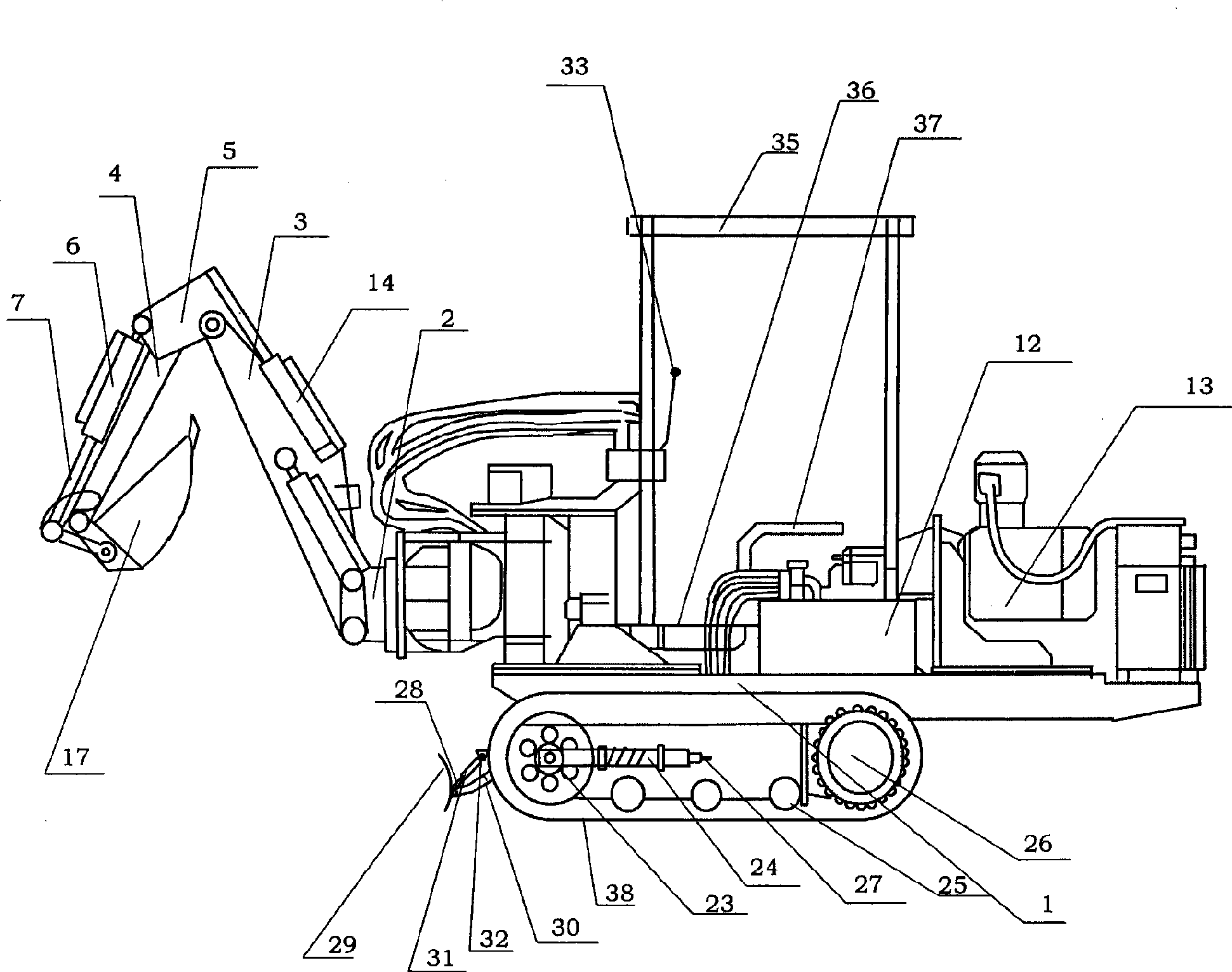

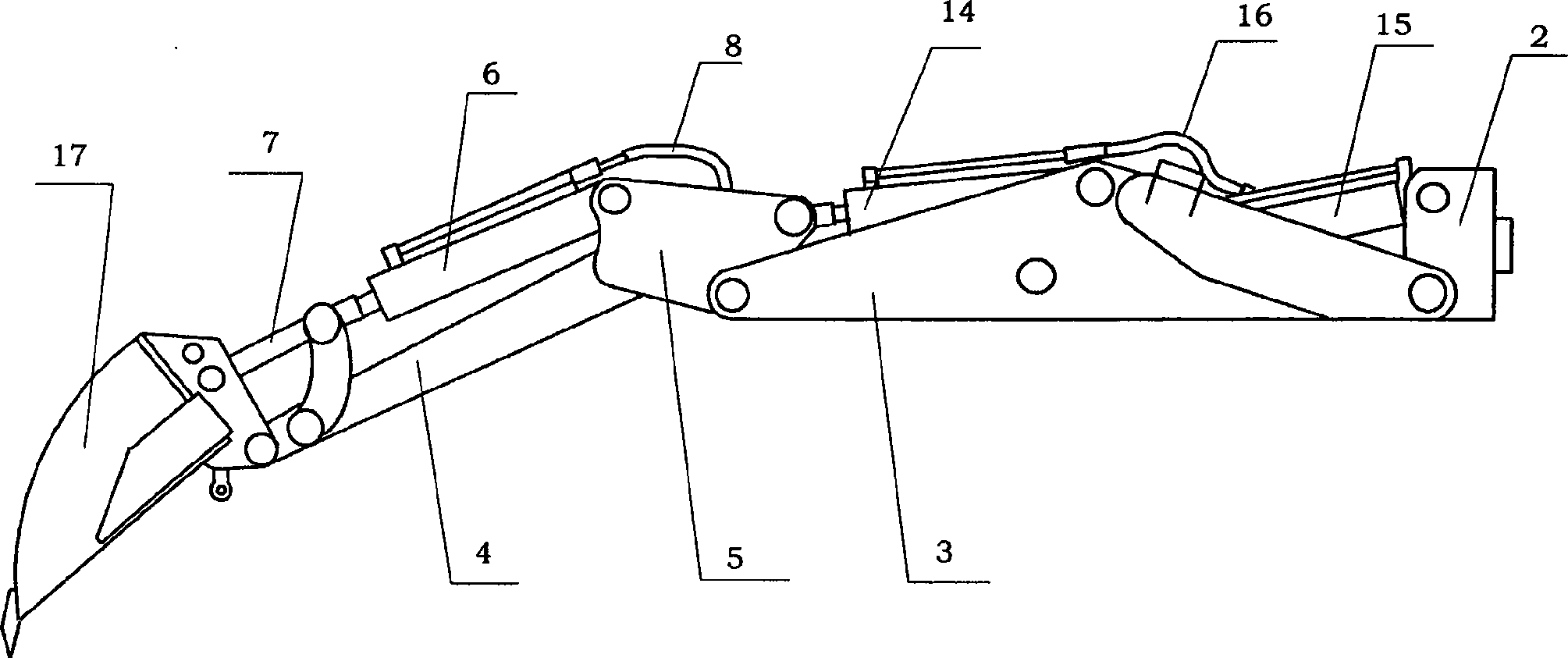

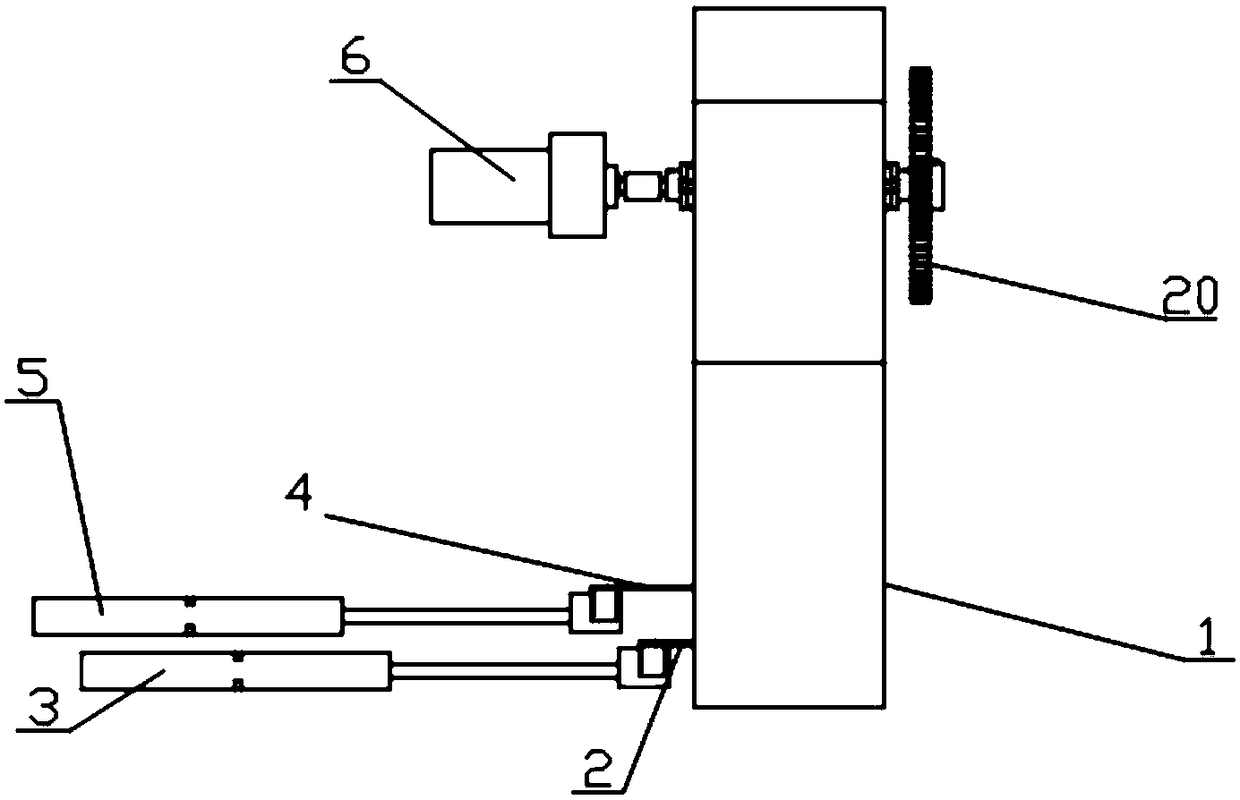

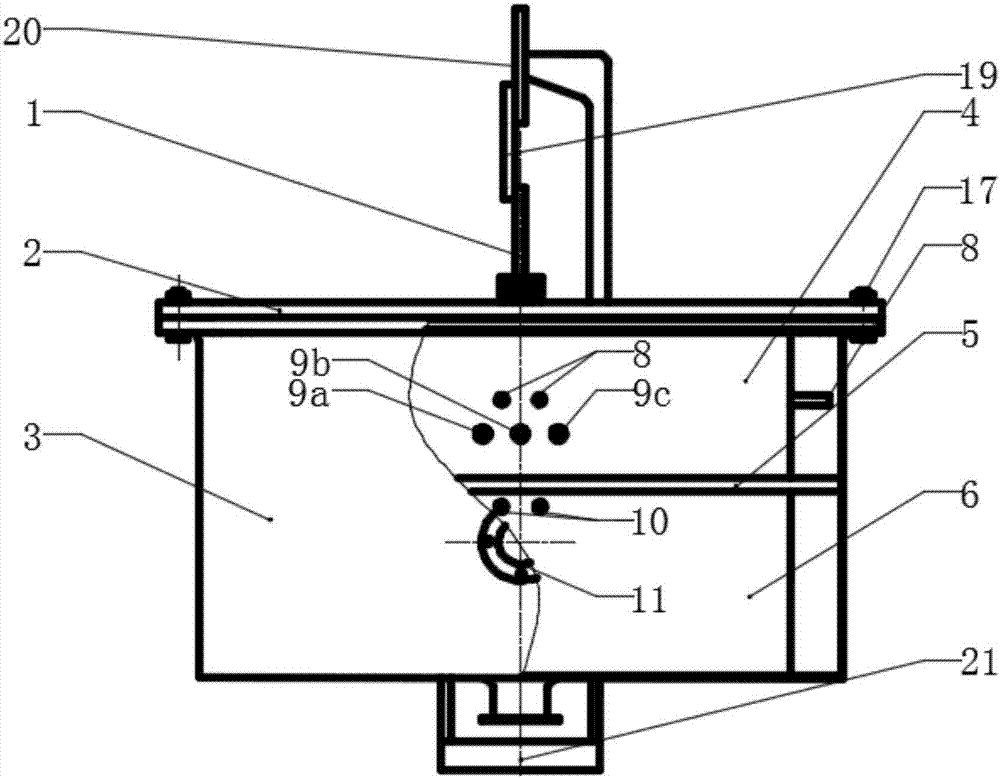

The invention discloses a multi-functional underground dinting machine. The head part of a digging arm of the multi-functional underground dinting machine is connected with an operating head, while the tail part is provided with a support (2), a revolving device is arranged between the digging arm and a worktable, one end of a small arm (4) is rotationally connected with the operating head, while the other end is connected with a movable arm (5), a movable arm oil cylinder (6) is arranged above the small arm (4) and is communicated with an oil inlet pipe (10) and an oil return pipe (11) through a connecting pipe I(8) and an oil channel control valve (9) of an operating device, one end of a large arm (3) is rotationally connected with the movable arm (5), while the other end is rotationally connected with the revolving device, a large arm oil cylinder I(14) and a large arm oil cylinder II(15) are arranged above the large arm (3), and the large arm oil cylinder I(14) is communicated with the oil inlet pipe (10) and the oil return pipe (11) sequentially through a connecting pipe II(16), the large arm oil cylinder II(15) and the oil channel control valve (9) of the operating device.

