Plain net welding machine

A flat screen and welding machine technology, applied in the direction of online nets, other household appliances, household appliances, etc., can solve the problem that the horizontal bars falling on the longitudinal bars are not aligned and corrected, the hooks of the net are inconvenient to pull, and the position of the longitudinal bars is misaligned, etc. problems, to achieve the effect of reducing the amount of manual labor, reducing the labor burden, and firmly stepping up the conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments.

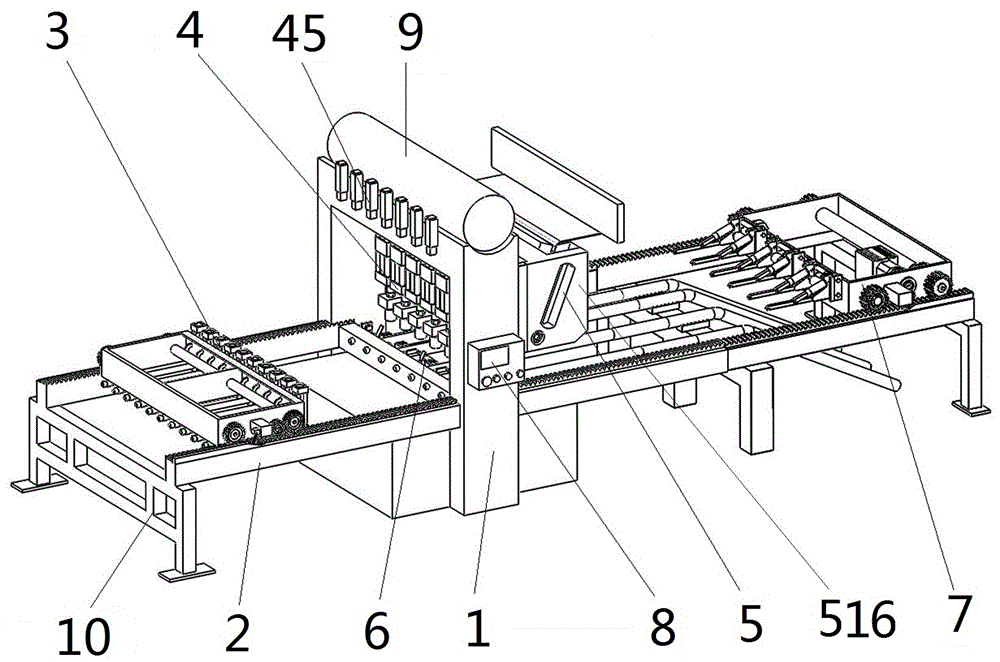

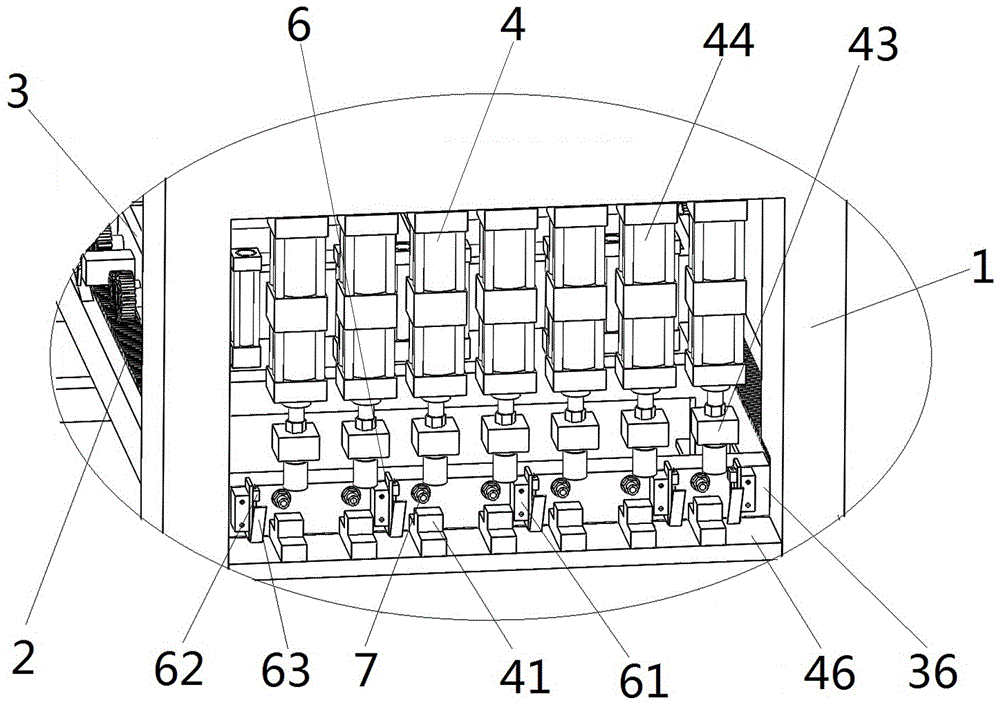

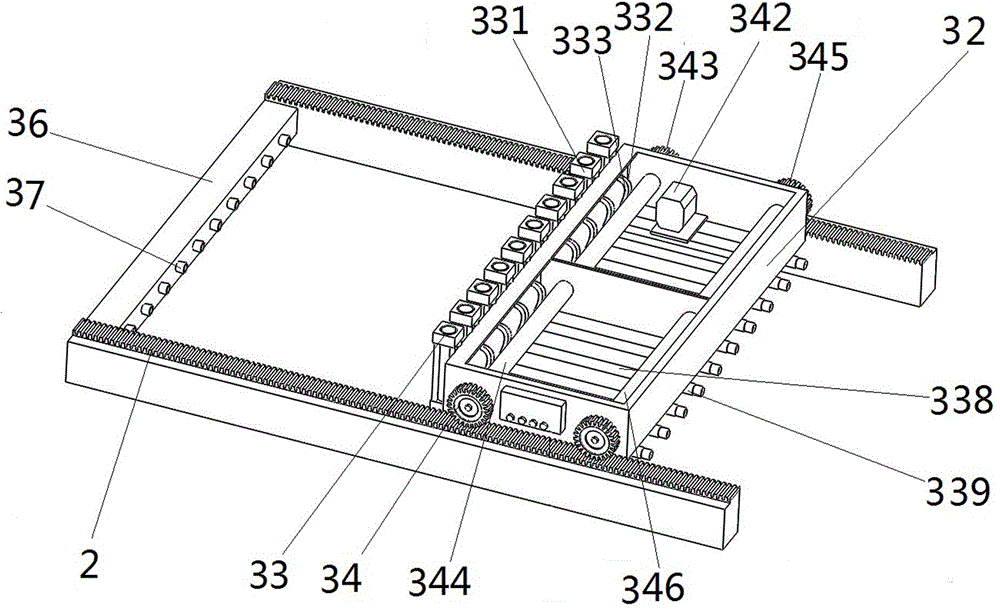

[0039] Flat screen welding machine, combined with Figure 1 to Figure 13 As shown, it includes a flat screen welding machine frame, a longitudinal bar wire feeding device 3 , a welding device 4 , a transverse bar blanking device 5 , a netting device 7 and a main controller 8 . Longitudinal bar wire feeding device 3, welding device 4, transverse bar blanking device 5 and mesh pulling device 7 are arranged on the frame of the flat screen welding machine in sequence from back to front, and the main controller 8 is also arranged on the frame of the flat screen welding machine , the main controller 8 can control the longitudinal wire feeding device 3, the welding device 4, the horizontal rib blanking device 5 and the stretching device 7 to coordinate operations. Longitudinal wire feeding device 3 is used to send longitudinal bars into welding device 4 for welding; wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com