Multifunction downhole bottom ripping machine

An undercover machine and multi-functional technology, applied in underground transportation, underground mining, mechanically driven excavators/dredgers, etc., can solve the problems of high labor intensity, high hidden dangers of operation safety, low efficiency and other problems, and achieve safe and convenient movement and handling, large transmission torque and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

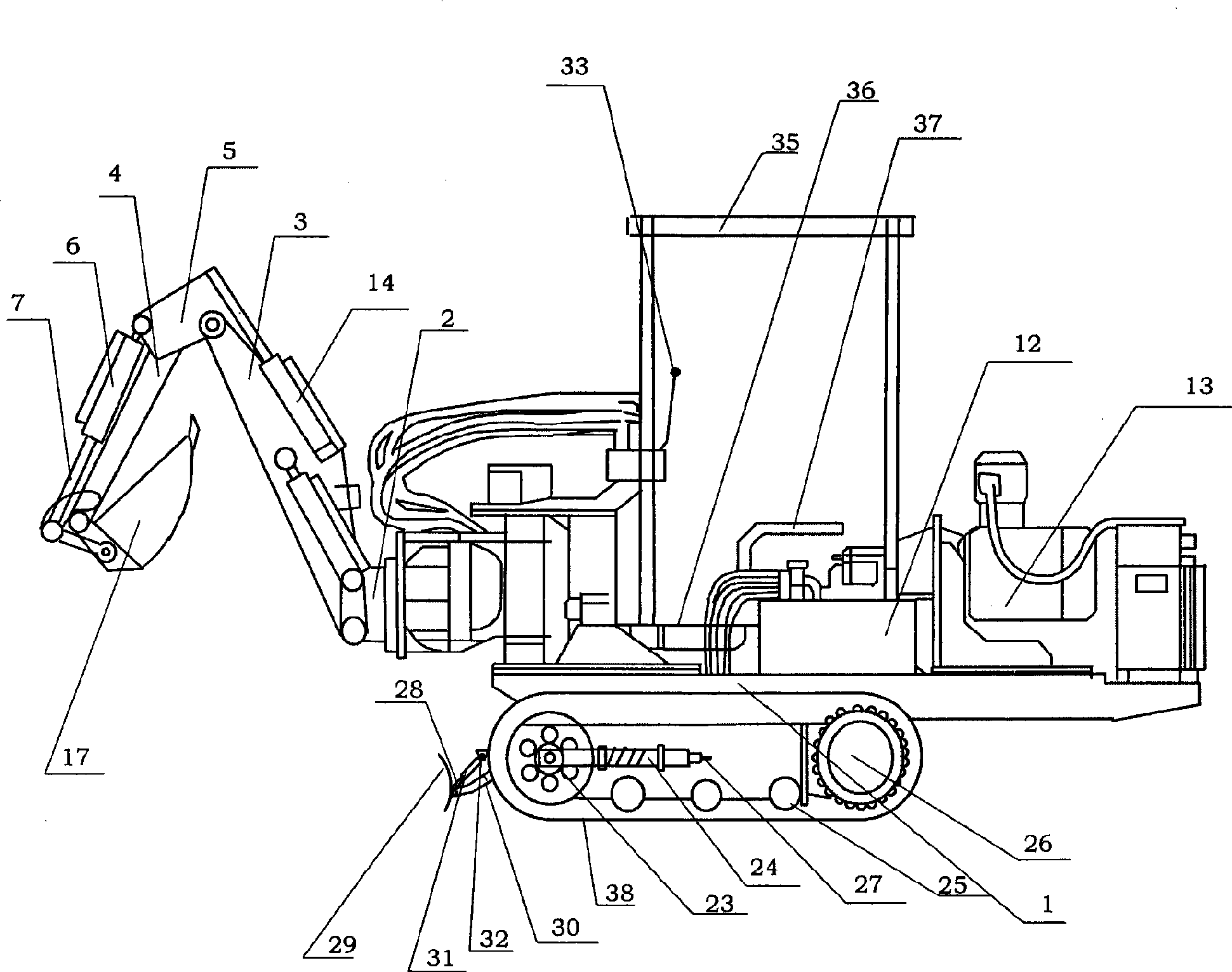

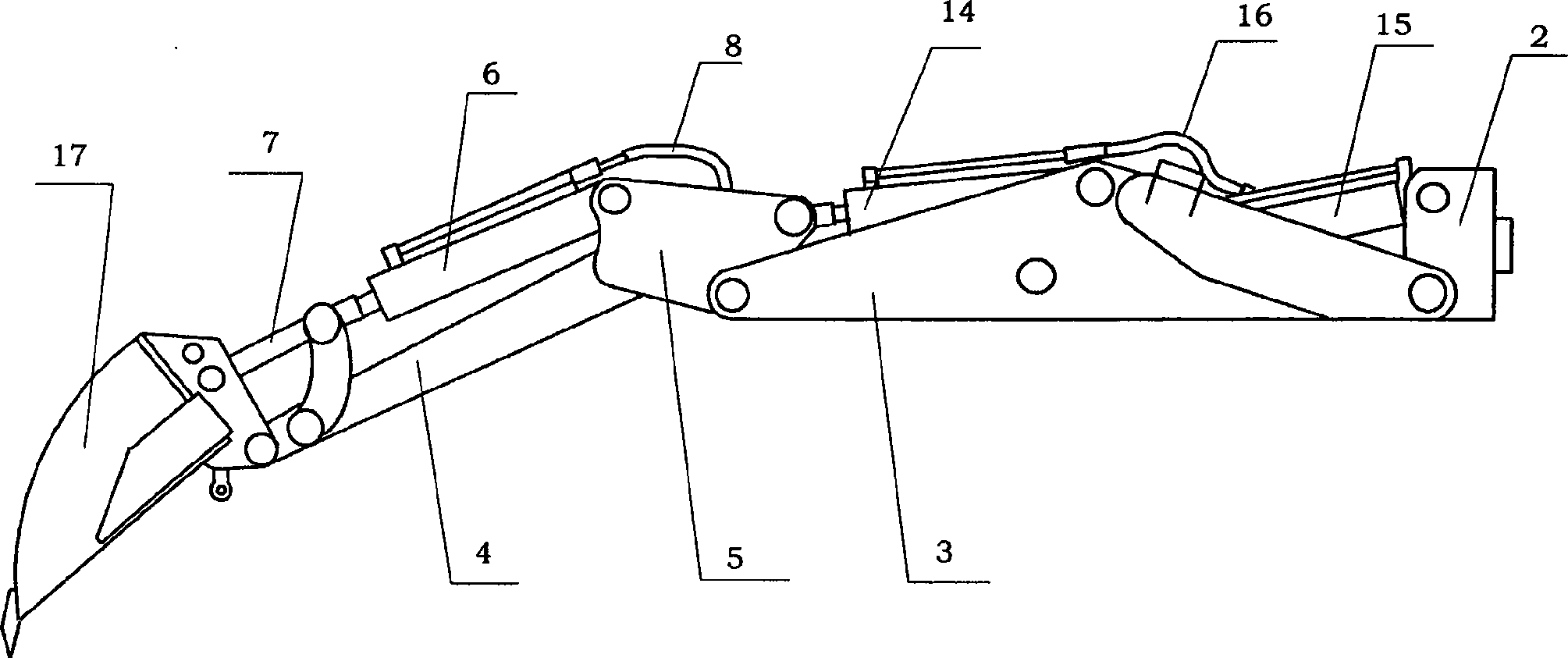