Owner:TAIZHOU XINGDONG COAL MINING MACHINERY

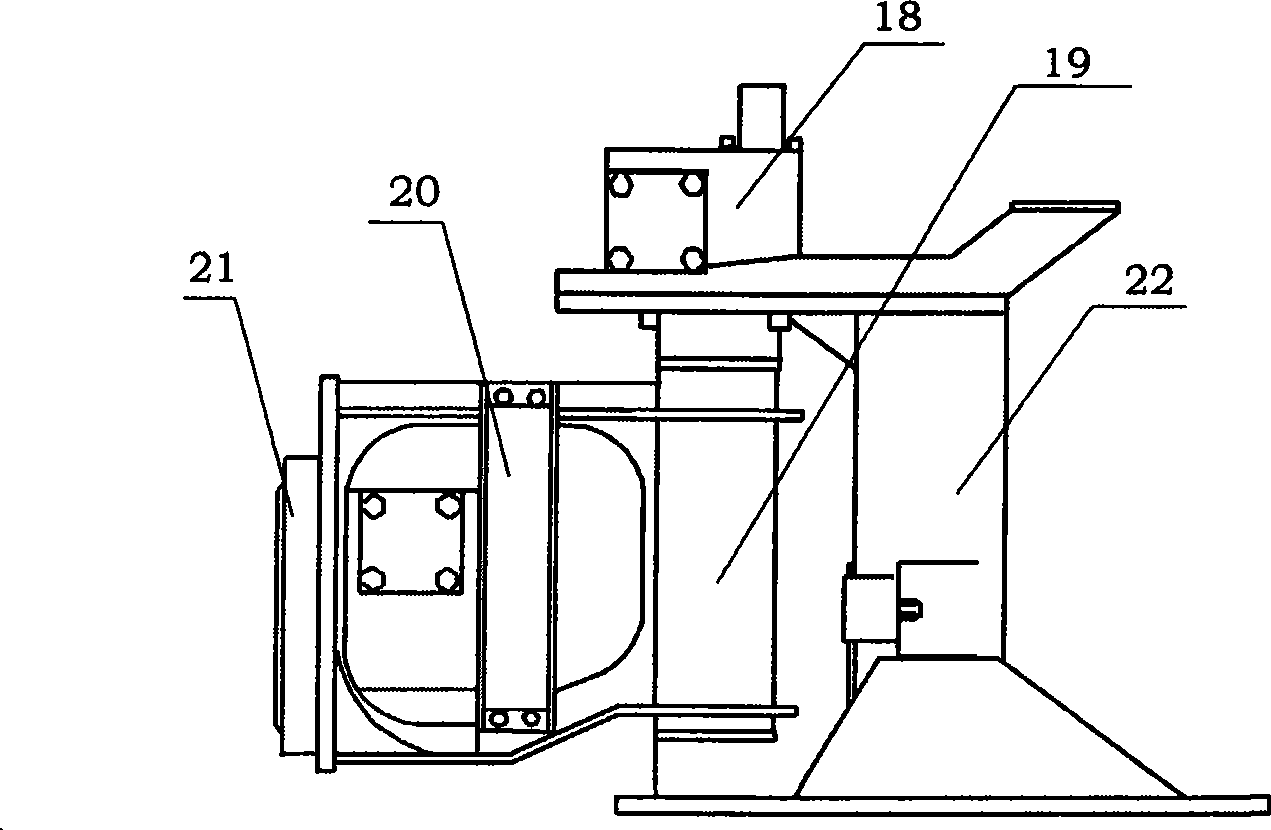

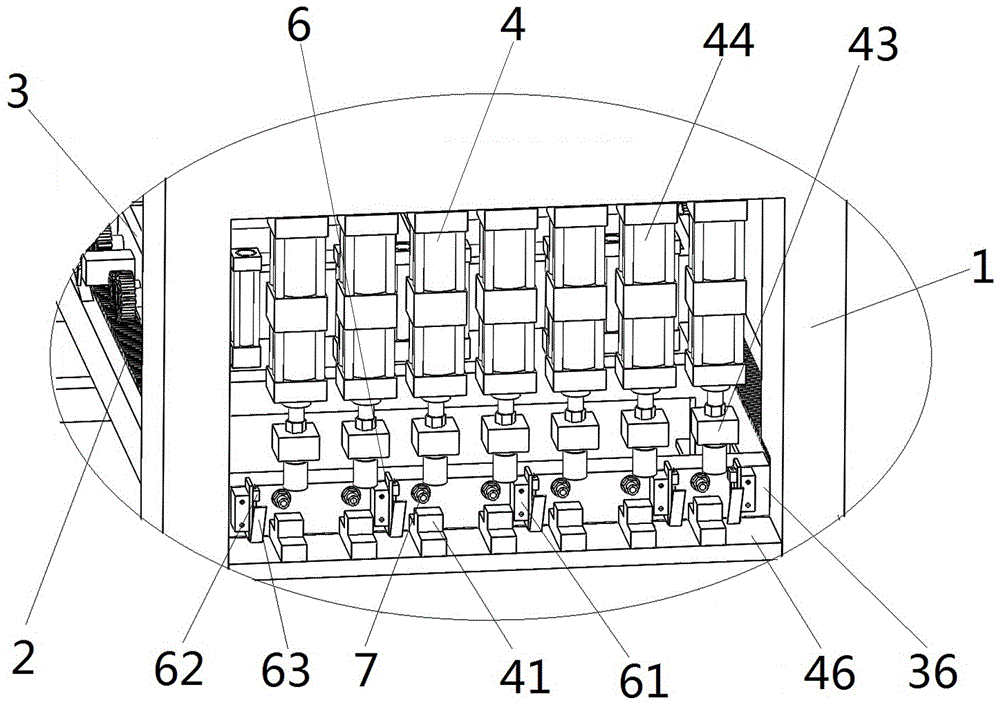

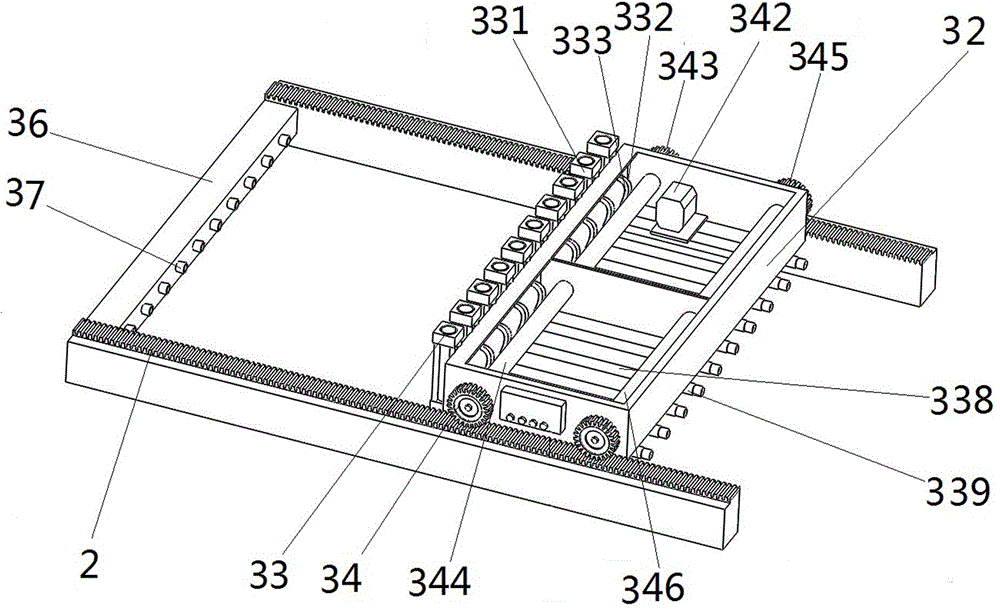

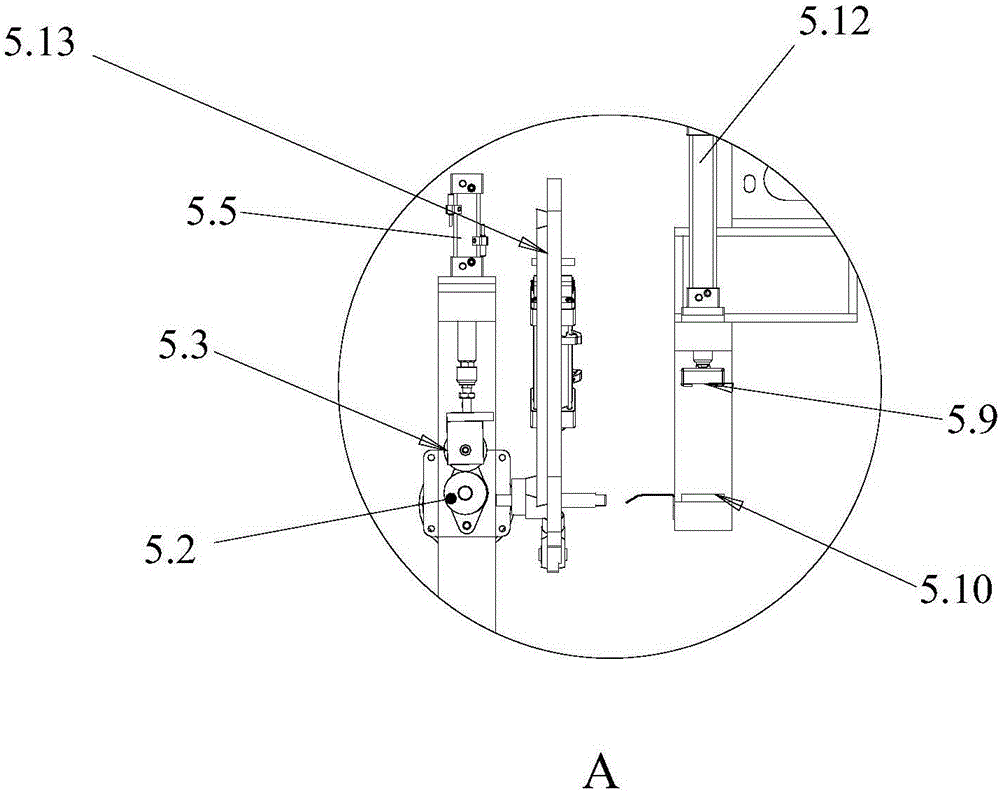

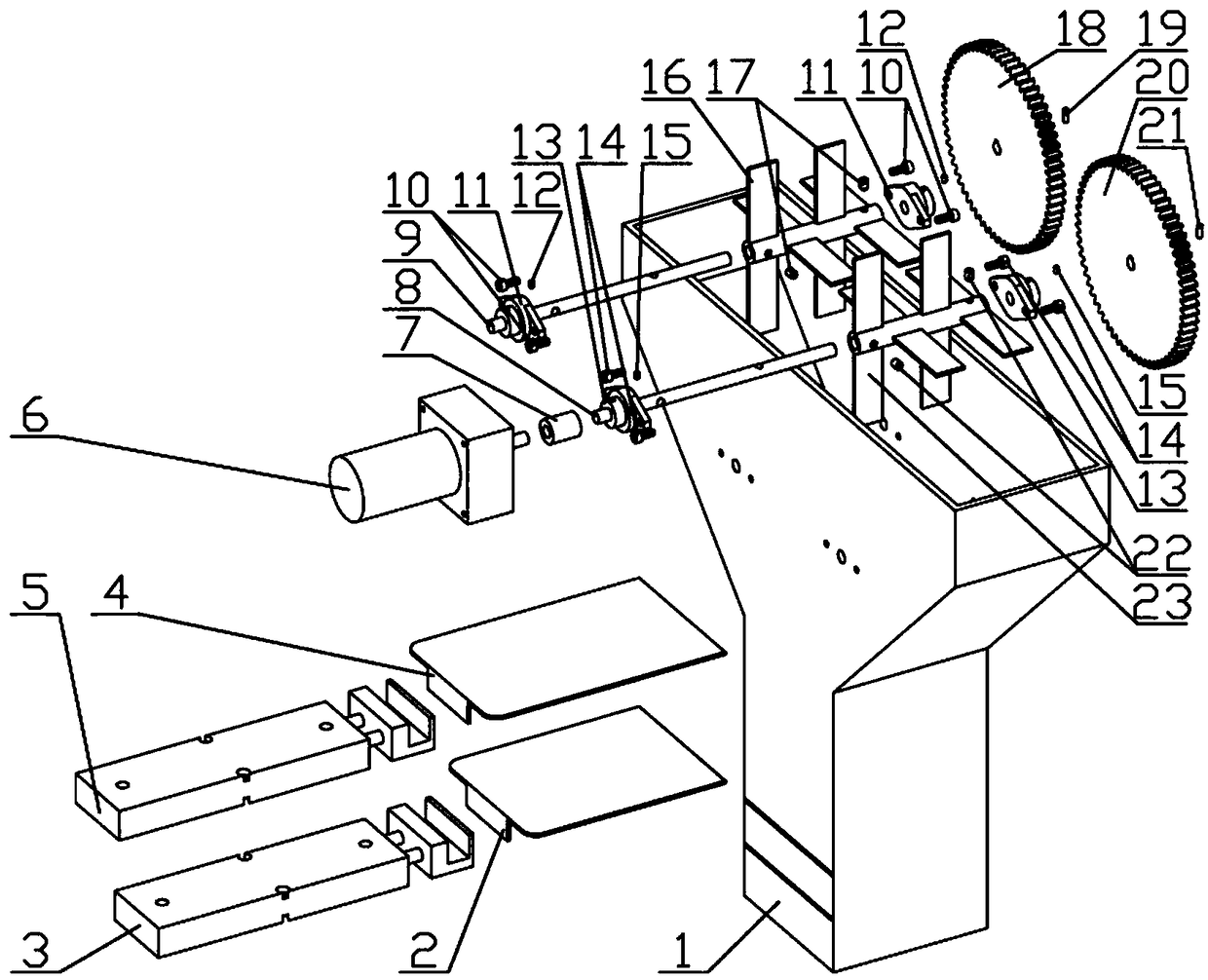

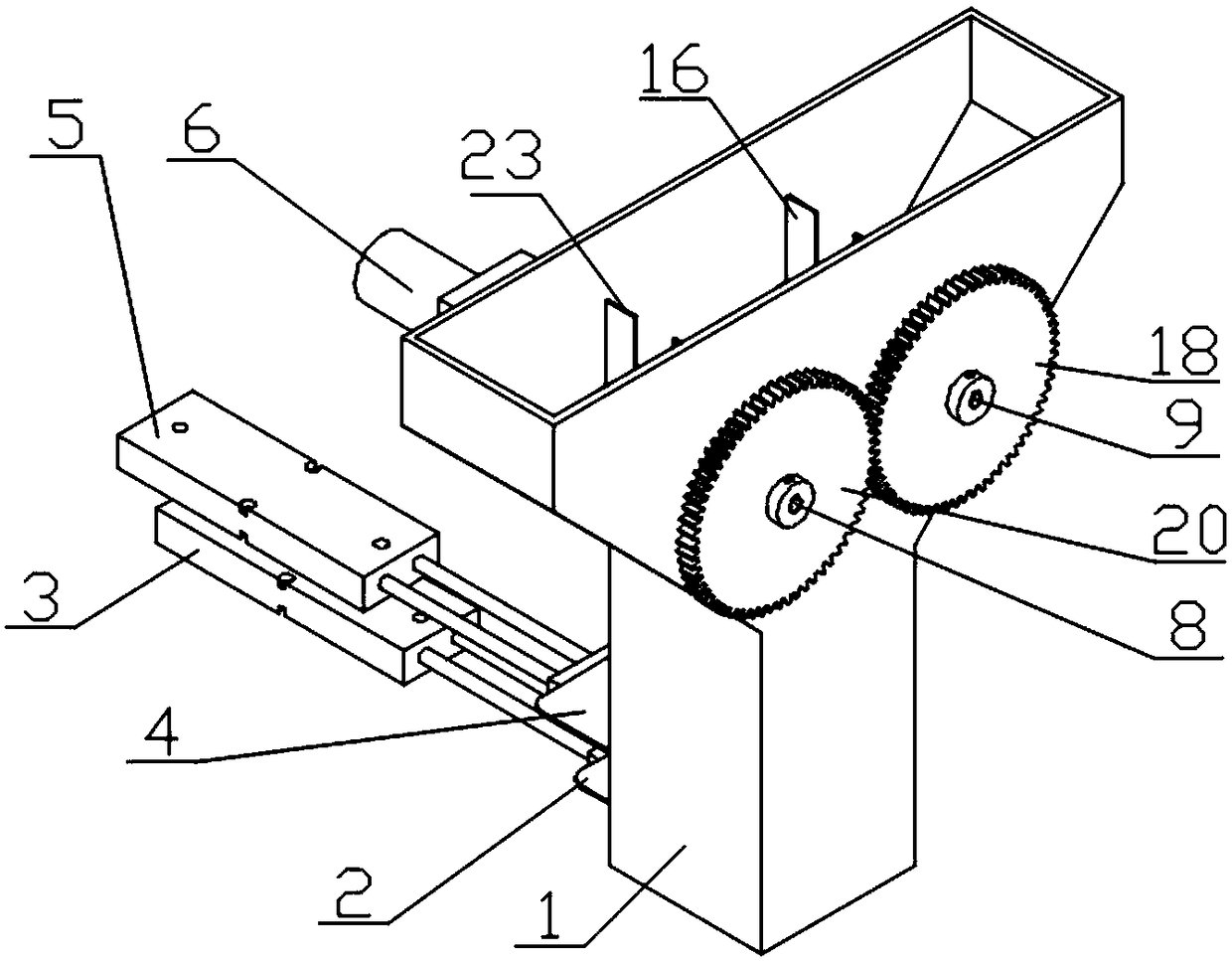

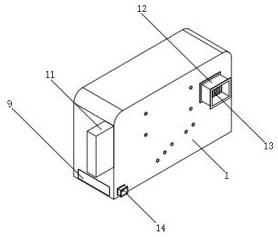

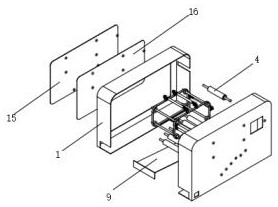

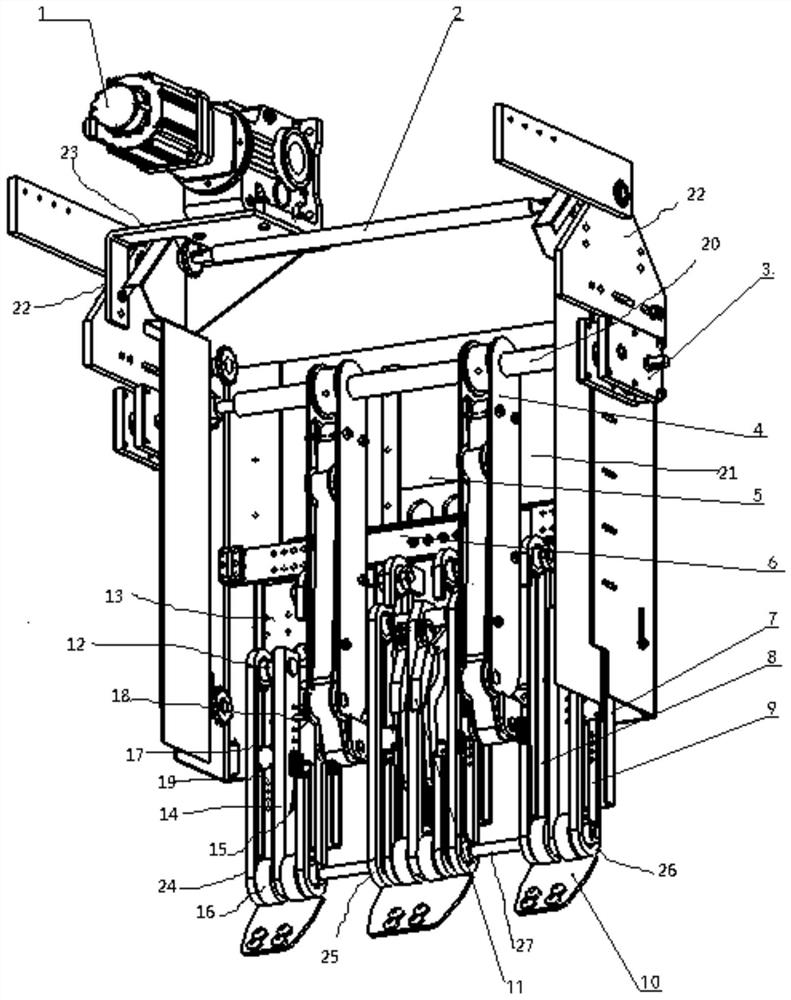

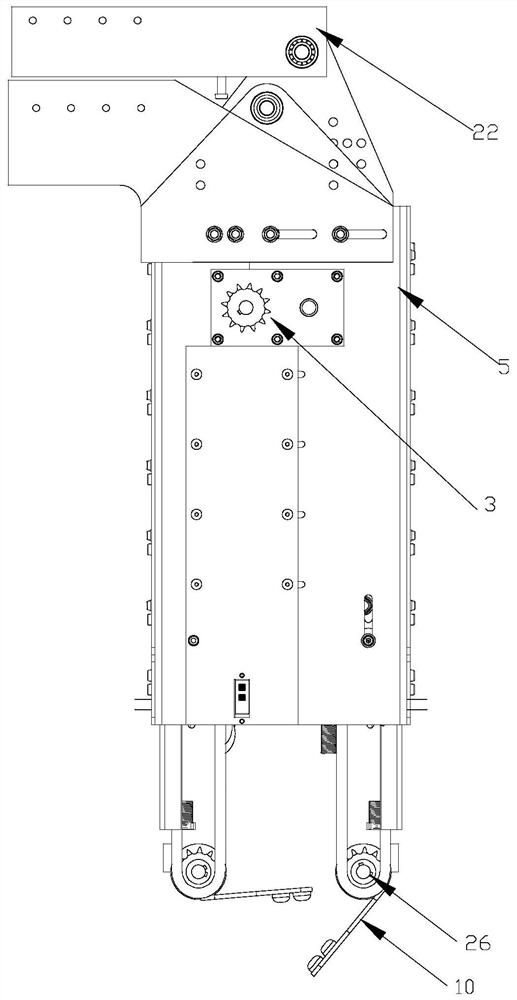

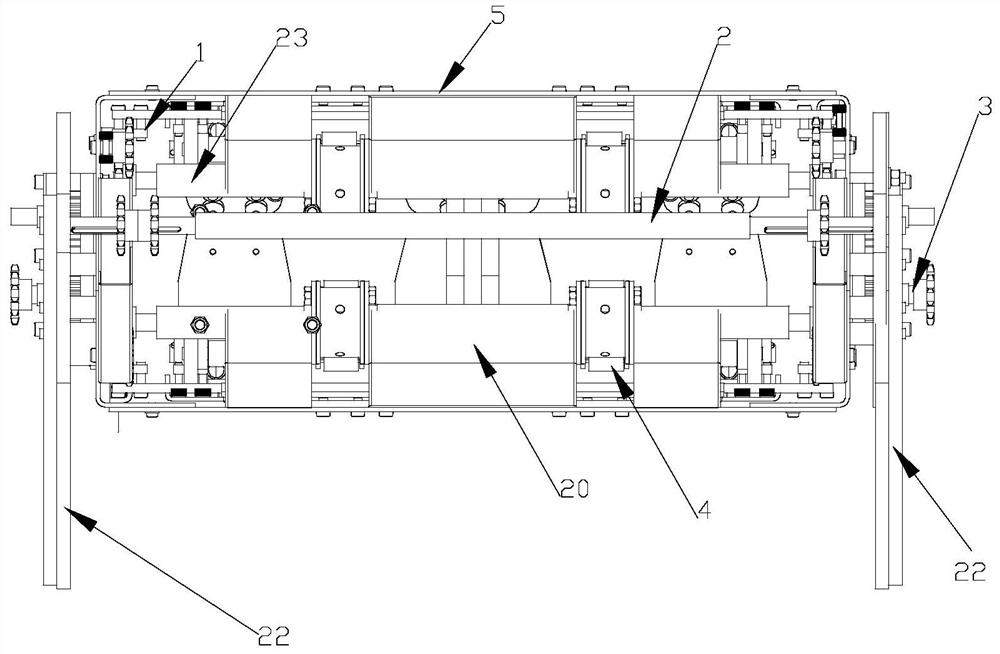

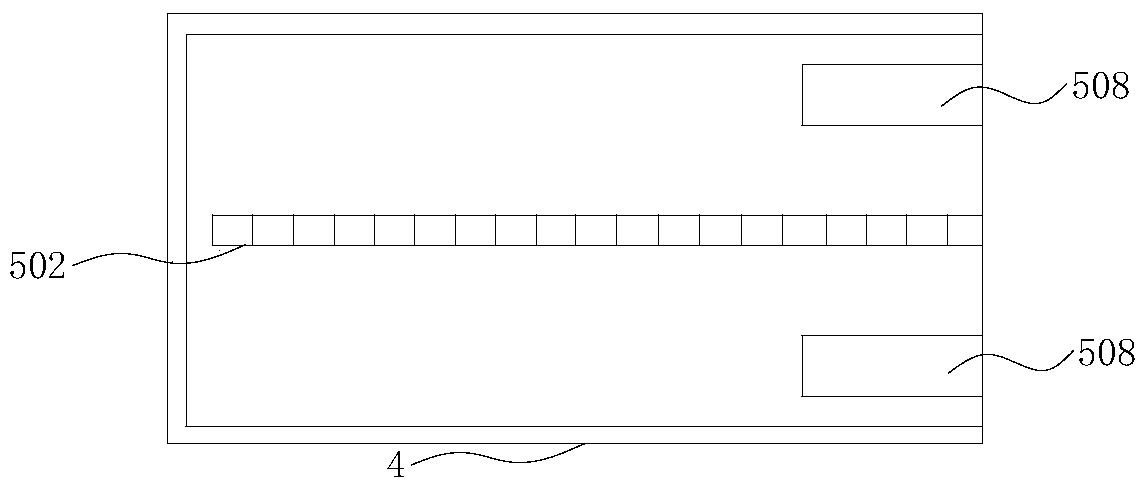

Plain net welding machine

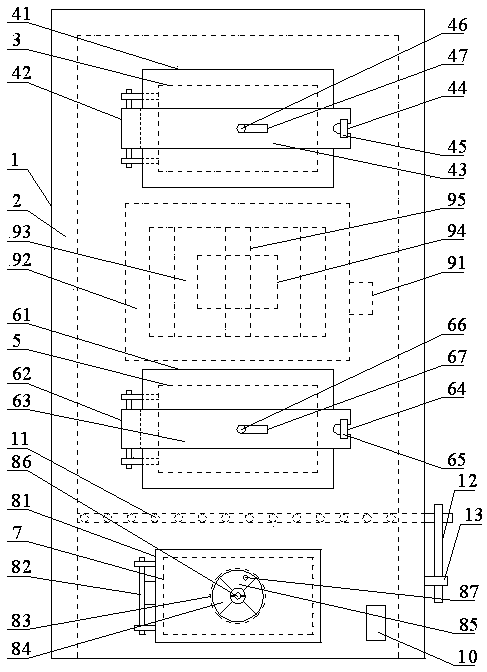

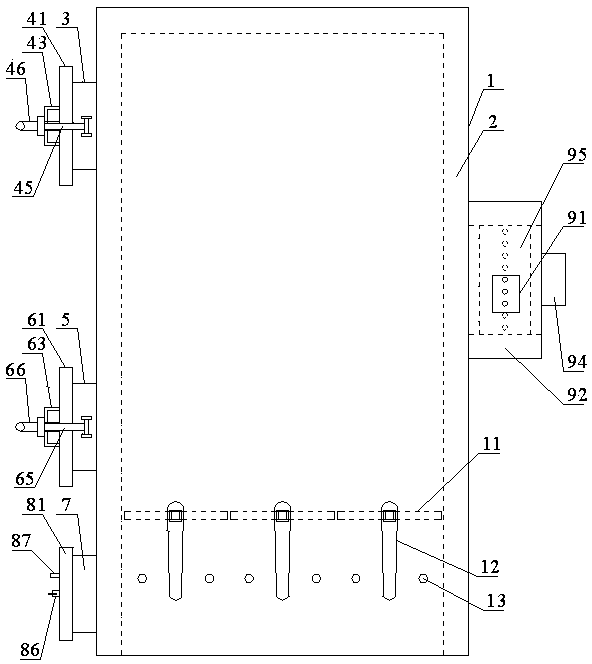

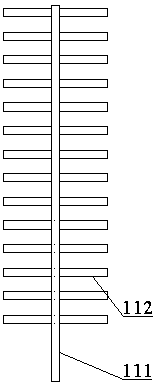

The invention discloses a plain net welding machine. The plain net welding machine comprises a plain net welding machine frame; a longitudinal rib wire feeding device, a welding device, a transverse rib blanking device and a net pulling device are arranged on the plain net welding machine frame in sequence from back to front; a transverse rib absorbing and detecting device for precisely positioning transverse ribs, dropping out from the transverse rib blanking device, into the welding device is arranged on one side of the welding device at the bottom end of the transverse rib blanking device; and the plain net welding machine frame is provided with a main controller for controlling coordinative operations of the longitudinal rib wire feeding device, the welding device, the transverse rib blanking device, the net pulling device and the transverse rib absorbing and detecting device. The plain net welding machine solves such problems as conveying position deviation of longitudinal ribs in the conveying process, influence on the production quality due to no aligned correction of transverse ribs dropping on the longitudinal ribs, deviation from the welding position of the transverse ribs dropping on the longitudinal ribs, incapability of full-automatically pulling nets by the net pulling device and inconvenience to pull the transverse ribs by net pulling hooks in actual production, and improves the production efficiency and the product quality.

Owner:河北森阳建筑设备科技有限公司

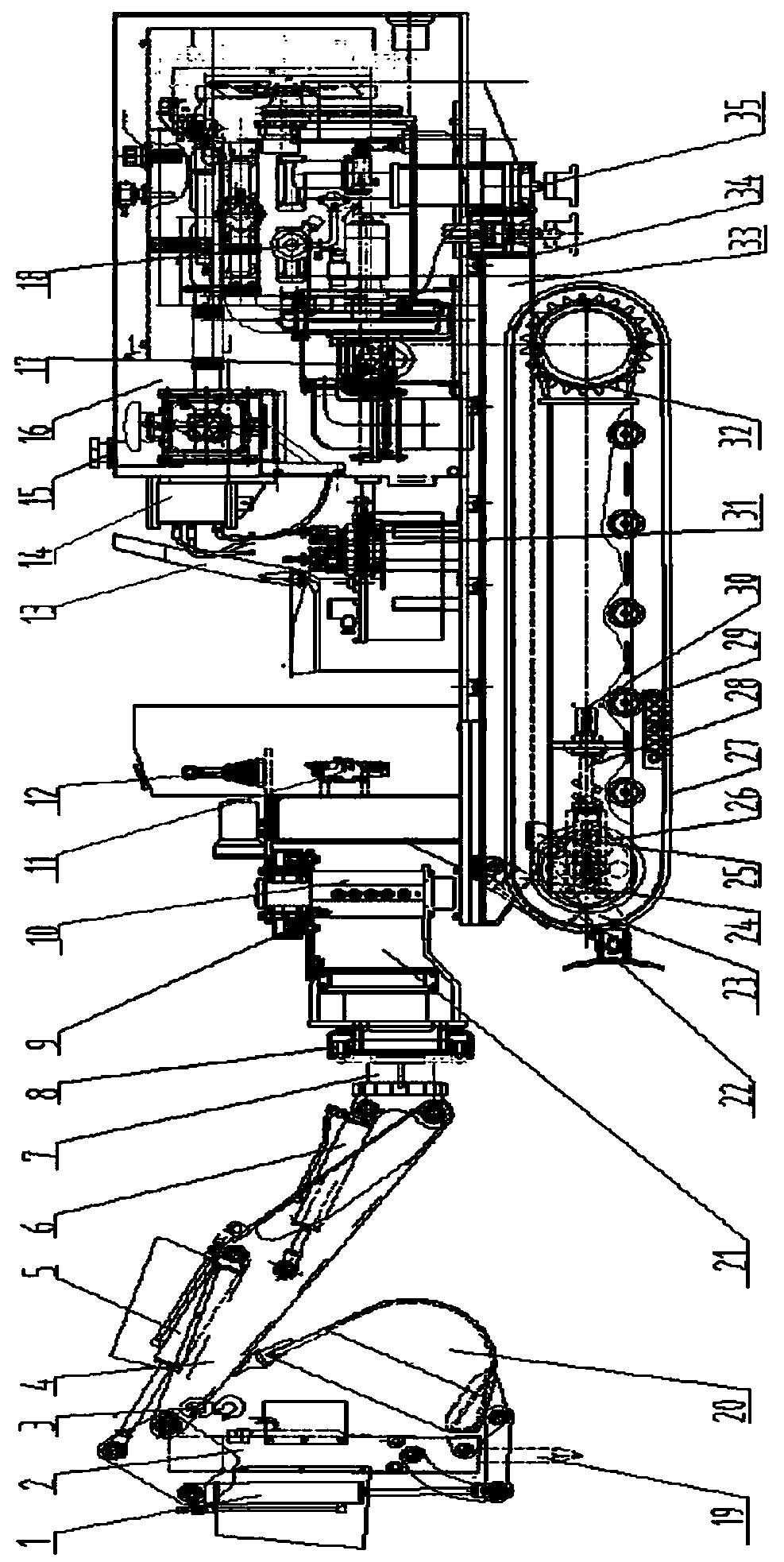

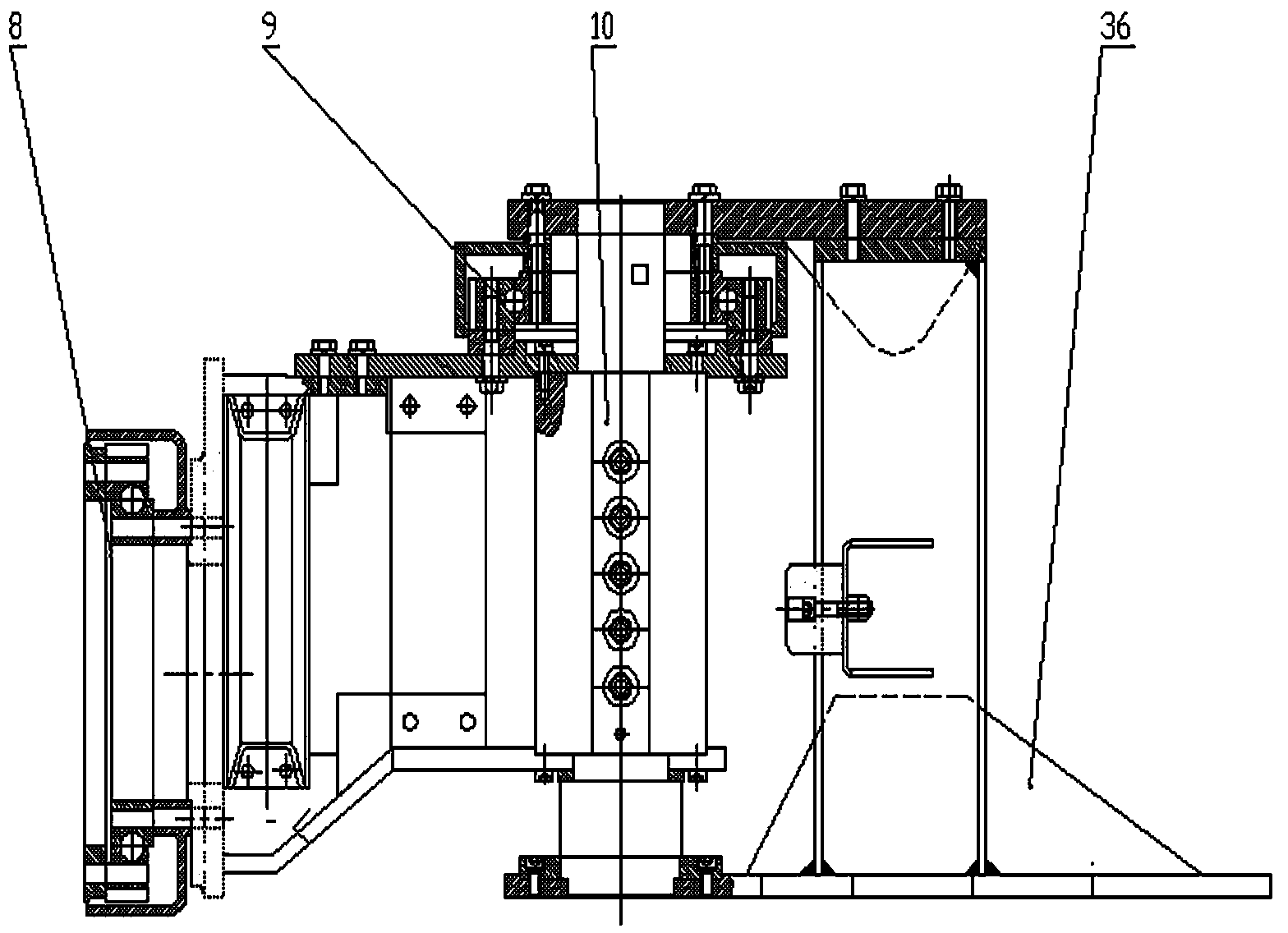

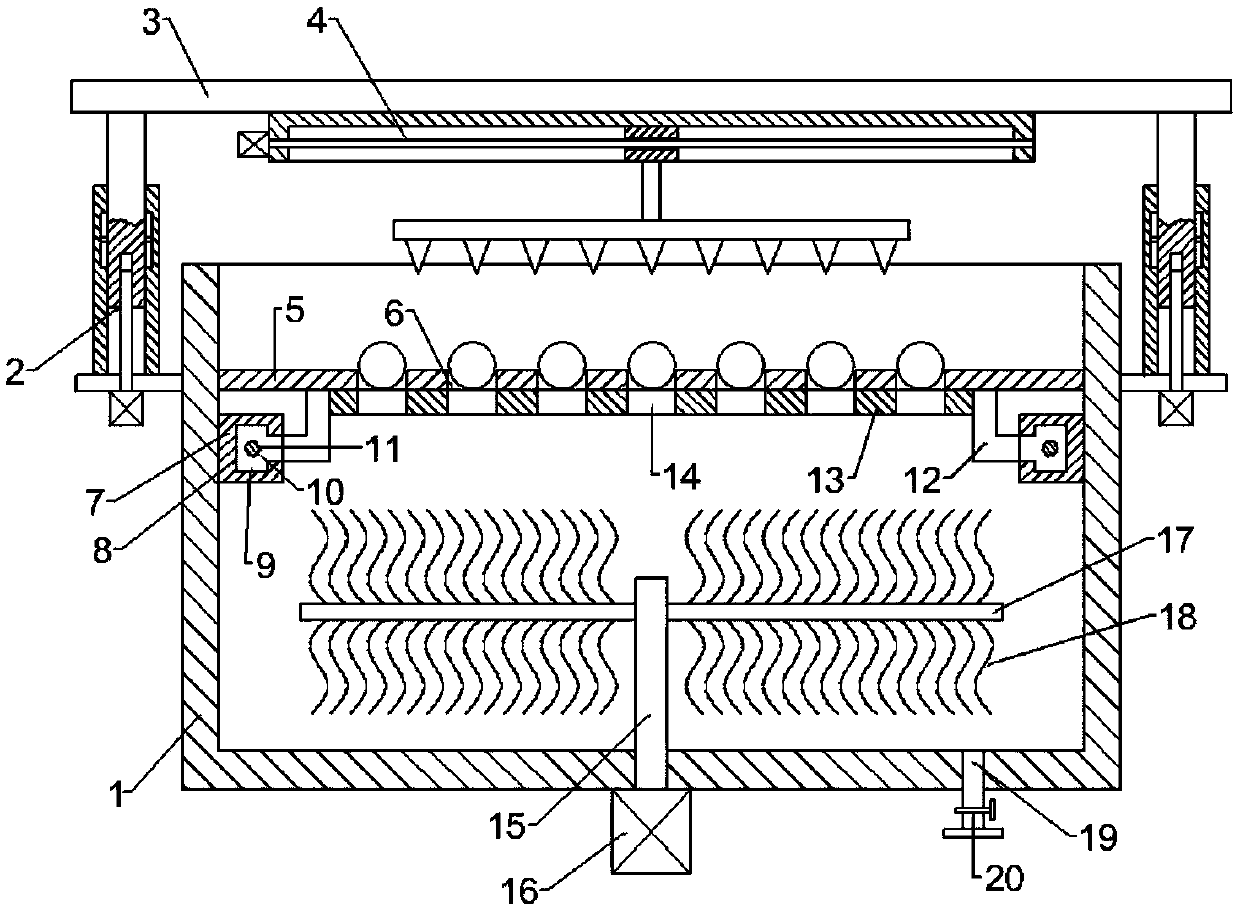

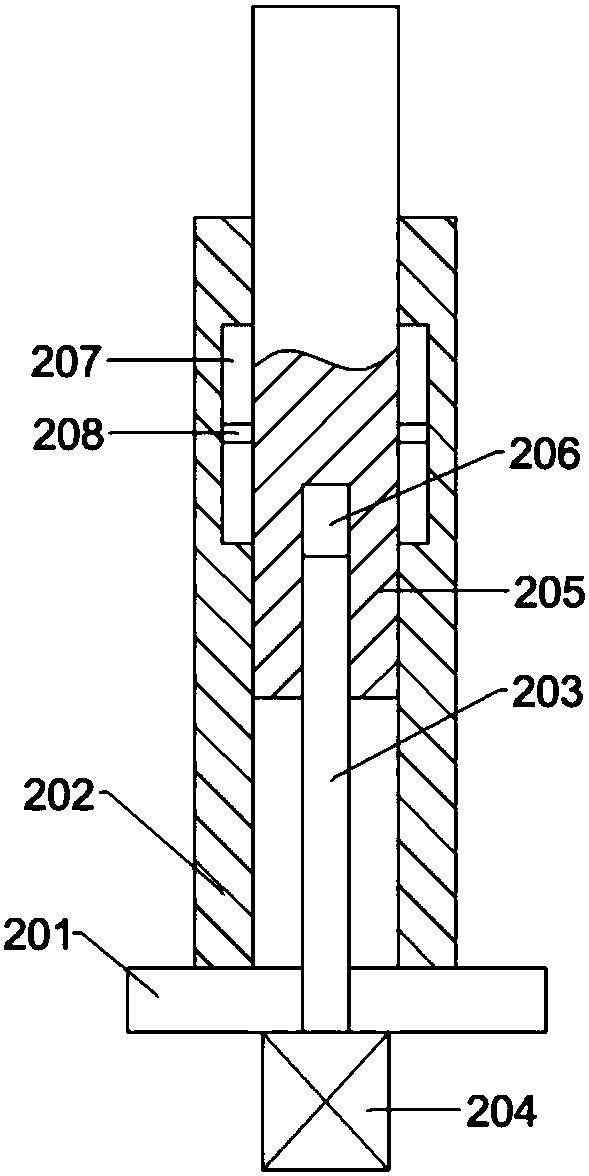

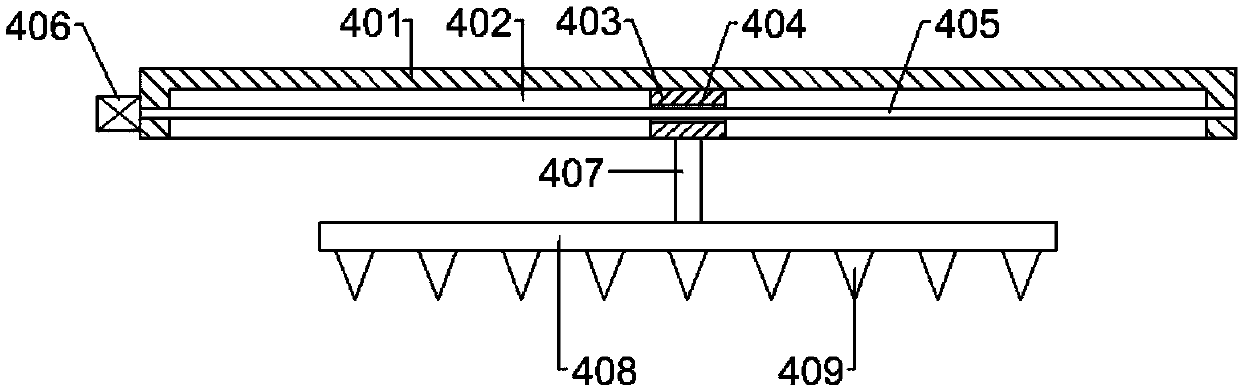

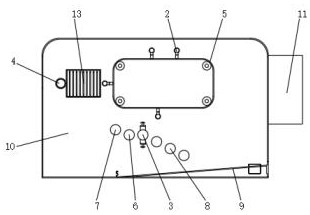

Breaking loading roadway repairing machine for coal mine

InactiveCN103669440AAchieve riseRealize the whereaboutsMechanical machines/dredgersCouplingFuel tank

The invention discloses a breaking loading roadway repairing machine. A vehicle body part comprises a worktable, a driving device, a running device, an oil tank and a supporting leg, wherein the driving device and the running device adopt a hydraulic transmission mode, the driving device is a hydraulic driving device, is arranged at the rear portion of the worktable and comprises an explosion-proof diesel engine and an oil pump, the explosion-proof diesel engine transmits the oil pump through a coupler, an input port of the oil pump and the oil tank are communicated through an oil path, and an output port of the oil pump and two sets of oil path control valves are communicated through oil paths. Liquid is supplied to the running device and each oil cylinder through the two sets of oil path control valves, the H-shaped supporting leg is arranged at the rear portion of a support of the vehicle body, and the supporting leg is matched with a supporting leg guide rail in a sliding mode.

Owner:许世东

Green walnut peeling device having rolling and rubbing functions

The present invention discloses a green walnut peeling device having rolling and rubbing functions. The green walnut peeling device comprises a frame body. A top part of the frame body is in an opening shape, two lifting devices are symmetrically fixedly connected with an outside wall of the frame body, a support plate is jointly fixedly connected with top ends of the lifting devices, and a rolling and rubbing device is fixedly connected with a lower side of the support plate; and a walnut placing plate is fixedly connected with an inside wall of the frame body and a plurality of through-holesare evenly opened in the walnut placing plate. Beneficial effects are as follows: when the support plate descends, the support plate drives a descending of the rolling and rubbing device, thus protrusions contact with green skins on upper sides of walnuts and are embedded in the green skins, then a first motor is started, the first motor drives a rotation of a first threaded rod, a first moving block cooperating with the first threaded rod moves left and right in a first moving groove to drive a left and right movement of a mounting plate, thus the protrusions move left and right, when the protrusions move left and right, the walnuts rotate, and the green walnut peeling device realizes a removal of the green skins on whole spherical surfaces of the walnuts and is high in removal efficiencies.

