Seeding machine for agricultural production

A kind of seeder and agricultural technology, which is applied in agriculture, application, fertilizer spreader with centrifugal wheel, etc. It can solve the problems that are not suitable for ordinary farmers, cumbersome operation process, missed seeding, etc., and achieve continuous sowing and operational flexibility High, the effect of avoiding missing broadcast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

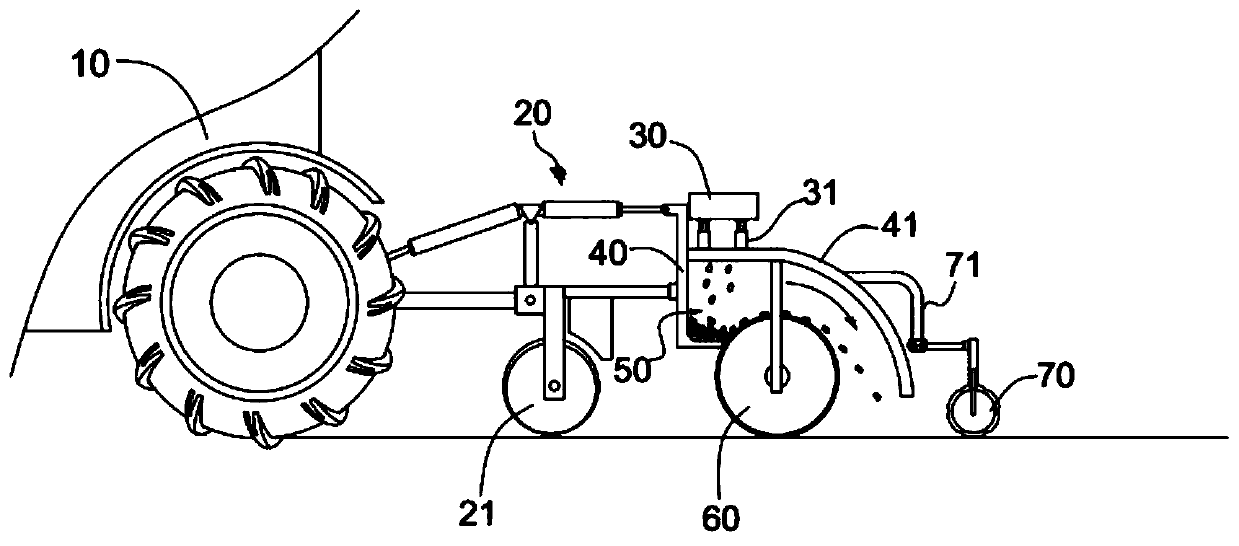

[0029] see Figure 1-5 Shown, a seeder for agricultural production, comprising:

[0030] A frame 40, the frame 40 is connected with a cover 41,

[0031] The soil turning part 70 is located at the front end of the frame 40, and the soil turning part 70 is connected with the cover body 41 through the second connecting frame 71, and

