Patents

Literature

42results about How to "Small load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

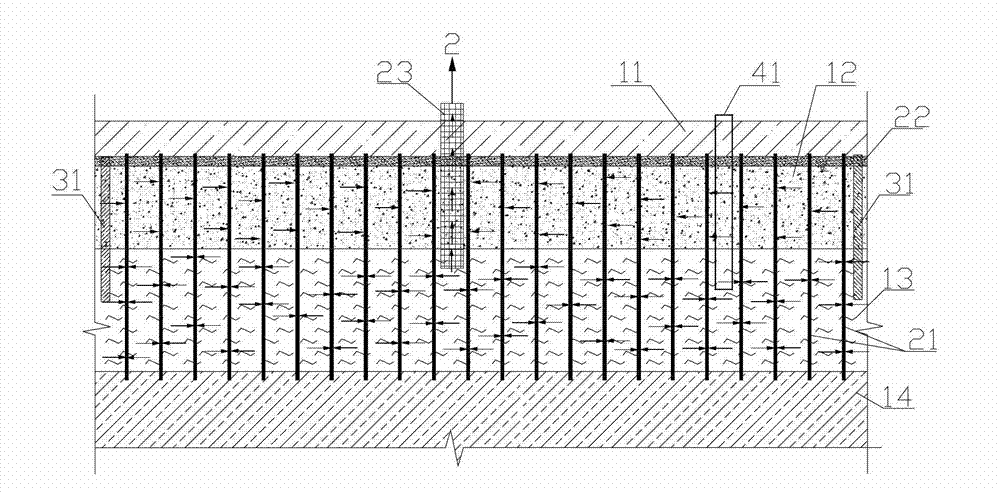

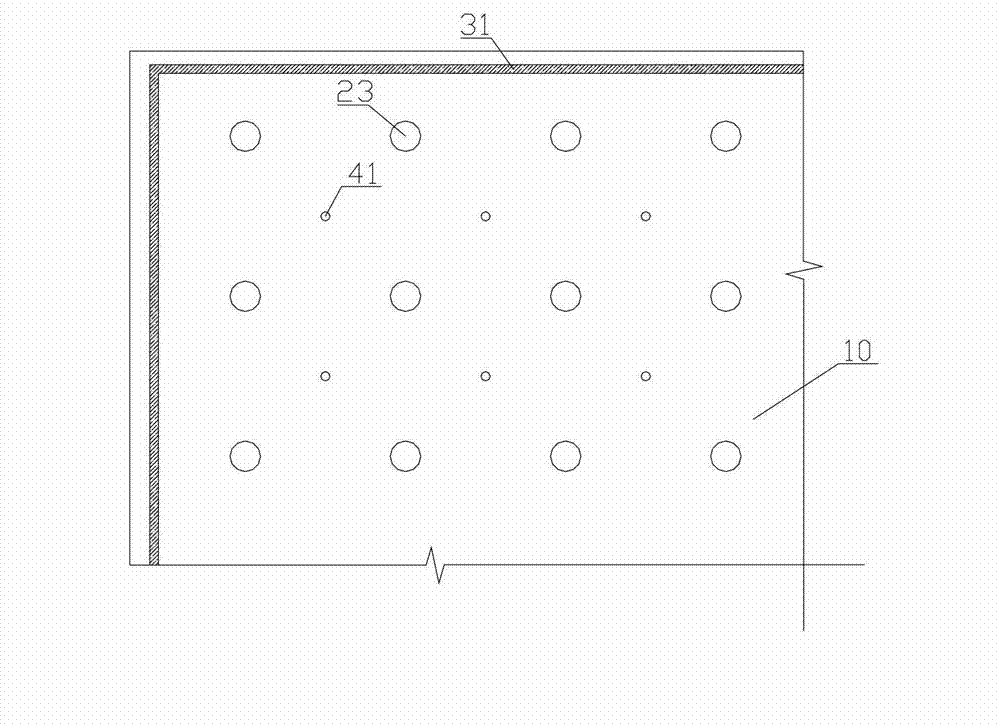

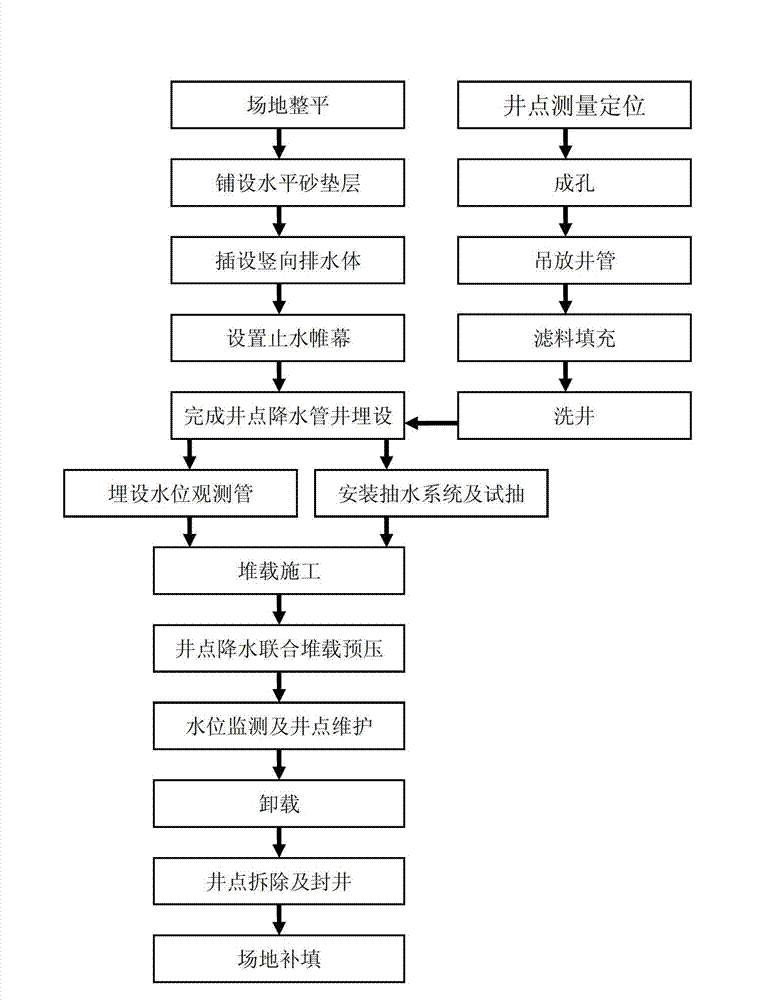

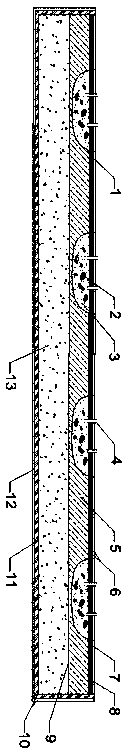

Method for reinforcing deep and soft soil foundation by combining well-points dewatering with preloading

ActiveCN103031837ANo tightness requiredReduce construction costsSoil preservationSurface layerSoil science

The invention discloses a method for reinforcing a deep and soft soil foundation by combining well-points dewatering with preloading. The method comprises the following steps: (1) a field is leveled; and a underwater soft soil foundation is backfilled above the water surface; (2) a horizontal drainage sand mat layer is laid on the surface layer of the field which is formed in the step (1); (3) a vertical drainage body is inserted downwards through a soft soil layer to a designed elevation from the drainage sand mat layer; (4) a waterproof curtain is arranged on the periphery of a foundation area to be reinforced; (5) well points are arranged on the horizontal drainage sand mat layer which is formed in the step (2) at intervals; (6) the well-points dewatering is begun; and the preloading is implemented in the foundation area to be reinforced; well-points dewatering equipment is protected by adopting measures in the preloading process; after the preloading is finished, the well-points dewatering is combined with the preloading; and (7) after the preloading is finished, the well points are unloaded and dismounted. The method is applied in the reinforcement of deep and soft soil layers to reduce the cost and to shorten the construction period.