Owner:江苏荣泽食品有限公司

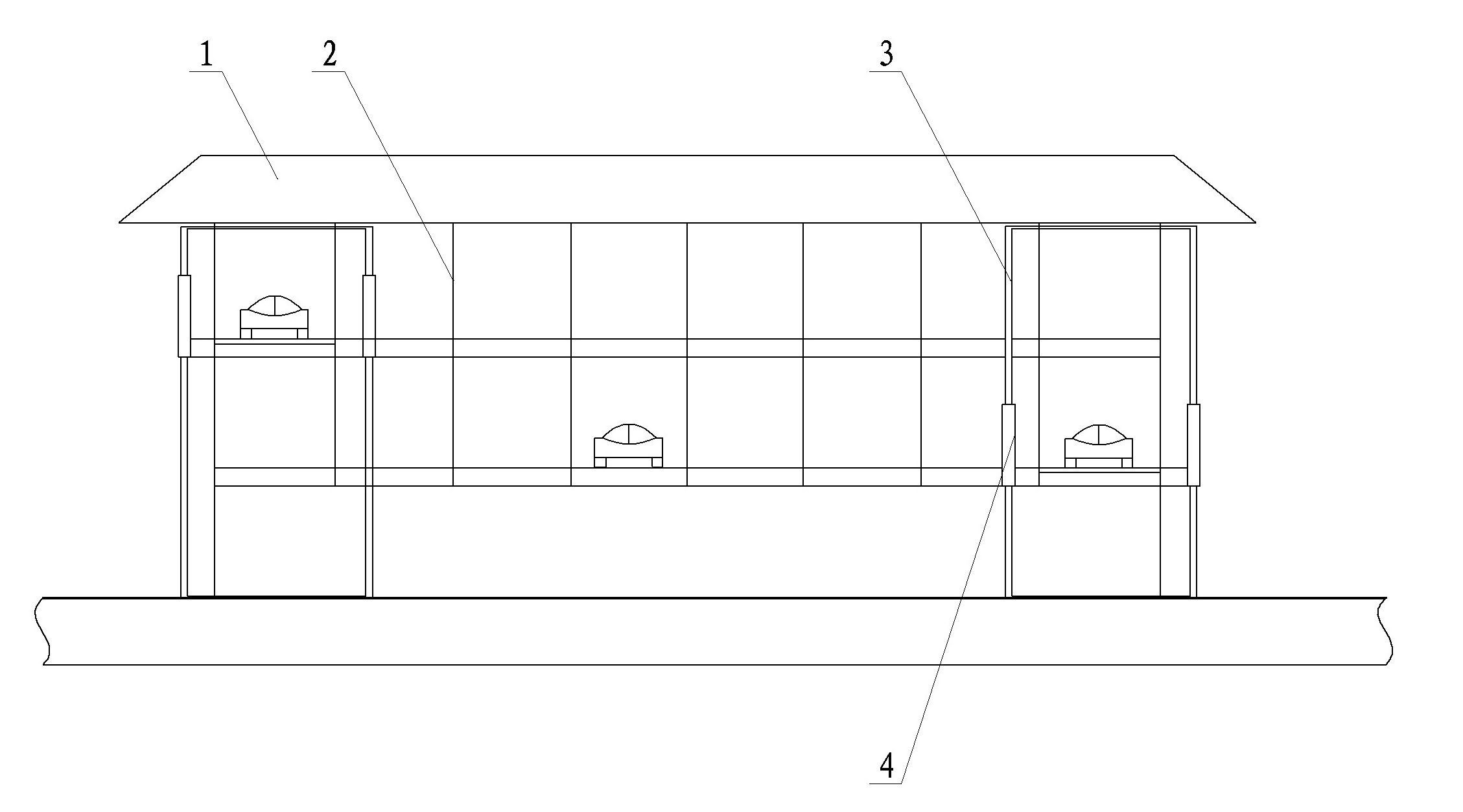

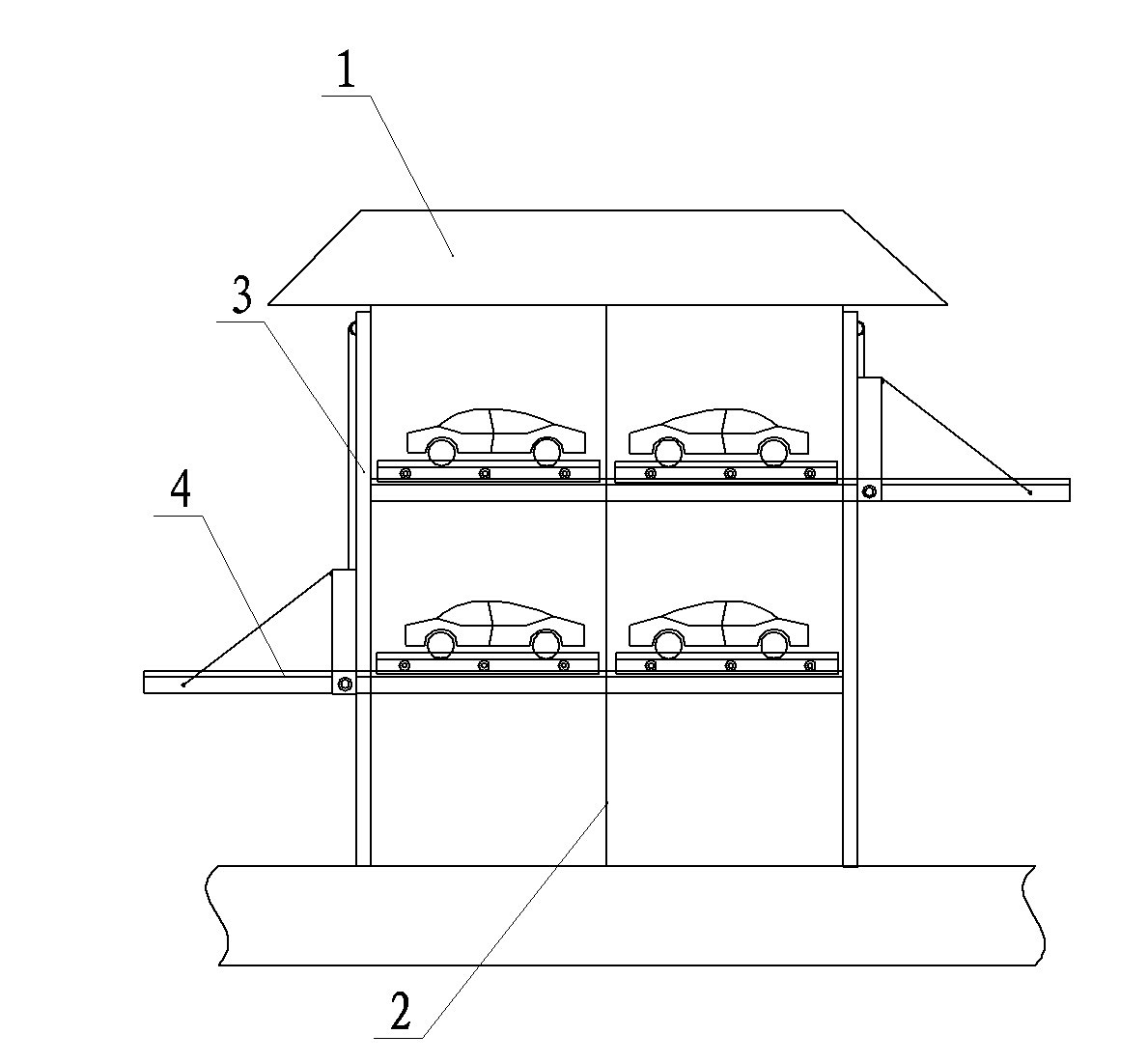

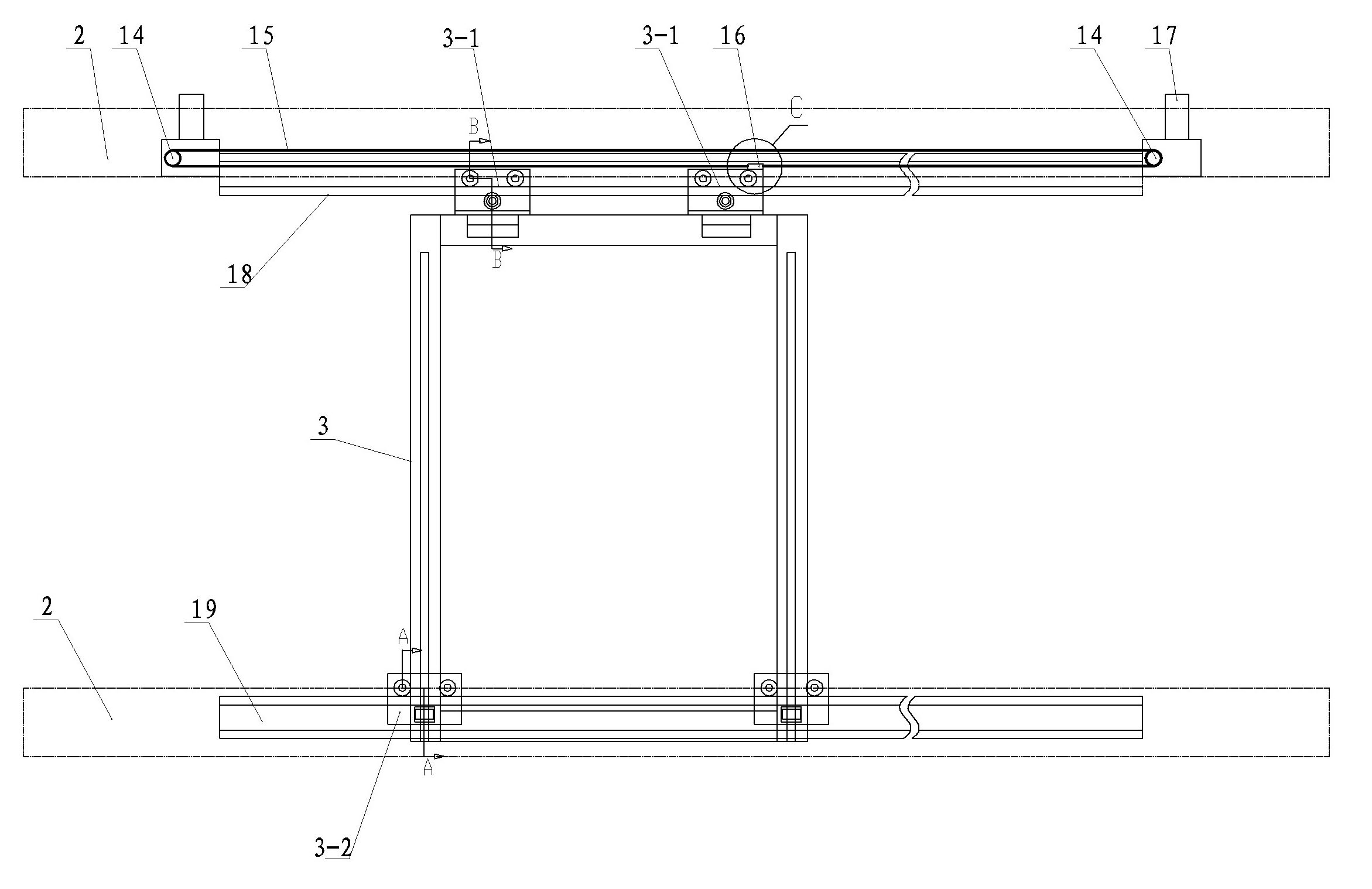

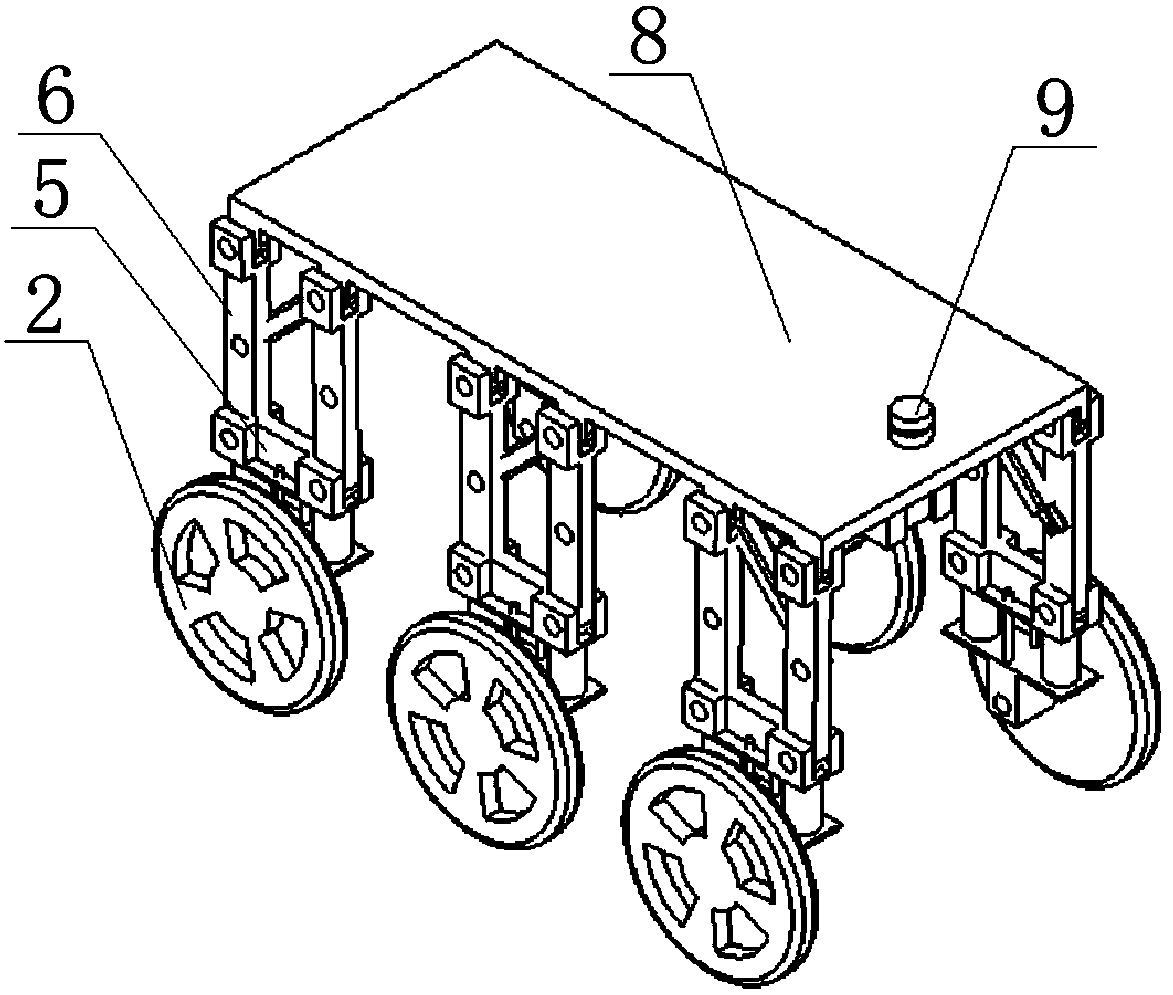

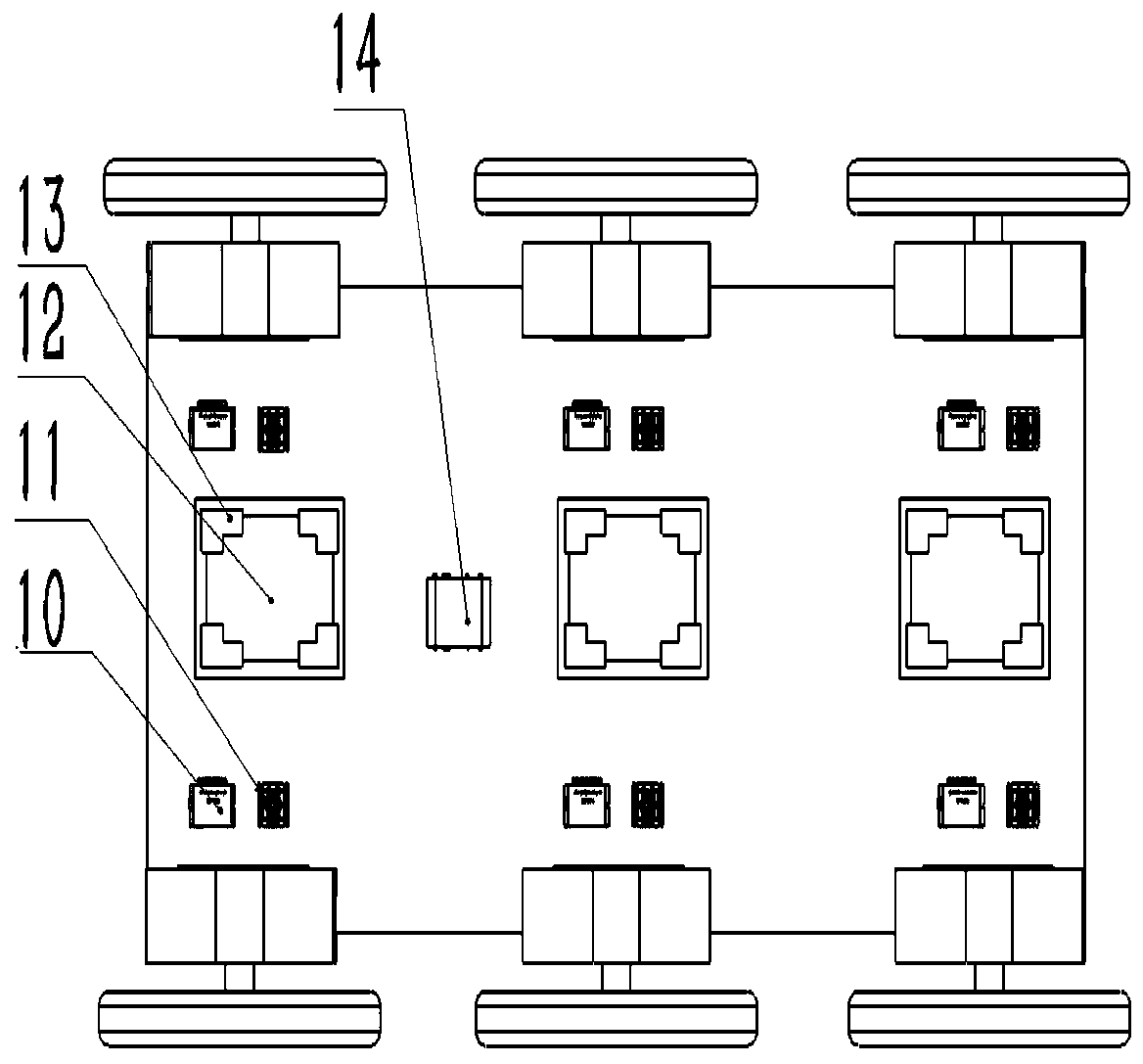

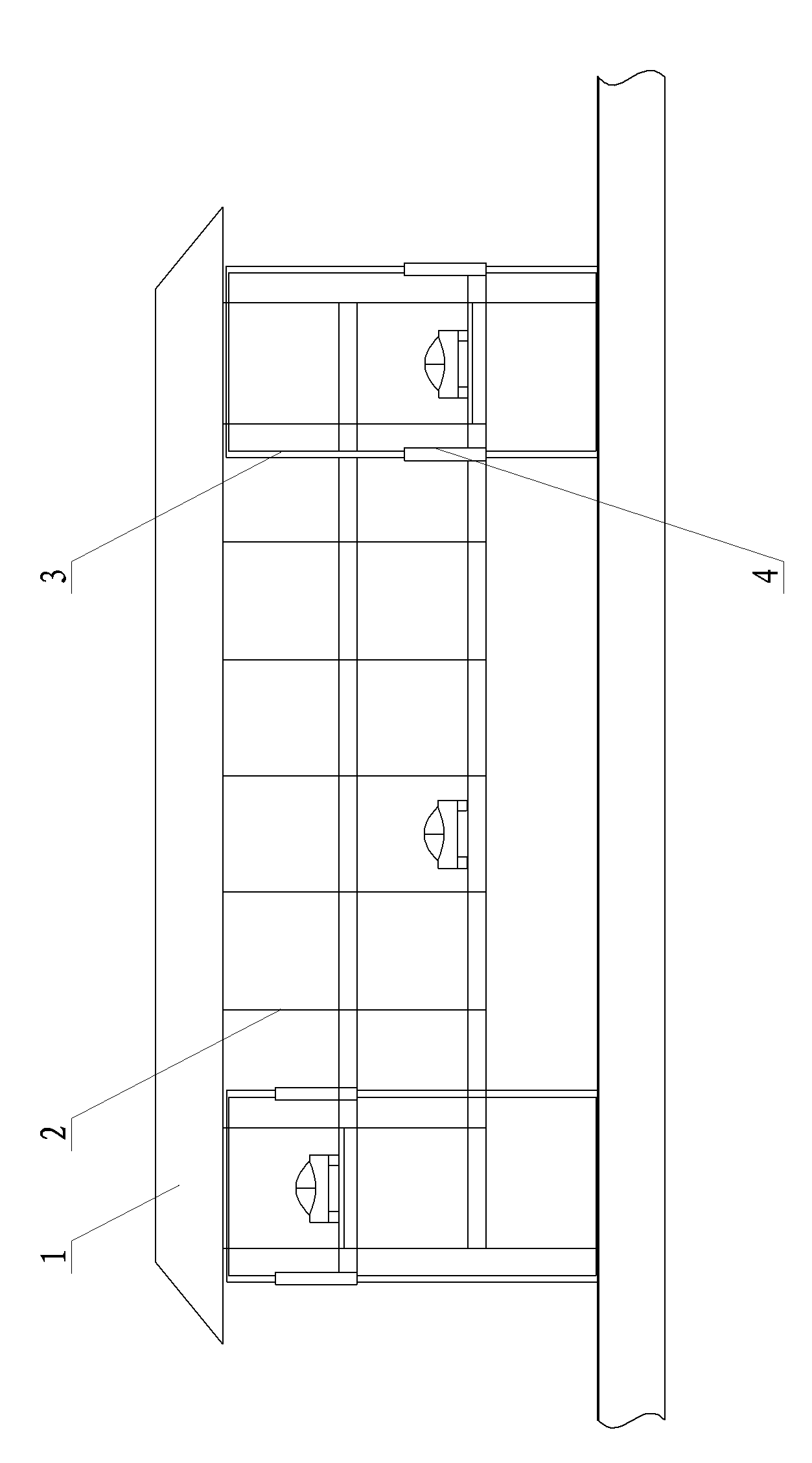

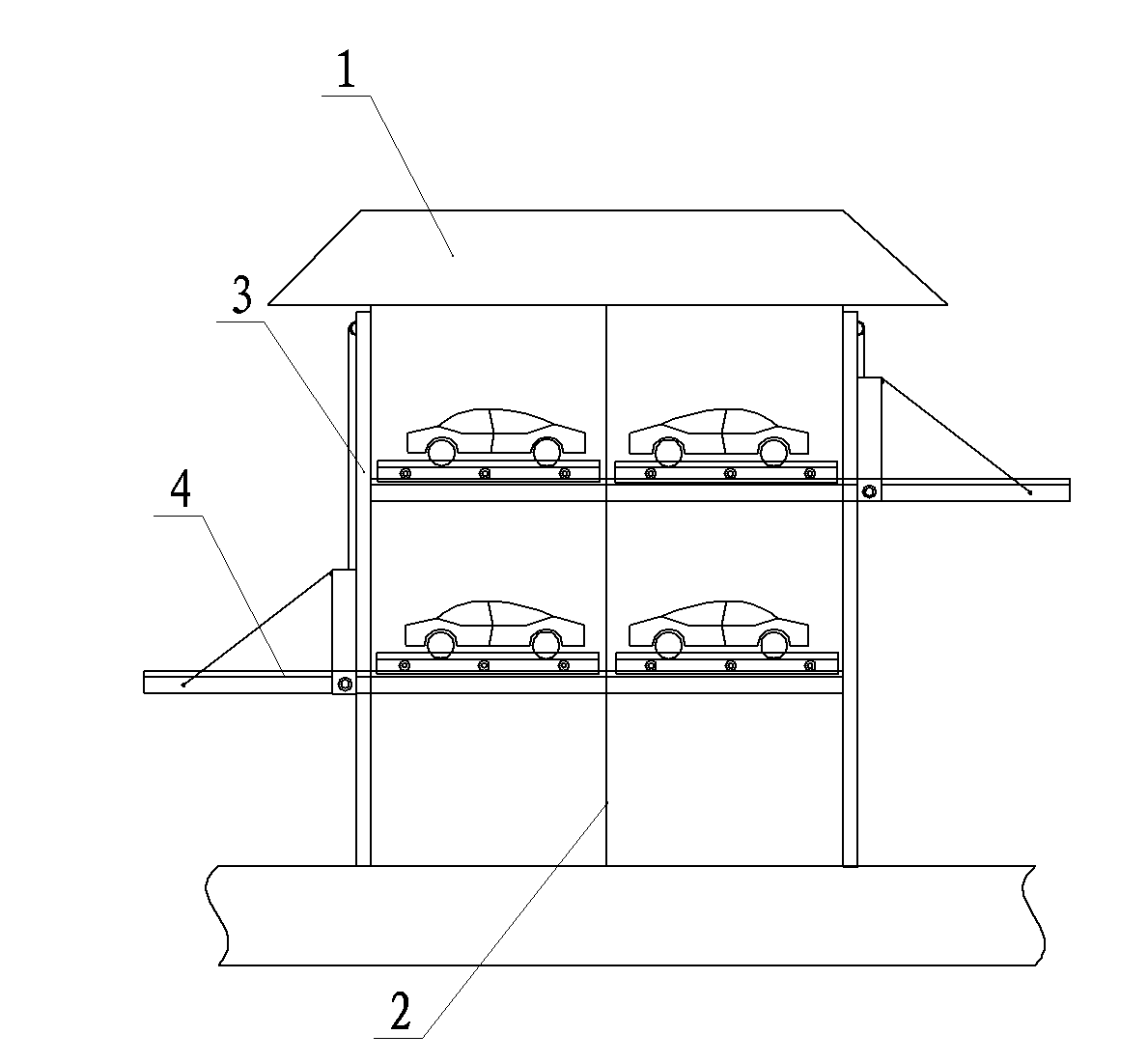

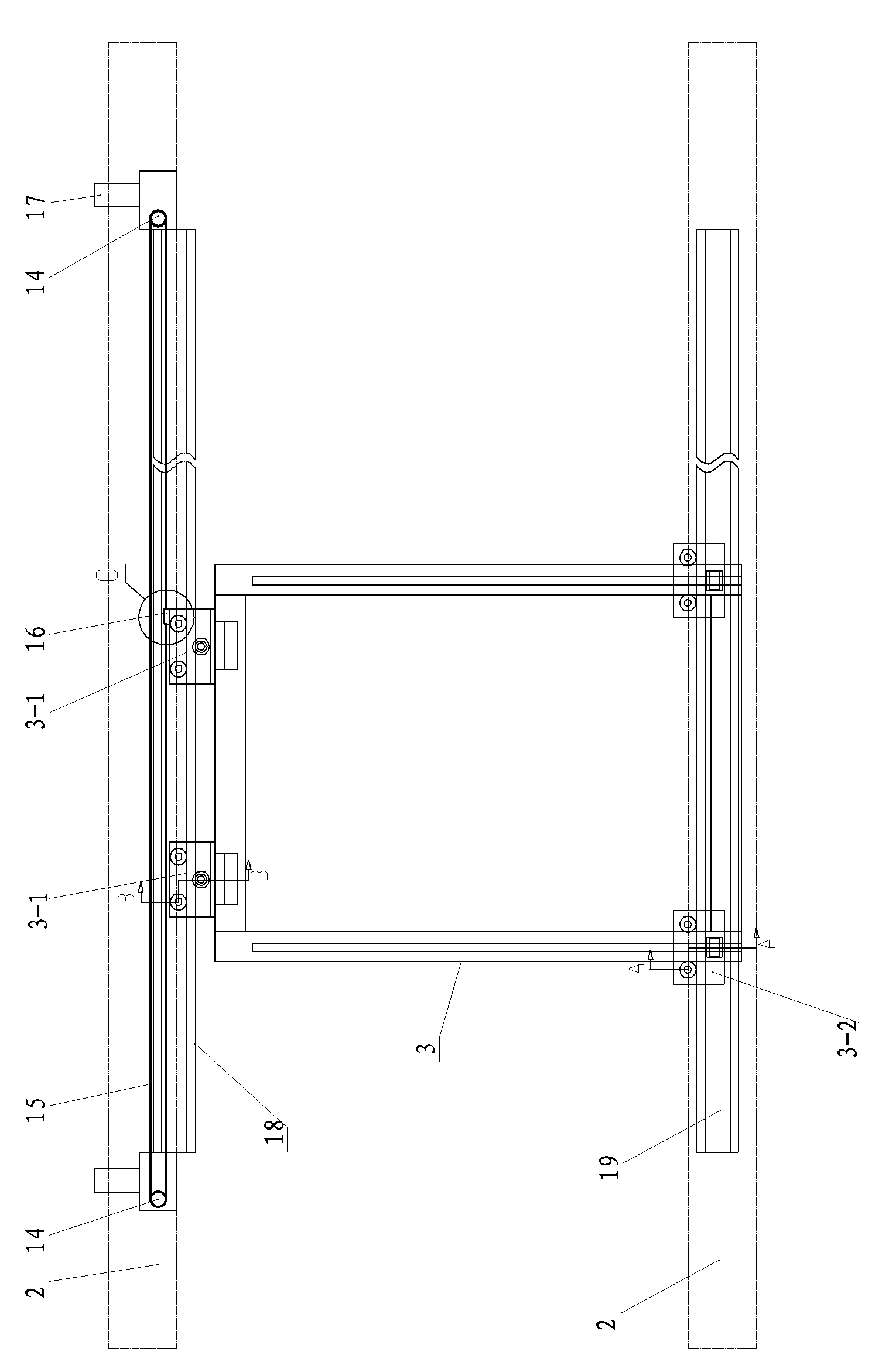

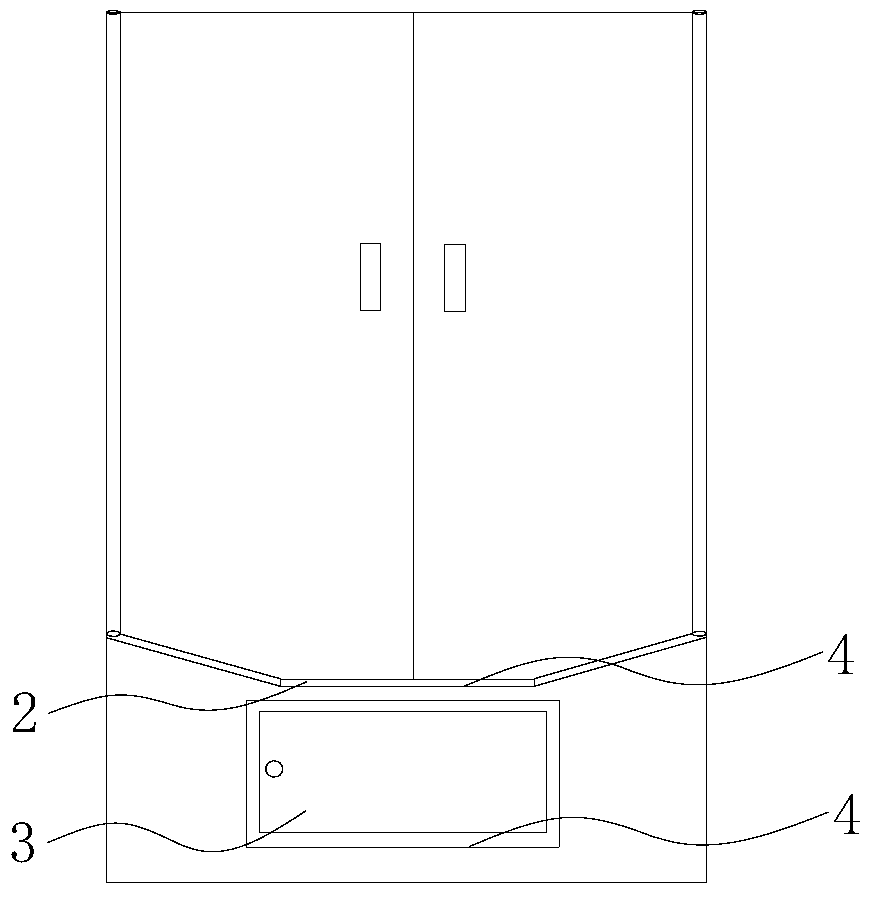

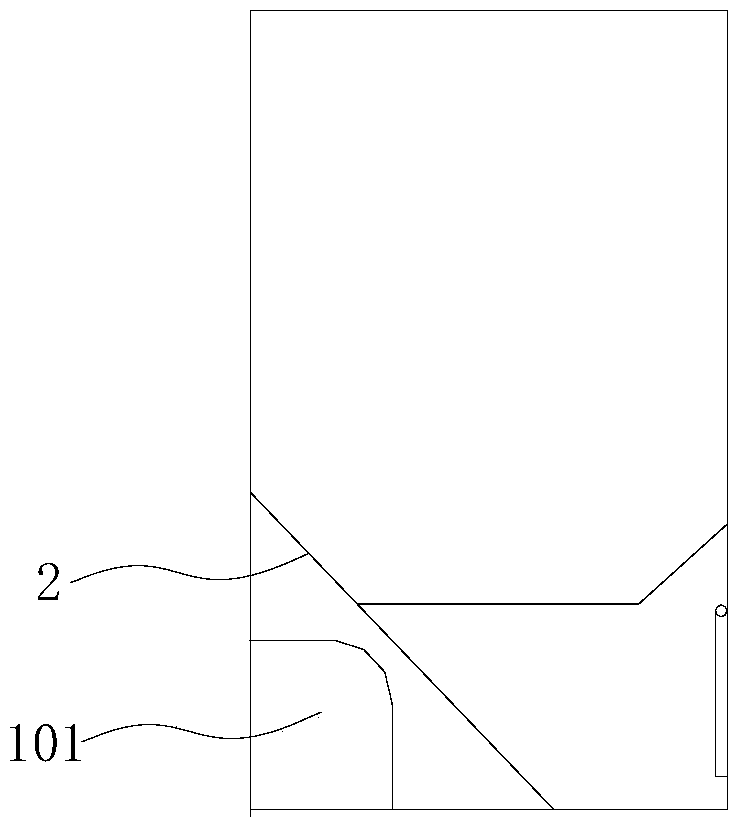

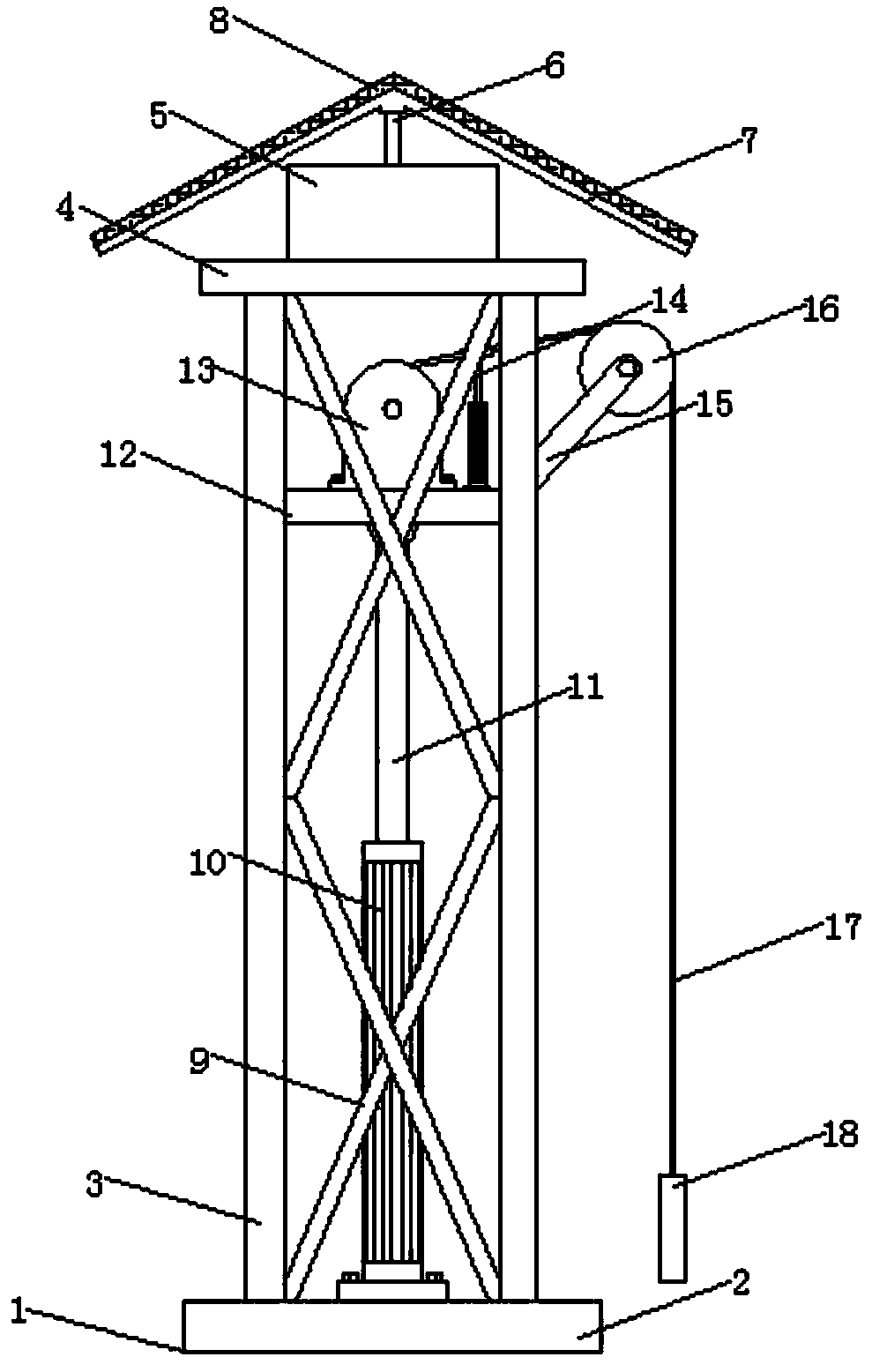

Stereoscopic garage of overhead bridge across street or along street

InactiveCN102587709ASolve the problem of land occupationSolve parking problemParkingsEngineeringRoad surface

A stereoscopic garage of an overhead bridge across a street or along the street comprises a multilayer box type garage main body frame, a ceiling and transfer movable rack. The ceiling is mounted on the upper portion of the frame, the bottom of the garage main body frame is distanced from a road surface by a certain altitude, the transfer movable racks are transversely slidably connected with the garage main body frame, lifting trays are vertically slidably connected with the transfer movable racks, a lifting driving device is disposed on each transfer movable rack and connected with the corresponding lifting tray, guide tracks A and a rotary disc are disposed on a bottom plate of each lifting tray, a fixing tray is arranged in each box of the main body frame, guide tracks B are arranged on each fixing tray, the garage is further provided with vehicle carrying plates, and rollers which match with the guide tracks A and the guide tracks B are disposed under the vehicle carrying plates. The stereoscopic garage is built above the street, does not affect traffic, not only solves parking problems, but also solves the problem that an existing stereoscopic garage occupies large area, vehicles can be parked and taken automatically by the aid of matching of the lifting trays and the transfer movable racks, drivers do not need to give way to other vehicles when parking or taking the vehicles, and efficiency is high.

