Storage device for full-biodegradable film storage

A technology of storage device and degradable film, which is applied in biological packaging, packaging, transportation and packaging, etc., can solve the problems of many manual intervention steps and dust entering the box, and achieve the effect of reducing manual intervention and realizing buffer protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

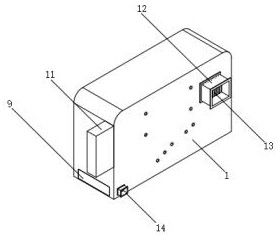

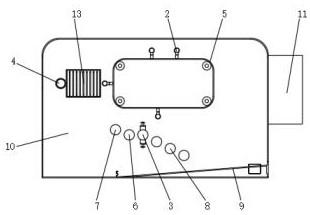

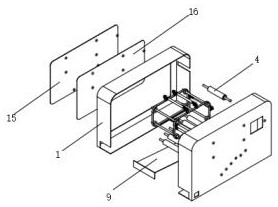

[0036] Such as figure 1 , 2 , 3, 4, 7, and 8, a storage device for full biodegradable film storage, including a casing 1, a moisture absorption roller 4 and a control box 11, the upper part of the inner cavity side of the casing 1 is provided with a moisture absorption roller 4 , the upper part of the other side of the outer wall of the box body 1 is provided with a control box 11;

[0037] There is a transmission belt 5 in the middle of the inner cavity of the box body 1, and a plurality of winding devices 2 are provided on the upper end of the transmission belt 5. The winding devices 2 accommodate fully biodegradable films, and the side of the lower end of the transmission belt 5 is for material falling In the lower part of the drive belt 5, there is a buffer receiving device 3, a second receiving roller 6, a blocking roller 7 and a stepped roller 8, and the buffer receiving device 3, the second receiving roller 6 and the blocking roller 7 are facing the transmission belt 5...

Embodiment 2

[0041] Such as figure 1 , 2 , 3, 4, and 5, wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference is that the winding device 2 includes a sliding block 201, a support frame 202, a linear drive 203, a stepper motor 204, a connecting head 205, a rubber pad 206 and a reel 207, and each transmission belt 5 is connected with a sliding Block 201, the upper end of sliding block 201 is provided with support frame 202, and wherein a support frame 202 frame is provided with linear drive 203, and the end of linear drive 203 is provided with a group of connecting head 205 and rubber pad 206, and another support frame 202 frame A stepping motor 204 is provided inside, and the end of the stepping motor 204 is provided with another set of connectors 205 and rubber pads 206, and a reel 207 is clamped between the...

Embodiment 3

[0044] Such as figure 2 , 6 , 7, 8, and 9, wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of brevity, only the differences from Embodiment 1 will be described below. The difference is that the buffer receiving device 3 includes a first receiving roller 301, a socket 302, a U-shaped frame 303, a waist hole 304, a movable rod 305, a retaining plate 306, a first return spring 307 and a second return spring 308 , the front and rear sides of the cabin of the processing warehouse 10 are provided with a U-shaped frame 303, and the end surface of the U-shaped frame 303 is provided with a waist hole 304, and the two waist holes 304 are inserted with a first receiving roller 301, and the two ends of the first receiving roller 301 The round rod is provided with a jack 302, the jack 302 is inserted with a movable rod 305, the movable rod 305 runs through the U-shaped frame 303 and is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com