A feeding device for profile packaging

A technology for feeding equipment and profiles, which is applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of high labor intensity and low efficiency, achieve low efficiency, improve efficiency and quality, and solve labor intensive problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

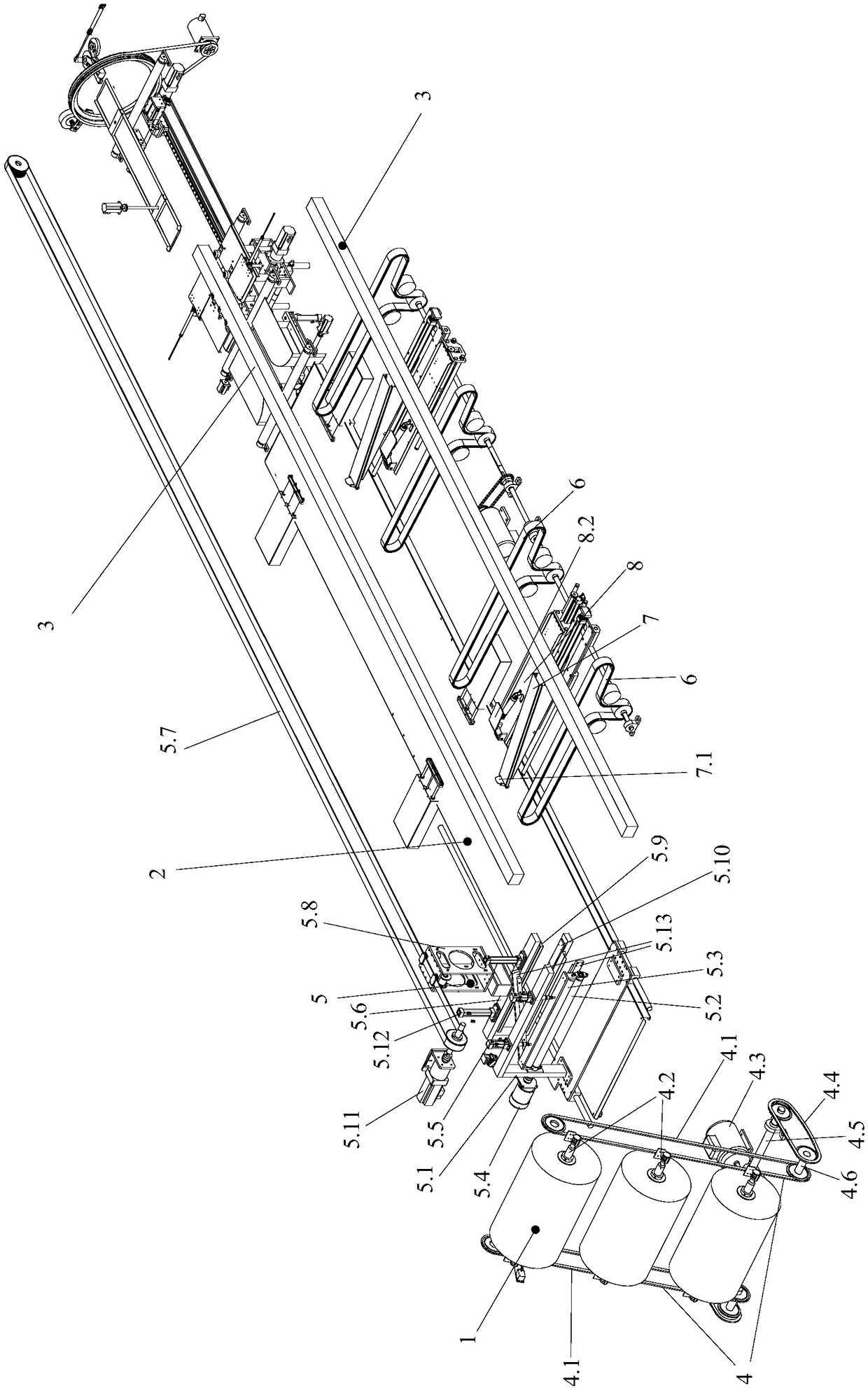

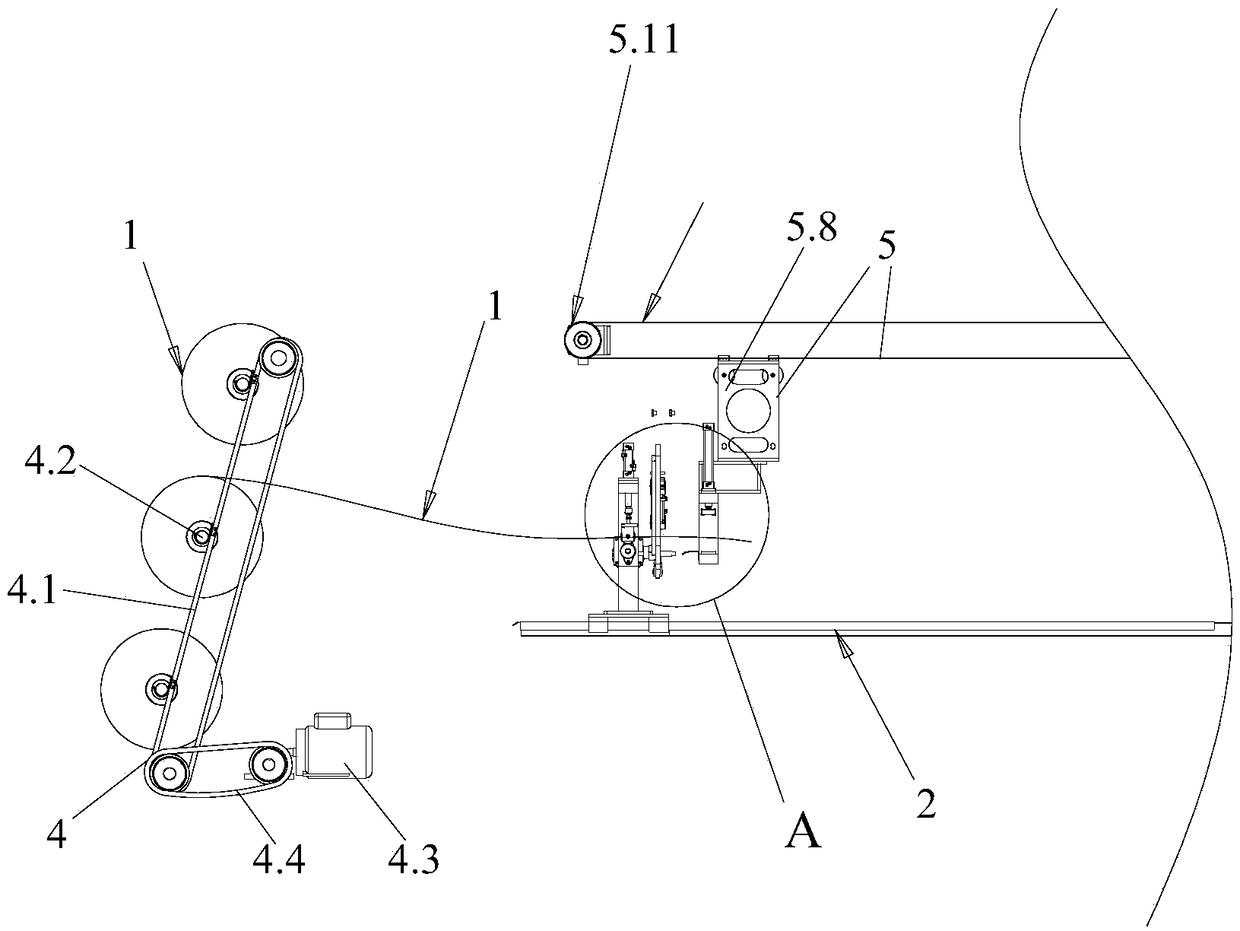

[0032] Such as Figure 1 to Figure 4 Shown, the present invention is used for the feeding equipment of profile packing, comprises:

[0033] A wrapping paper feeding mechanism for lifting, pulling out and cutting the wrapping paper 1 on the platform 2;

[0034] A profile feeding mechanism for transferring and positioning the profile 3 in the middle of the platform 2 on which the wrapping paper 1 is laid;

[0035] And the control mechanism respectively connected with the signals of the wrapping paper feeding mechanism and the profile feeding mechanism;

