Heap construction process for fine particle industrial solid waste and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Heap leaching of low-grade sulfide ore in Yulong, Tibet

[0044] The low-grade sulfide ore used in this example comes from the Yulong Copper Mine in Tibet, and the particle size of most of the ore is less than 10mm.

[0045] The low-grade sulfide ore of this embodiment is processed by using the heaping process of fine particle industrial solid waste of the present invention, which specifically includes the following steps:

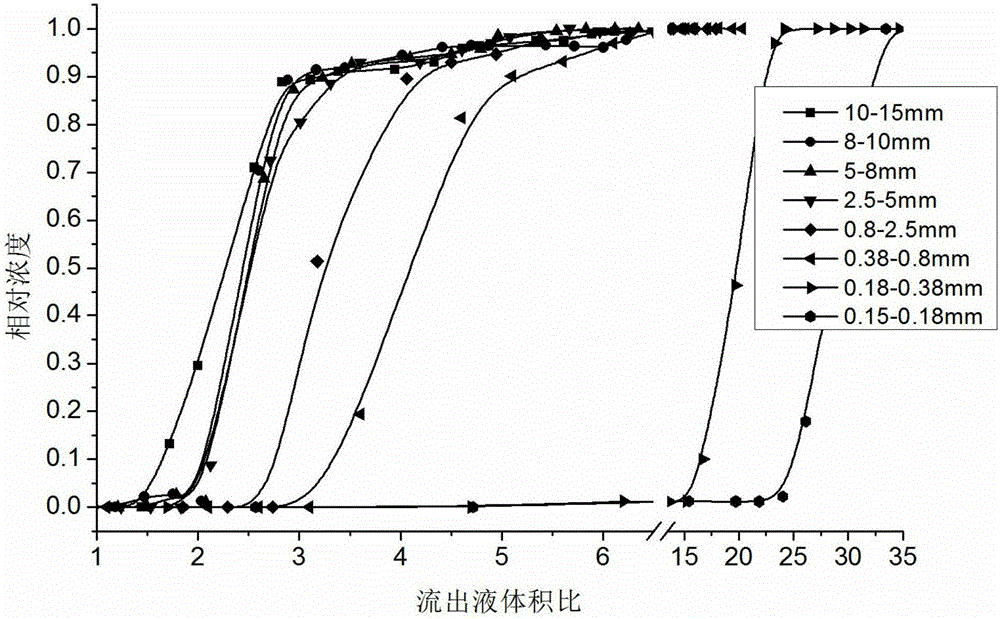

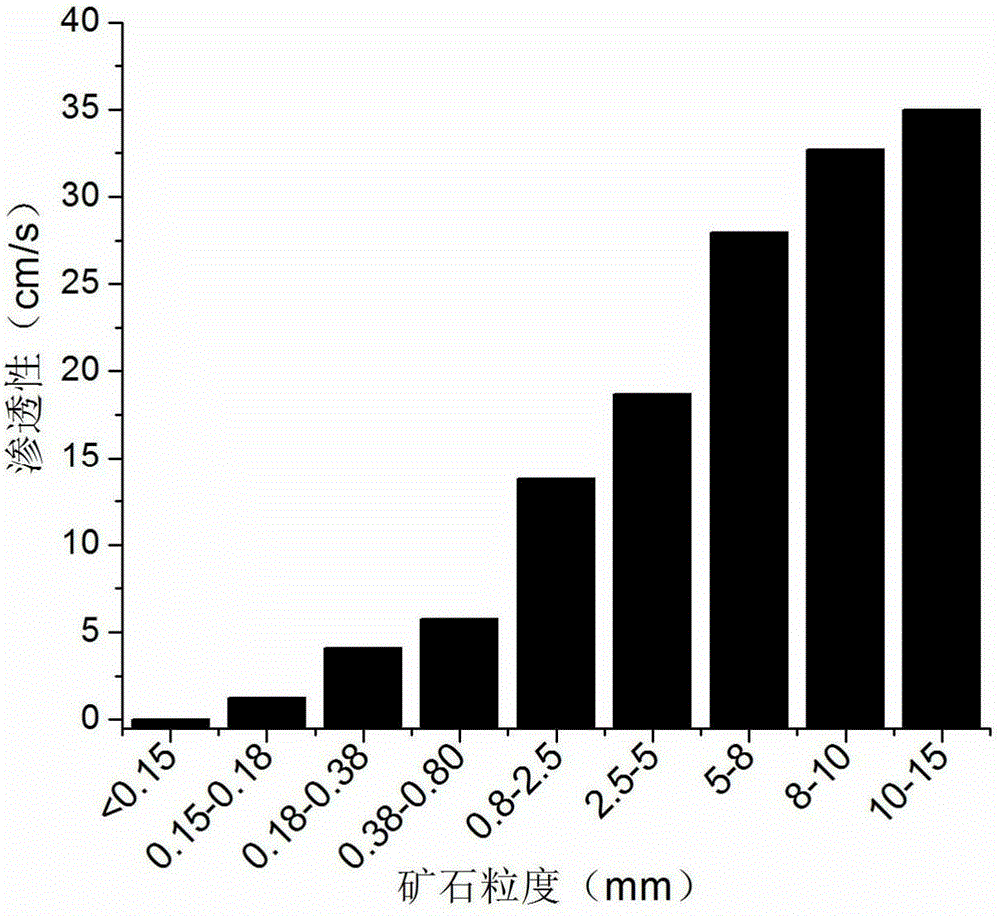

[0046] (1) Screen the low-grade sulfide ore in this embodiment into 8 particle sizes, specifically including: 10-8mm, 8-5mm, 5-2.5mm, 2.5-0.8mm, 0.8-0.38mm, 0.38-0.18mm, 0.18 ~ 0.15mm and less than 0.15mm; the particle size of low-grade sulfide ore after screening is less than 10mm.