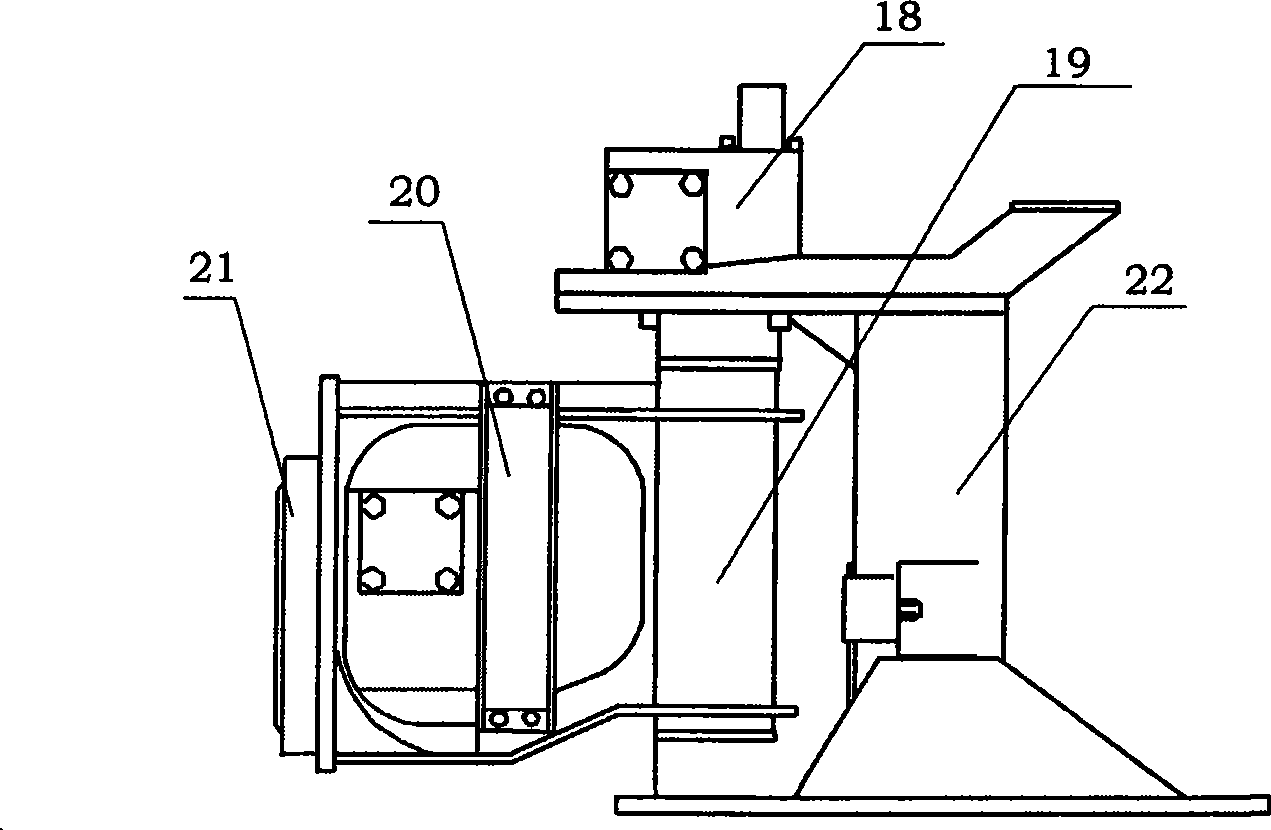

[0012] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the present invention is A multifunctional underground undercover machine, which includes a car body part and an actuator, and the car body part includes a workbench and a driving device 1 , walking gear and fuel tank 12, the top of fuel tank is provided with air filter and oil return pipe 11 and is connected, is provided with ceiling 35, step plate 36 and bottom stool 37 on the workbench, and walking gear is proposed to have assembled steel track 22, in The assembled steel crawler 22 is provided with a guide wheel 23, a tension cylinder 24, a support wheel 25, a travel motor 26, a guide wheel 23, and a tension cylinder 24 from front to back. One end of the tension cylinder 24 is connected to the guide wheel 23 connection, the other end is provided with an oil filling check valve 27, the driving device 13 is connected to the traveling device as a transmission, the worktable is connected to the traveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com