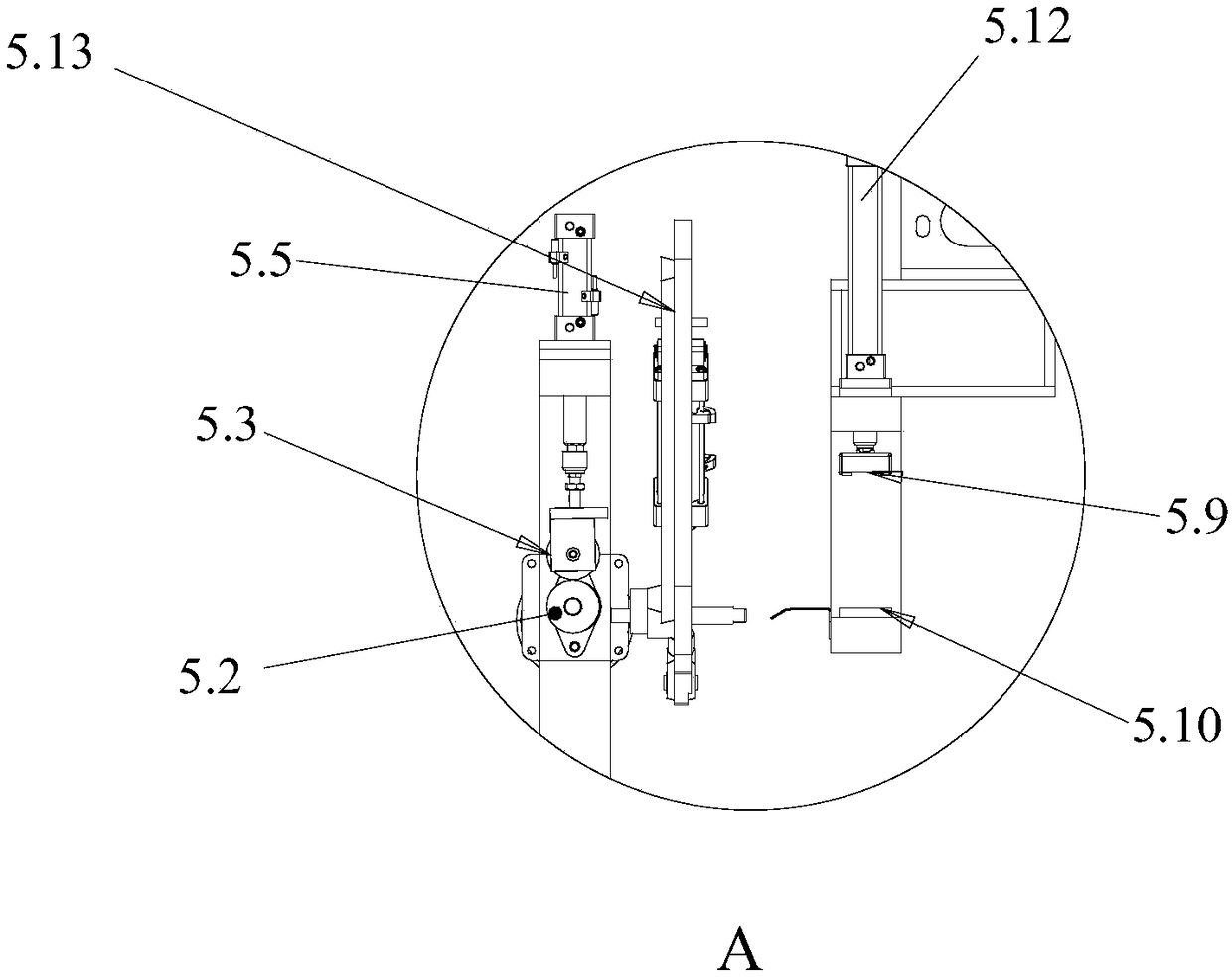

[0036] Wherein, the wrapping paper feeding mechanism includes a paper roll lifting device 4 for lifting the roll wrapping paper 1, and a paper cutting device 5 for pulling out, cutting and laying the wrapping paper 1 on the platform 2, The pull-cut paper device 5 is arranged on the platform 2, and the paper roll lifting device 4 is opposite to the pull-cut paper device 5 and is arranged on the front end of the platform 2;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com