Self-inspection plastic mould for producing wood-plastic co-extrusion house roof plate

A technology for plastic molds and roof slabs, which is applied in the field of self-inspection plastic molds, can solve problems such as undetectable deformation, decreased product precision, and low service life, and achieve the effects of improving self-inspection performance, maintaining product accuracy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

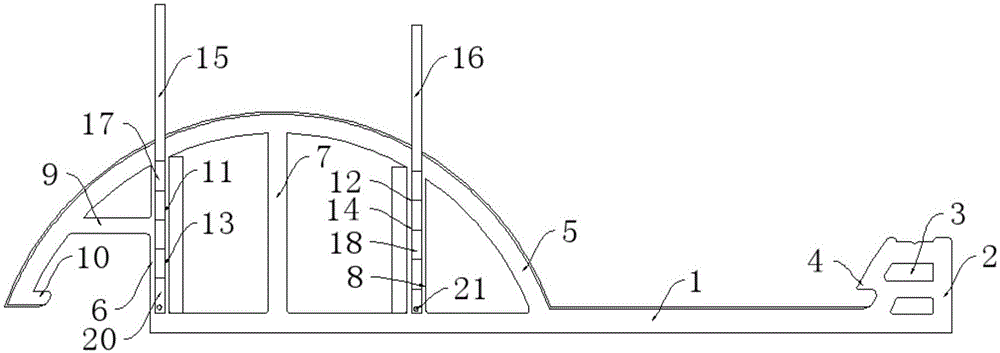

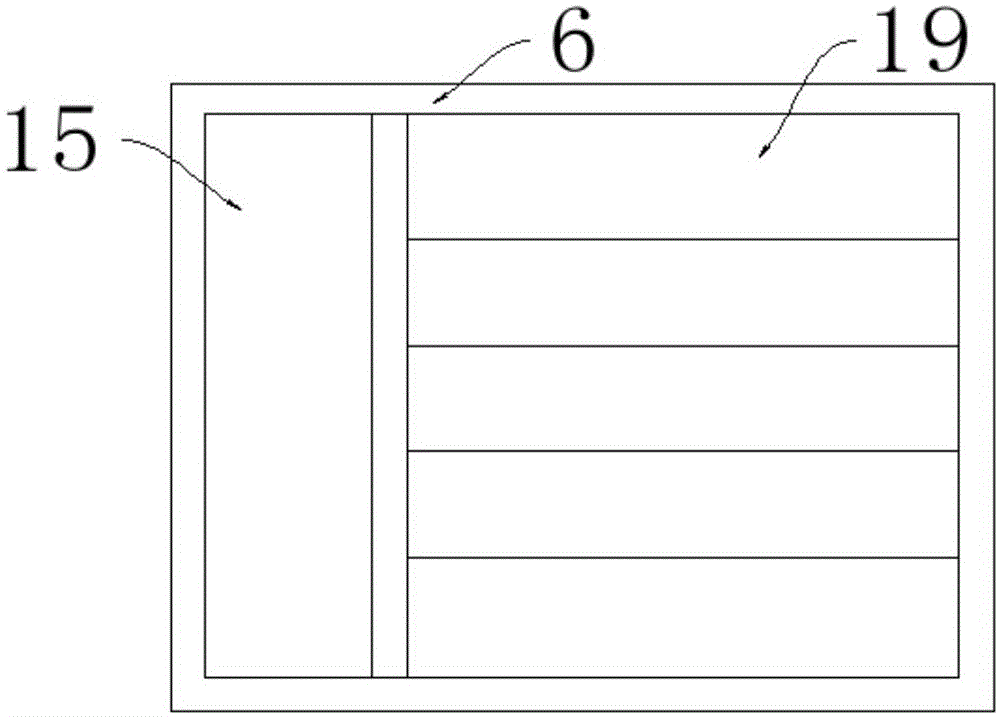

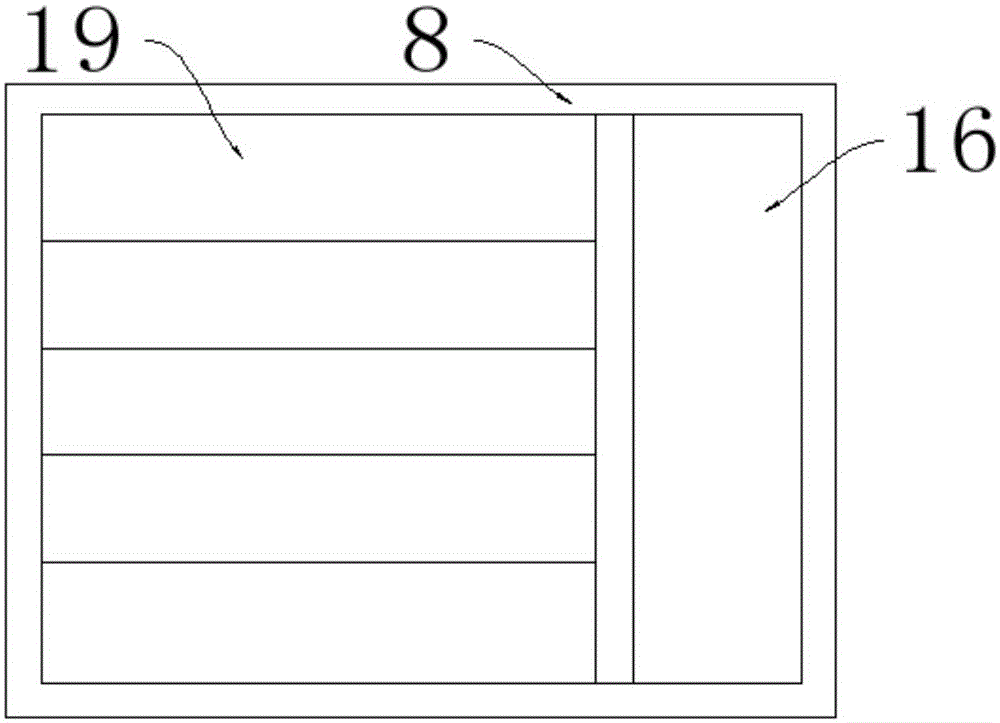

[0014] The present invention will now be described in further detail with reference to the drawings. These drawings are simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0015] figure 1 , figure 2 with image 3 A self-checking plastic mold for the production of wood-plastic extruded roof slabs is shown, comprising a bottom main template 1, the upper surface of the bottom main template 1 has an upwardly protruding right assembly mechanism 2, and a right assembly mechanism 2. There are two right weight-reducing holes 3 for lowering the weight of the plastic mold. The right assembly mechanism 2 has a left assembly hook 4 on the left side. The upper surface of the bottom main template 1 has an upwardly convex arc cover on the left side. 5. A first support plate 6, a second support plate 7 and a third support plate 8 are provided between the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com