Owner:CCCC FOURTH HARBOR ENG INST +3

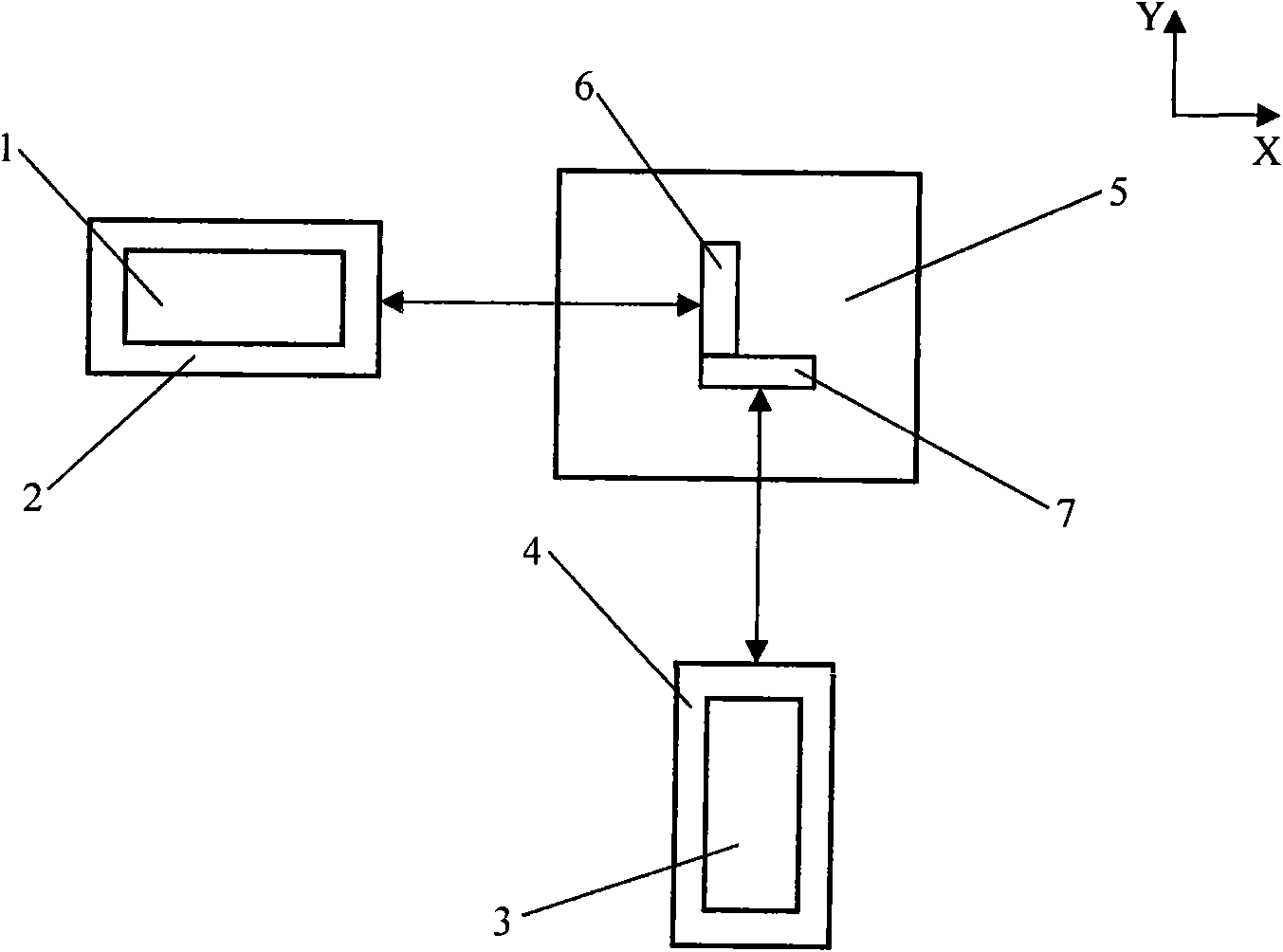

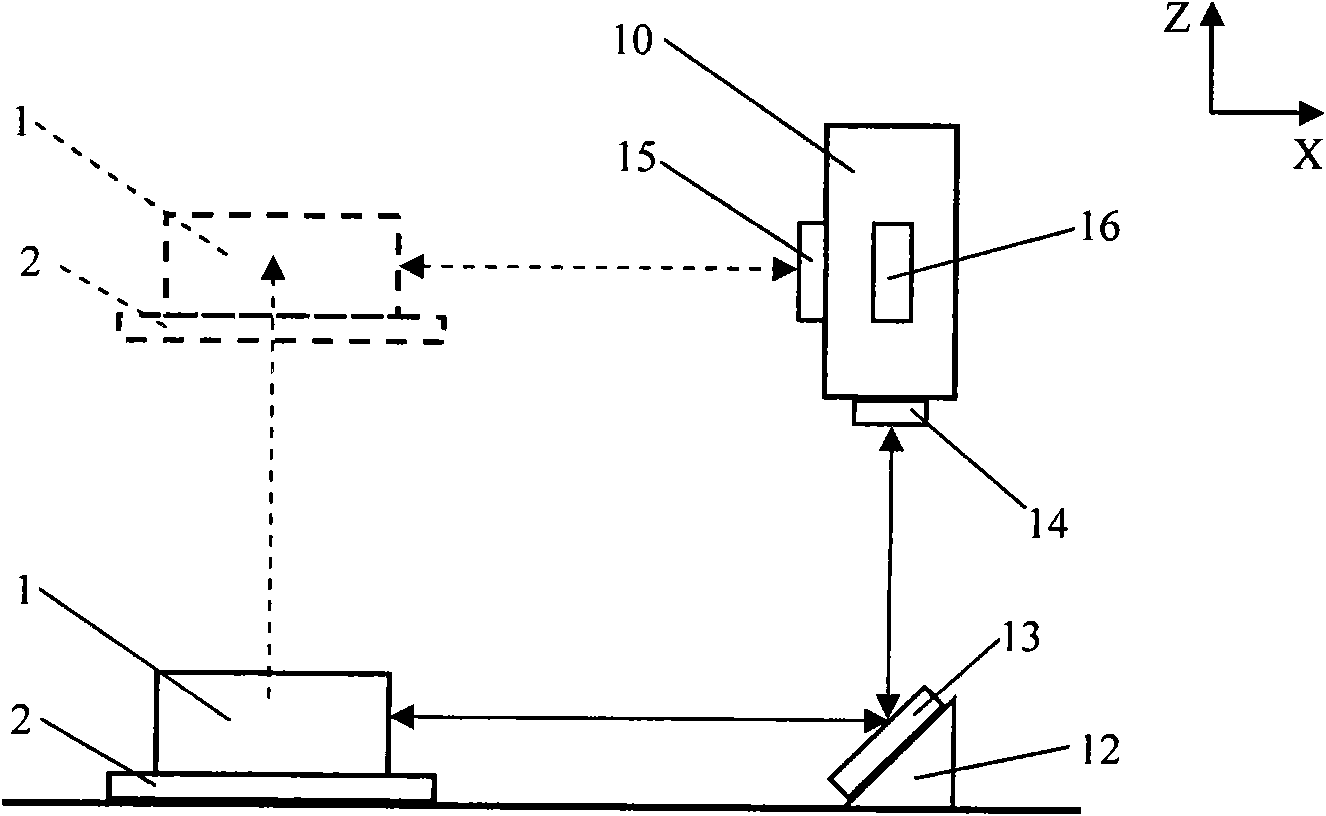

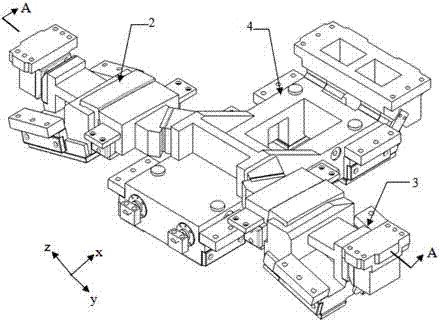

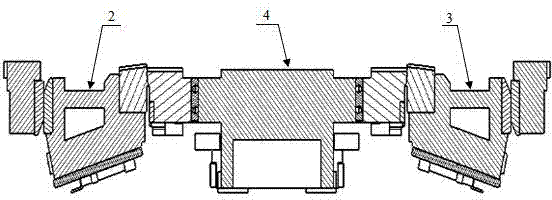

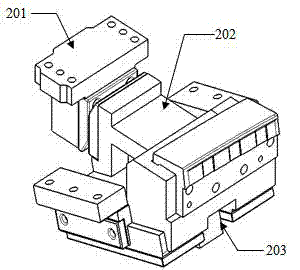

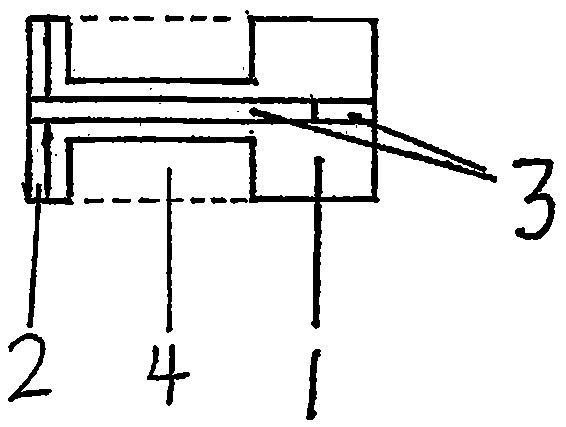

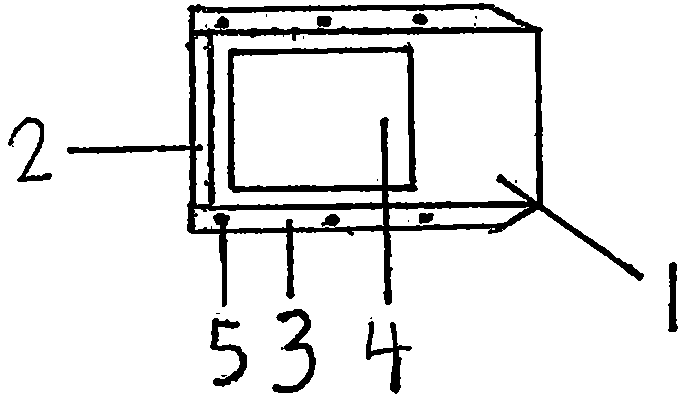

Error detecting system of minitype high accuracy three coordinate measuring machine

InactiveCN101571374AImprove test efficiencySimplify verification stepsUsing optical meansVertical edgeOptical axis

The invention relates to an error detecting system of a minitype high accuracy three-coordinate measuring machine, which is characterized by comprising an X / Y axis target lens, an optical transition target lens, a Z axis target lens, a vertical edge laser interferometer having optical axis being parallel to X axis direction and a transverse edge laser interferometer having optical axis being parallel to Y axis direction. The error detecting system is synchronously tested by multiple items of high accuracy geometrical error, and can realize nanoscale precision detection for the geometrical error of the three-coordinate measuring machine. Furthermore, the error detecting system has high working efficiency and simple operating way.