Owner:HENAN AUSPIC TECH

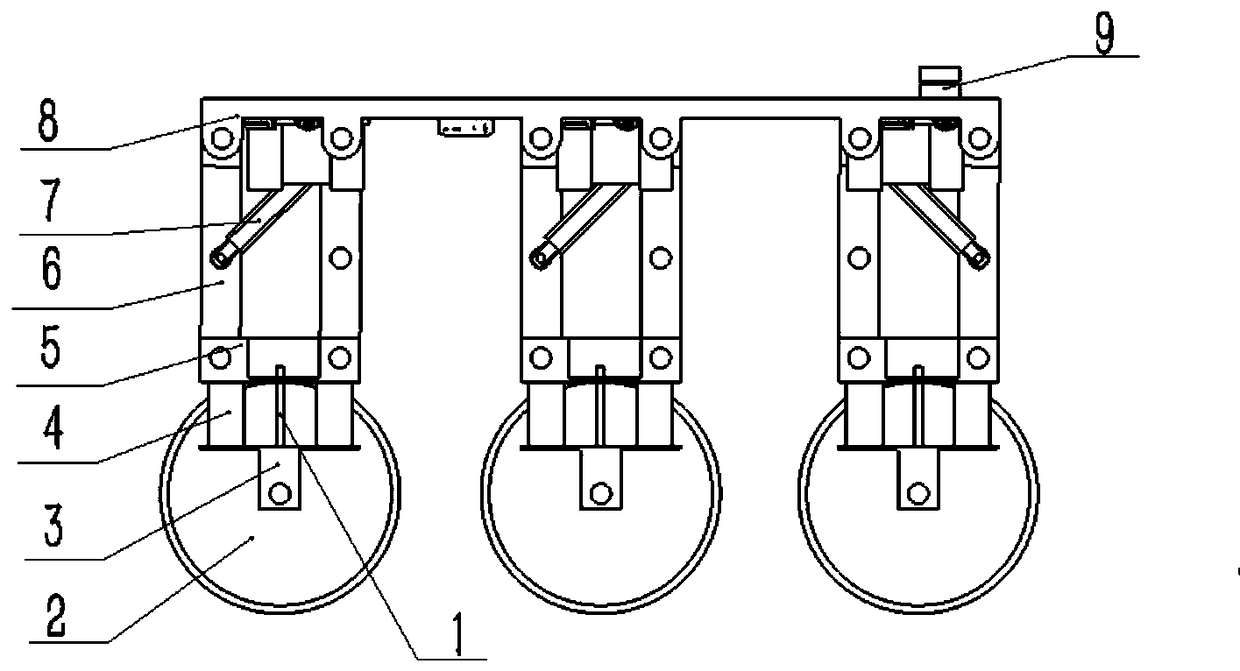

Suspended wheel type mobile platform capable of crossing obstacle

PendingCN109305245AActively adjust the height from the groundActively adjust the tilt angleResilient suspensionsVehiclesRadarRoad surface

The invention discloses a suspended wheel type mobile platform capable of crossing an obstacle. The suspended wheel type mobile platform capable of crossing the obstacle comprises a laser radar and anindustrial personal computer, wherein the laser radar is mounted on the upper end surface of a vehicle body main body and used for monitoring and sensing the surrounding environment; the industrial personal computer is mounted in the vehicle body main body and used for controlling a whole vehicle; the suspended wheel type mobile platform capable of crossing the obstacle further comprises wheels mounted at the bottom of the vehicle body main body; the wheels are connected to wheel carriers; and the wheel carriers are connected with short supporting rods through shock absorbing devices. According to the suspended wheel type mobile platform capable of crossing the obstacle, the ground clearance and the inclination angle of the vehicle body can be actively adjusted, the passing ability of a narrow space and an inclined road surface is improved, and different functional demands are satisfied.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

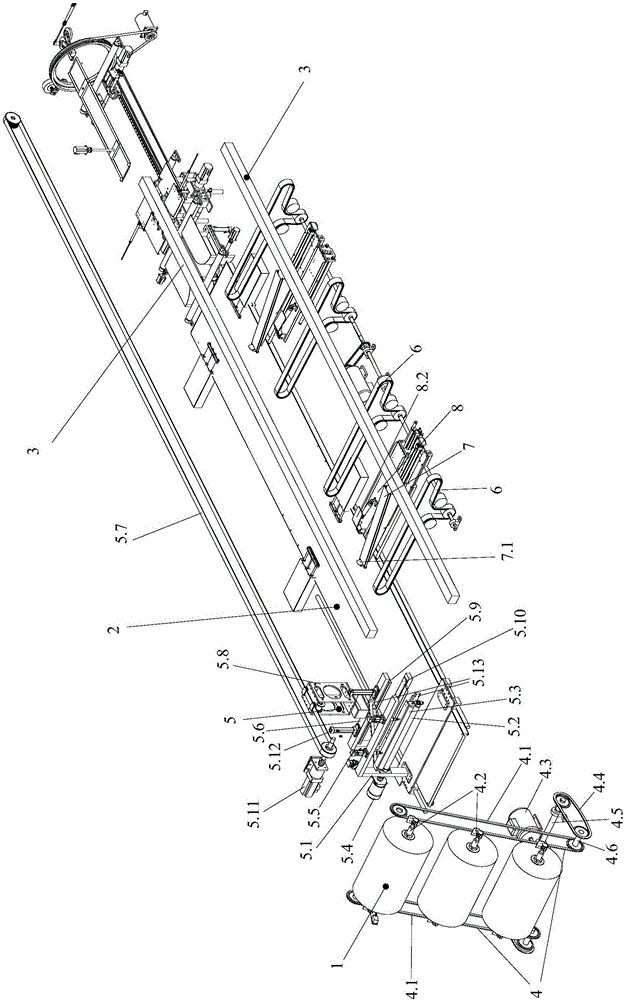

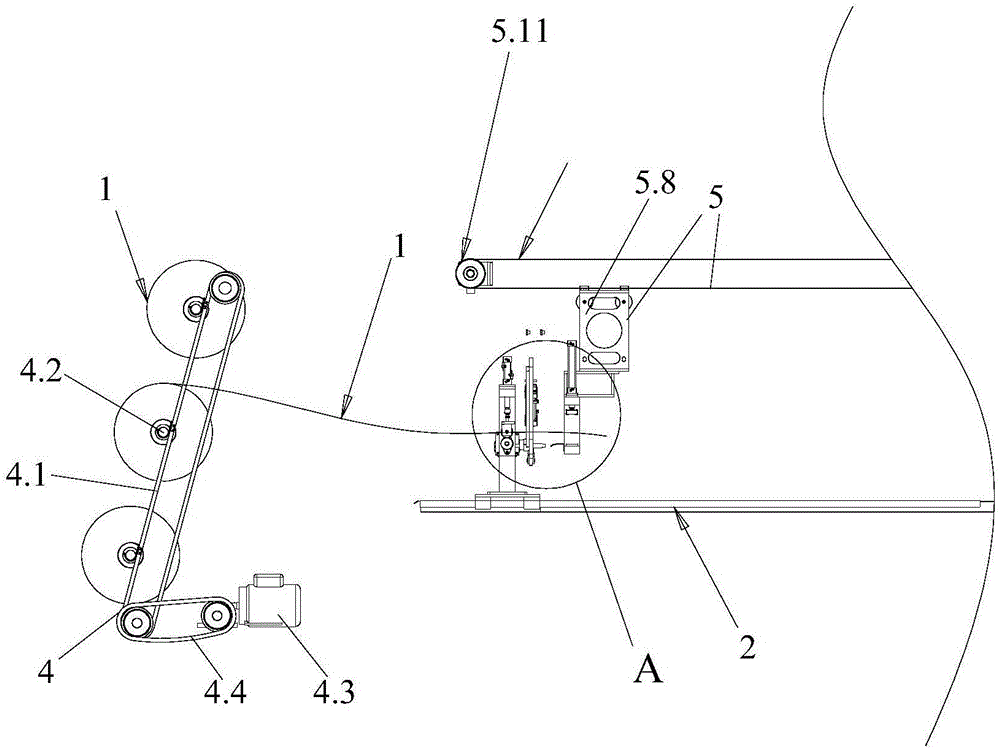

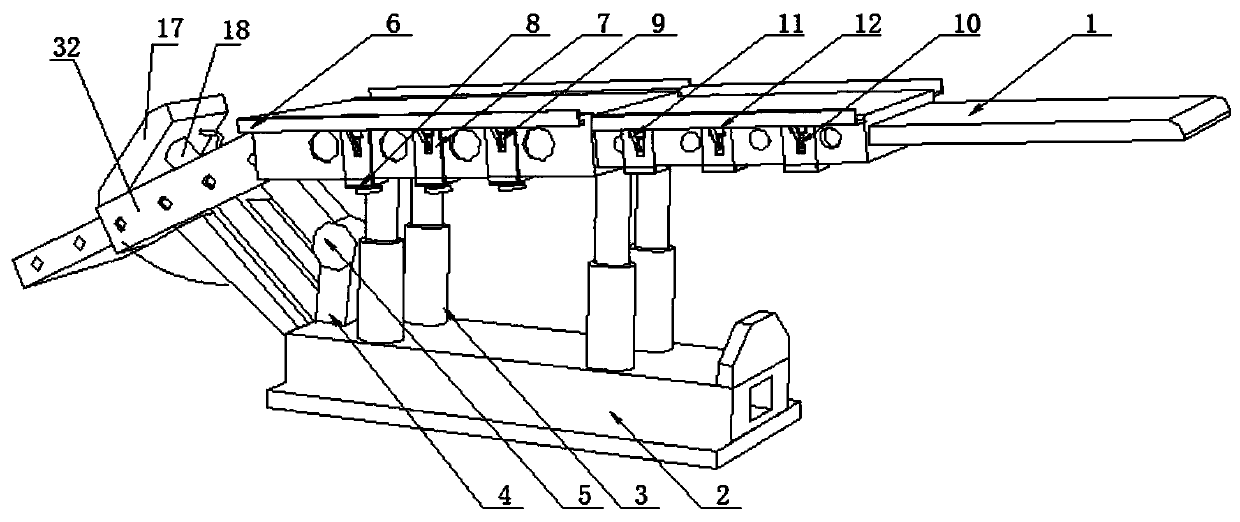

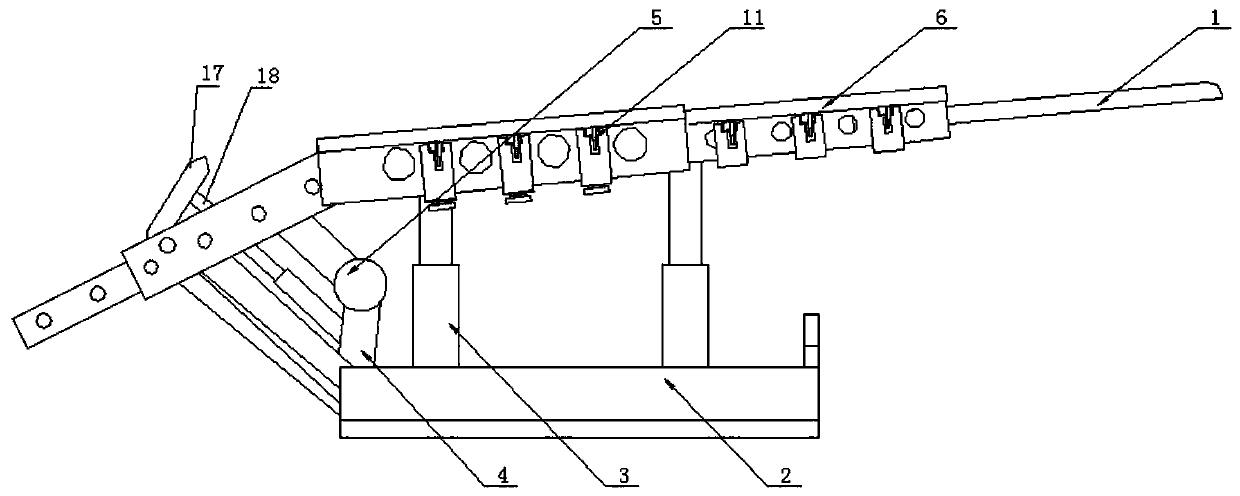

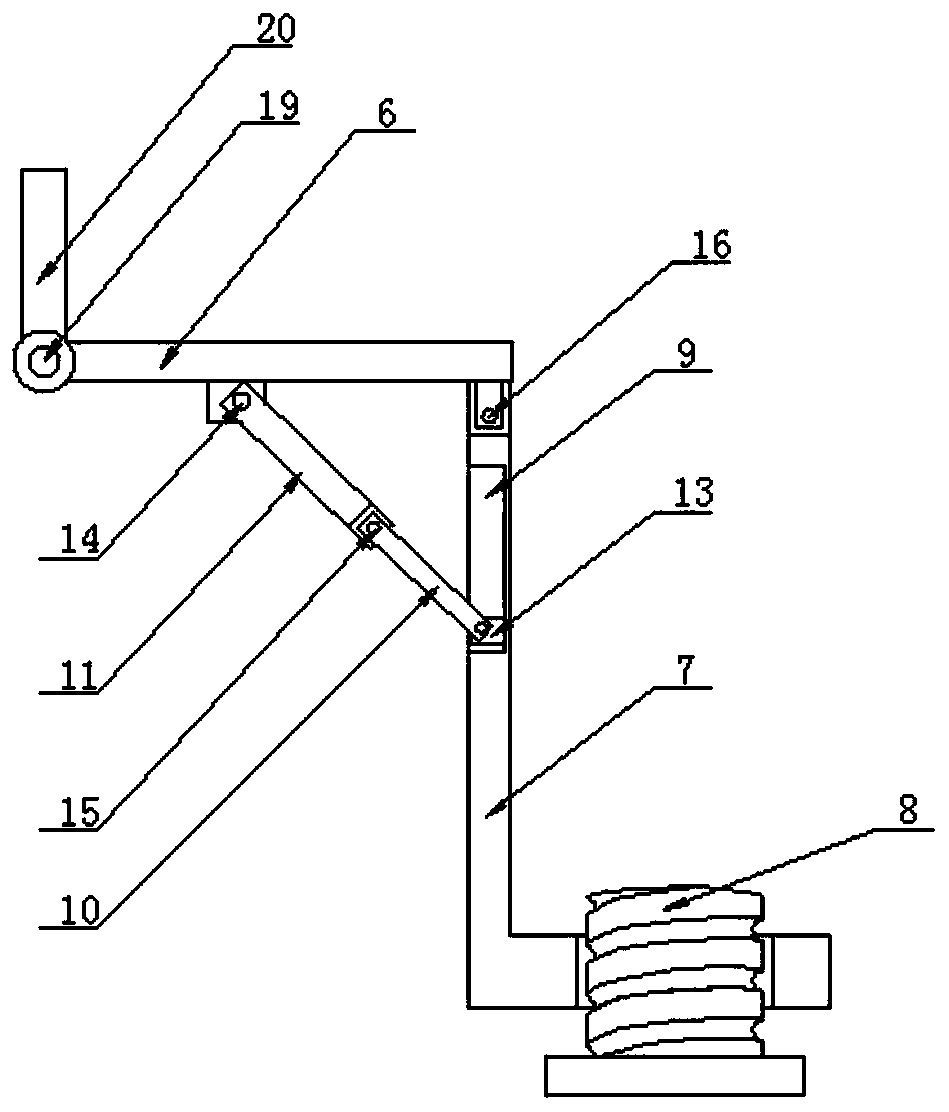

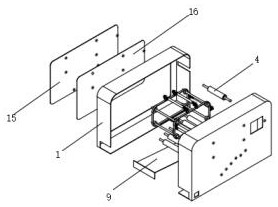

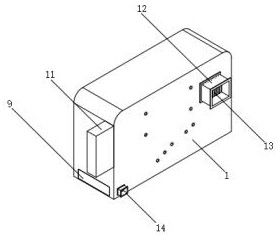

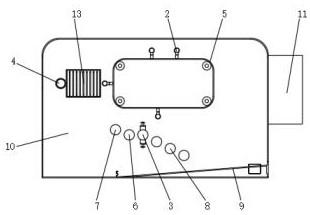

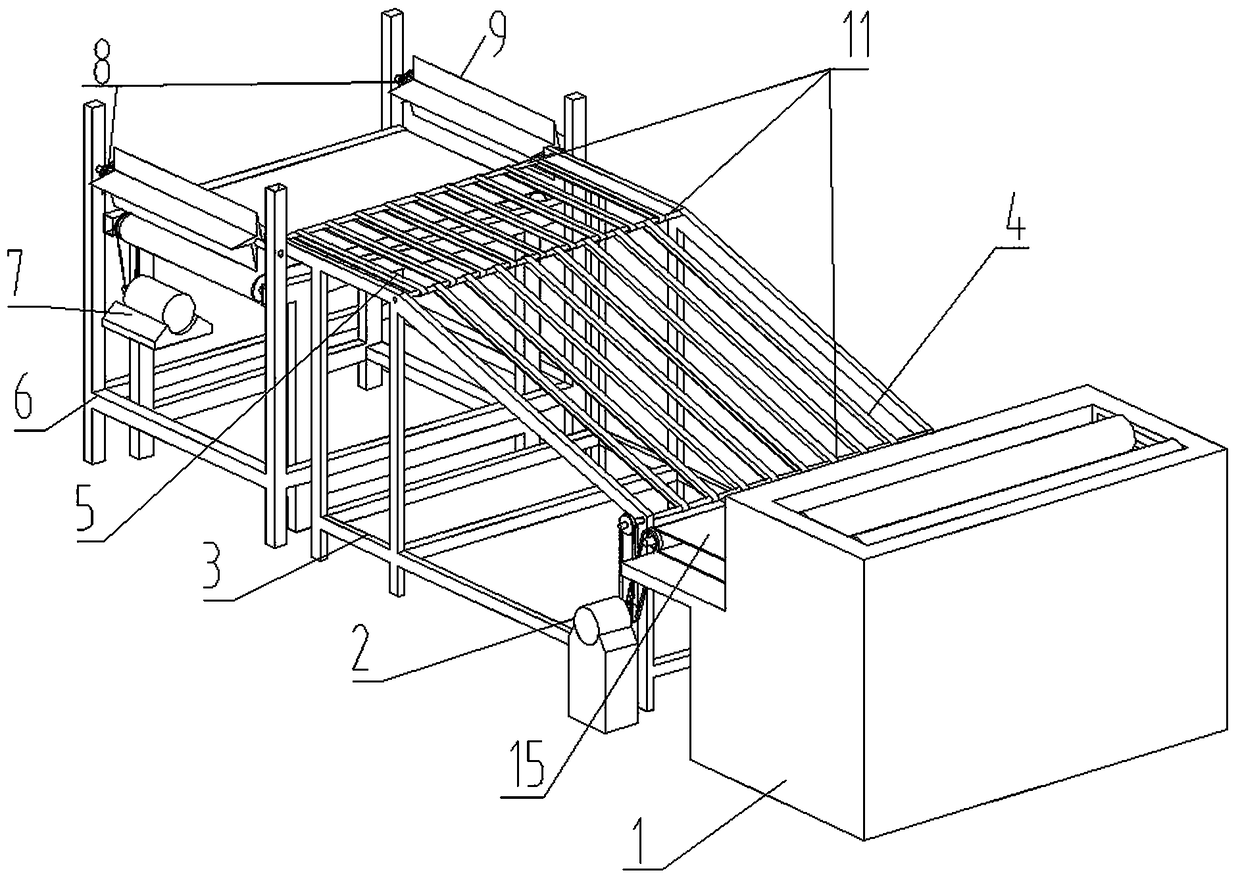

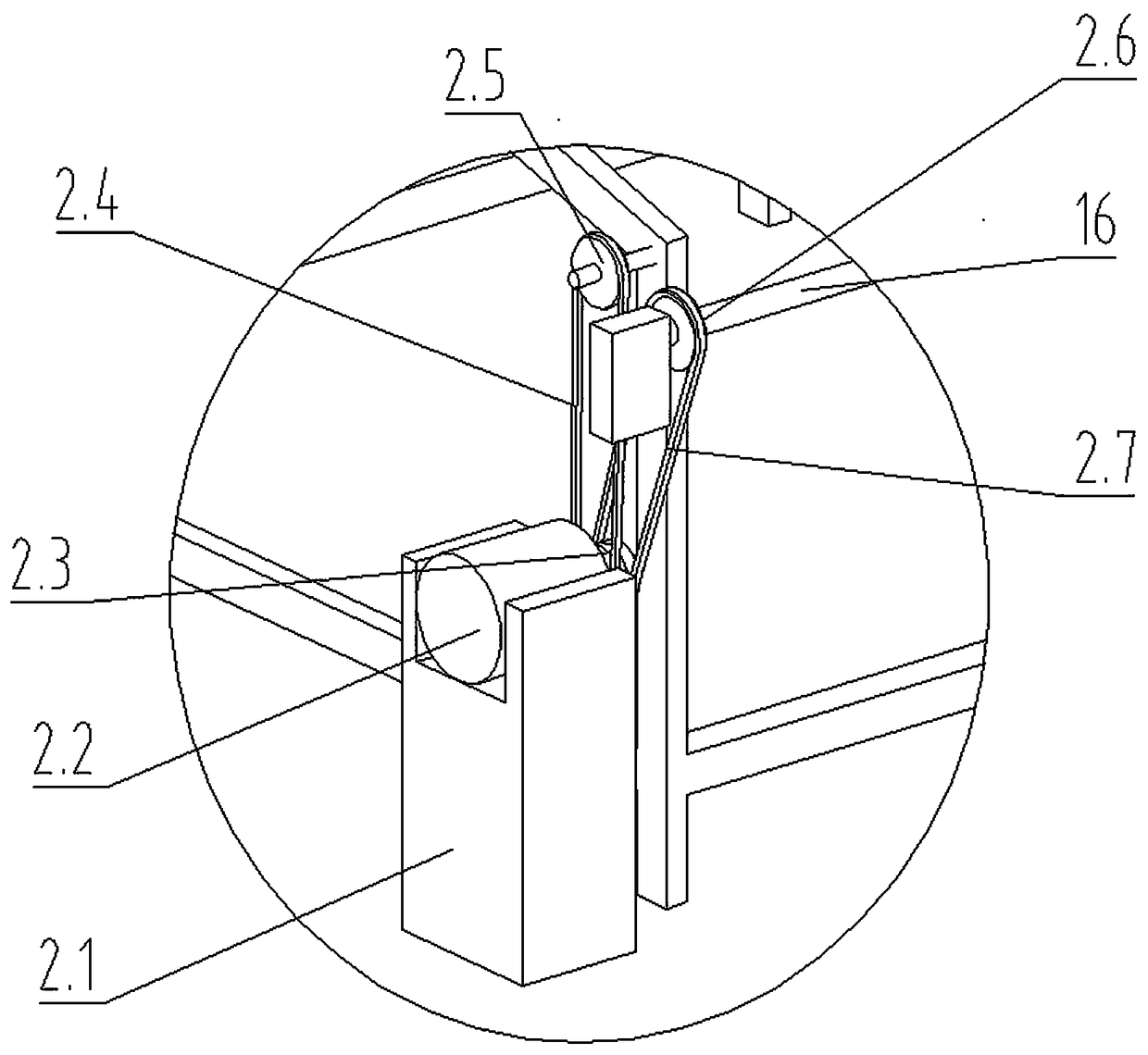

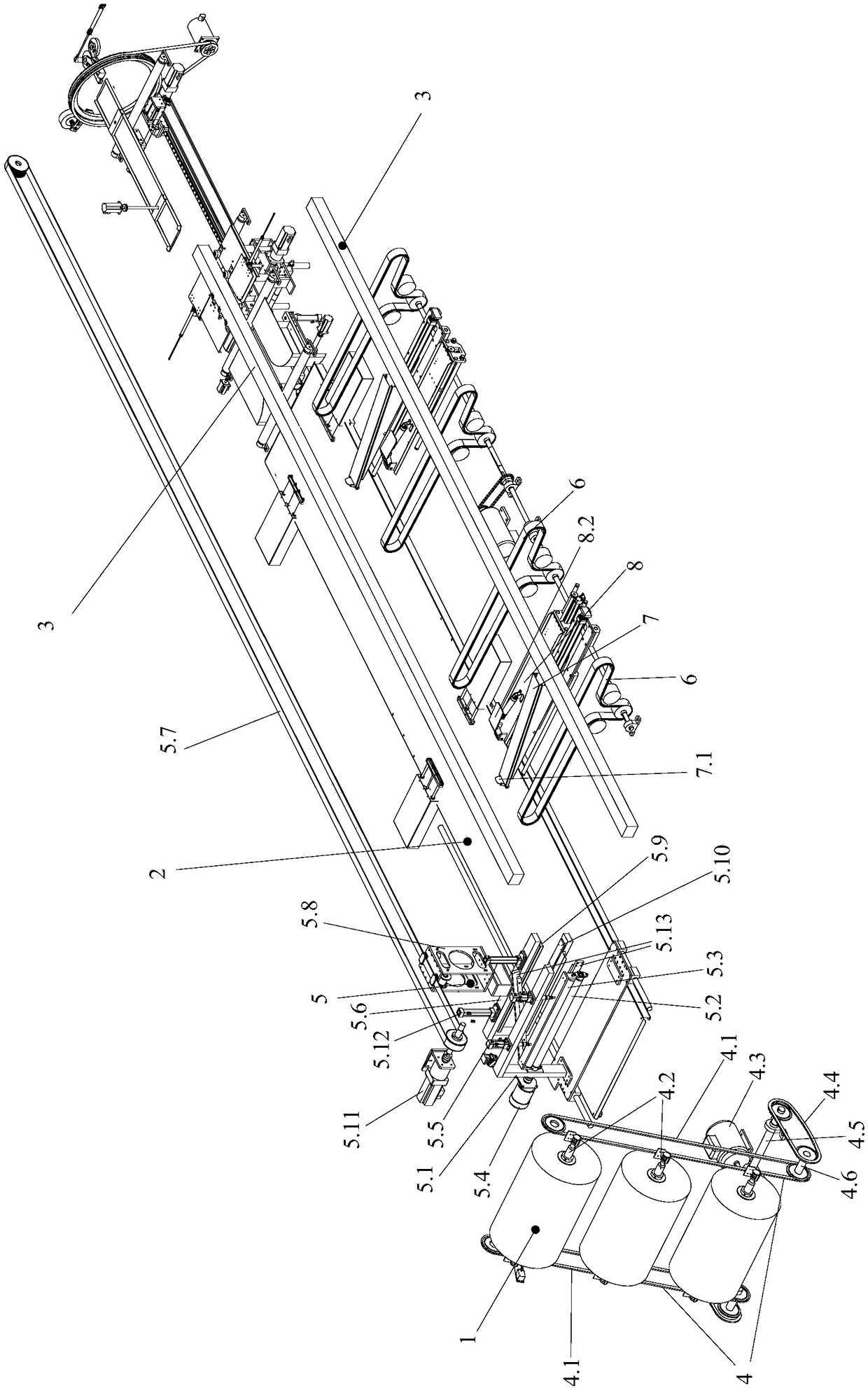

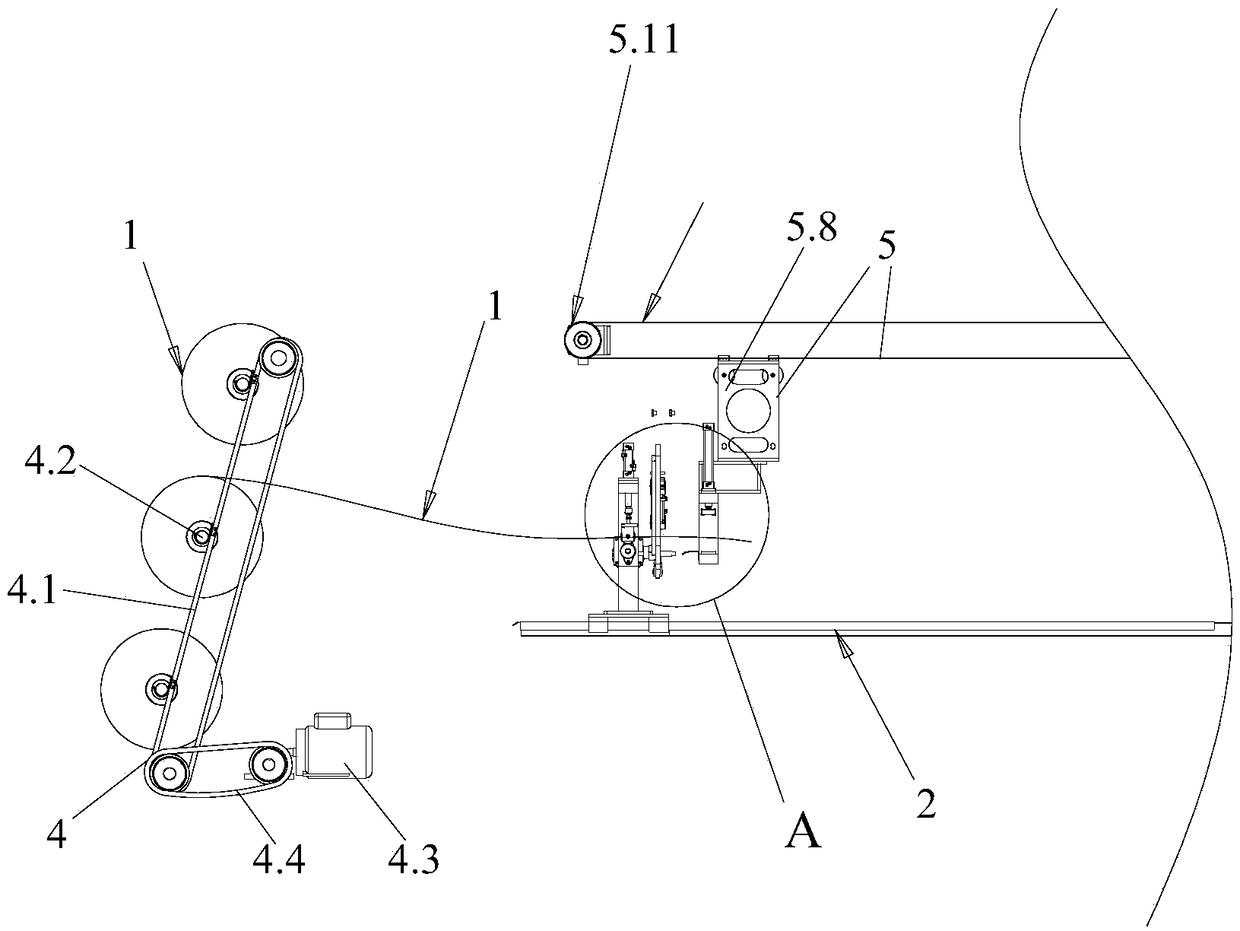

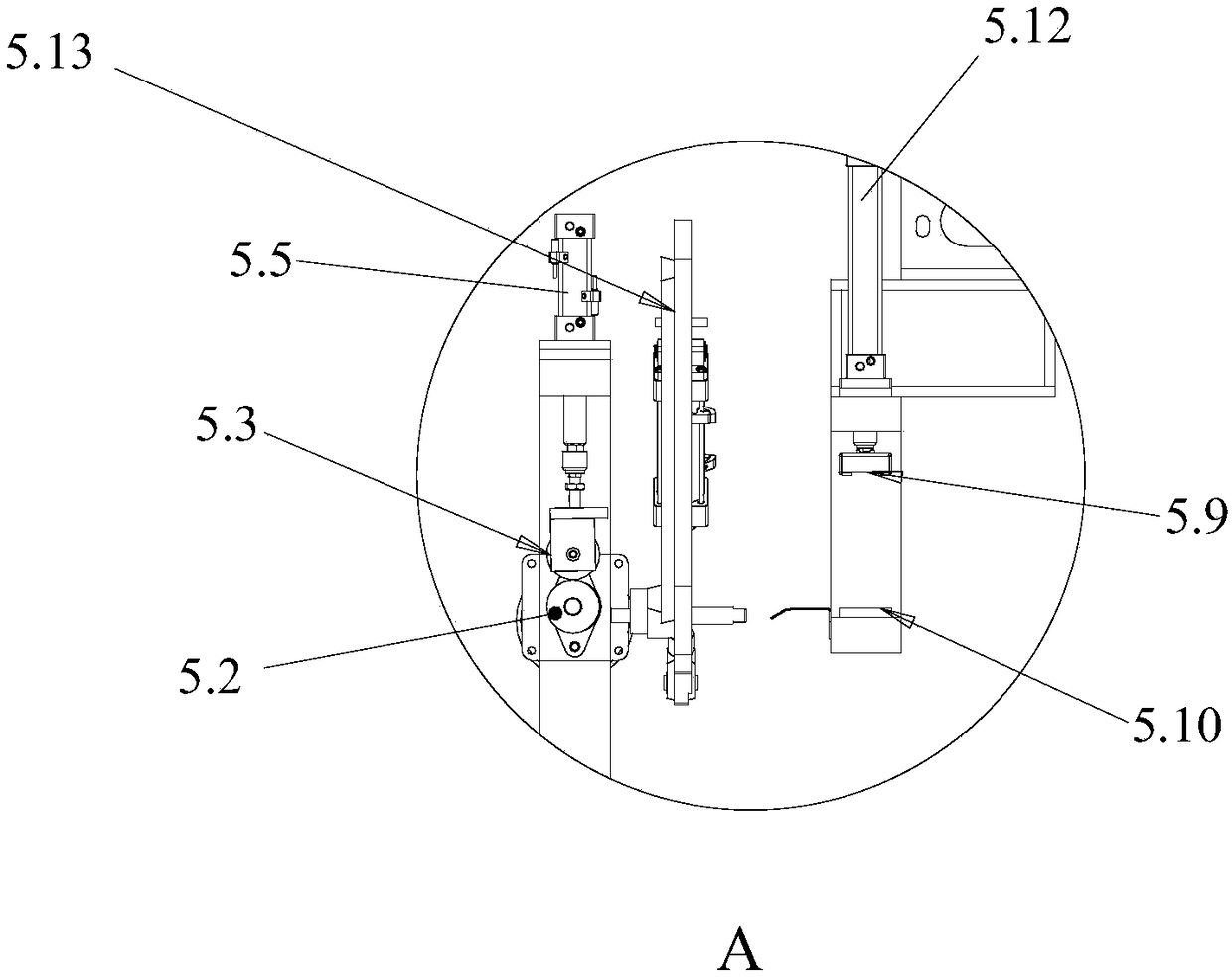

Feeding device used for sectional material packaging

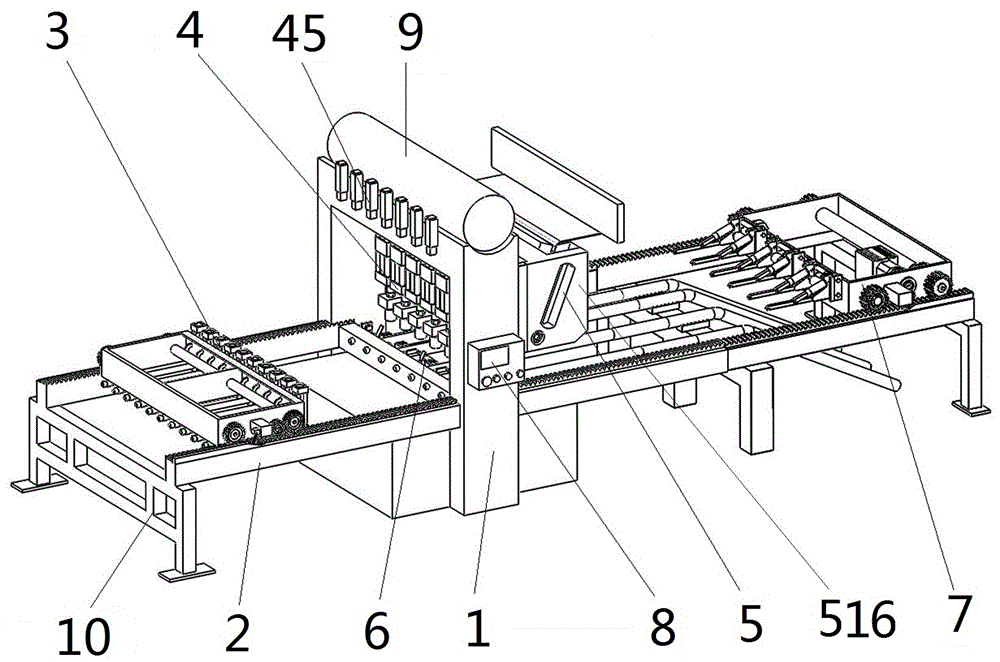

ActiveCN106218967ARealize the whereaboutsAvoid back-shiftingWrapping material feeding apparatusWrappingUltimate tensile strengthMechanical engineering

