High-temperature melt granulation smelting furnace

A system and furnace technology, applied in the field of furnaces, can solve the problems of dripping of molten particles and wear and tear of graphite crucibles, and achieve the effect of preventing rapid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

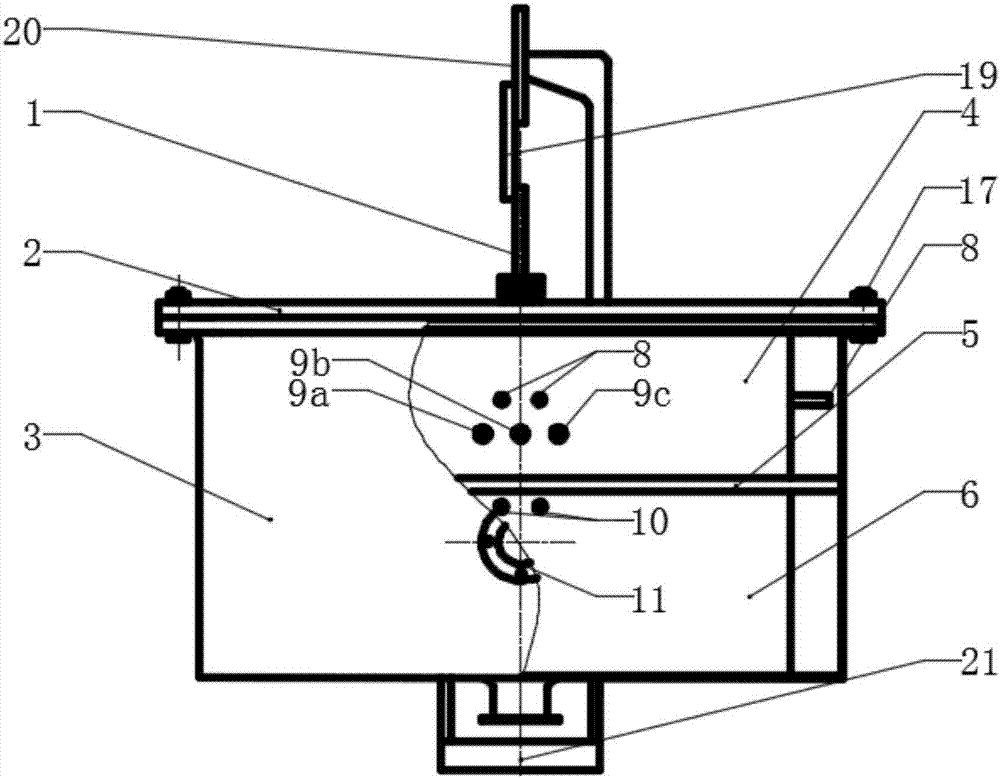

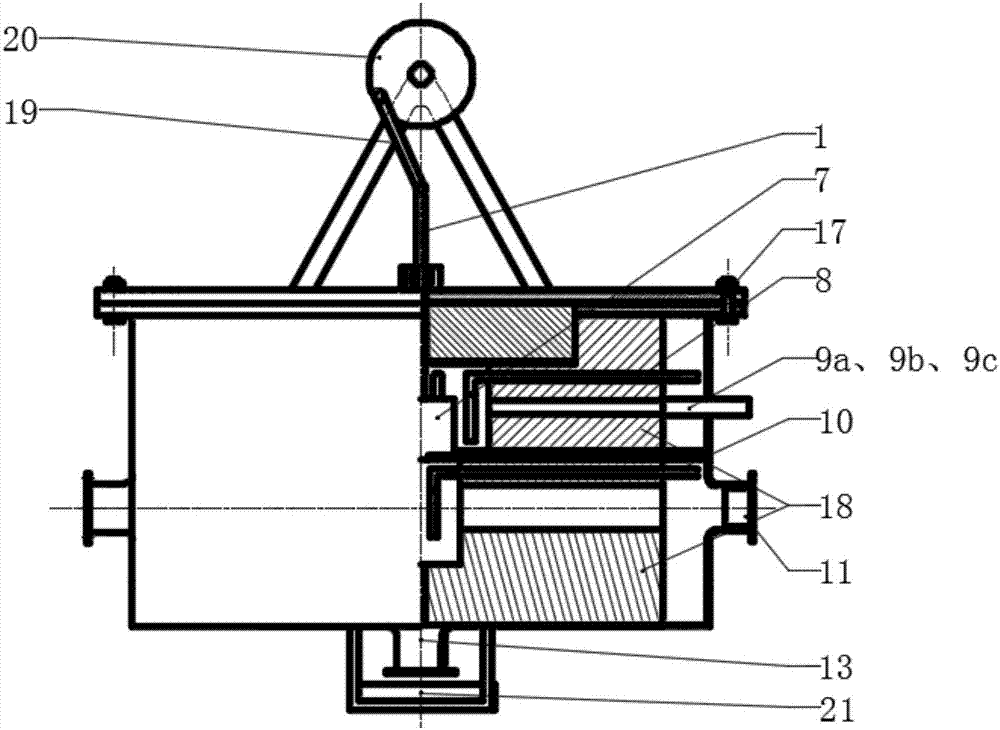

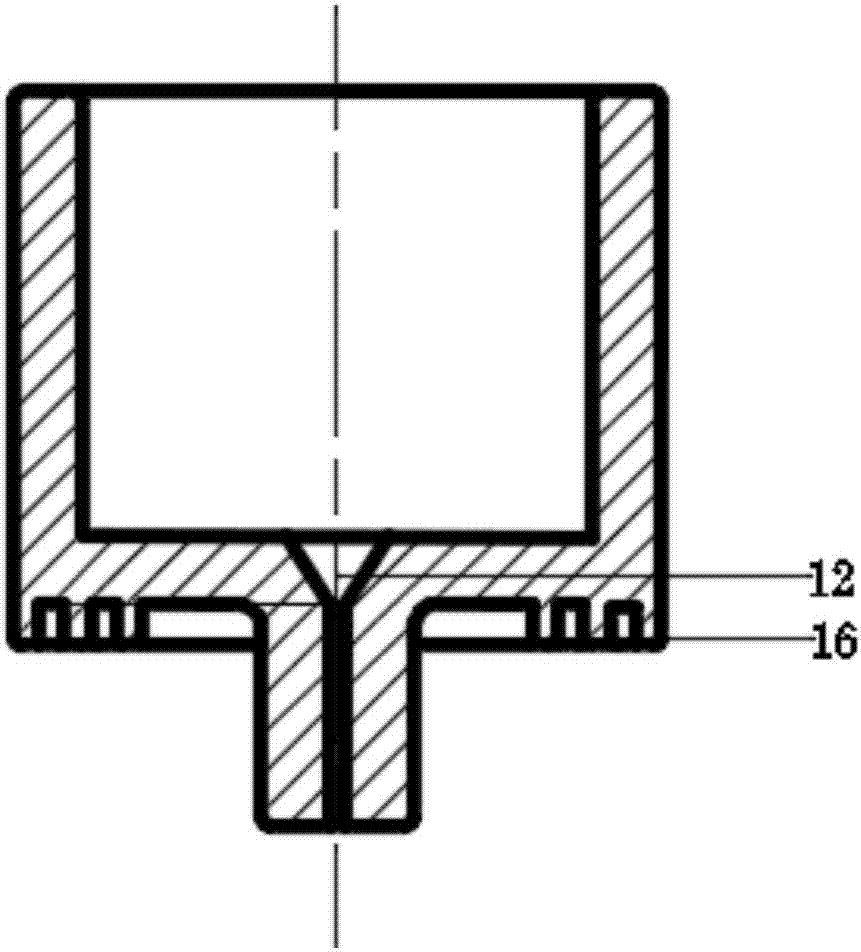

[0014] A high-temperature melt granulation melting furnace, the melting furnace includes a metal shell 3, the metal shell 3 is sealed by the heating furnace closure cover 2; the metal shell 3 is provided with a partition 5, and the partition 5 divides the interior of the metal shell 3 into upper Box 4 and lower box 6, the partition 5 is provided with a central through hole, the crucible 7 is placed on the partition 5, the bottom of the crucible 7 is funnel-shaped and is provided with a leakage hole 12, the bottom of the crucible 7 passes through The central through hole is inserted into the lower box body 6; a heat insulation layer 18 is provided between the outer wall of the crucible 7 and the inner wall of the metal shell 3; 12 corresponds to; a safety device 21 is provided below the discharge opening 13, and the safety device 21 can be arranged in a drawer shape; a via hole is provided on the closing cover 2 of the heating furnace, and one end of the lifting rod 1 is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com