Gasket combined nut press-fitting equipment

A technology for combining nuts and washers, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of looseness and falling off, the washer is crushed, and the washer cannot be rotated freely, so as to achieve high versatility, low production cost, and improved The effect on labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

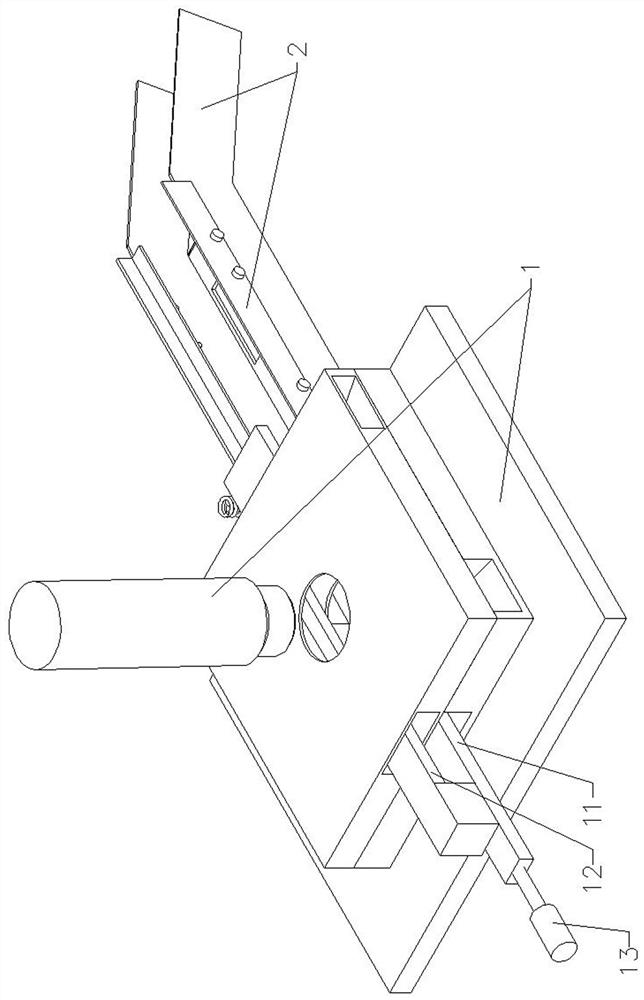

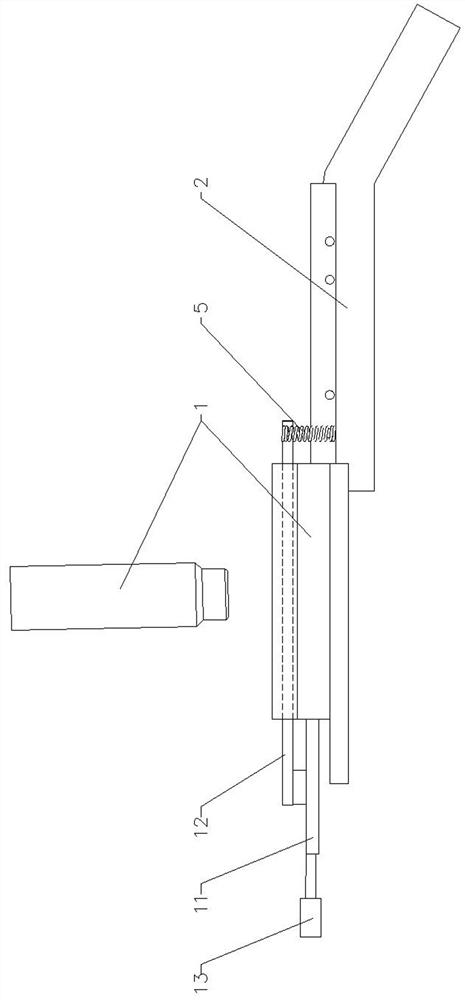

[0017] Such as figure 1 , figure 2 with image 3 As shown, a washer combined nut press-fitting equipment includes a press-fitting machine 1 and a blanking slideway 2, the feed end of the blanking slideway is connected with the discharge end of the press-packing machine, and the sliding cavity of the blanking slideway is used to guide the workpiece The nut part 3 of the blanking chute is used to guide the washer part 4 of the workpiece on the upper sliding cavity of the blanking chute, and the intermittent vibration part 5 is provided on the blanking chute, and the workpiece on the blanking chute relies on its own weight for self-inspection during the vibration process;

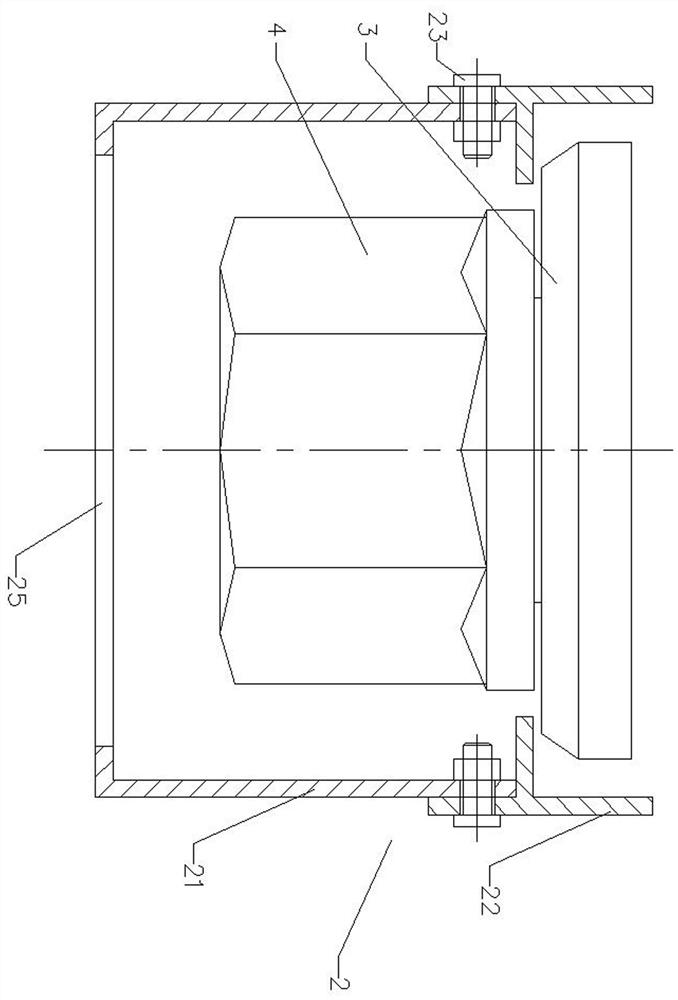

[0018] Such as image 3 with Figure 4 As shown, the blanking slideway 2 is composed of a slideway 21 and an upper slideway 22, and the upper slideway is detachably fixed on the connecting end of the slideway; according to the width and depth of the product, a split structure is adopted to facilitate Adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com