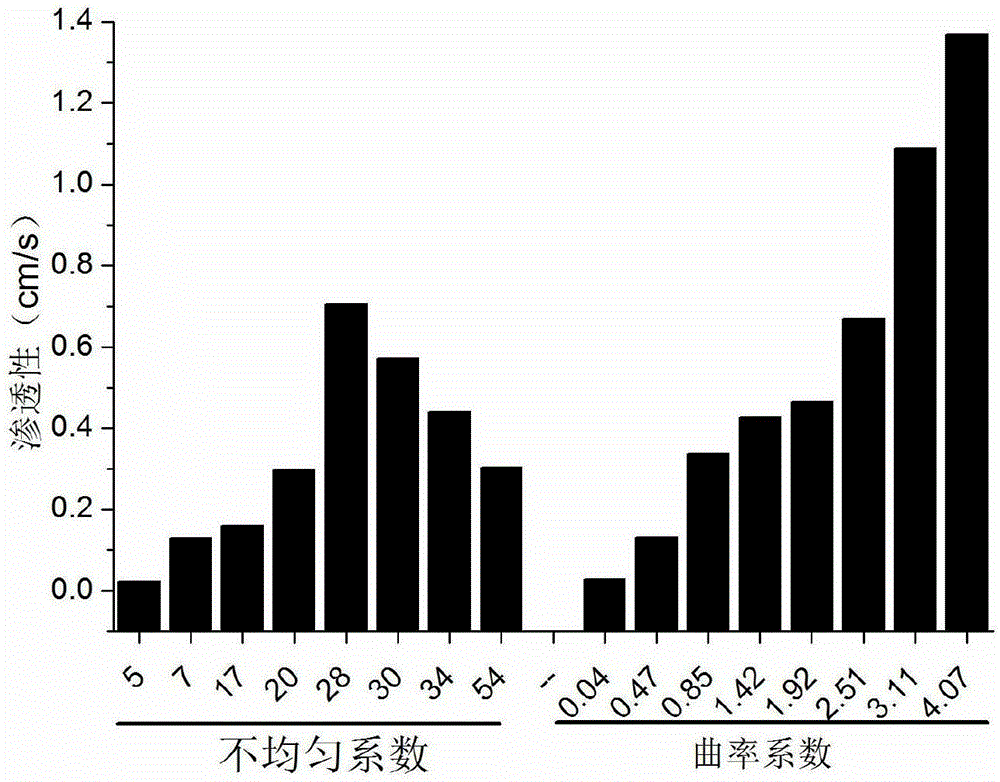

[0047] (2) Grading and mixing the graded low-grade sulfide ores with different particle sizes according to the set coefficient of inhomogeneity and curvature, and then aging to obtain a graded dispersion. Among them, the inhomogeneity coefficient Cu of the...

Embodiment 2

[0056] Example 2: Heap leaching of low-grade arsenic-containing refractory gold ores

[0057]The low-grade arsenic-containing refractory gold ore used in this example comes from the flotation tailings and waste ore of a certain gold mine in Liaoning.

[0058] The low-grade arsenic-containing refractory gold ore of this embodiment is treated by using the heaping process of fine particle industrial solid waste of the present invention, which specifically includes the following steps:

[0059] (1) The low-grade arsenic-containing refractory gold ore in this embodiment is screened into 8 particle sizes, specifically including: 10-8mm, 8-5mm, 5-2.5mm, 2.5-0.8mm, 0.8-0.38mm, 0.38mm ~0.18mm, 0.18~0.15mm and less than 0.15mm; the particle size of low-grade arsenic-containing refractory gold ore after screening is all less than 10mm.

[0060] (2) The graded low-grade arsenic-containing refractory gold ores with different particle sizes are graded and mixed according to the set coeffic...

Embodiment 3

[0068] Example 3: Heap leaching of low-grade copper sulfide ore in Dexing, Jiangxi

[0069] The low-grade sulfide ore used in this example comes from Jiangxi Dexing Copper Mine.

[0070] The low-grade sulfide ore of this embodiment is processed by using the heaping process of fine particle industrial solid waste of the present invention, which specifically includes the following steps:

[0071] or 10~7mm, 7~4mm, 4~2mm, 2~1mm, 1~0.25mm and less than 0.25mm. The particle size of the screened low-grade sulfide ore is less than 10mm.

[0072] (2) Grading and mixing the graded low-grade sulfide ores with different particle sizes according to the set coefficient of inhomogeneity and curvature, and then aging to obtain a graded dispersion. Corresponding to the first particle size, the unevenness coefficient Cu of the graded dispersion III is 25, and the curvature coefficient Cc is 3.1; the unevenness coefficient Cu of the graded dispersion IV is 16, and the curvature coefficient C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com