3D color printer capable of monitoring product quality online

A color printer and product quality technology, applied in the direction of additive processing, etc., can solve the problems of single printing color, easy deformation of the model, and inability to monitor the quality of the printed matter online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

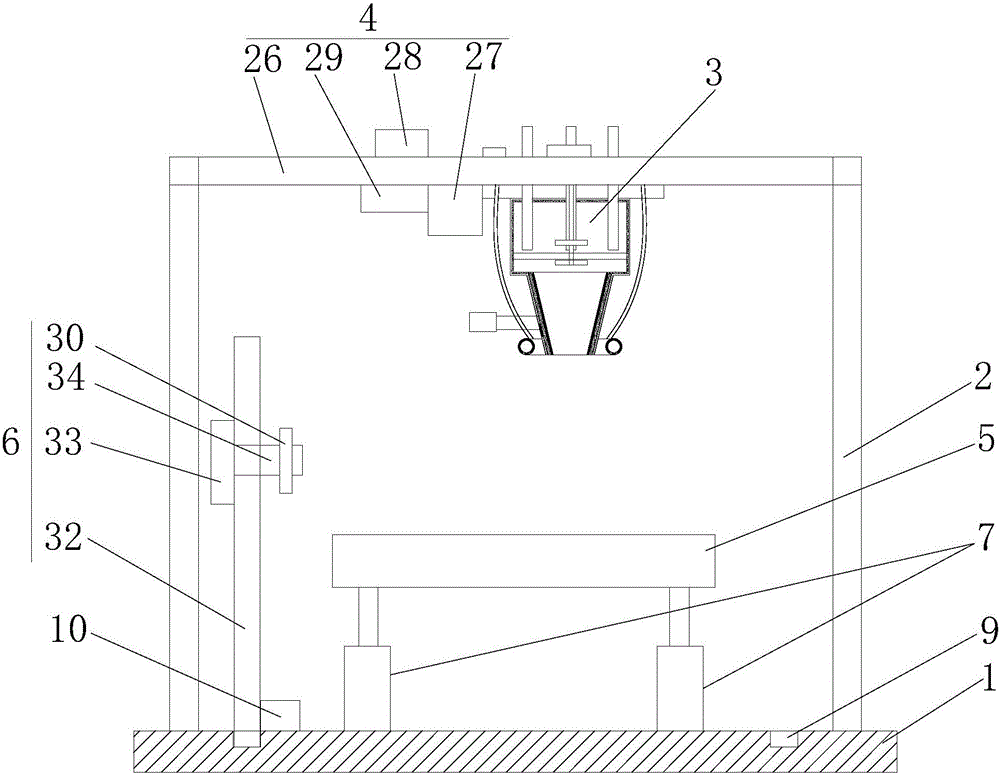

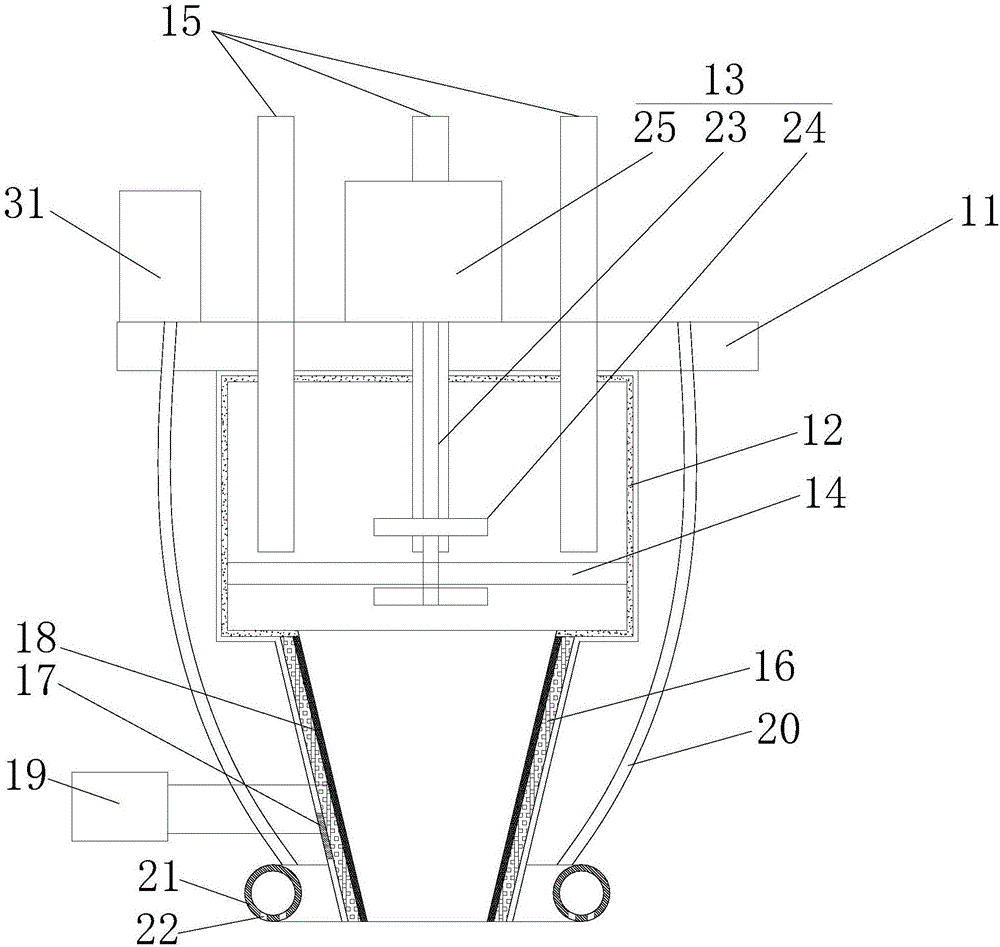

[0020] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a 3D color printer that can monitor product quality online; figure 2 It is a structural schematic diagram of a printing head in a 3D color printer that can monitor product quality online proposed by the present invention.

[0021] refer to figure 1 , a kind of 3D color printer that can monitor product quality on-line that the present invention proposes, comprises base 1, column 2, printing nozzle 3, printing traveling mechanism 4, workbench 5, scanning device 6 and control processor;

[0022] The column 2 is set on the base 1, and the printing running mechanism 4 is set on the top of the column 2. The printing running mechanism 4 is connected with the printing nozzle 3, and drives the printing nozzle 3 to move in the XY plane. The printing running mechanism 4 includes a support beam 26, a sliding beam 27. The third driving mechanism 28 and the fourth driving mechanism 29, the supporting beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com