Energy-saving durable dewatering and drying centrifuge

A centrifuge and durable technology, applied in the field of centrifuges, can solve the problems of long spindle, heavy weight and large yaw, and achieve the effects of improving production efficiency, improving service life and reducing yaw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

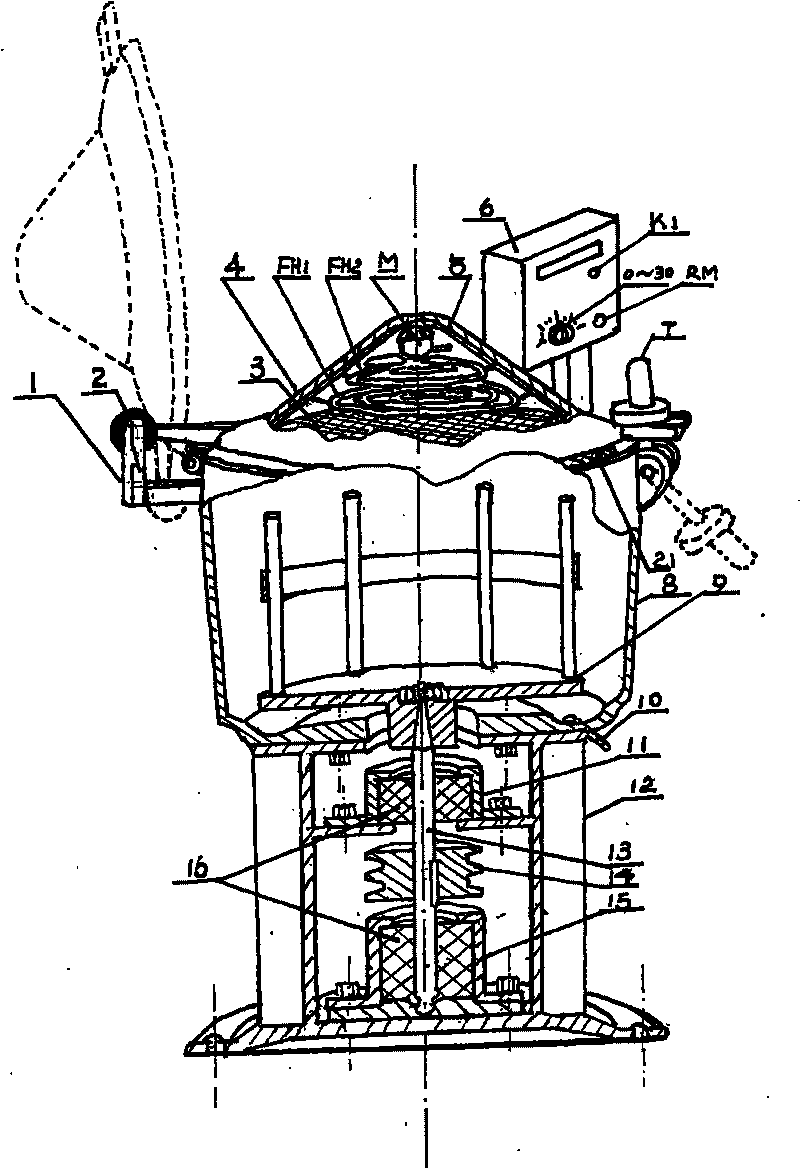

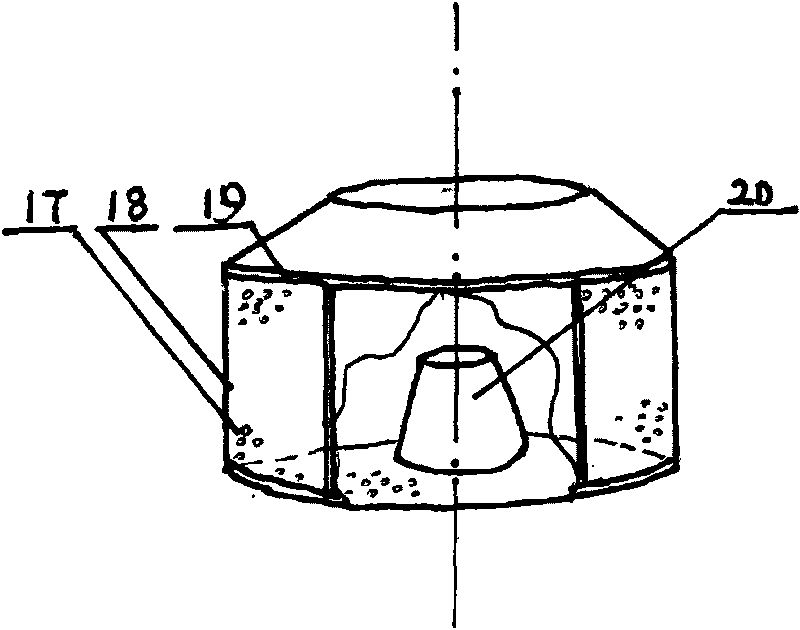

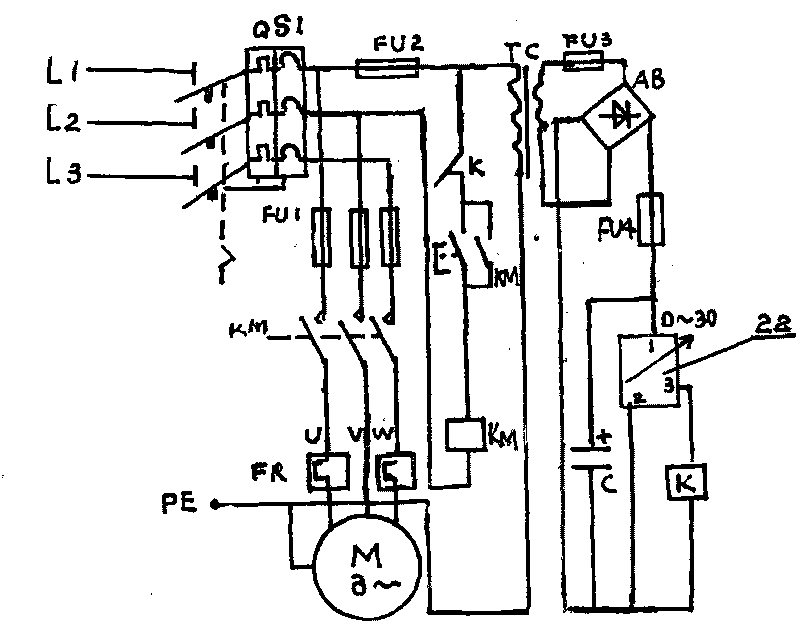

[0011] Referring to the figure, in the energy-saving and durable dewatering and drying centrifuge of the present invention, the main shaft (13) in the middle of the lower support (12) of the centrifuge is made of high-carbon rubber rings (16) fixed in the upper and lower stable seats (11, 15). Bearing sleeve, the upper end of the main shaft passes through the upper seat dewatering and drying bucket (8) and is connected and fixed with the stainless steel plate (9) containing the stainless steel parts dewatering basket (18). , The centrifuge cover (4) on the dehydration and drying bucket is equipped with a far-infrared tapered reflector rapid heat heating device. The power supply switch of the heating device is completed by the contacts in the reed switch (1) that are not corroded. The permanent magnet (2) installed in the rotating part behind the opening and closing of the centrifuge cover controls the connection and disconnection of the contacts in the reed switch. When the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com