The invention provides a feeding device used for sectional material packaging. The feeding device comprises a packaging paper feeding mechanism used for lifting, pulling out and shearing packaging paper and flatly laying the packaging paper on a platform, a sectional material feeding mechanism which is used for conveying a sectional material and is positioned at the middle portion of the platform where the packaging paper is laid, and a control mechanism in signal connection with the packaging paper feeding mechanism and the sectional material feeding mechanism. The packaging paper feeding mechanism comprises a paper roll lifting device used for lifting the roll type packaging paper and a paper pulling and cutting device used for pulling out and cutting the packaging paper and laying the packaging paper on the platform. The paper pulling and cutting device is arranged on the platform. The paper roll lifting device and the paper pulling and cutting device are opposite and are arranged at the front end of the platform. The sectional material feeding mechanism is arranged on one side of the platform. The feeding device used for sectional material packaging can be used for automatically feeding the packaging paper and the sectional material respectively, the problems that the efficiency is low and the labor intensity is large due to manual operation can be solved, and therefore the sectional material packaging efficiency and quality are improved.

Owner:佛山市嘉荣智能机械有限公司

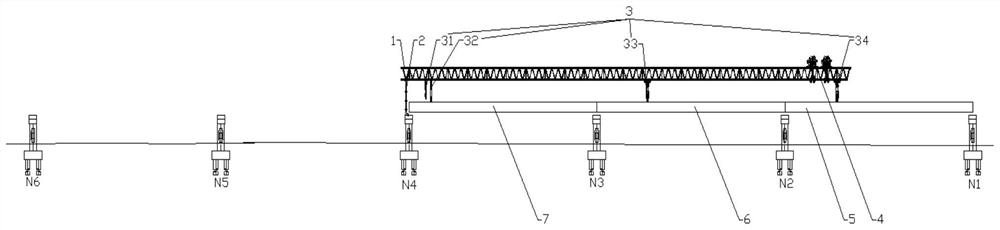

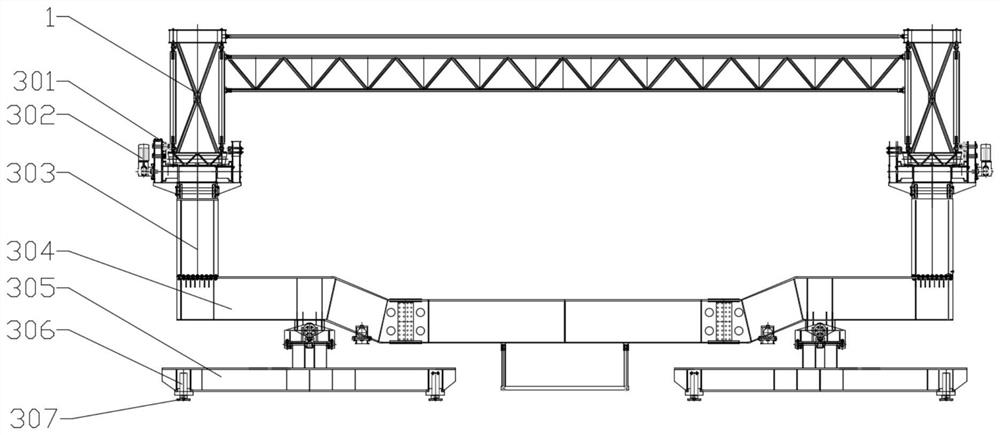

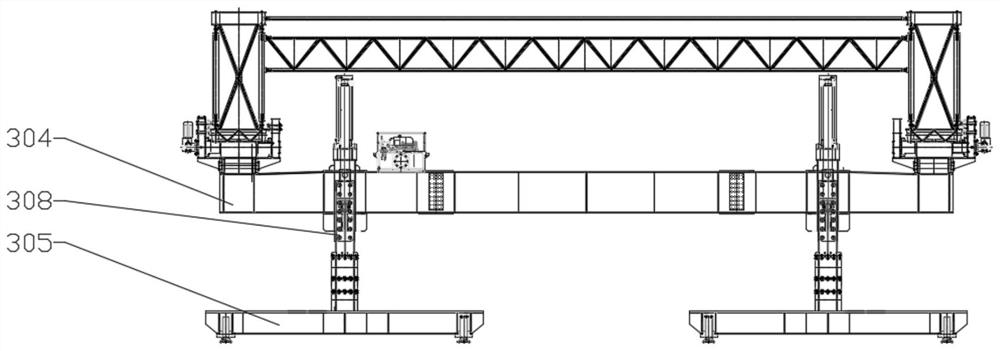

Bridge girder erection machine for overall erection construction of upper structure of large-span bridge and construction method

PendingCN113136810AImprove erection efficiencyGuaranteed stabilityBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a bridge girder erection machine for overall erection construction of the upper structure of a large-span bridge and a construction method thereof. The bridge girder erection machine comprises a main truss arranged in the longitudinal bridge direction, a lifting device connected with the upper end face of the main truss in a sliding mode, a front support fixedly arranged at the front end of the main truss in the longitudinal bridge direction and a supporting leg system connected with the main truss in a sliding mode. The supporting leg system comprises a plurality of supporting legs, any supporting leg is of a telescopic structure and is provided with a driving device, and the driving device drives the supporting leg to slide on the main truss in the bridge erecting direction; and the multiple supporting legs are alternately fixed to support the main truss, and driving devices fixed to the supporting legs drive the main truss to advance for multiple spans in the bridge erecting direction. Multi-span steel beams can be erected at a time, the bridge erecting effect is improved, and the stability of the bridge girder erection machine is guaranteed.

Owner:CCCC SECOND HARBOR ENG

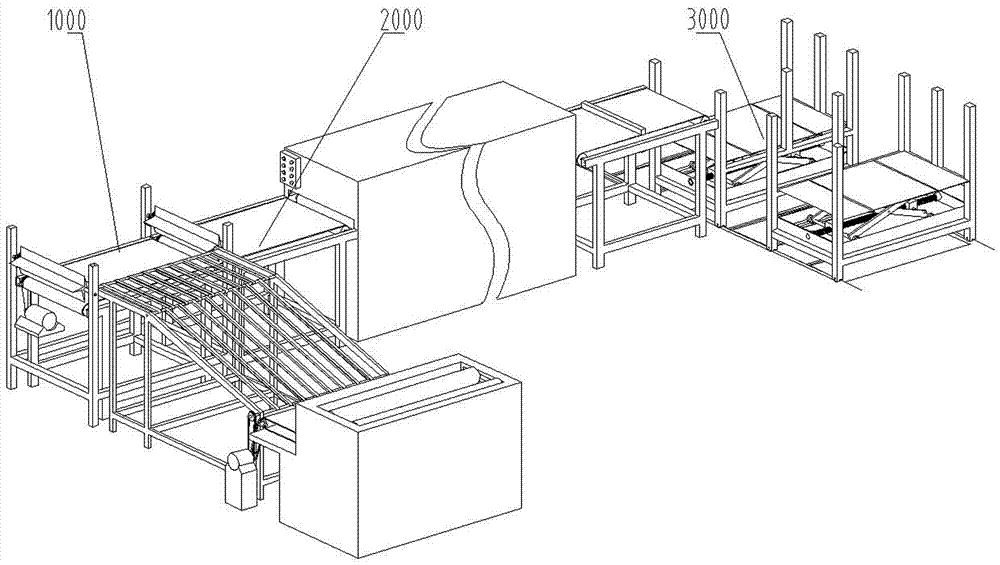

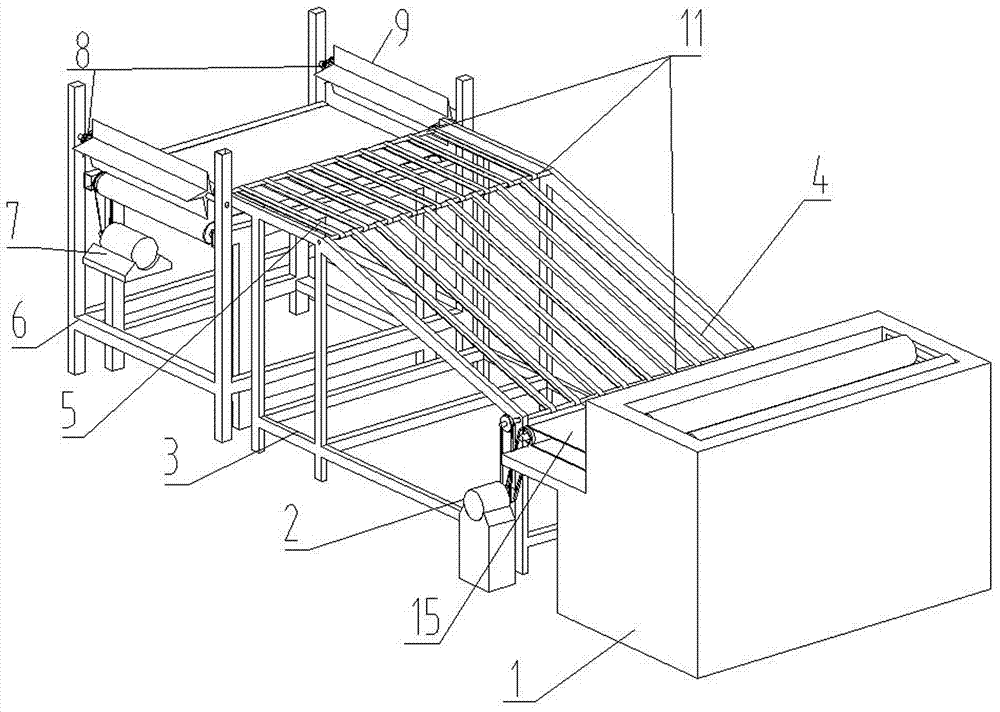

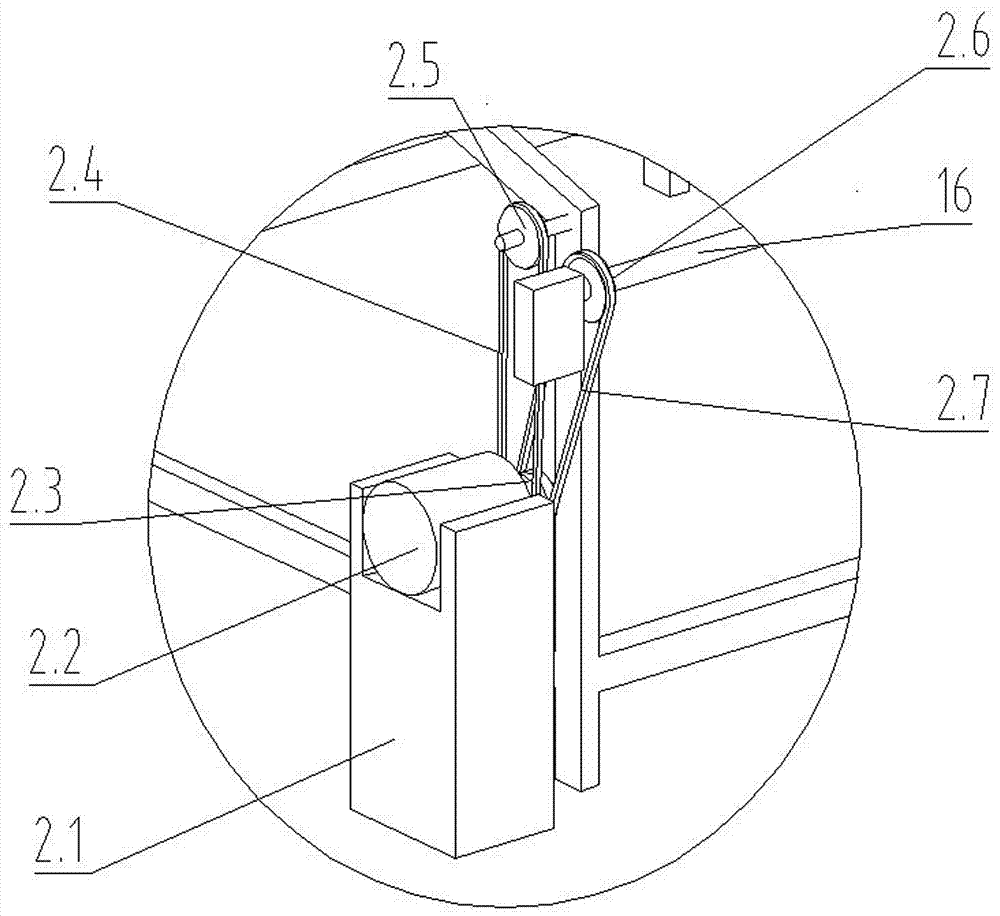

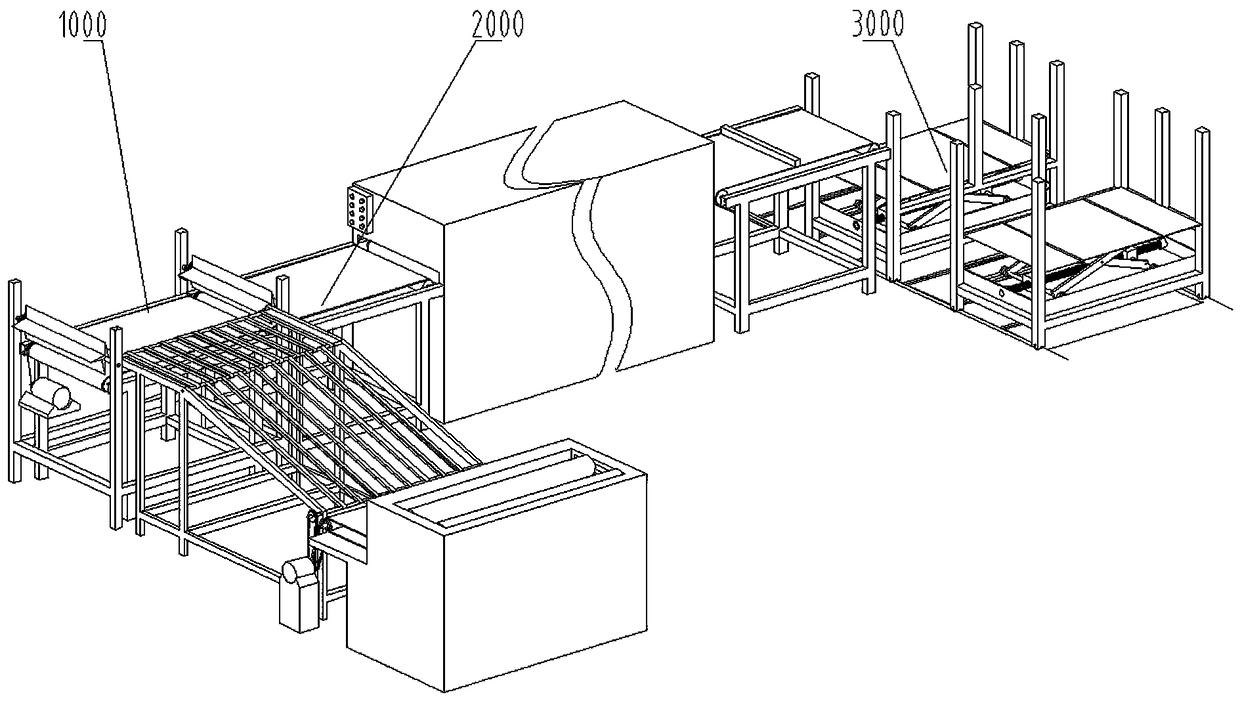

Round wood rotary cutting, drying, planishing and panel stacking automatic production device

ActiveCN107020668AFree laborImprove productivityMulti-purpose machinesProduction lineProduction rate

The invention discloses a round wood rotary cutting, drying, planishing and panel stacking automatic production device. The device comprises a round wood rotary cutting conveying device, a veneer drying and planishing device and a panel stacking device; the round wood rotary cutting conveying device mainly has the effects of conducting rotary cutting on round wood, machining the round wood into panels in appointed size and conveying the panels to a next working process; the veneer drying and planishing device can be used for drying and planishing the panels; and the panel stacking device enables the machined panels to be stacked in order, and finally panel packaging is facilitated. According to the round wood rotary cutting, drying, planishing and panel stacking automatic production device, the working processes such as wood rotary cutting, veneer drying and panel stacking are used in a matched manner, an automatic production line operation manner is formed, labor force is liberated, the production rate is improved, and the development of economy is promoted.

Owner:江苏百事吉服饰有限公司

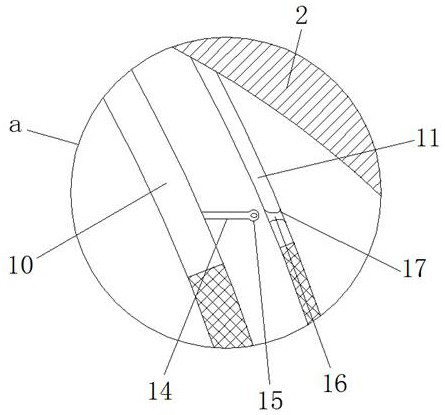

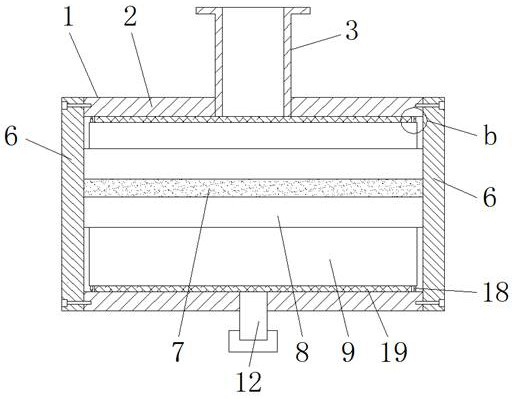

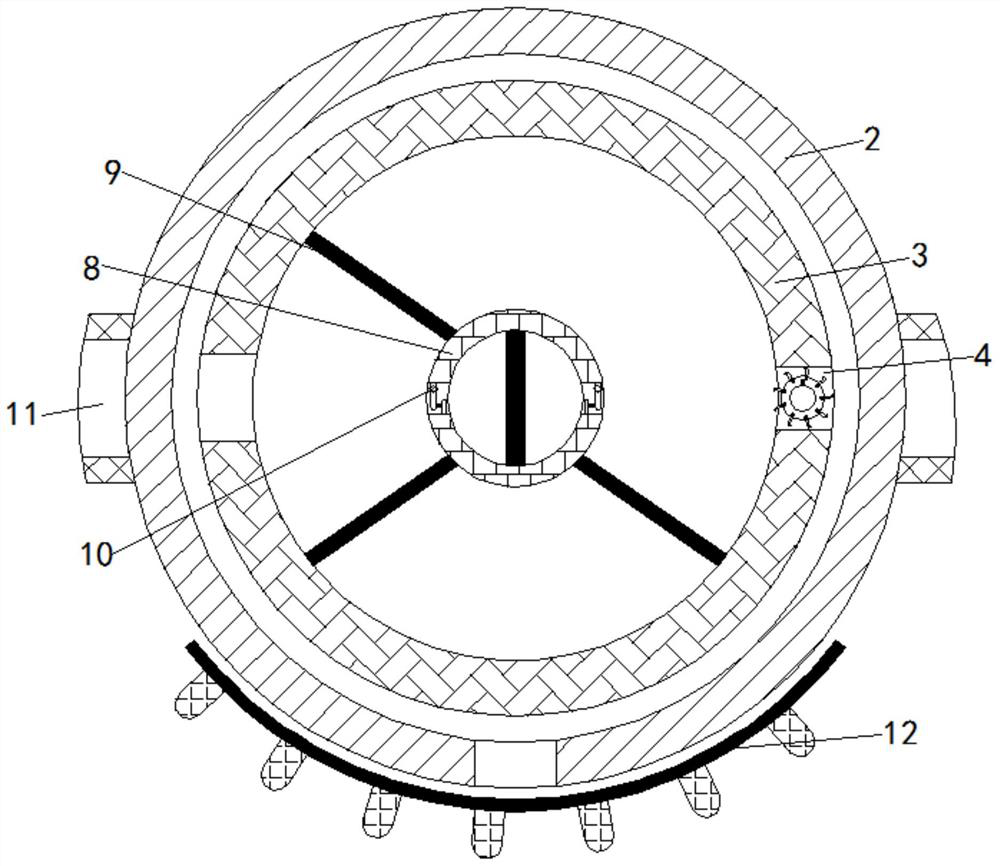

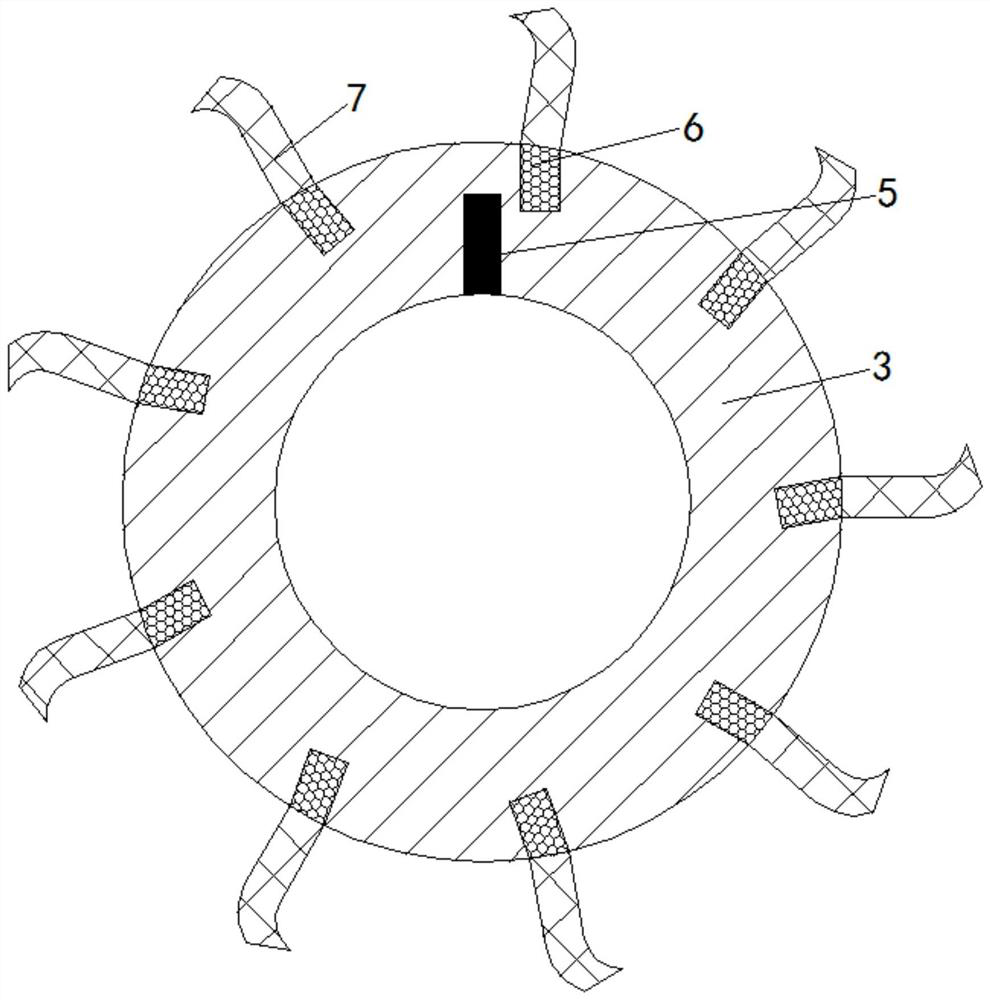

Paddle type filtering and conveying type oil exploitation all-in-one machine

InactiveCN112090141AAvoid cloggingAchieve vibrationFluid removalMoving filtering element filtersMachineBrush

The invention discloses a paddle type filtering and conveying type oil exploitation all-in-one machine which comprises a filtering machine, a filtering barrel, an oil inlet pipe, a flange plate, an oil outlet pipe, a sealing cover plate, a rotating rod, a first paddle, a second paddle, a supporting wheel, a brush and a spring, the filtering machine is provided with the filtering barrel, and the oil inlet pipe is welded to the top of the filtering barrel; and the oil outlet pipe is welded to the side portion of the filtering barrel, the first paddle is welded to the outer side of the rotating rod, the slidable second paddle is arranged on the first paddle, supporting wheels are fixed to the two sides of the outer end of the second paddle, and meanwhile brushes are arranged at the positions,on the inner sides of the two supporting wheels, of the outer end of the second paddle. According to the paddle type filtering and conveying type oil exploitation all-in-one machine, when crude oil is filtered, the filtering net can be cleaned, blocking of the filtering net is avoided, through arrangement of double-layer filtering, vibration of the double-layer filtering net can be achieved whenthe paddles rotate, impurities on the filtering net brushed by the brush fall off, and blocking of the filtering net is effectively avoided.

Owner:韩世强

Automatic rice discharging device for ordering machine

PendingCN109285287ARealize the whereaboutsRealize the function of automatically filling riceApparatus for meter-controlled dispensingEngineering

The invention provides an automatic rice discharging device for an ordering machine, relates to the technical field of automatic vending, and aims at solving the technical problems that in the prior art, all existing automatic ordering machines do not have the automatic rice discharging function and cannot meet the market requirement. The device comprises a rice bucket, a first flashboard and a second flashboard; the rice bucket is provided with a rice inlet and a rice outlet, and a first flashboard gap and a second flashboard gap are formed in the rice outlet; the thickness of the first flashboard is matched with that of the first flashboard gap, and the first flashboard is inserted into the first flashboard gap; the thickness of the second flashboard is matched with that of the second flashboard gap, and the second flashboard is inserted into the second flashboard gap; and the distance between the first flashboard gap and the second flashboard gap is the same as the thickness of needed rice. The automatic rice discharging device is used for providing an automatic rice containing function for the ordering machine.

Owner:北京以诚智控科技有限公司

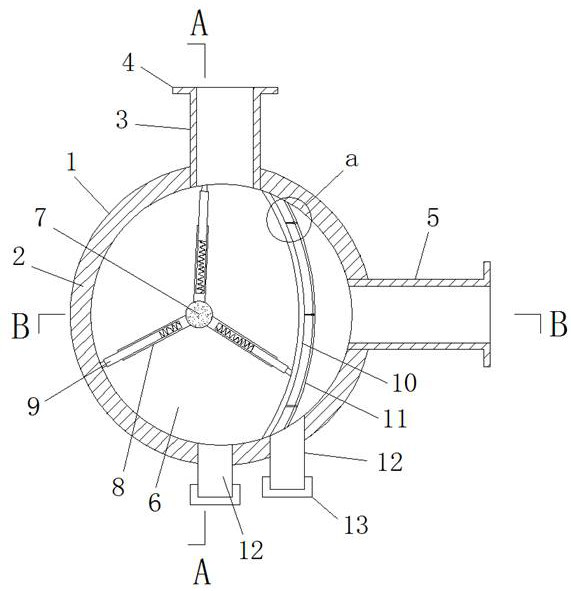

Biomass burner

InactiveCN104197317AImprove airtightnessImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustorSlag

A biomass burner comprises a furnace, a filling port, a slag removal port and an ash cleaning port. The filling port, the slag removal port and the ash cleaning port are arranged in the front side face of the furnace from top to bottom, a filling port opening and closing mechanism, a slag removal port opening and closing mechanism and an ash cleaning port opening and closing mechanism are arranged on the filling port, the slag removal port and the ash cleaning port correspondingly, and grates are arranged in the furnace. A circular secondary air duct with a secondary tuyere is arranged on the side face of the furnace body, the inner circular wall of the secondary air duct forms a secondary air cavity communicated with the inside of the furnace, and burning units communicated with the secondary air duct are arranged in the secondary air cavity. A fire outlet communicated with the secondary air cavity is arranged at the outer end of the secondary air duct. The biomass burner is simple in structure, a large amount of fuel can be stored above the grates inside the furnace at one time, sustained burning time can be prolonged greatly, and fuel types are unlimited; by means of secondary air distribution of the burning units, oxygen needed during fuel burning can be supplemented effectively, and fuel burning heat efficiency and fuel utilization rate are increased greatly.

