Forest fruit hard branch grafting seedling beveling testing device

A technology of hard branch grafting and test equipment, which is applied in the field of agricultural machinery, can solve the problems of low versatility, failure to meet test requirements, and overall low level of cutting surface, and achieve good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

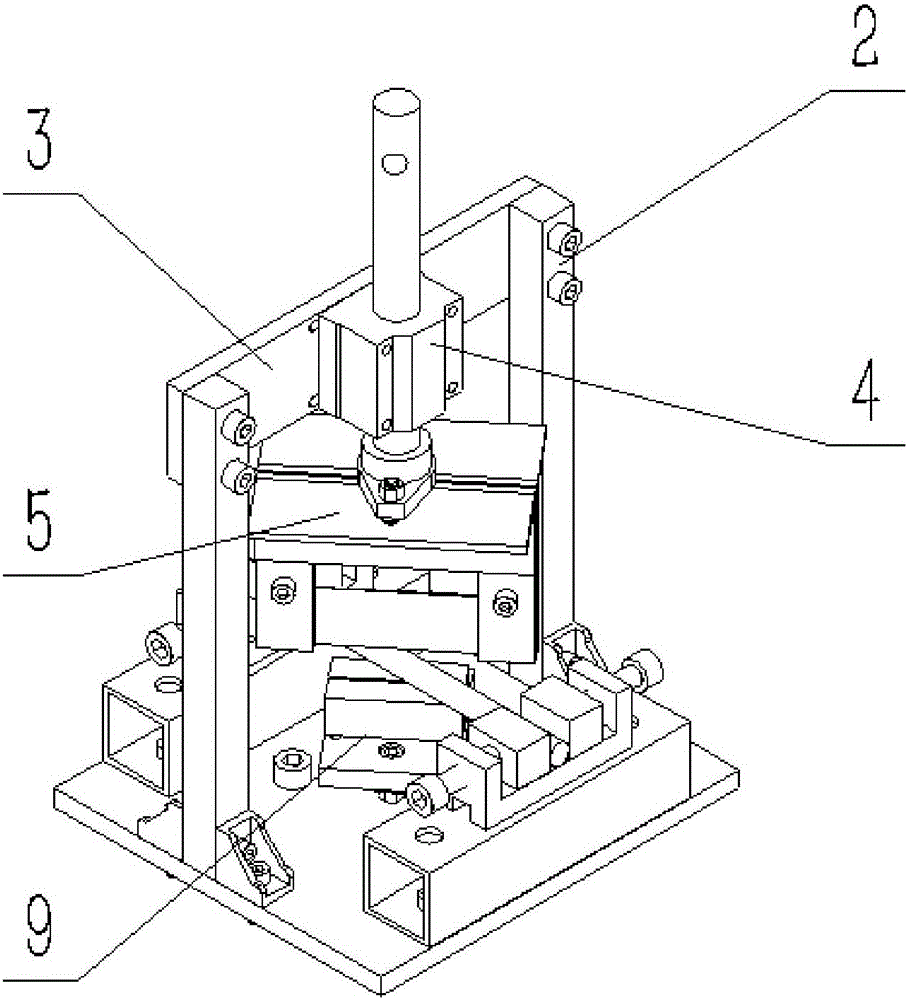

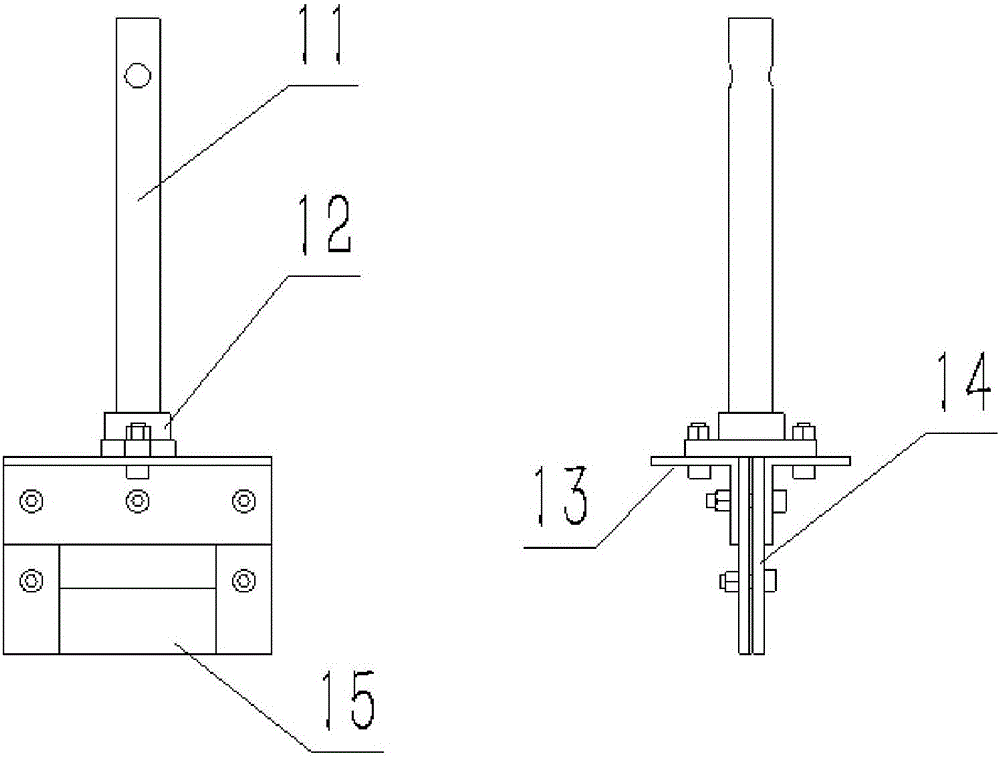

[0030] The present invention is based on following idea: (1) can be installed on the universal material testing machine conveniently, utilize