Owner:HEFEI UNIV OF TECH

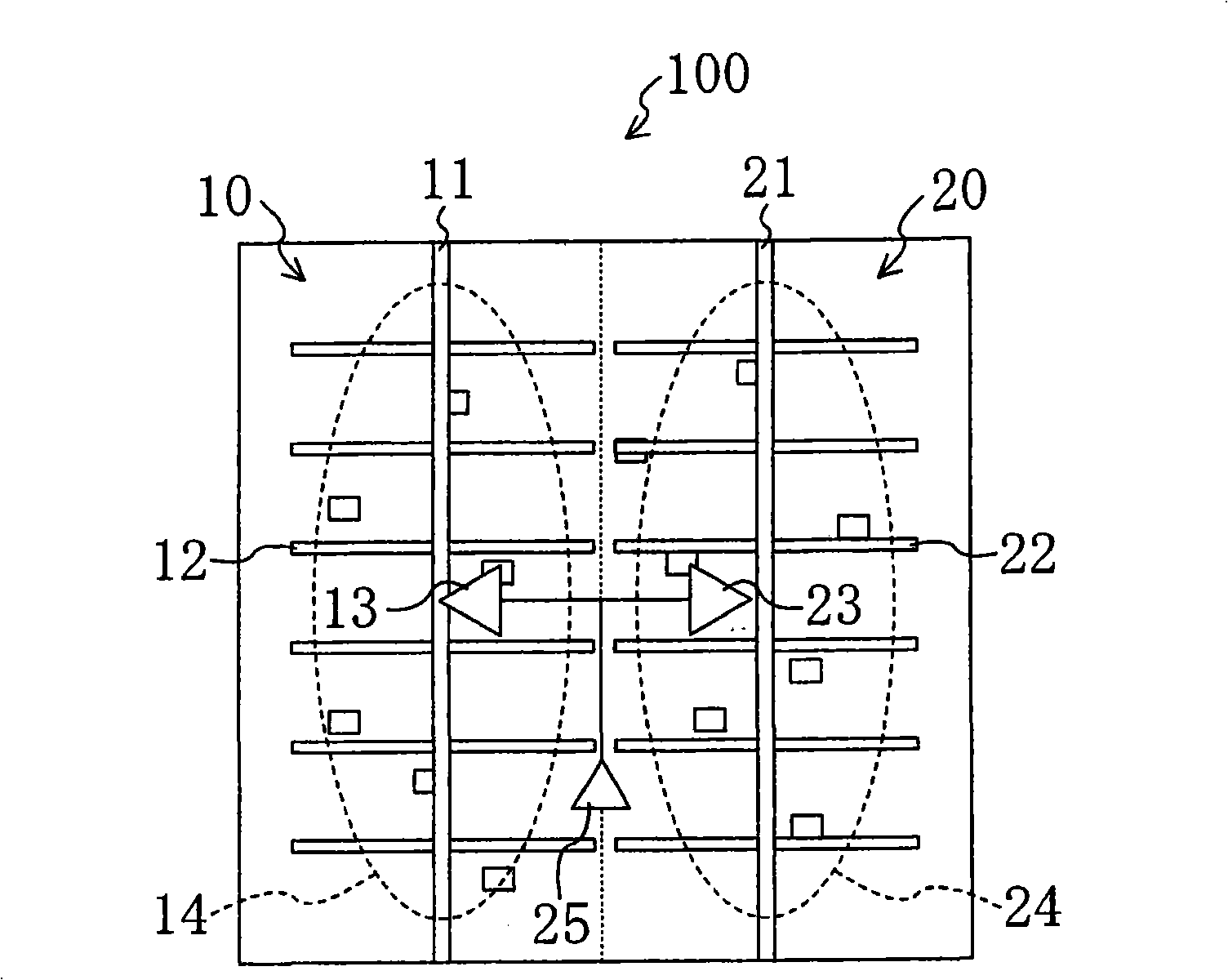

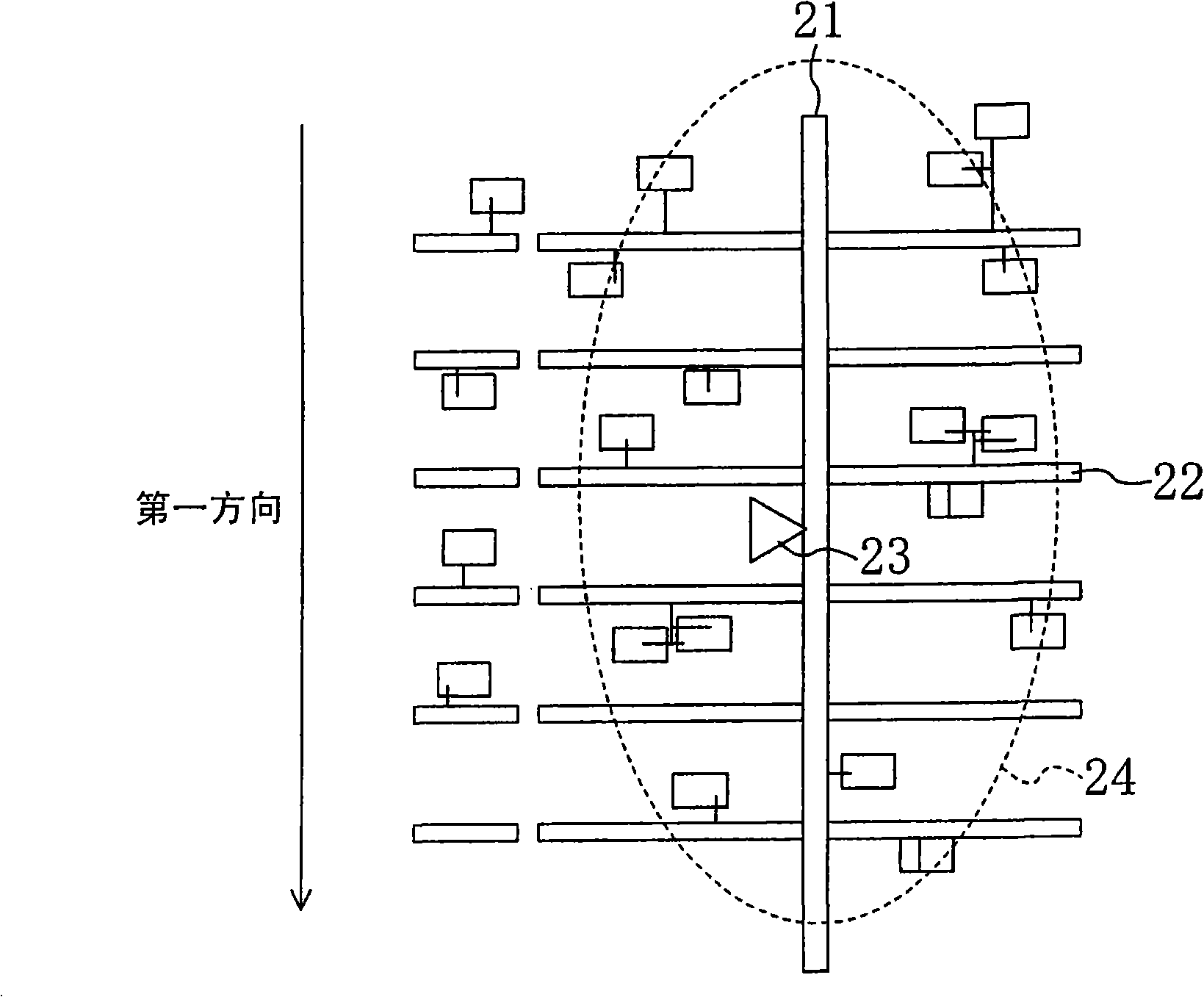

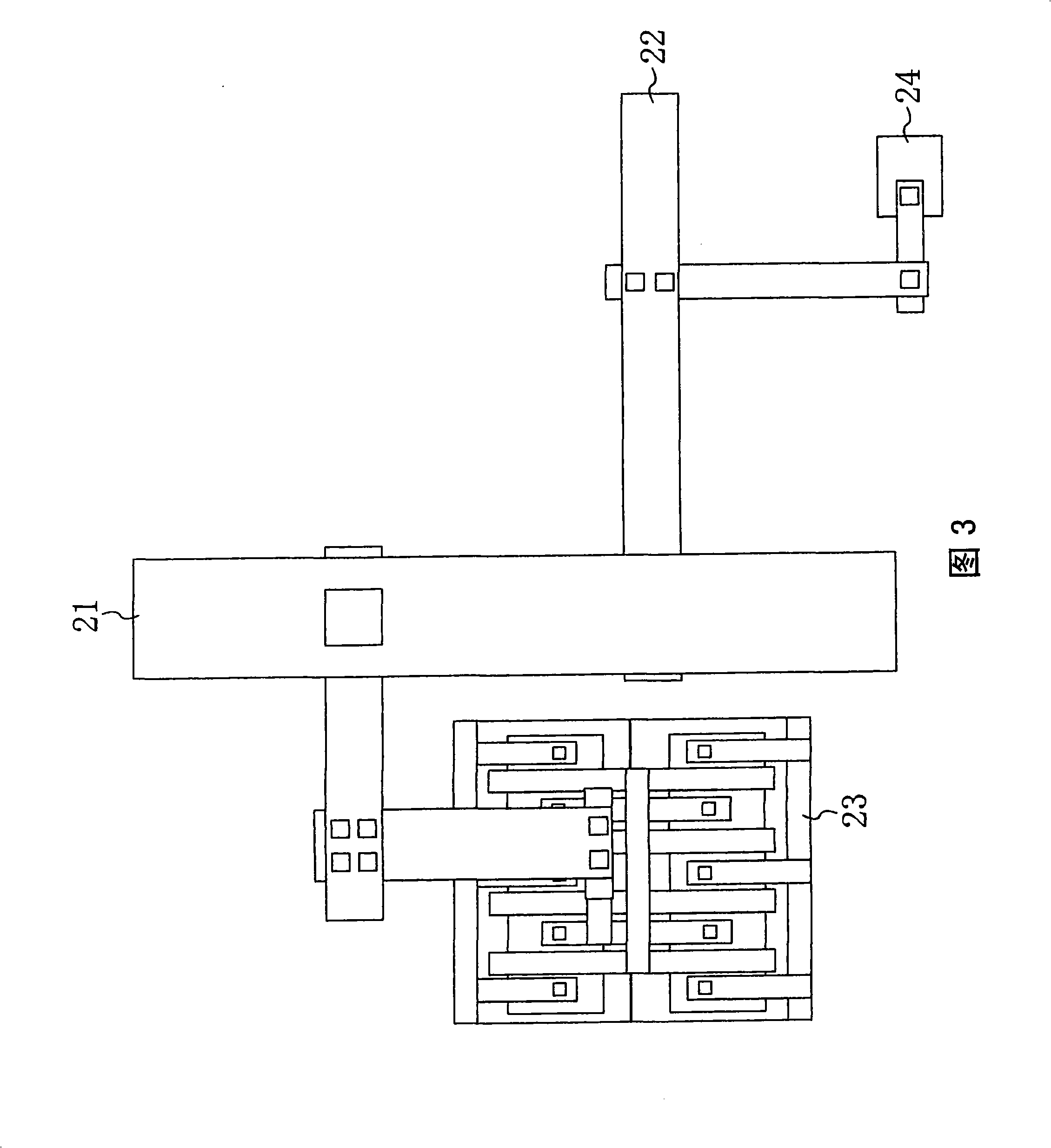

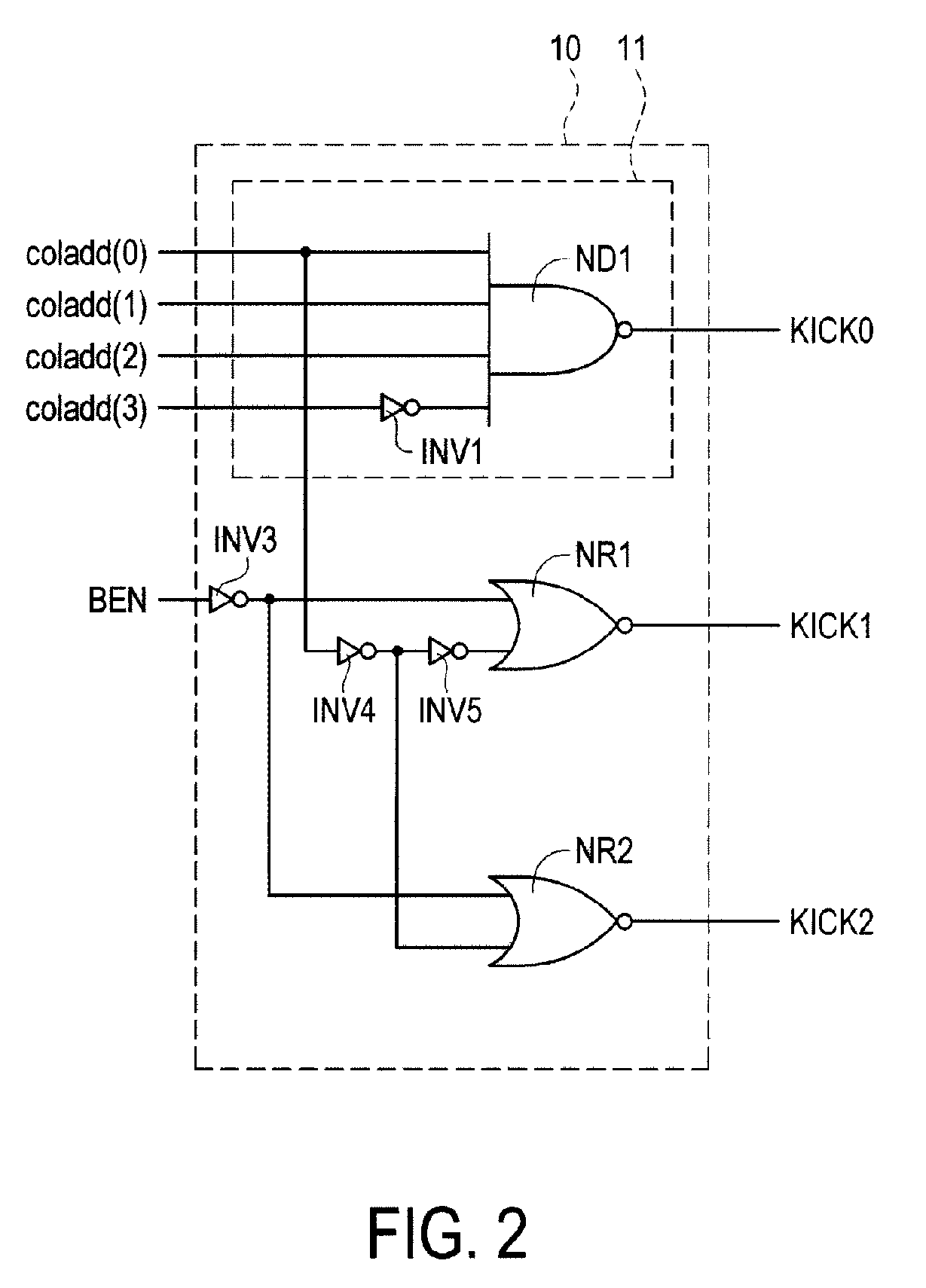

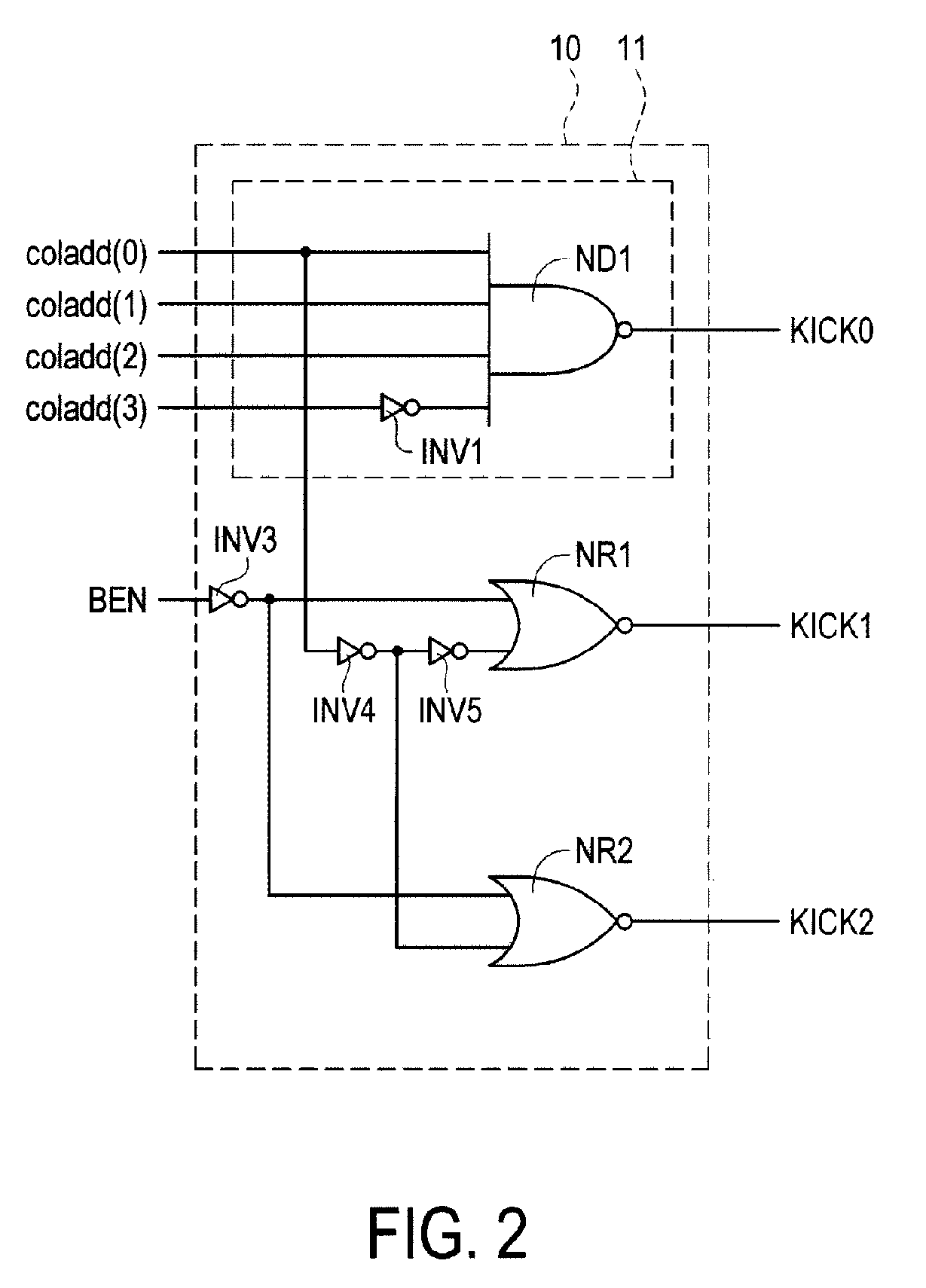

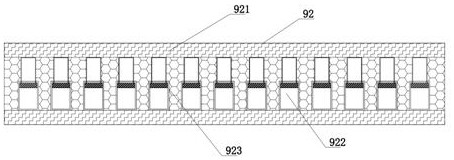

Semiconductor integrated circuit and layout method for the same