Owner:关要领

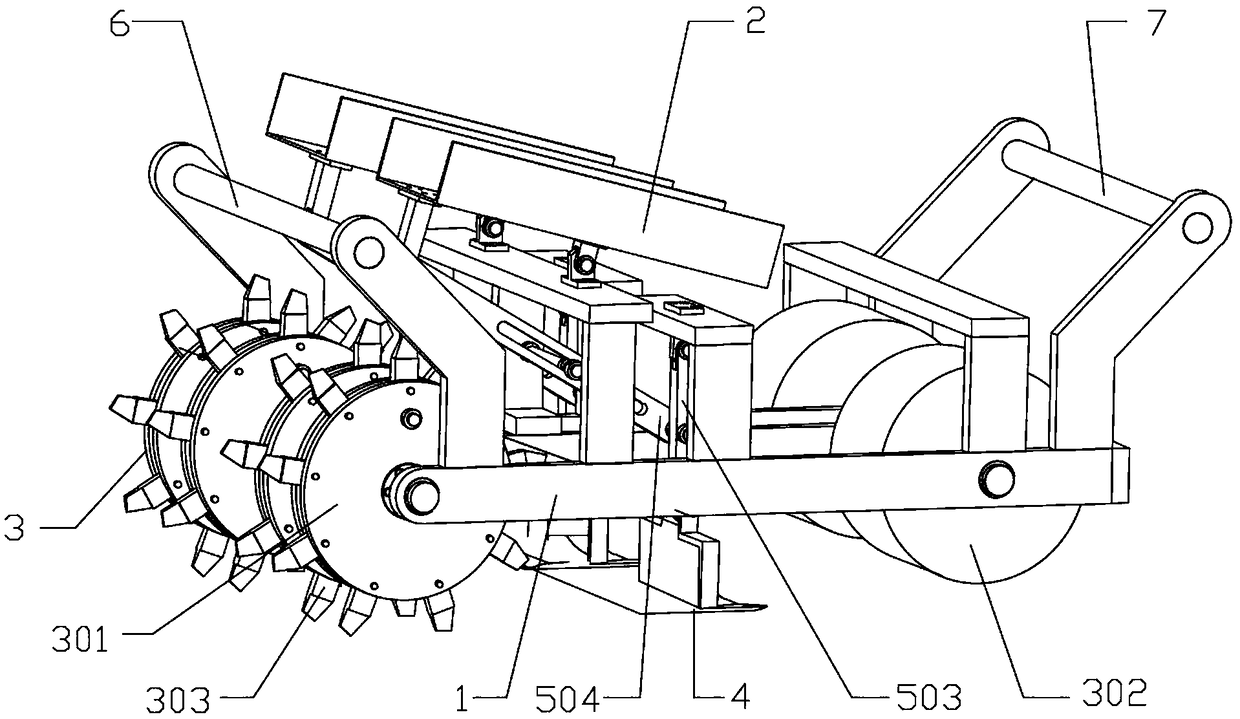

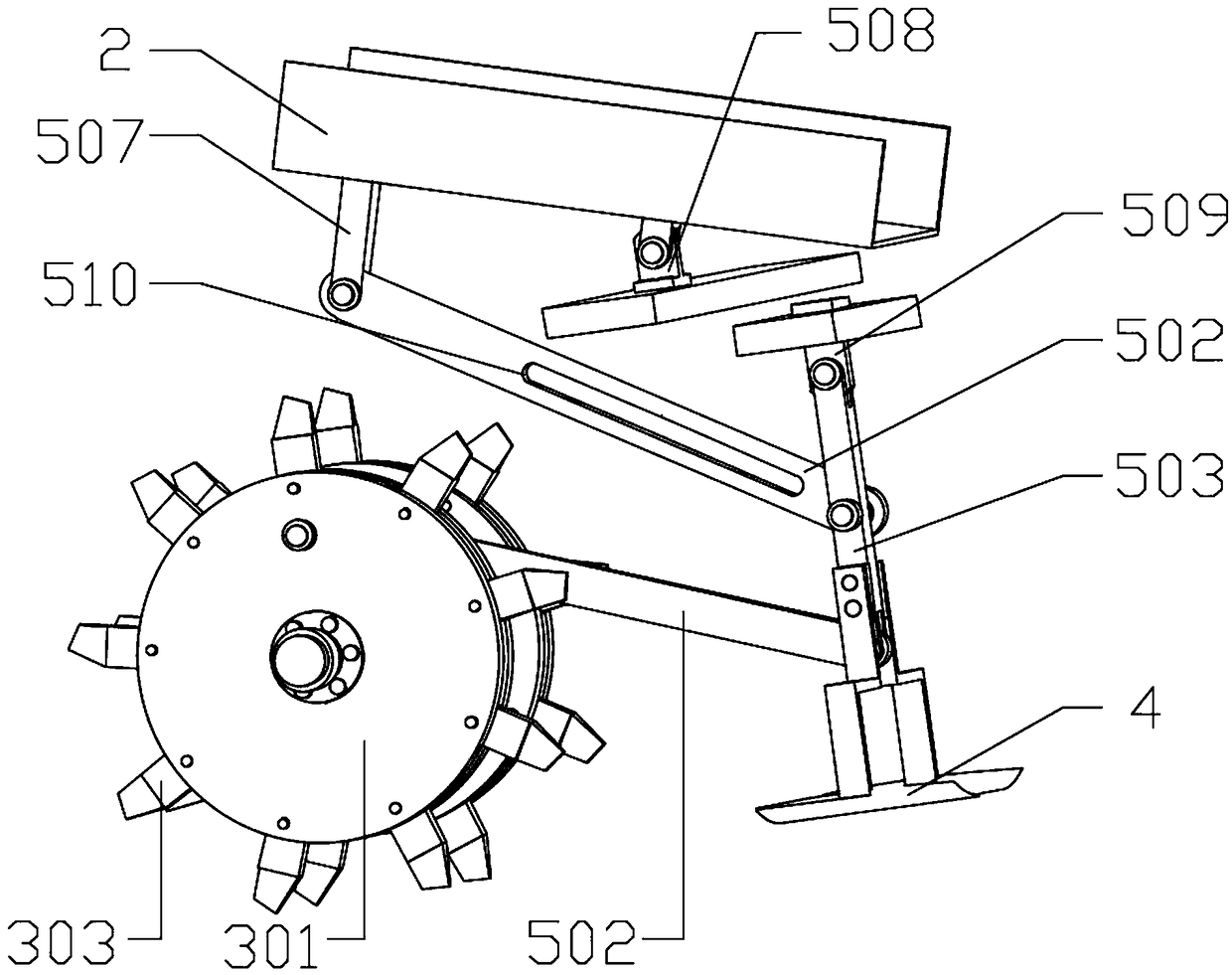

Seeding machine for agricultural production

InactiveCN110149867ARealize the whereaboutsConvenient whereaboutsCentrifugal wheel fertilisersSeederAgricultural engineering

The invention discloses a seeding machine for agricultural production, comprising: a frame connected with a cover; a tilling unit arranged at the front end of the frame and connected with the cover through a second connection rack; a roller arranged below the cover, wherein two ends of the roller are connected with coaxial rolling members which are connected with the cover through connectors, andwherein the frame has a horizontal plate, the roller and the horizontal plate are adjacent and form a temporary storage space to hold seeds, a distance from the surface of the roller to the lateral side of the horizontal plate is less than the diameter of the seeds, and when rolling, the roller brings away the temporary storage space and enables the seeds to drop on the land surface. Miniature mechanical equipment is utilized herein to perform seeding; automated continuous seeding is achieved; damage to seeds or missing of seeds to be sowed is avoided during seeding.

Owner:ZHEJIANG OCEAN UNIV

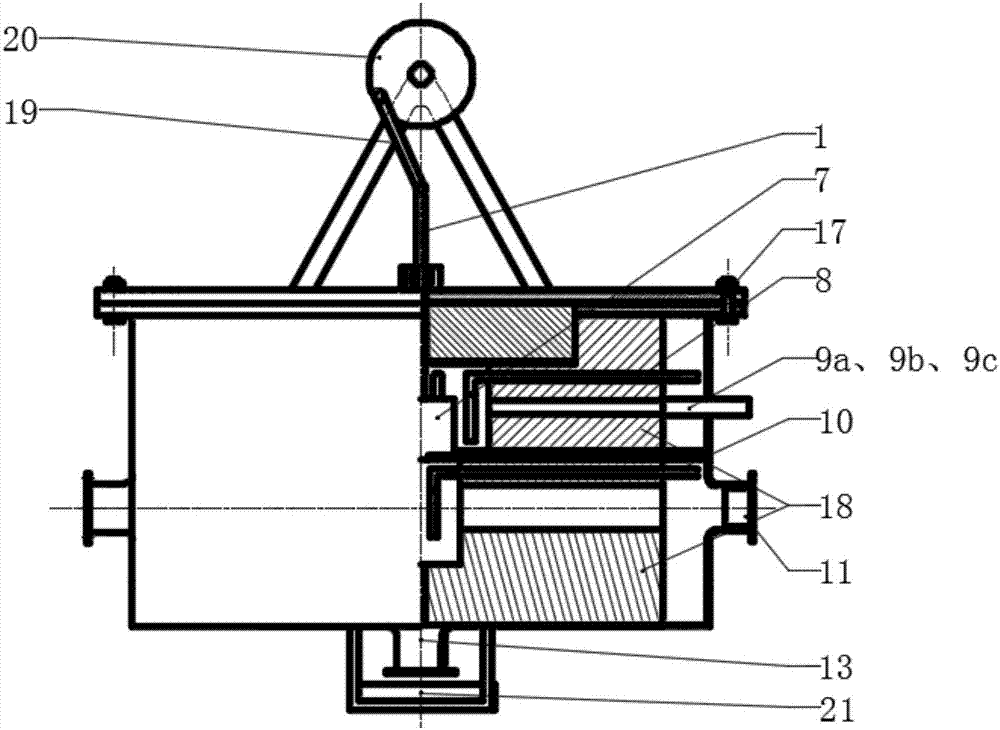

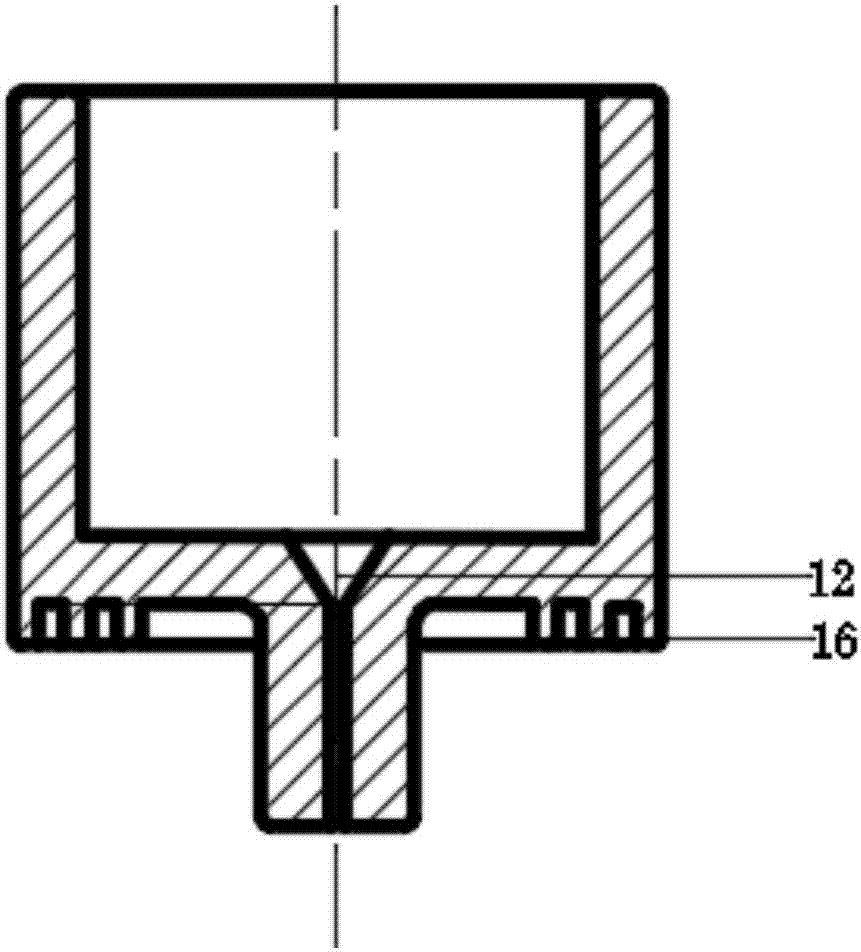

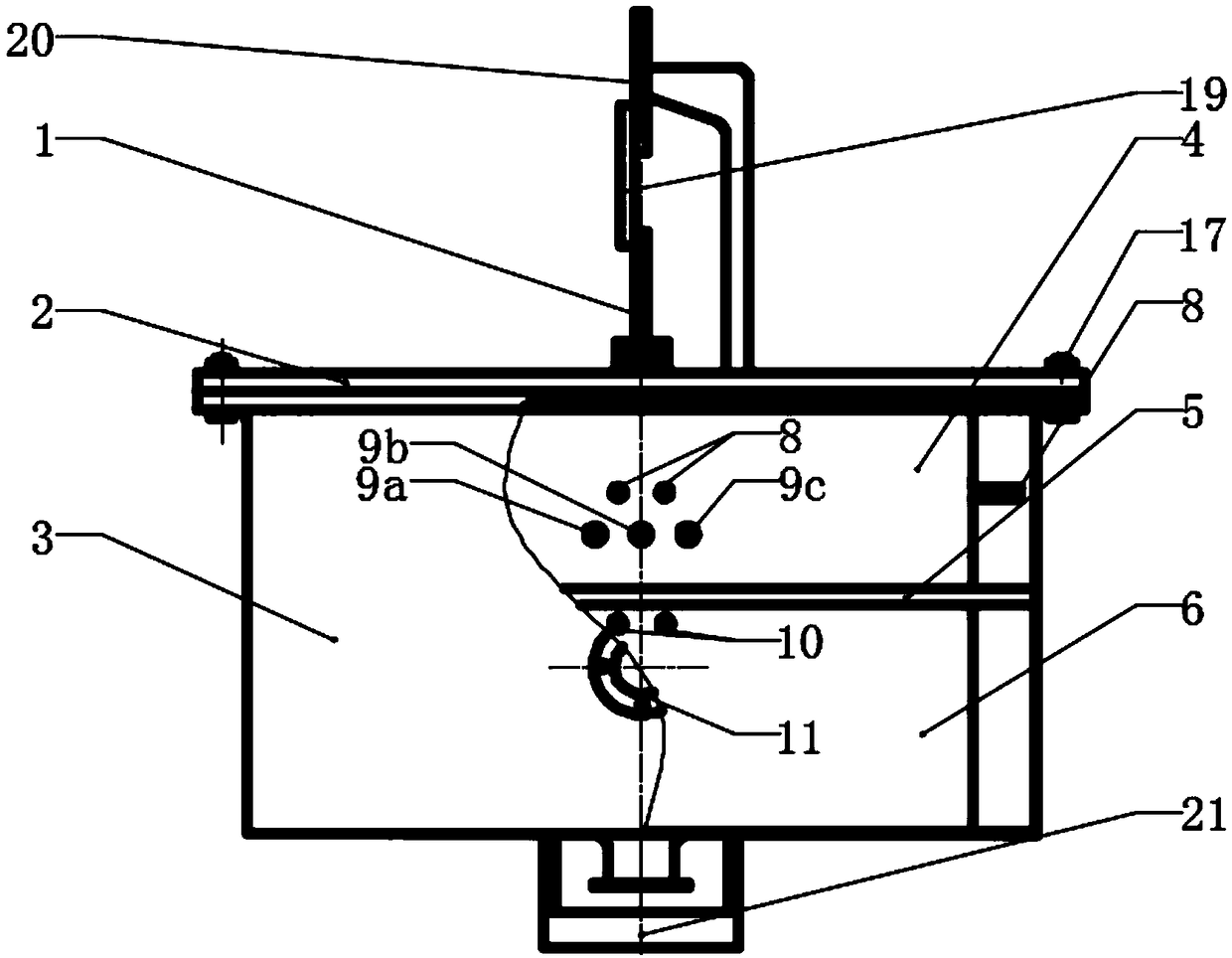

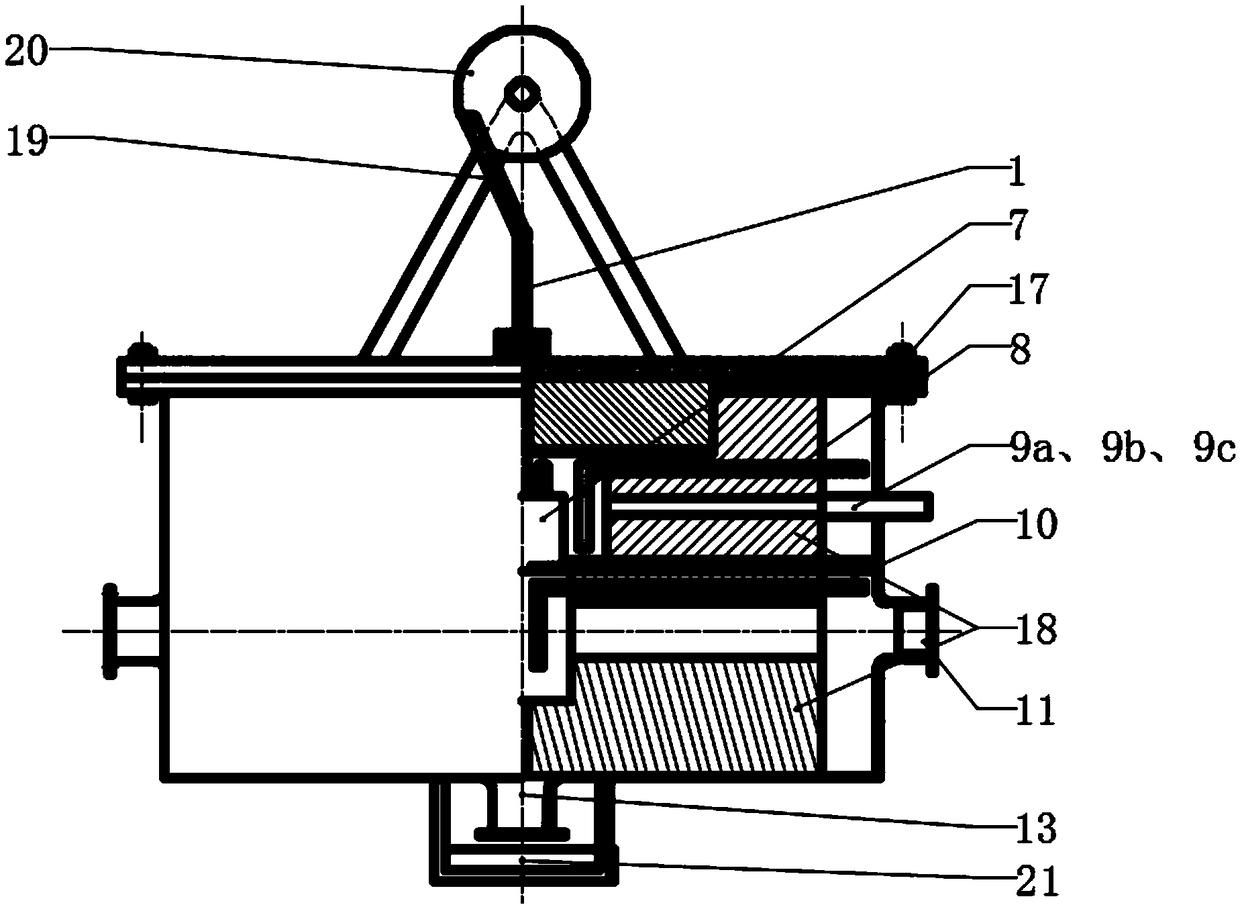

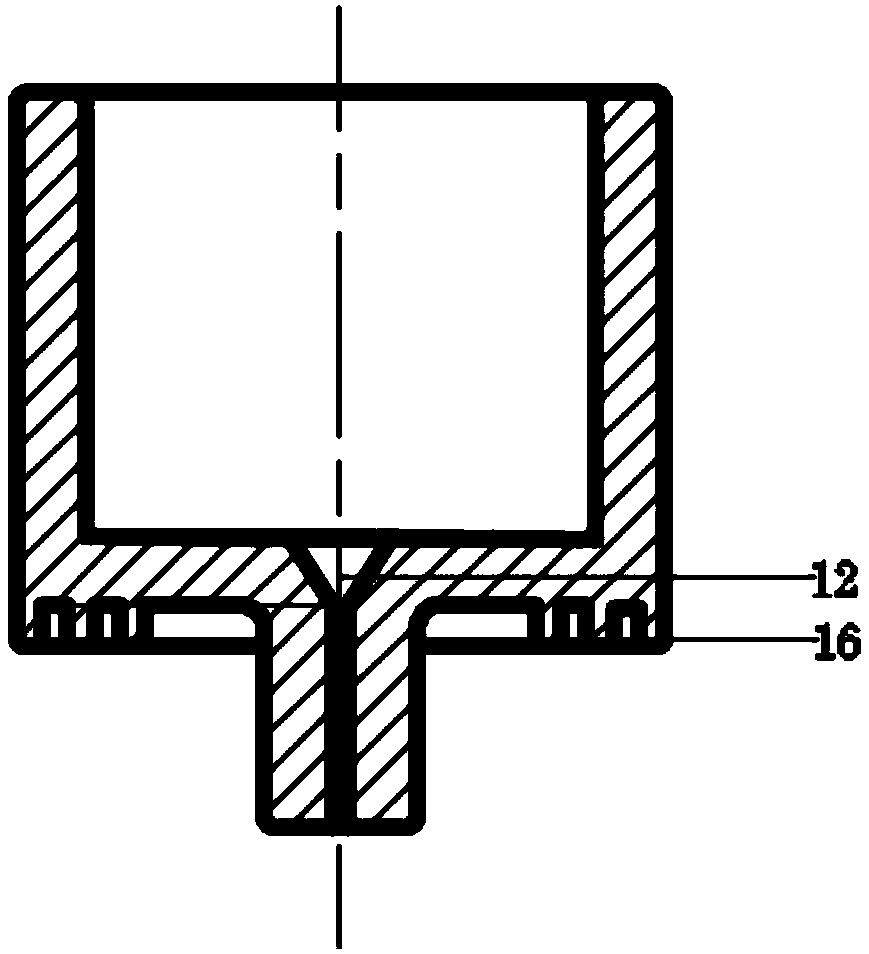

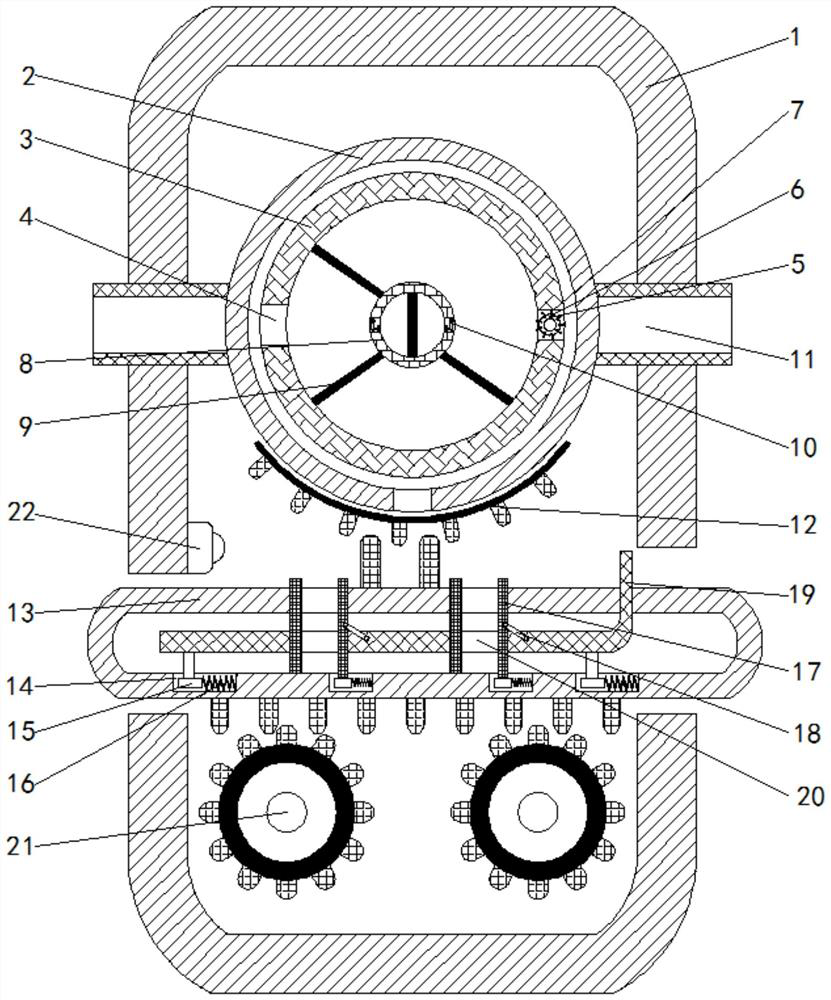

High-temperature melt granulation smelting furnace

ActiveCN107300324APrevent rapid oxidationPrevent oxidationMaintainance of heating chambersCrucible furnacesChemical industryVacuum pumping

The invention discloses a high-temperature melt granulation smelting furnace which comprises a metal shell, wherein the metal shell is sealed by a heating furnace closed cover. The high-temperature melt granulation smelting furnace is characterized in that a partition plate is arranged in the metal shell, the inside of the metal shell is divided into an upper box and a lower box by the partition plate, a center through hole is formed in the partition plate, a crucible is placed on the partition plate and provided with a funnel-shaped bottom, a discharging hole is formed in the bottom of the crucible, the bottom of the crucible penetrates the center through hole and is inserted into the lower box, a heat insulation layer is arranged between the wall of the crucible and the inner wall of the metal shell, a discharging port is formed in the bottom of the metal shell and corresponds to the discharging hole, a through hole is formed in the heating furnace closed cover, one end of a lifting bar penetrates the through hole and is inserted into the crucible, the discharging hole is plugged, the other end of the lifting bar is arranged outside the heating furnace closed cover and is connected with a rotating wheel through a connecting rod, and a vacuum pumping pipe, an air inflation pipe and an exhaust pipe are arranged in the metal shell. The high-temperature melt granulation smelting furnace can generate high-temperature molten particles meeting requirements and can be widely applied to the fields of chemical industries, steel and the like.

Owner:CHONGQING UNIV

Top coal caving hydraulic support mining equipment

ActiveCN110725710ARealize the whereaboutsRealize auxiliary coal dischargeSlitting machinesMine roof supportsCoalMining engineering

The invention relates to the technical field of a top coal caving hydraulic support, and particularly relates to a top coal caving hydraulic support mining equipment. A coal caving plate is hinged tothe inner side of a coal caving control plate, an angle between the coal caving plate and the coal caving control plate is adjustable, the coal caving plate can extend upwards out of the top end faceof the coal caving control plate, falling of coal sheets on the coal caving control plate can be realized through the coal caving plate, a plurality of vibration swing coal falling mechanisms are arranged on the top end face of the coal caving plate, the vibration swings coal falling mechanisms can swing in a certain angle, auxiliary coal caving can be well achieved without lifting a hydraulic column on a base, only partial coal sheets need to be oscillated, auxiliary falling of the coal can be well achieved, an falling angle can be effectively controlled, coal protection mechanisms are arranged on the two sides of a top coal caving top plate, an included angle between the coal protection mechanisms and the top surface of the top coal caving top plate is adjustable, the angle of the coal block falling down can be accurately controlled, and the top coal caving precision is improved.