its test system to control and monitor the size of cutting force and cutting speed; (3) The size and position of the gap formed between the left and right seedling support sliders can be adjusted to prevent the overall low level of cutting surface; (5) can also be adjusted Other seedlings with harder materials were subjected to cutting tests.

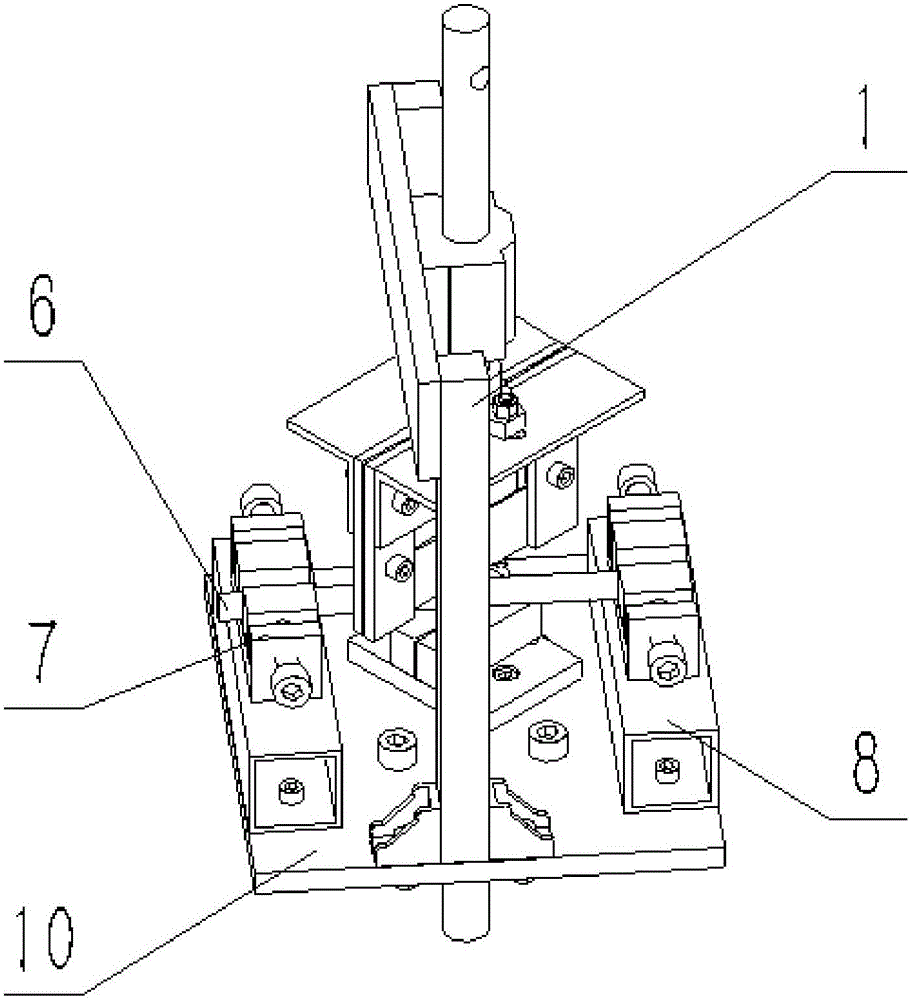

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a test device for oblique cutting of seedlings grafted with hard branches of forest fruits includes a frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com