Sectional dismantling method for cable-stayed hanging basket

A segmented and dragline technology, which is applied in construction, bridge construction, bridges, etc., can solve the problems of the weight of the dragline hanging basket, and the inability of the dragline hanging basket to be lowered and dismantled as a whole, so as to reduce the risk of working at heights, The effect of low investment construction cost and low mechanical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

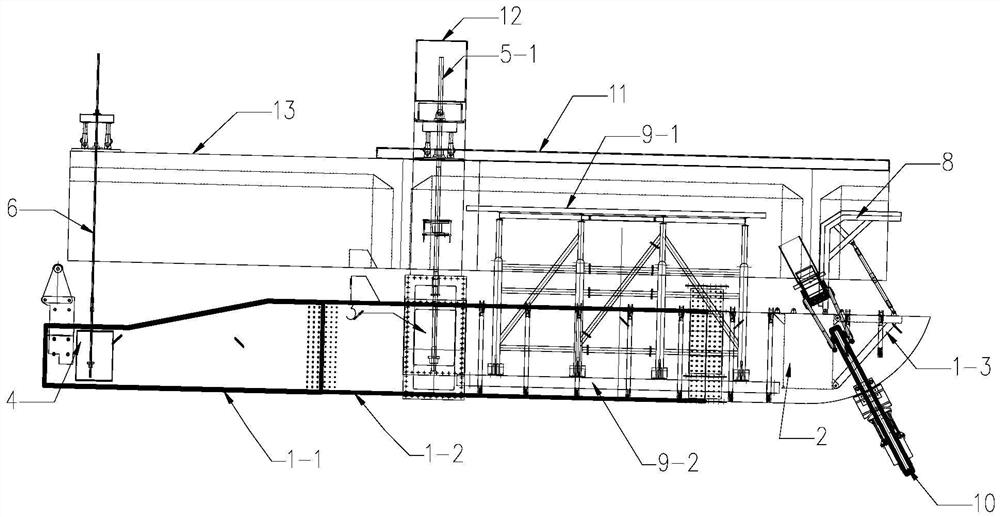

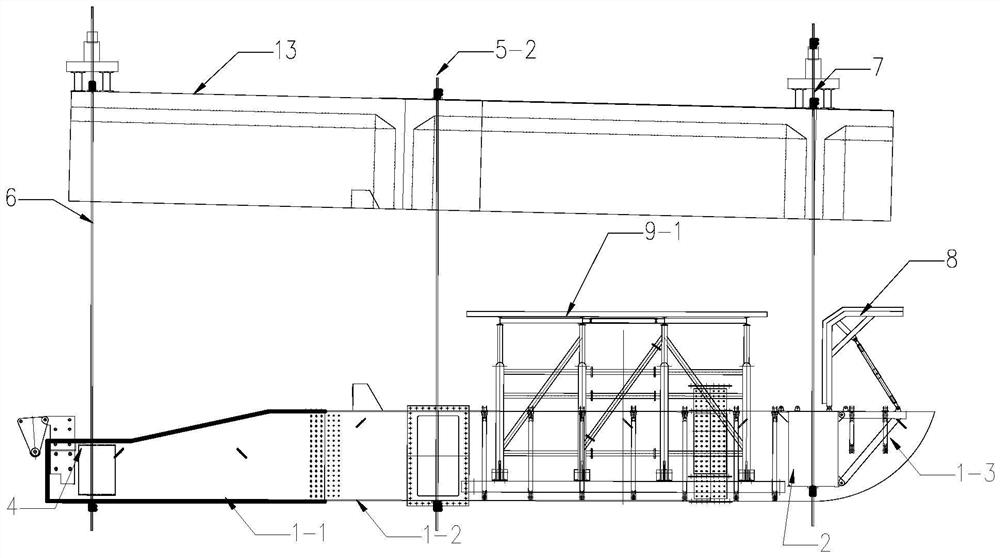

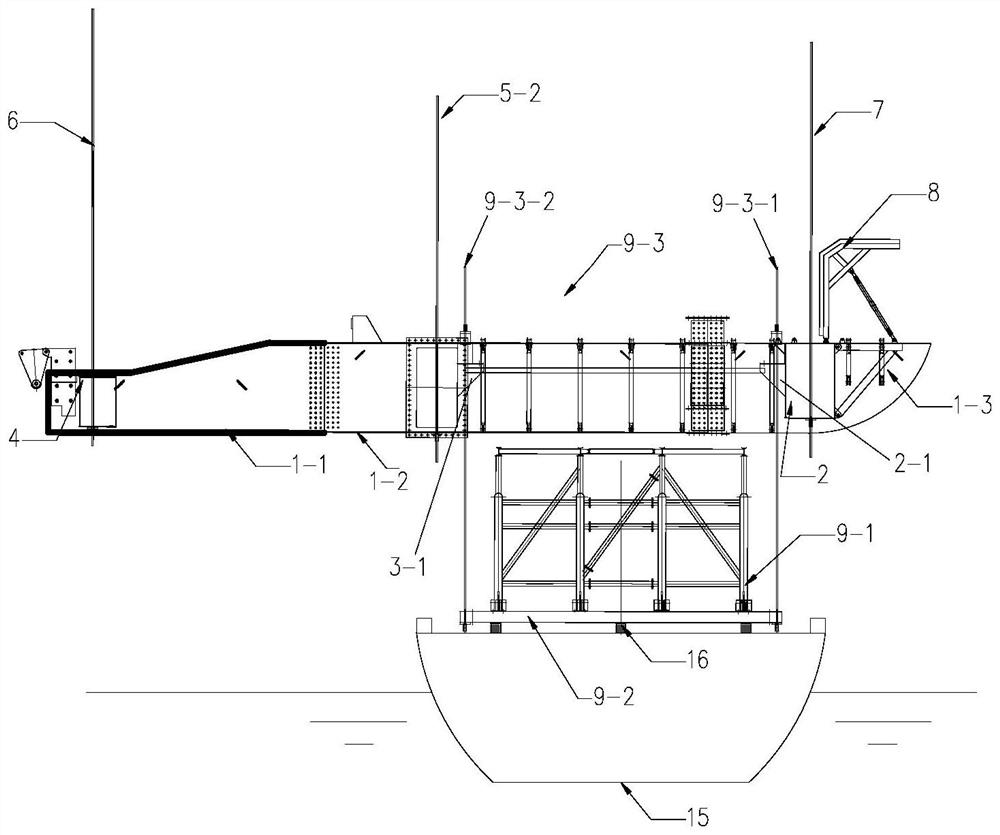

[0069] Such as Figure 1 to Figure 6 Shown is a segmental removal method for a dragline hanging basket, the method comprising the following steps:

[0070] Step 1. Work before removal:

[0071] Step 101, using the cable-stayed basket to complete the concrete pouring of the main girder of the cable-stayed bridge to form the main girder 13 of the cable-stayed bridge;

[0072] Step 102, after the operation, anchor the suspender 6 and the steel rod 5-1 of the mid-anchor suspender, so that the lanyard hanging basket is lowered to the demoulding state;

[0073] Step 103, remove the C-shaped hanging legs 12 on both sides of the dragline hanging basket, the outer mold, the slideway 11 on the main girder of the cable-stayed bridge, and the tensioning system 10 to the barge and float to the required position;

[0074] Step 2. Installation of the front boom and replacement of the boom during anchorage:

[0075] Step 201, opening two sets of lower mounting holes in the front beam 2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com