Integrated nut connector

A connecting piece, integrated technology, applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of unrealizable, unable to adjust the distance, etc., and achieve the effect of reasonable structure, ingenious design and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

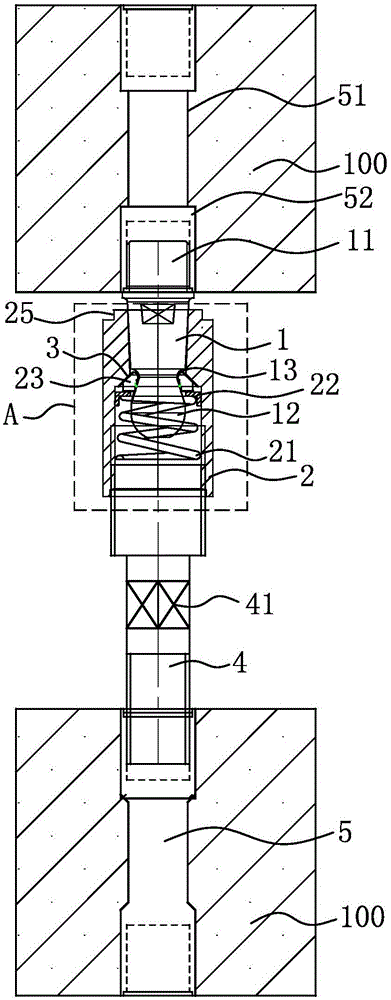

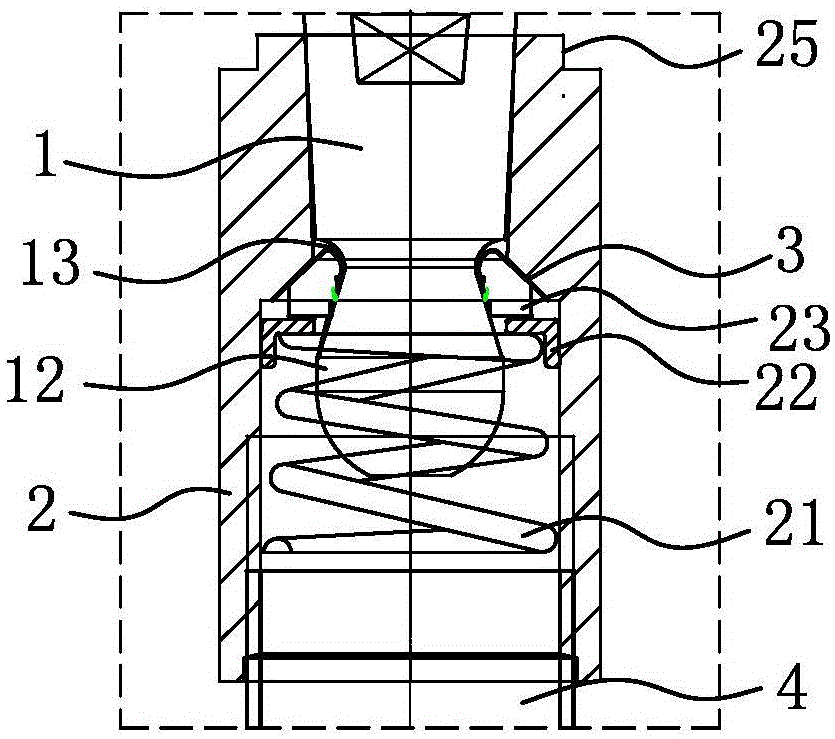

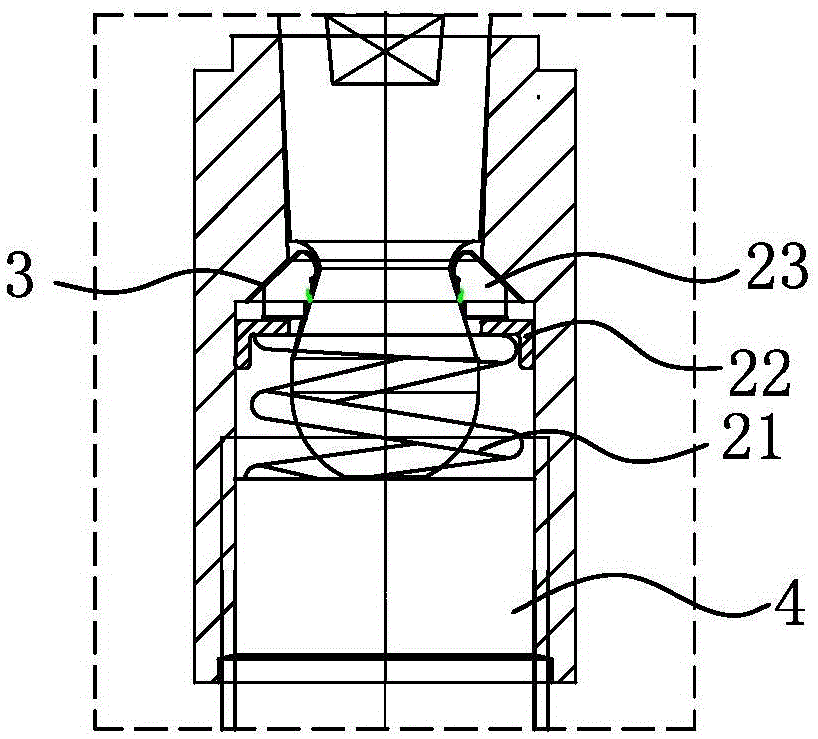

[0026] Such as figure 1 As shown, a one-piece nut connector includes a plug joint 1 and a connecting nut 2. The connecting nut 2 has a clamping platform 3 protruding in the direction of the axis line, and the connecting nut 2 is screwed with connecting bolts. 4. A plug connector 1 is plugged into the connecting nut 2 and the plug connector 1 is clamped and fixed with the card table 3 . By adjusting the length of the connecting bolt 4 entering the connecting nut 2, the length of the entire connecting piece can be adjusted. The end of the connecting nut 2 away from the connecting bolt 4 has a polygonal positioning step 25, which is convenient for positioning and fixing with a wrench or other fastening tools, so as to facilitate fixing the connecting nut 2. The connecting nut 2 of the present invention has an integrated structure, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com