Owner:HENAN POLYTECHNIC UNIV

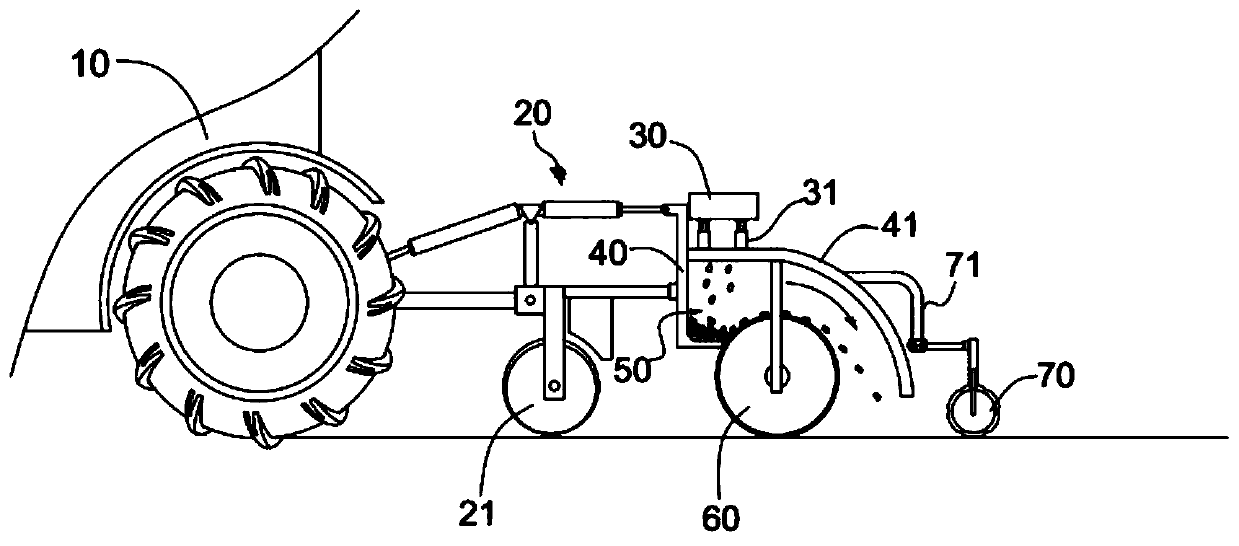

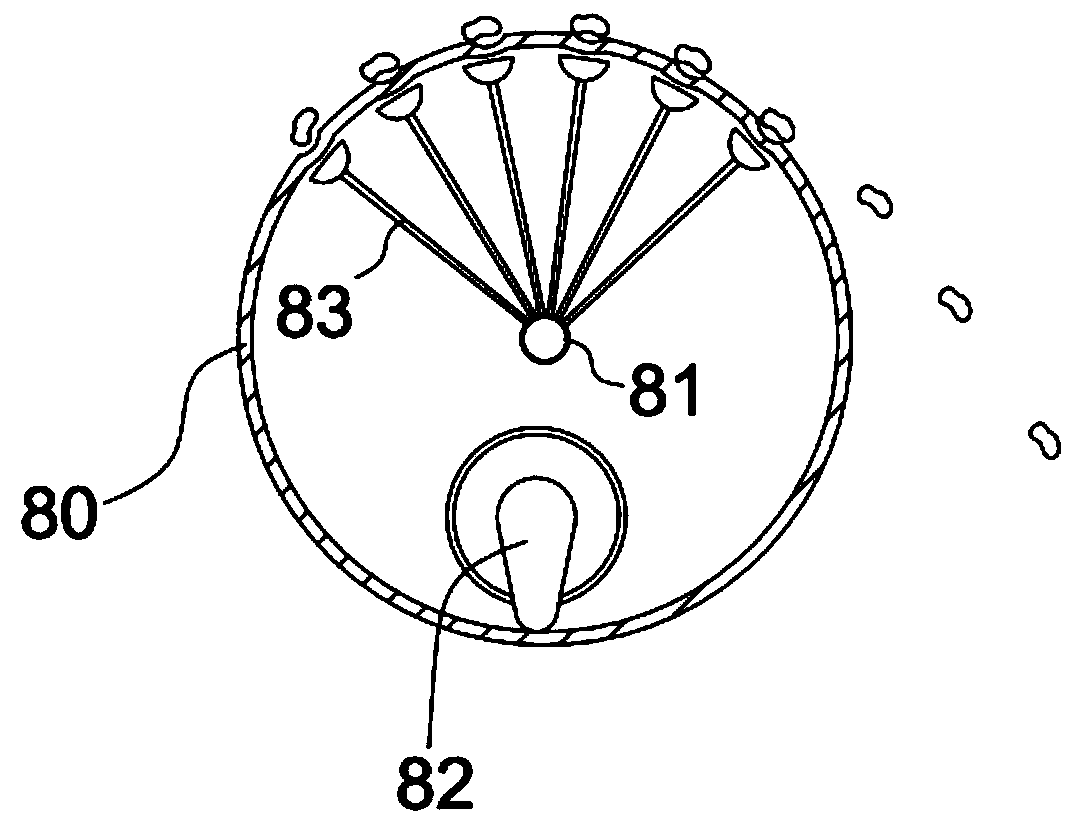

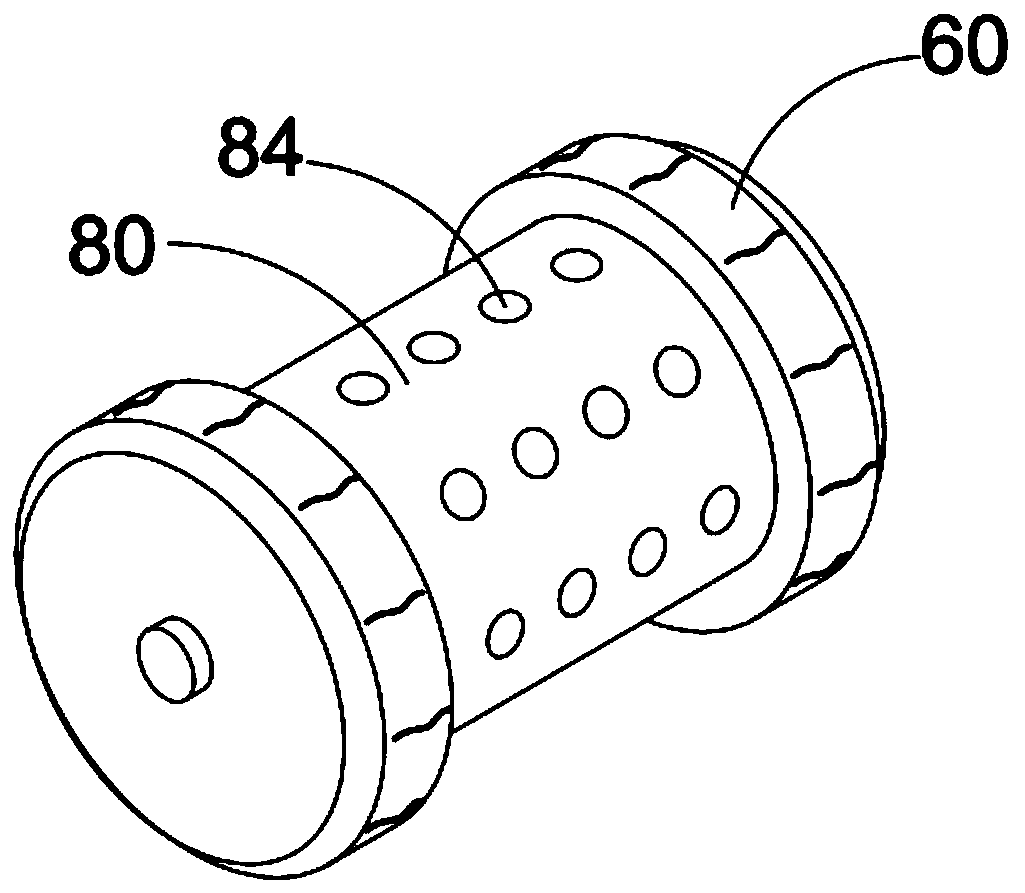

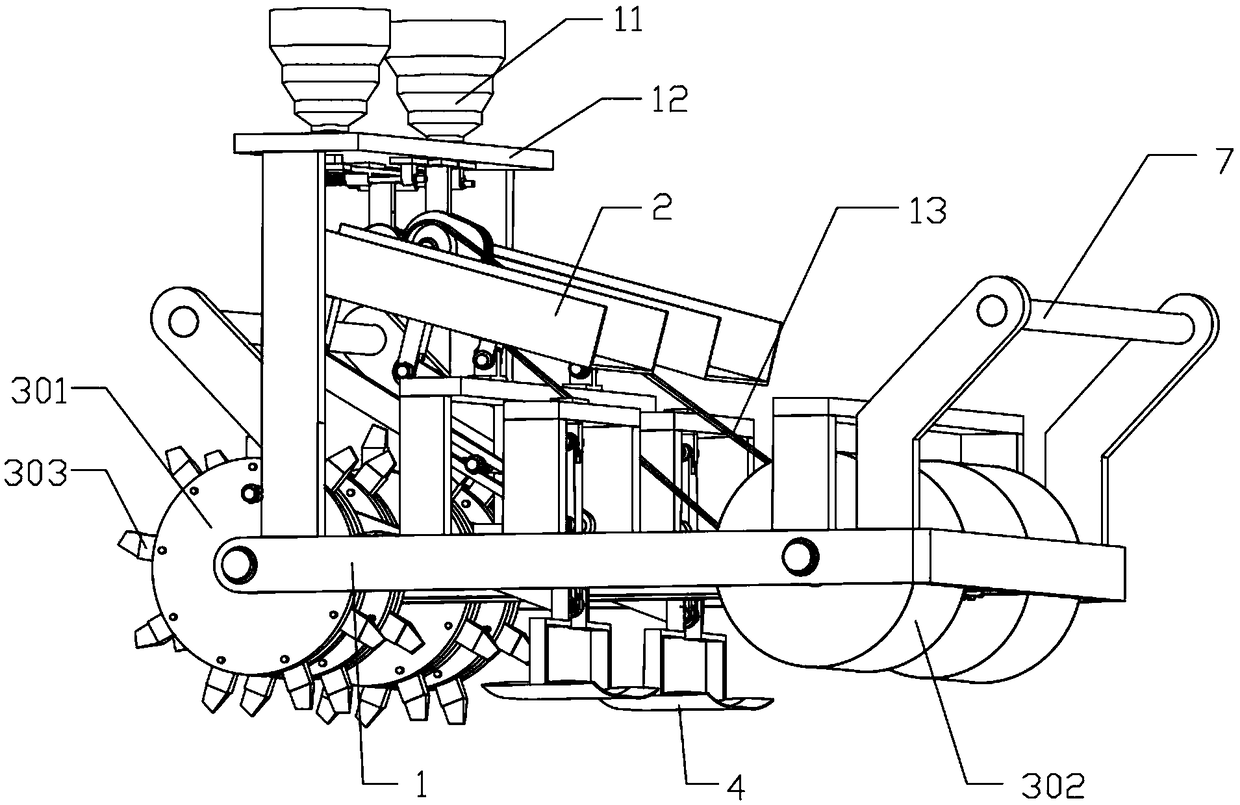

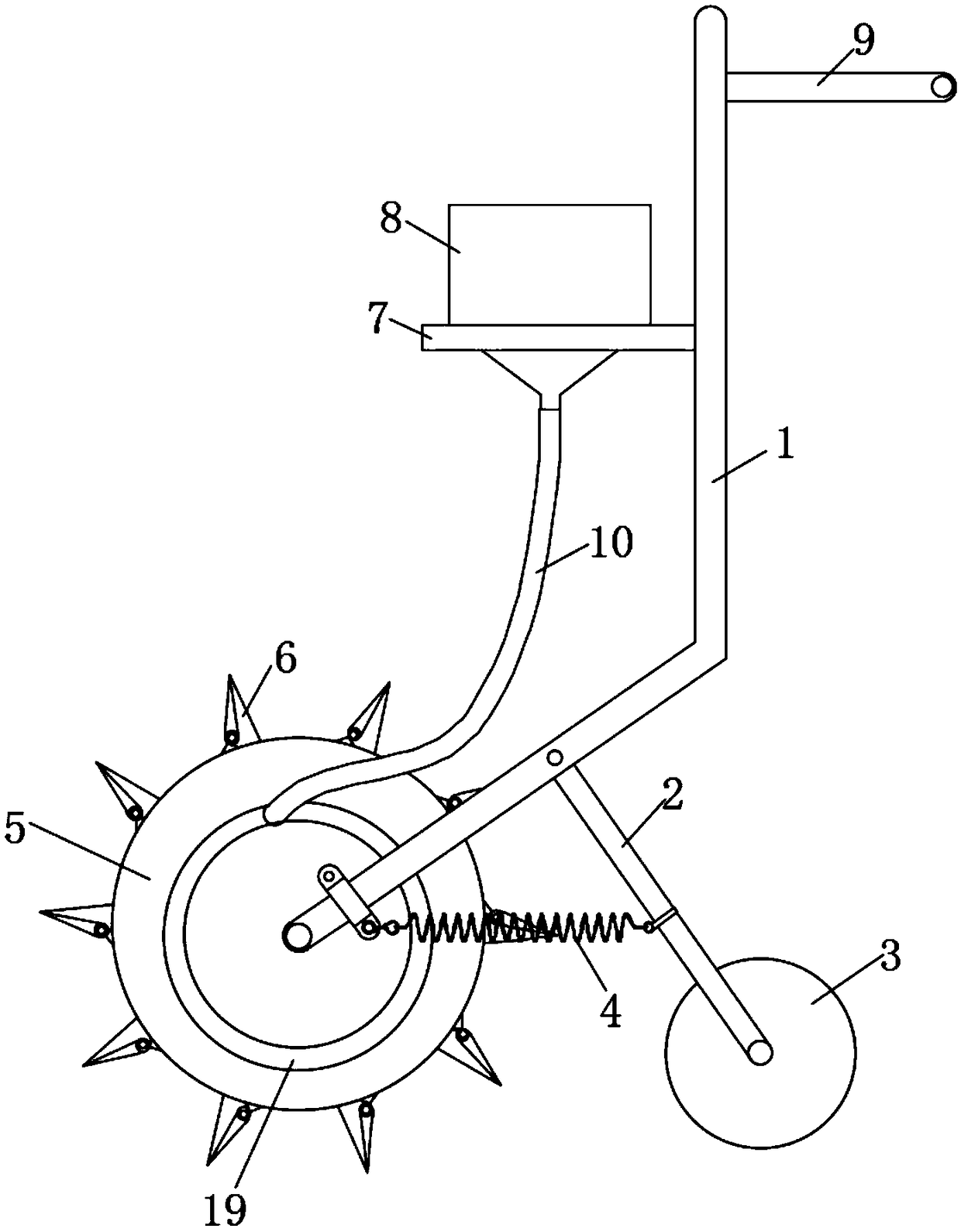

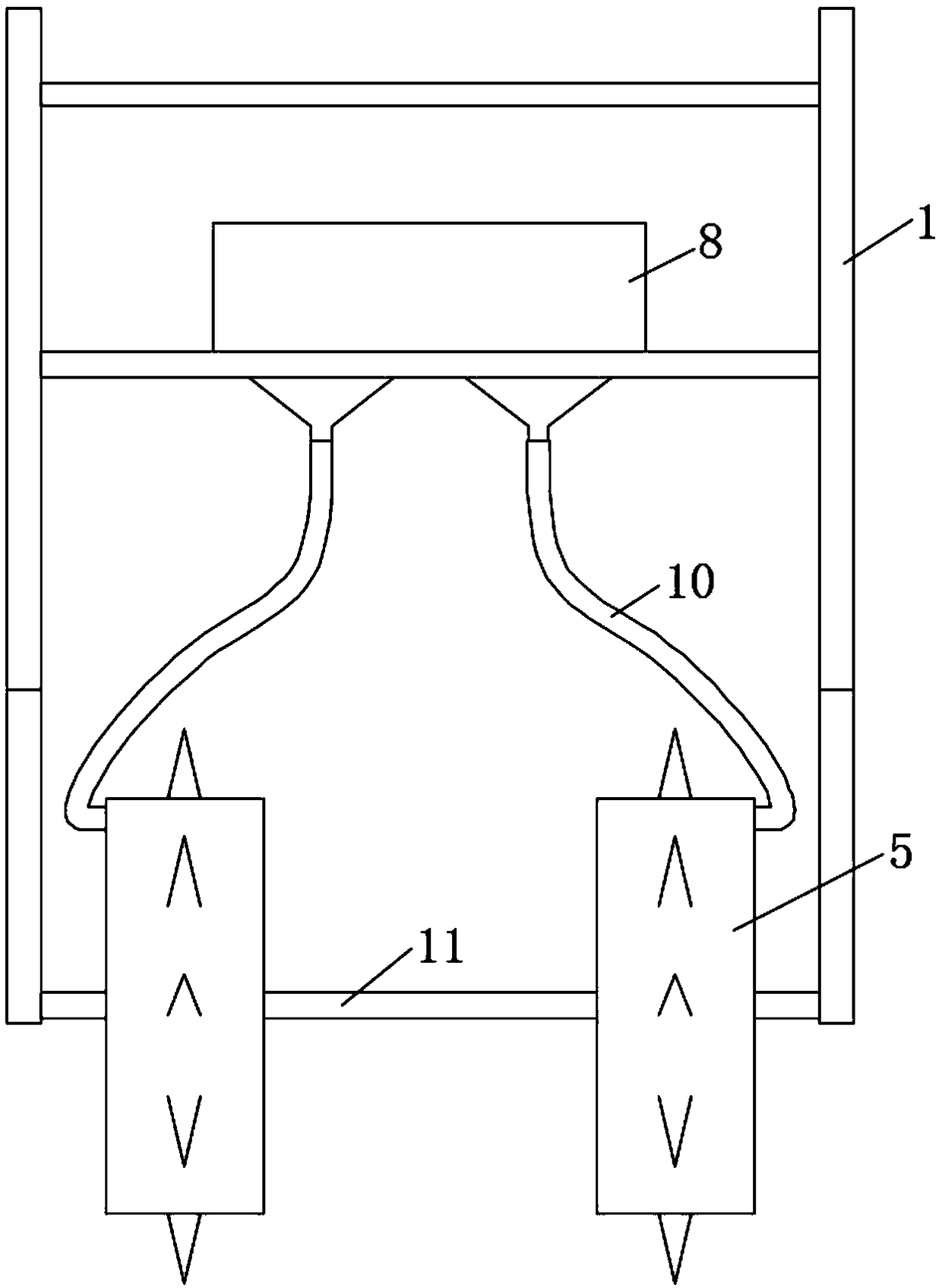

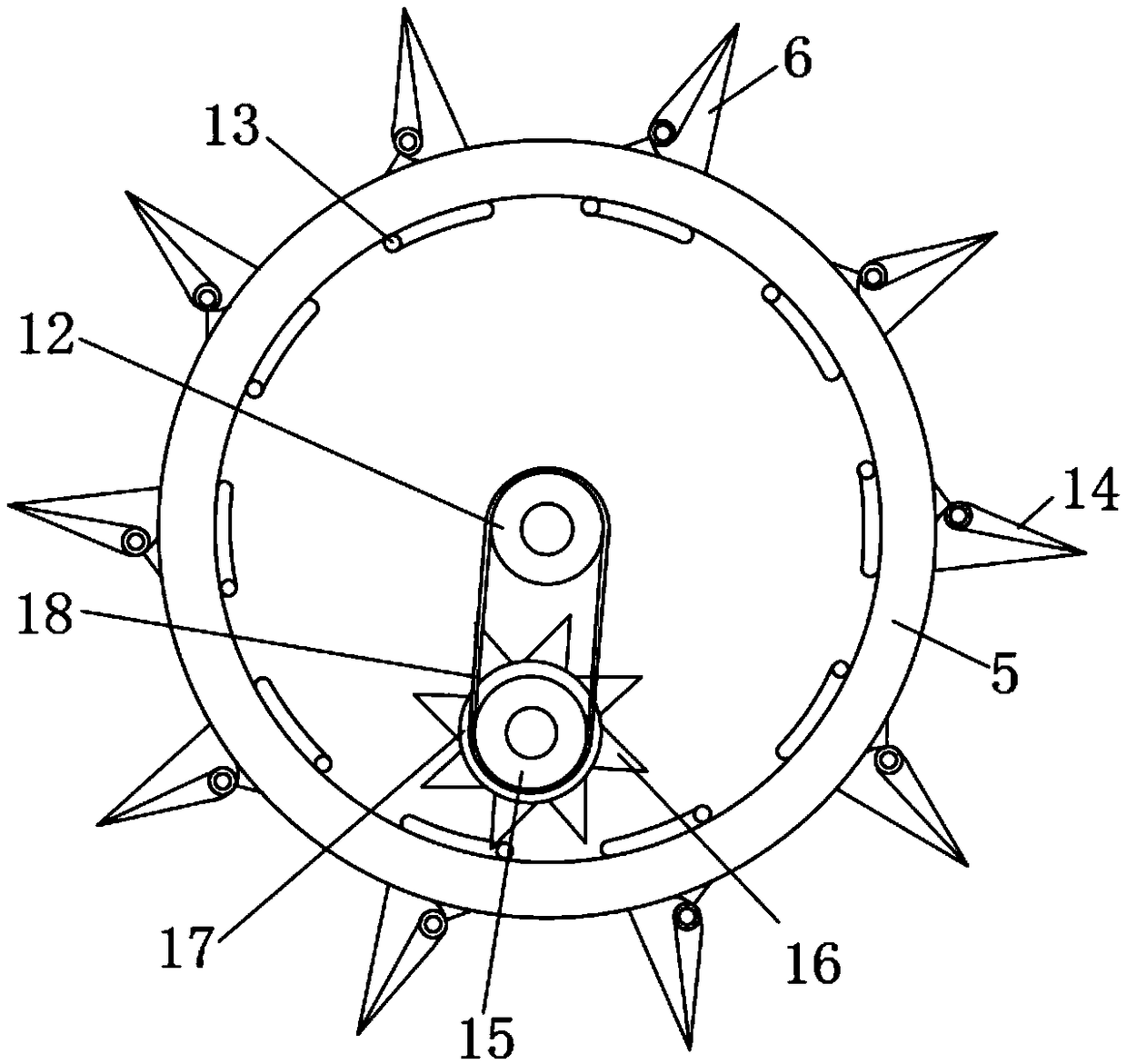

Full-automatic seeding ripper

InactiveCN109479422ALabor savingCompact structureSpadesPloughsGear transmissionAgricultural engineering

The invention provides a full-automatic seeding ripper, and belongs to the technical field of agricultural machinery. The ripper comprises a ripper device and a seeding device arranged above the ripper device. The ripper device comprises a main frame, a seeding chute, a ripping mechanism and a shoveling mechanism. The shoveling mechanism includes a front wheel, ripping teeth and a rear wheel, andthe front wheel drives the seeding chute and the shoveling mechanism to move through a transmission mechanism. The seeding device comprises a main frame horizontal plate, a seeding funnel, a baffle, atwo-way motor and a second transmission mechanism. The seeding funnel is clamped on a main machine transverse plate, and the second transmission mechanism drives the baffle to move back and forth bythe two-way motor. A first transmission mechanism includes a gear transmission assembly and a cam transmission assembly.

Owner:TIANJIN JIABANGNUO TECH CO LTD

A storage device for full biodegradable film storage

ActiveCN113716189BAir drySpeed up the churn rateBio-packagingContainers preventing decayTransmission beltFresh air

The invention discloses a storage device for fully biodegradable film. The upper part of the rear end of the box is provided with a fresh air duct, and the mouth of the fresh air duct is provided with guide vanes. The other side of the rear end of the box is The lower part is provided with an air outlet duct, and the fresh air duct blows out fresh air toward the processing warehouse, the guide blades aim at the moisture absorption roller and the fully biodegradable film at the moisture absorption roller to blow air, and the fresh air in the treatment warehouse is discharged through the air outlet pipe; The storage device for biodegradable film storage belongs to the field of biodegradable film storage equipment. The fresh air is blown to the moisture absorption roller and the fully biodegradable film at the moisture absorption roller to speed up the moisture loss rate of the moisture absorption roller and the fully biodegradable film at the moisture absorption roller, and realize the moisture absorption of the moisture absorption roller. Air-drying of the fully biodegradable film at the moisture absorption roller, the winding device, the transmission belt, the receiving roller, the stepped roller and the inclined storage plate cooperate with each other, and the fully biodegradable film that is rolled can be transported to the inclined storage plate for storage, reducing labor intervene.

Owner:苏州环诺新材料科技有限公司

High temperature melt granulation furnace

ActiveCN107300324BPrevent oxidationPromote oxidationMaintainance of heating chambersCrucible furnacesChemical industryVacuum pumping

The invention discloses a high-temperature melt granulation smelting furnace which comprises a metal shell, wherein the metal shell is sealed by a heating furnace closed cover. The high-temperature melt granulation smelting furnace is characterized in that a partition plate is arranged in the metal shell, the inside of the metal shell is divided into an upper box and a lower box by the partition plate, a center through hole is formed in the partition plate, a crucible is placed on the partition plate and provided with a funnel-shaped bottom, a discharging hole is formed in the bottom of the crucible, the bottom of the crucible penetrates the center through hole and is inserted into the lower box, a heat insulation layer is arranged between the wall of the crucible and the inner wall of the metal shell, a discharging port is formed in the bottom of the metal shell and corresponds to the discharging hole, a through hole is formed in the heating furnace closed cover, one end of a lifting bar penetrates the through hole and is inserted into the crucible, the discharging hole is plugged, the other end of the lifting bar is arranged outside the heating furnace closed cover and is connected with a rotating wheel through a connecting rod, and a vacuum pumping pipe, an air inflation pipe and an exhaust pipe are arranged in the metal shell. The high-temperature melt granulation smelting furnace can generate high-temperature molten particles meeting requirements and can be widely applied to the fields of chemical industries, steel and the like.

Owner:CHONGQING UNIV

Storage device for full-biodegradable film storage

ActiveCN113716189AAir drySpeed up the churn rateBio-packagingContainers preventing decayPolymer scienceTransmission belt

The invention discloses a storage device for full-biodegradable film storage. A fresh air pipeline is arranged on the upper portion of one side of the rear end of a box body, a flow guide blade is arranged at a pipe opening of the fresh air pipeline, an air outlet pipeline is arranged on the lower portion of the other side of the rear end of the box body, the fresh air pipeline blows fresh air to a treatment bin, the flow guide blade is aligned with a moisture absorption roller and a full-biodegradable film at the moisture absorption roller to blow air, and the fresh air in the treatment bin is discharged through the air outlet pipeline. The storage device for full-biodegradable film storage belongs to the field of biodegradable film storage equipment, the fresh air is blown to the moisture absorption roller and the full-biodegradable film at the moisture absorption roller, the loss rate of moisture at the moisture absorption roller and the full-biodegradable film at the moisture absorption roller is increased, air drying of the moisture absorption roller and the full-biodegradable film at the moisture absorption roller is achieved, a winding device, a transmission belt, a bearing roller, a stepped roller and an inclined storage plate are matched with one another, the wound full-biodegradable film can be conveyed to the inclined storage plate to be stored, and manual intervention is reduced.

Owner:苏州环诺新材料科技有限公司

Hole-sowing duckbilled soil opener for crop planting

The invention discloses a hole-sowing duckbilled soil opener for crop planting. The hole-sowing duckbilled soil opener comprises two fixing frames arranged symmetrically; and a handrail frame and a supporting frame are jointly welded between the two fixing frames, a mounting rod is jointly and rotatably connected between the two fixing frames, two rotating boxes are symmetrically mounted on the mounting rod, a plurality of discharging outlets are evenly formed in the outer side wall of each rotating box, each discharging outlet is fixedly connected with a fixed nozzle, each fixed nozzle is rotatably connected with a rotating nozzle, one ends of the rotating nozzles extend into the rotating boxes through the discharging outlets and fixedly connected with shifting blocks, two first belt wheels are symmetrically mounted on the mounting rod, and a second belt wheel and a shifting seat are coaxially arranged on the inner side wall of each rotating box. The hole-sowing duckbilled soil openerhas the advantages that the hole-sowing duckbilled soil opener is ingenious in structure and convenient to use, and is suitable for farmland with small and medium-sized soil area, the labor amount ofgrowers is lowered, the device efficiency is improved, and the empty seed rate is low.

Owner:余杰

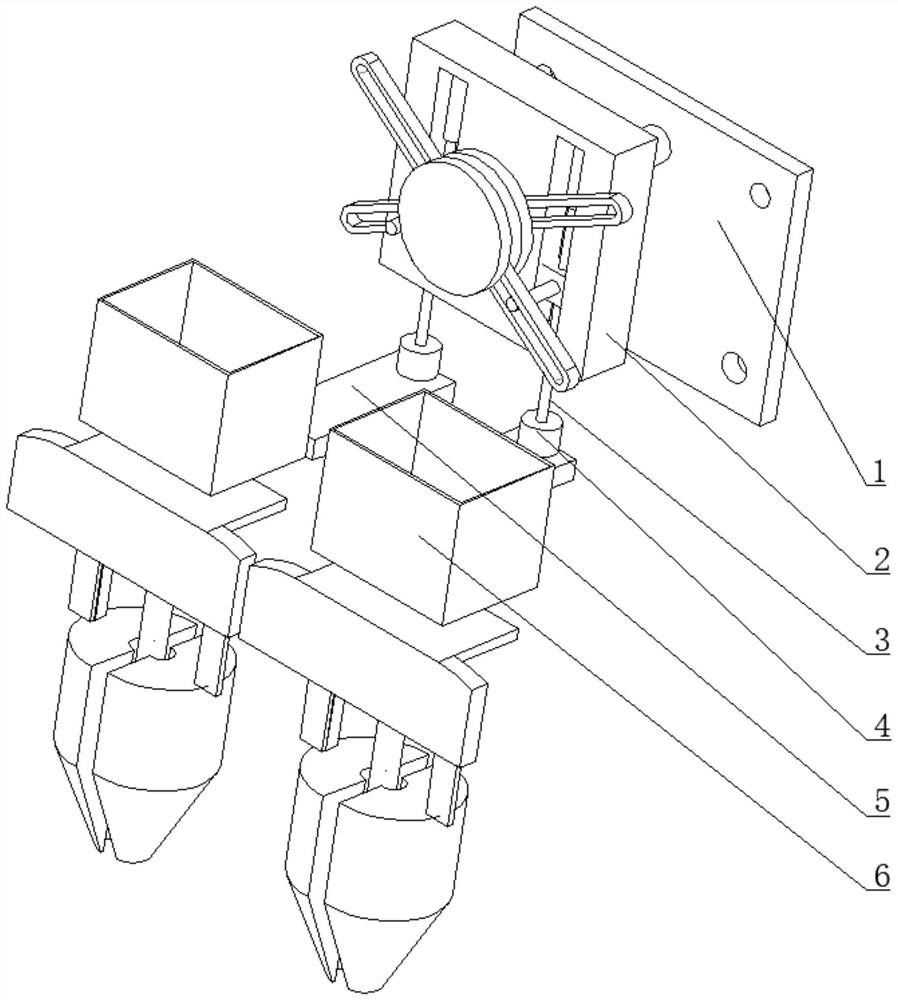

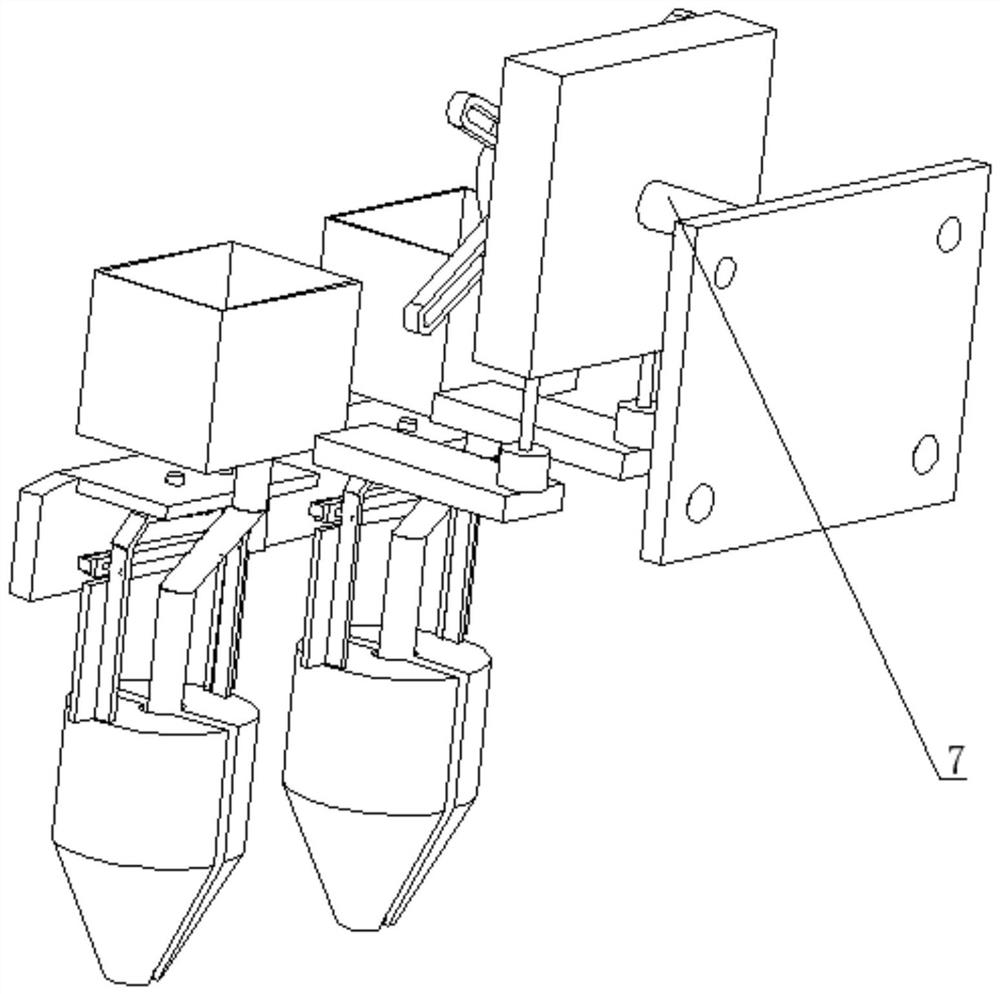

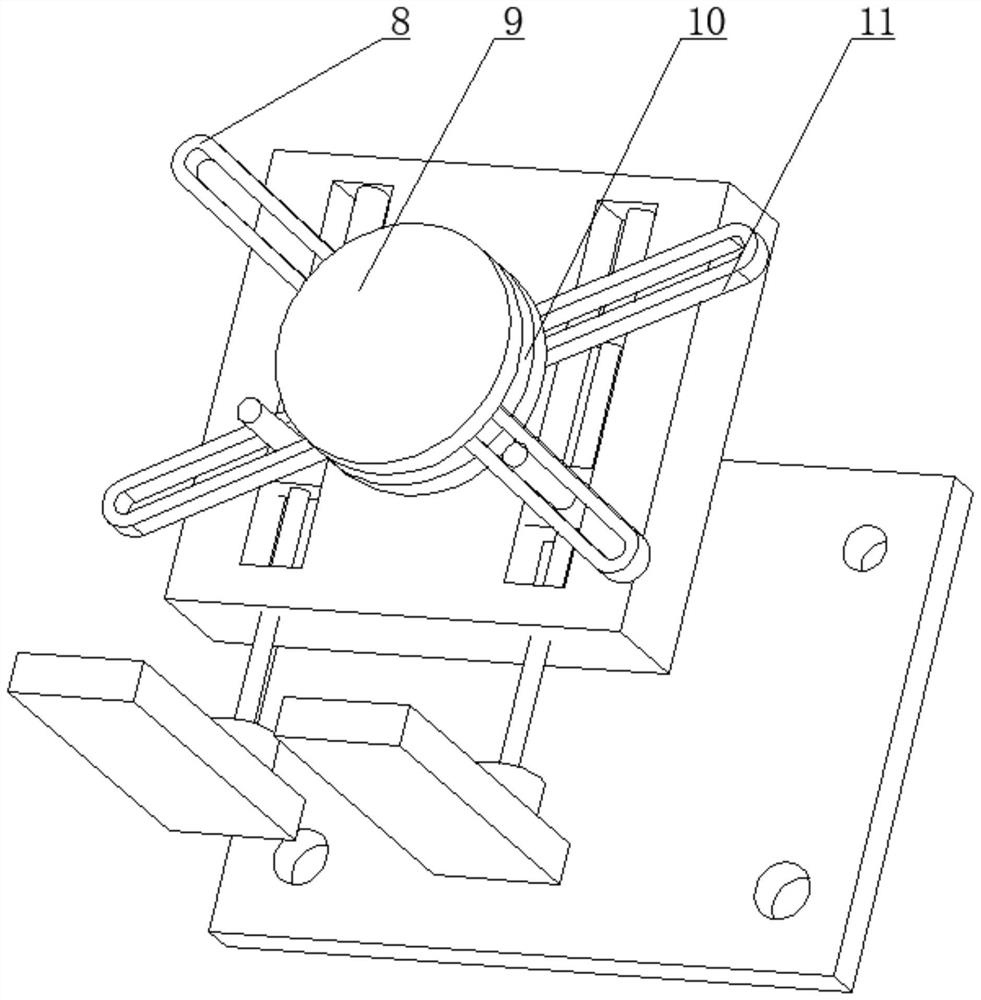

Vertical constraint turnover manipulator

PendingCN111923079ARealize the whereaboutsPrevent proliferationGripping headsMetal working apparatusElectric machineryDrive motor

The invention relates to the technical field of manipulators, and particularly discloses a vertical constraint turnover manipulator. The vertical constraint turnover manipulator comprises a fixed backplate and a plurality of manipulator bodies arranged on the fixed back plate. The back plate is provided with a driving motor, a penetrating shaft, speed reducers, belt assemblies, a lifting beam, alifting base plate, buffer supporting plates and shifting forks. The driving motor and the penetrating shaft are connected with the manipulator bodies, the belt assemblies are connected with a manipulator combination body and the speed reducers, the shifting forks and the manipulator bodies are connected with the lifting beam, the lifting base plate and the buffer supporting plates, and the lifting base plate is connected with the buffer supporting plates. The vertical constraint turnover manipulator avoids dust dispersion caused by free falling motion of materials, guarantees accuracy of falling point postures, effectively realizes material falling constraints, and is convenient and fast to switch, stable and reliable in operation and flexible to adjust in lifting amplitude.

