A tension beam based on bamboo structure

A bamboo and string beam technology, applied in the field of string beams and string beams based on bamboo structures, can solve the problems of increasing the applicable span and poor stiffness of bamboo structures, and achieve the effects of light weight, large space and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

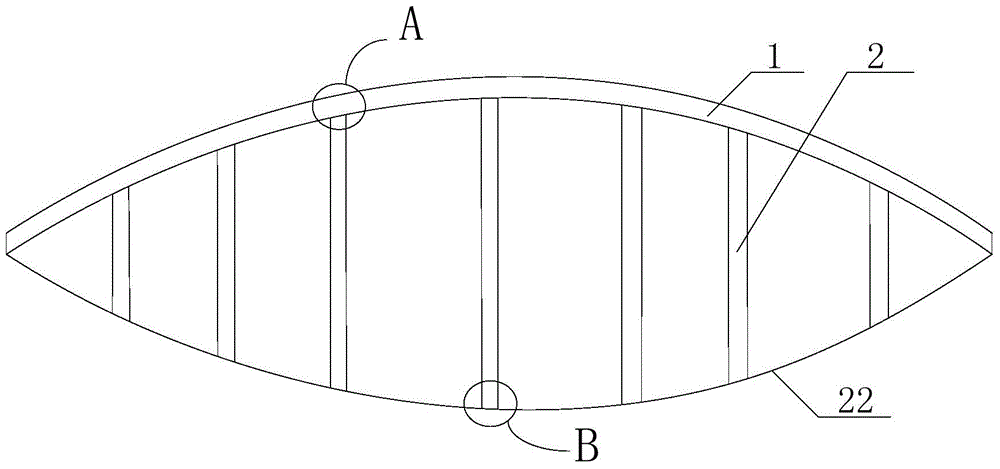

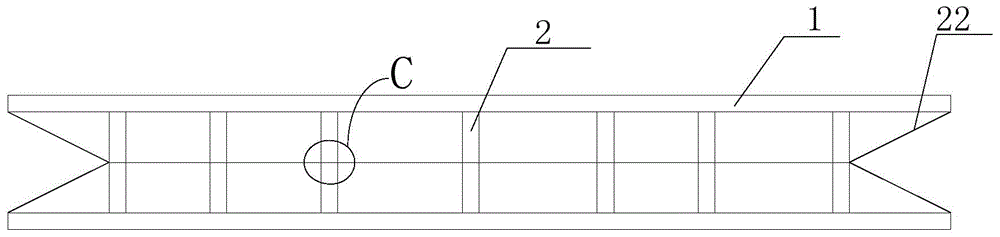

[0023] refer to figure 1 , the tension beam based on the bamboo structure of the present invention comprises the first original bamboo 1, some second original bamboos 2 and drag cables 22, the upper end of each second original bamboo 2 is connected with the side of the first original bamboo 1, and the drag cables One end of 22 is connected with one end of the first raw bamboo 1, and the other end of the dragline 22 passes through the lower end of each second raw bamboo 2 successively and is connected with the other end of the first raw bamboo 1, and each second raw bamboo 2 are of different lengths.

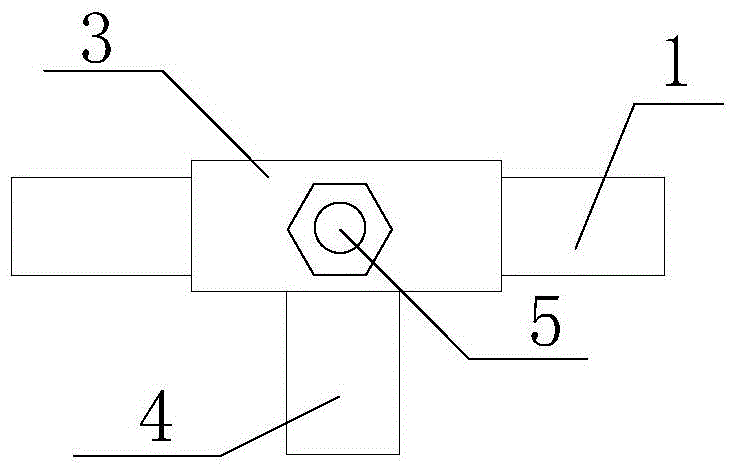

[0024] It should be noted that the upper end of the second raw bamboo 2 is connected with the side of the first raw bamboo 1 through a first connecting piece, and the first connecting piece includes a first pipeline 3 and a second pipeline 4, and the first pipeline 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com