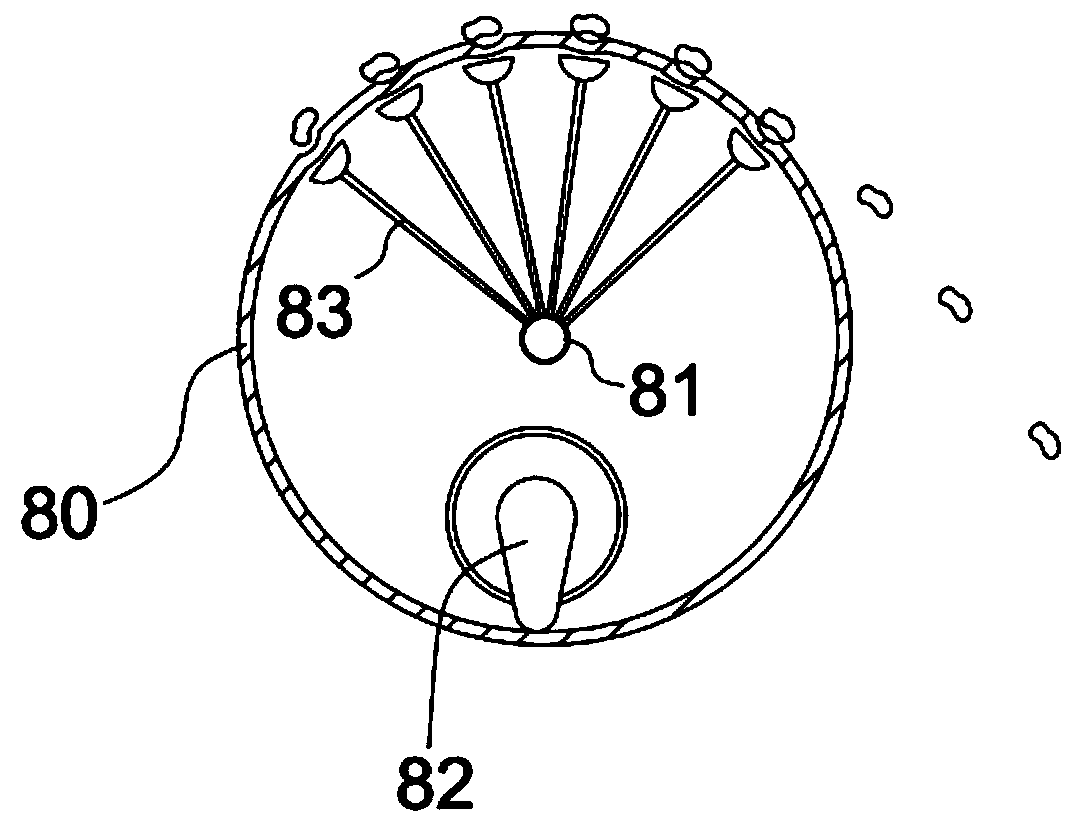

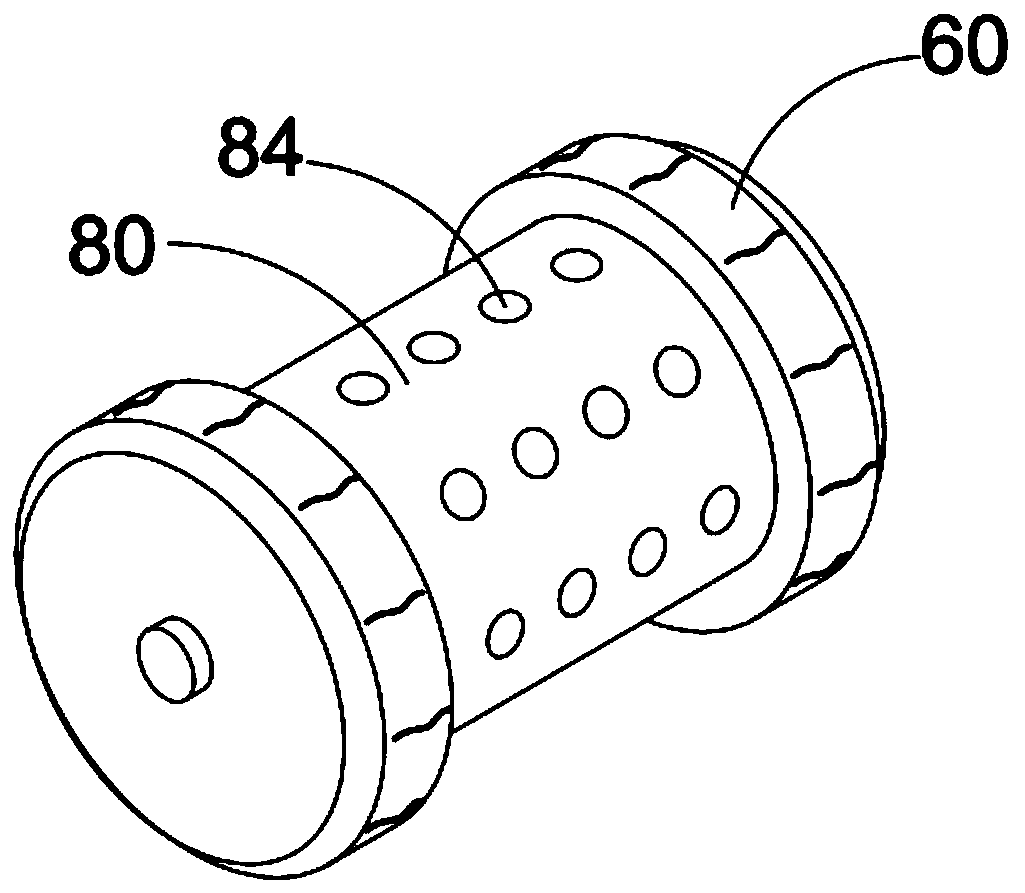

[0032] The roller 80 is arranged under the cover body 41, and coaxial rolling parts 60 are connected to both ends, and the rolling parts 60 are connected to the cover body 41 through the connecting parts.

[0033] Wherein, the frame 40 has a horizontal plate, and the cylinder 80 is adjacent to the horizontal plate to form a temporary storage space 50 for placing the sown. The distance between the surface of the cylinder 80 and the side of the horizontal plate is less than the diameter of the sown. The storage space 50 is taken away and the sown material falls to the ground.

[0034]The present invention utilizes the soil turning member 70 to turn...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is: see Figure 6 , 7 As shown, the technical solution of the drum 80 in this implementation is that there is a coaxial pipe inside, the pipe is connected with the rolling parts 60 on both sides, the surface of the pipe is surrounded by evenly distributed splints 91, and the gap between the splints 91 is used to limit the position of the seeds. , the height of the roller 80 is higher than the bottom surface and the roller 80 does not rotate with the rolling member 60 during the rolling process of the rolling member 60. During the rotating process of the rolling member 60, it drives the pipe fitting to rotate, and the pipe fitting synchronously drives the splint 92 to rotate. Fixed connection, therefore do not drive cylinder 80 to rotate, cylinder 80 has some feeding ports 93, the seeds in the temporary storage space 50 enter the feeding ports 93, cylinder 80 also has some discharging ports 92, and the discharging p...

Embodiment 3

[0046] When the seeder for agricultural production of the present invention is actually used, there are the following two modes:

[0047] The sowing material of the present embodiment is paddy seed.

[0048] Method 1: When the sowing site is small and it is inconvenient to use the driving body 10 such as a tractor, the frame 40 is pushed by manpower, and the seeds are poured into the sieving bucket 30 for sieving during the sowing process, and the sieved The seeds fall into the temporary storage space 50, and the rolling member 60 rolls to drive the drum 80 to roll, and the drum 80 drives the seeds in the temporary storage space 50 to rotate clockwise and fall into the sowing ditch that the soil turning part 70 has turned over in the front. 40. During the moving process, the bulldozing part 21 is driven to roll forward with the driving force to realize bulldozing and to cover the seed in the soil.

[0049] Method 2: When the sowing field is relatively large, the driving body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com