Owner:六度人和(天津)科技有限公司

Stereoscopic garage of overhead bridge across street or along street

InactiveCN102587709BSolve the problem of land occupationSolve parking problemParkingsRoad surfaceEngineering

A stereoscopic garage of an overhead bridge across a street or along the street comprises a multilayer box type garage main body frame, a ceiling and transfer movable rack. The ceiling is mounted on the upper portion of the frame, the bottom of the garage main body frame is distanced from a road surface by a certain altitude, the transfer movable racks are transversely slidably connected with the garage main body frame, lifting trays are vertically slidably connected with the transfer movable racks, a lifting driving device is disposed on each transfer movable rack and connected with the corresponding lifting tray, guide tracks A and a rotary disc are disposed on a bottom plate of each lifting tray, a fixing tray is arranged in each box of the main body frame, guide tracks B are arranged on each fixing tray, the garage is further provided with vehicle carrying plates, and rollers which match with the guide tracks A and the guide tracks B are disposed under the vehicle carrying plates. The stereoscopic garage is built above the street, does not affect traffic, not only solves parking problems, but also solves the problem that an existing stereoscopic garage occupies large area, vehicles can be parked and taken automatically by the aid of matching of the lifting trays and the transfer movable racks, drivers do not need to give way to other vehicles when parking or taking the vehicles, and efficiency is high.

Owner:HENAN AUSPIC TECH

A box lunch vending machine

ActiveCN105427461BRealize the whereaboutsWhereabouts will notCompression machines with non-reversible cycleCoin-freed apparatus detailsControl systemProcess engineering

The invention discloses a novel box lunch self-vending machine, which belongs to the technical field of refrigeration systems and includes a machine body. The upper part of the machine body is a storage unit, and the lower part of the machine body is a pick-up unit. A first leak-proof cold door placed horizontally is arranged between the storage unit and the picking unit, a second leak-proof cold door is arranged at the exit of the picking unit, the body is equipped with a refrigeration system, and the body is also equipped with A control system, the control system includes a controller, and the controller is at least connected to the actuator of the first leak-proof cold door. The present invention is a new box lunch self-vending machine, which adds a refrigeration system on the basis of the existing equipment, and has strong freezing capacity; double leak-proof unpopular technology prevents cold air from leaking out, greatly enhances the fresh-keeping ability, and saves resources; the first leak-proof The cold door is controlled by the control system, which can realize automatic opening and closing with high accuracy; and the box lunches can be dropped one by one through the material channel structure.

Owner:AUCMA

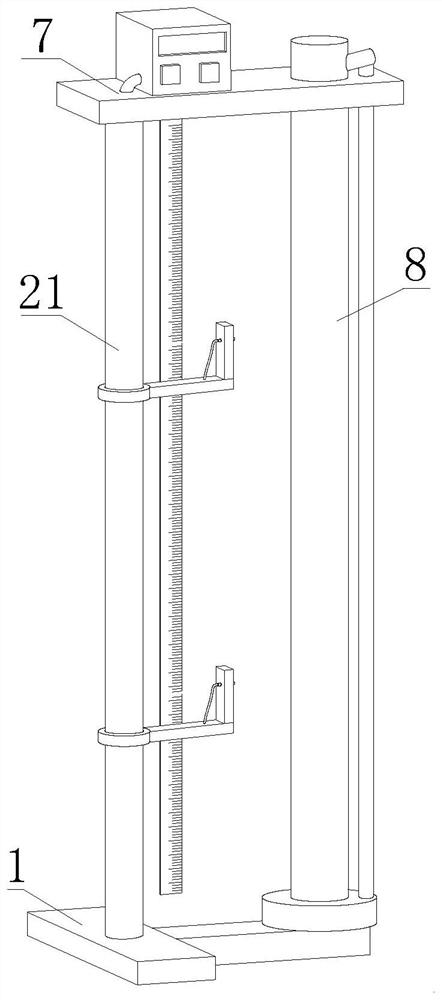

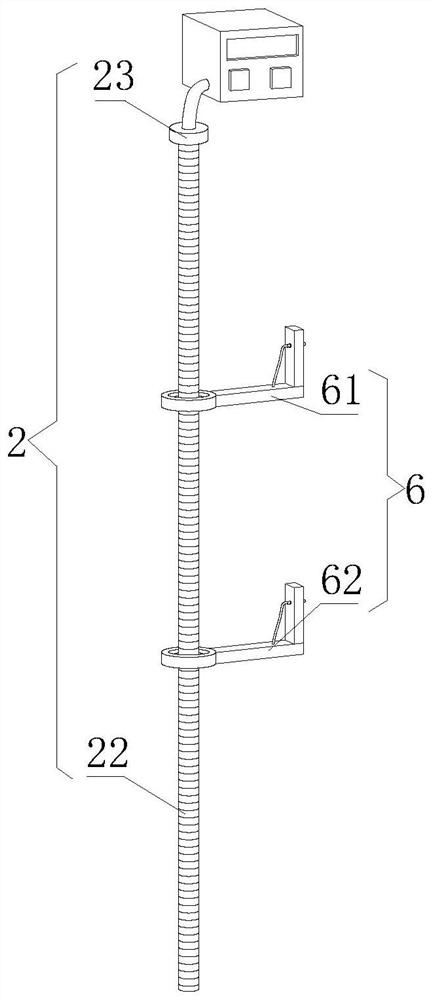

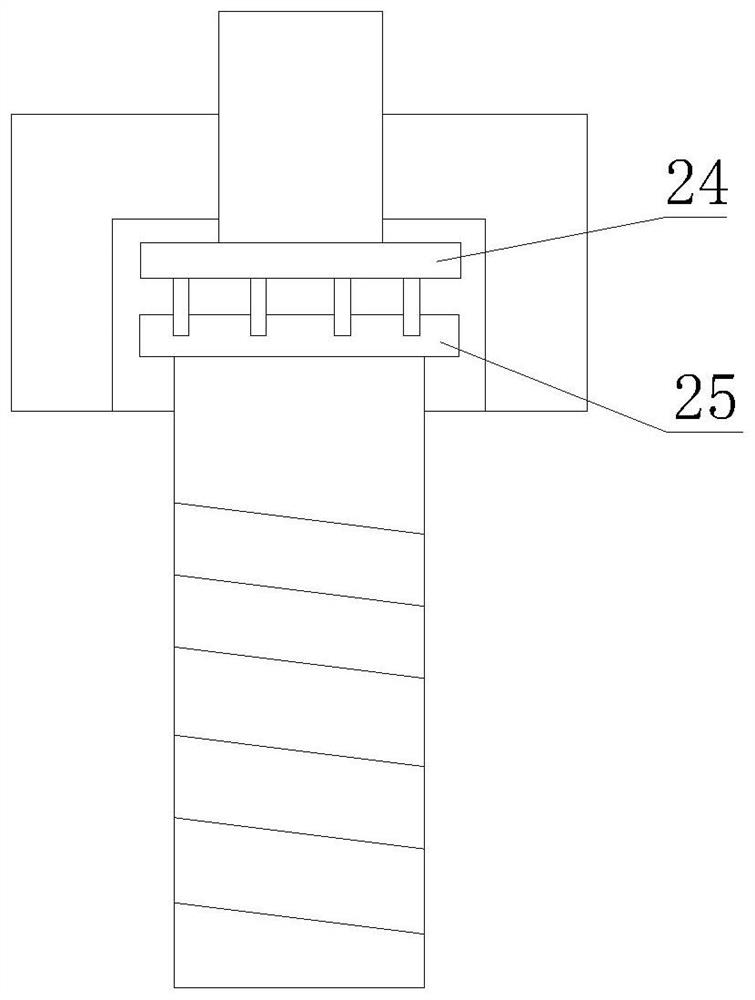

Free falling body demonstration device

InactiveCN114141111ATo achieve the purpose of power supplyRealize the whereaboutsEducational modelsFree fallingEngineering

A free fall demonstration device disclosed by the present invention comprises a base, the upper surface of the base is provided with a guide data transmission assembly, a rotary damping assembly, a power assembly and a small ball conveying assembly, the guide data transmission assembly is sleeved with two sets of photoelectric detection assemblies, and the top end of the guide data transmission assembly is provided with a transverse plate. A vacuum pipe is connected to the rotary damping assembly, the vacuum pipe and the small ball conveying assembly penetrate through the transverse plate, and the vacuum pipe is connected with the small ball conveying assembly. According to the free falling body demonstration device provided by the invention, the distance is recorded through the measuring scale, and the free falling body formula is obtained by adjusting the distance of the detection head for multiple times. Through vacuum setting, resistance in air is reduced, measured data are more accurate, meanwhile, automatic small ball feeding and falling are achieved through machinery, the whole operation does not need manual work, and manual errors are avoided.

Owner:吴宸希

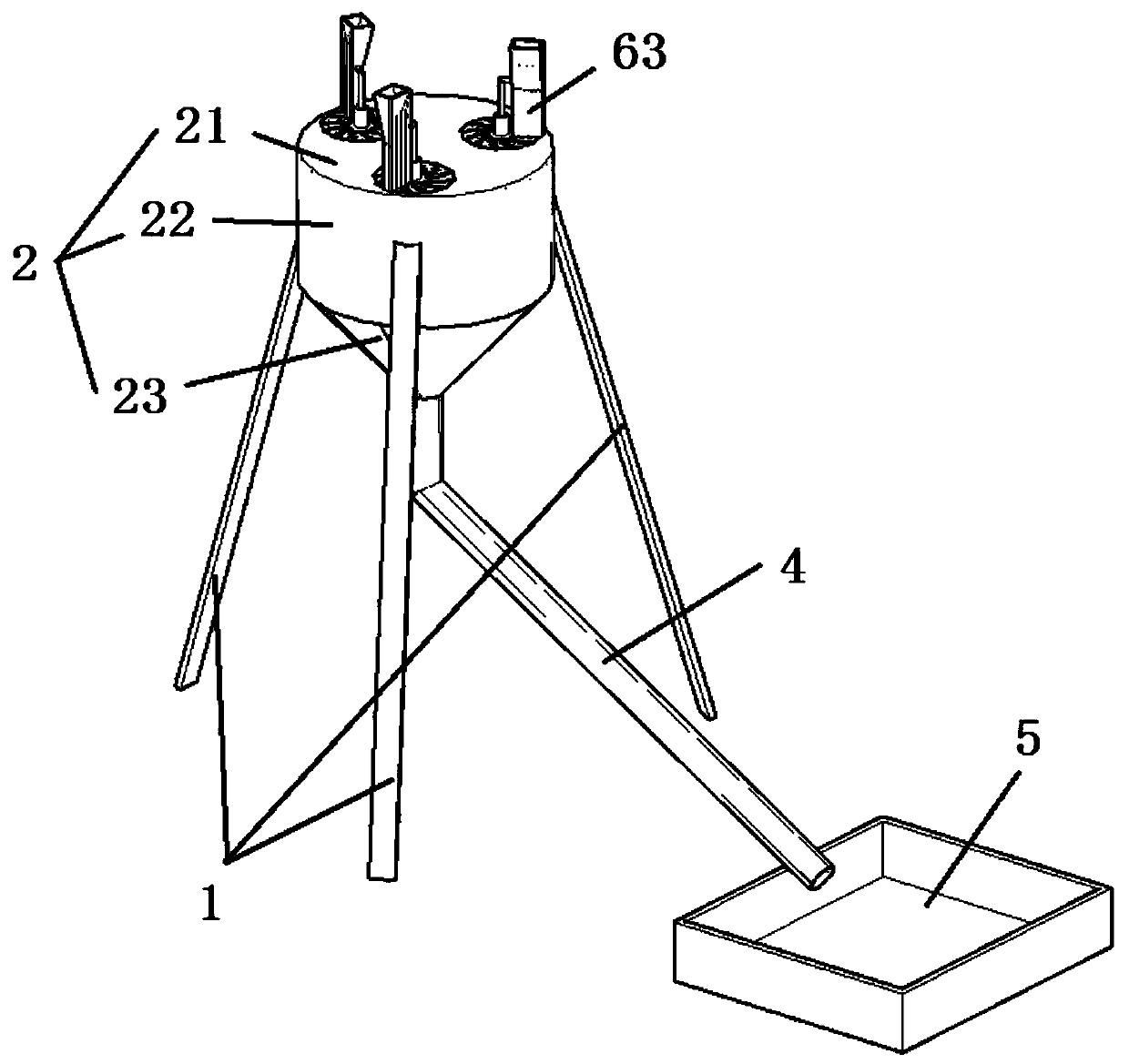

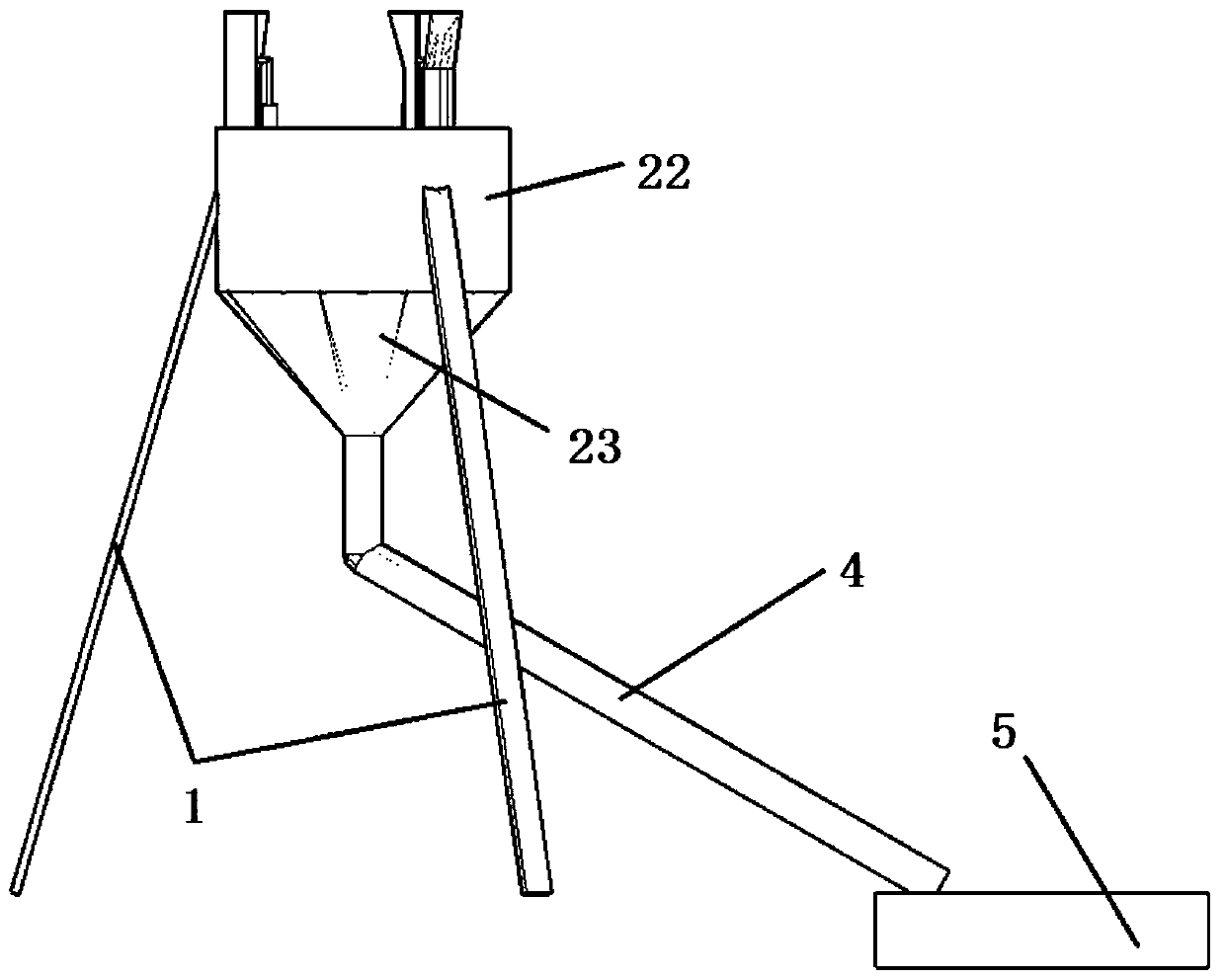

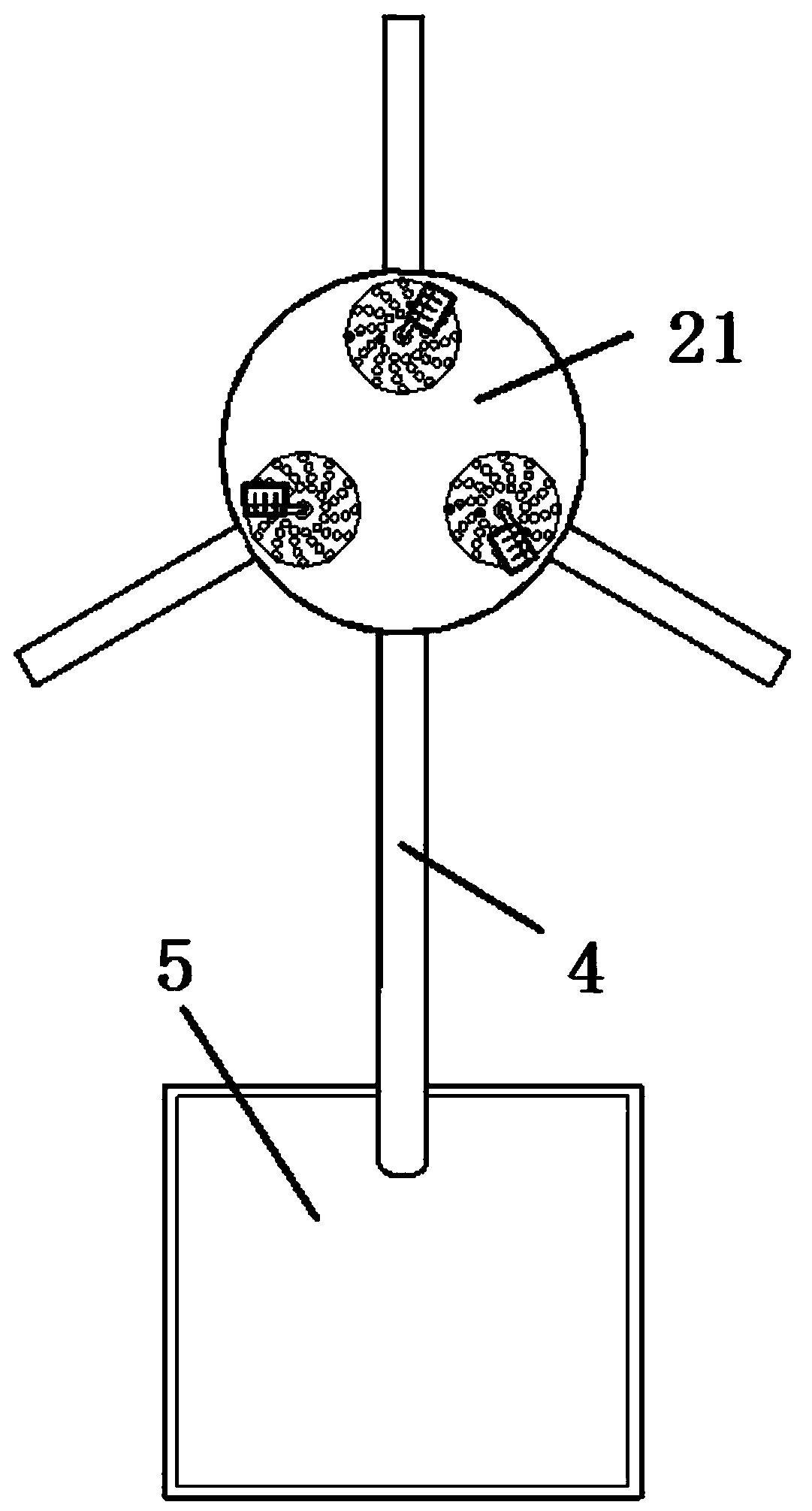

Rotary falling type blood collection pipe conveying device and selection method thereof

ActiveCN110498194ARealize the whereaboutsReduce manual laborDiagnostic recording/measuringSensorsBlood Collection TubeEngineering

The invention relates to the field of medical devices, in particular to a rotary falling type blood collection pipe conveying device and a selection method thereof. The rotary falling type blood collection pipe conveying device comprises supporting legs, a conical barrel, a rotary execution mechanism, a falling pipe, a collecting box and a feeding device, wherein the supporting legs are used for fixing the conical barrel; the rotary execution mechanism is arranged in the conical barrel; the falling pipe is connected with the bottom of the conical barrel; the collecting box is positioned at theoutlet of the falling pipe; and the feeding device is positioned above the conical barrel. The rotary falling type blood collection pipe conveying device solves the problems of low working efficiencyand error in selection during selection of the blood collection pipes.

Owner:苏州翌恒生物科技有限公司

An intelligent device for filling ink with a gel pen

ActiveCN112046169BDeceleration achievedRealize the whereaboutsFilling devicesCircular discRotating disc

The invention relates to the technical field of stationery, and discloses an intelligent ink filling device for gel pens, comprising a main body of the ink filling device, a fixed disc is fixedly installed inside the main body of the ink filling device, and the fixed disc The inner part of the rotating disk is equipped with a rotating disc, the outer wall of the rotating disc is provided with a water outlet, the inner part of the water outlet is equipped with a rotating disc, and the inside of the rotating sphere is fixedly equipped with a baffle, and the water outlet A one-way valve is fixedly installed inside. Through the clockwise rotation of the rotating disc, the water outlet in the ink area will be preferentially connected to the water outlet. With the help of the water receiving box on the water outlet, the rotating disc, the metal stopper and the plastic deceleration lever, the ink will decelerate. The rotating disk continues to rotate, and the water outlet in the lithium-based grease area will be docked with the water outlet to realize the whereabouts of the lithium-based grease, achieving the effect of adding ink and lithium-based grease to the refill barrel in an orderly manner.

Owner:山东一枝笔文化科技有限公司

An intelligent peanut sowing equipment

ActiveCN111990022BRealize reciprocating motionRealize the whereaboutsPlantingDibble seedersSeederAgricultural engineering

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

An automatic production device for round wood rotary cutting, drying and flattening laminated boards

ActiveCN107020668BReduced physical outputFree laborMulti-purpose machinesProduction rateProduction line

The invention discloses a round wood rotary cutting, drying, planishing and panel stacking automatic production device. The device comprises a round wood rotary cutting conveying device, a veneer drying and planishing device and a panel stacking device; the round wood rotary cutting conveying device mainly has the effects of conducting rotary cutting on round wood, machining the round wood into panels in appointed size and conveying the panels to a next working process; the veneer drying and planishing device can be used for drying and planishing the panels; and the panel stacking device enables the machined panels to be stacked in order, and finally panel packaging is facilitated. According to the round wood rotary cutting, drying, planishing and panel stacking automatic production device, the working processes such as wood rotary cutting, veneer drying and panel stacking are used in a matched manner, an automatic production line operation manner is formed, labor force is liberated, the production rate is improved, and the development of economy is promoted.

Owner:江苏百事吉服饰有限公司

A feeding device for profile packaging

ActiveCN106218967BRealize the whereaboutsAvoid back-shiftingWrapping material feeding apparatusWrappingPaper sheet

The invention provides a feeding device used for sectional material packaging. The feeding device comprises a packaging paper feeding mechanism used for lifting, pulling out and shearing packaging paper and flatly laying the packaging paper on a platform, a sectional material feeding mechanism which is used for conveying a sectional material and is positioned at the middle portion of the platform where the packaging paper is laid, and a control mechanism in signal connection with the packaging paper feeding mechanism and the sectional material feeding mechanism. The packaging paper feeding mechanism comprises a paper roll lifting device used for lifting the roll type packaging paper and a paper pulling and cutting device used for pulling out and cutting the packaging paper and laying the packaging paper on the platform. The paper pulling and cutting device is arranged on the platform. The paper roll lifting device and the paper pulling and cutting device are opposite and are arranged at the front end of the platform. The sectional material feeding mechanism is arranged on one side of the platform. The feeding device used for sectional material packaging can be used for automatically feeding the packaging paper and the sectional material respectively, the problems that the efficiency is low and the labor intensity is large due to manual operation can be solved, and therefore the sectional material packaging efficiency and quality are improved.

Owner:佛山市嘉荣智能机械有限公司

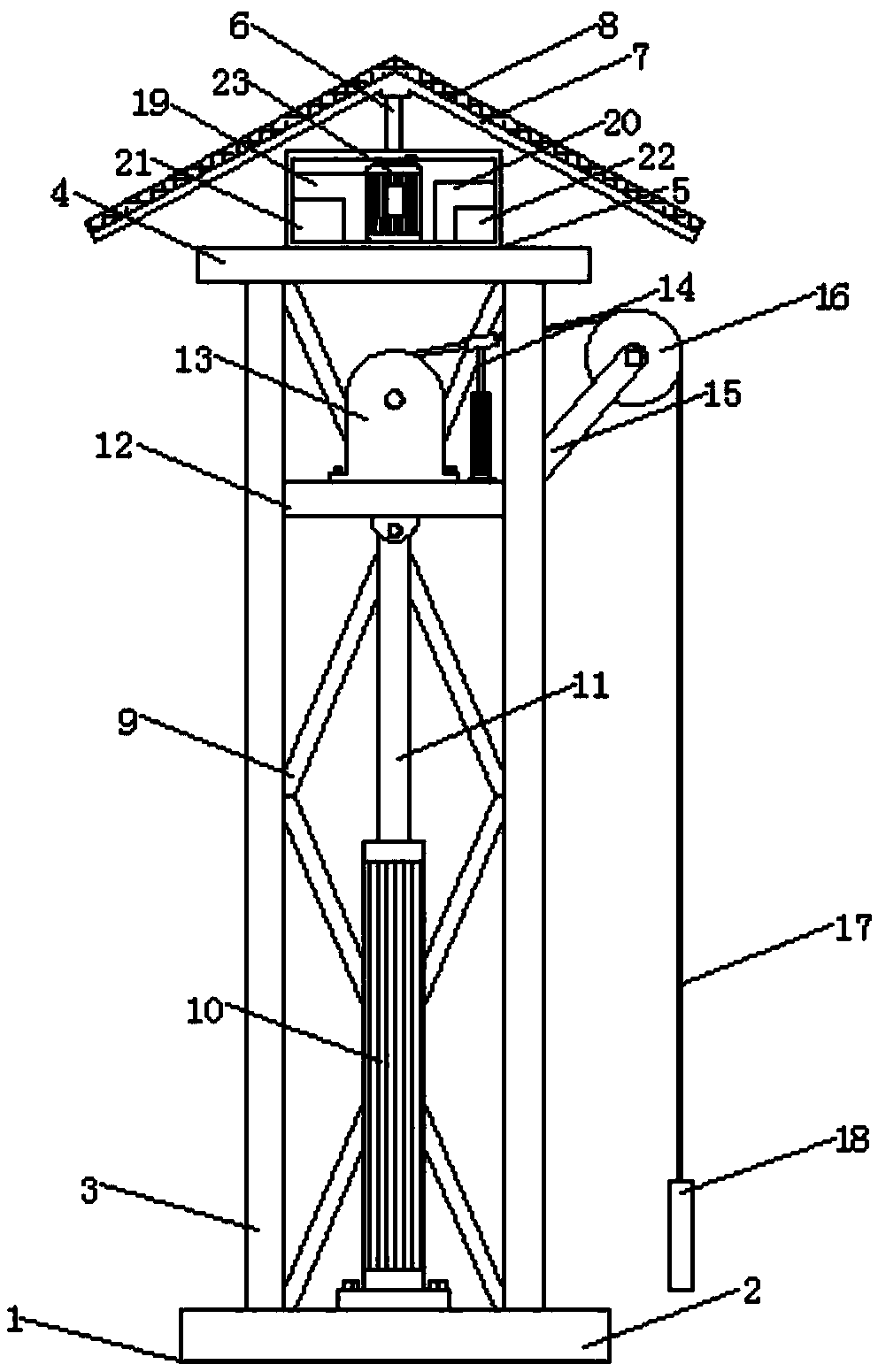

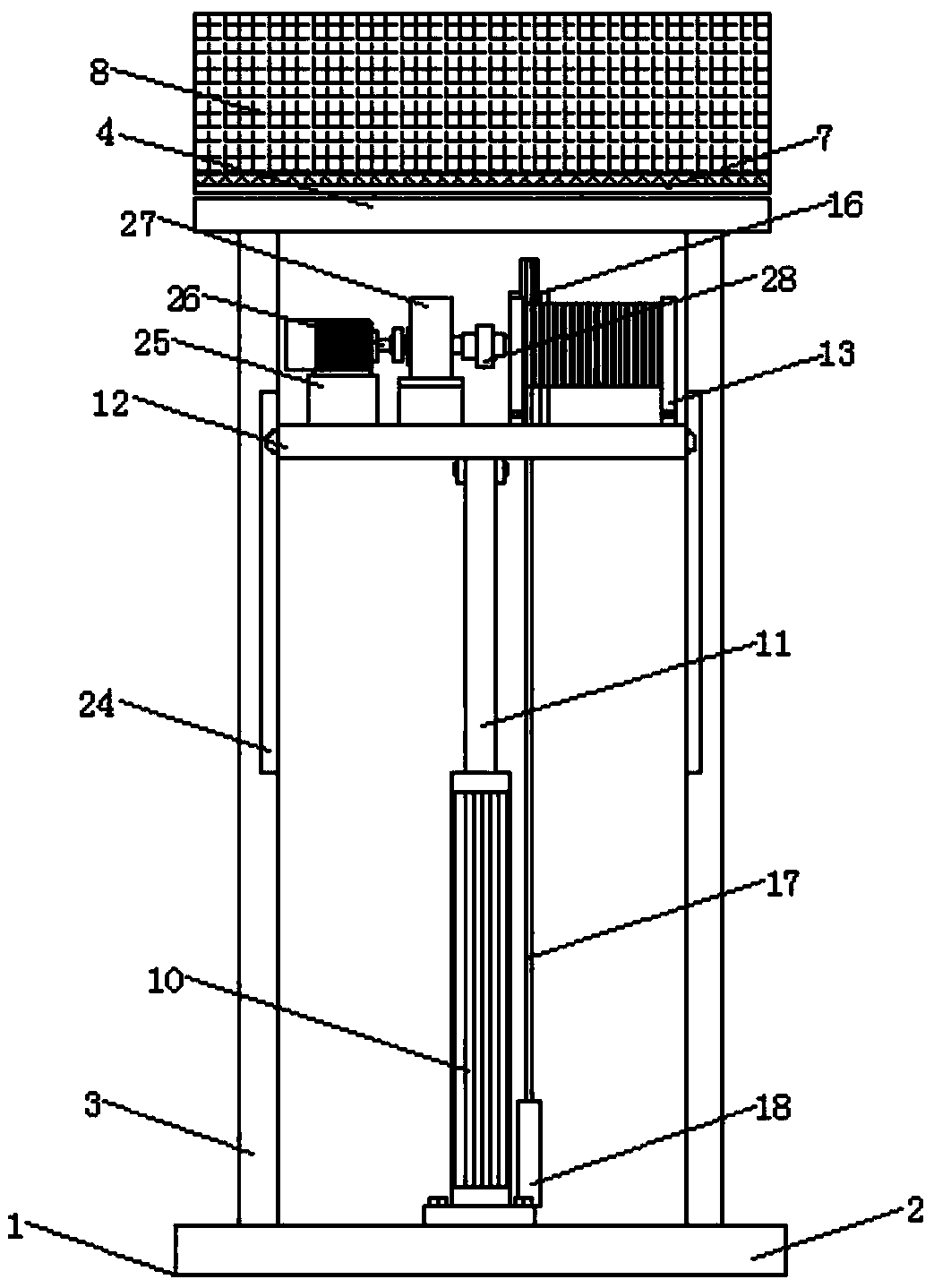

Energy saving oil pumping unit

ActiveCN108691522AImprove work efficiencySlide fastBatteries circuit arrangementsFluid removalHydraulic cylinderDrive shaft

The invention discloses an energy saving oil pumping unit, wherein the bottom of the oil pumping unit body is provided with a base; a support is installed on a top of the base; a chute is opened on atop end of the inner side of the support; a slide plate is installed inside the chute; a second Y355 electric motor is installed on one end of the top of the slide plate; a transmission shaft is fixedly connected to one end of the second Y355 electric motor; a speed reducer is installed at one end of the transmission shaft; a connecting shaft is fixedly connected to one end of the speed reducer; areel is installed at one end of the connecting shaft; a wire rope is arranged around the outer side of the reel; a sucker rod is installed at the bottom end of the wire rope, and a hydraulic cylinderis installed at the bottom of the slide plate; the top of the hydraulic cylinder is provided with a telescopic rod, and a top plate is mounted on the top of the support. The hydraulic cylinder of thepresent invention is hinged to the slide plate by a telescopic rod. The hydraulic cylinder can move the slide plate up and down through the telescopic rod, thereby realizing the change of the strokeof the pumping unit body. The operation is simple and quick, and it is convenient to freely adjust according to the needs, which expands the applicable range of the pumping unit body and improves itspracticability.

Owner:东营市东达机械制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com