InactiveCN101290639ASmall load capacityReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesSemiconductorClock synchronization

A functional block is divided into a plurality of regions. In each region, a clock main line extending along a first direction, a clock branch line group including a plurality of clock branch lines extending along a second direction perpendicular to the first direction and electrically connected to the clock main line, a clock driving cell electrically connected to the clock main line and a clock synchronous cell group including a plurality of clock synchronous cells electrically connected to the clock main line or the clock branch line group are provided. The clock branch line groups of the respective regions are electrically separated from each other, and the clock driving cell singly drives the clock main line connected thereto and the clock branch line group connected to the clock main line.

Owner:PANASONIC CORP

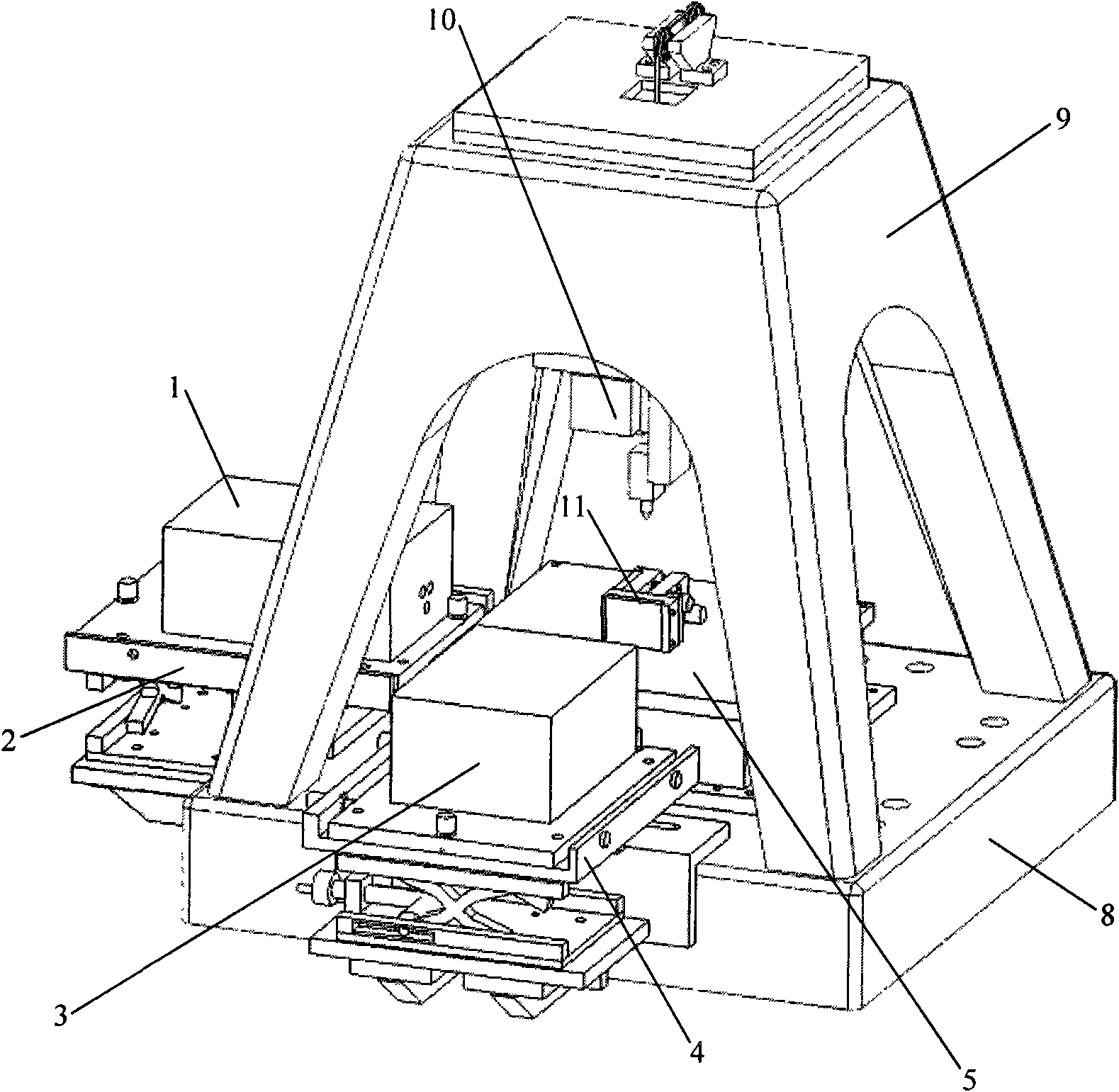

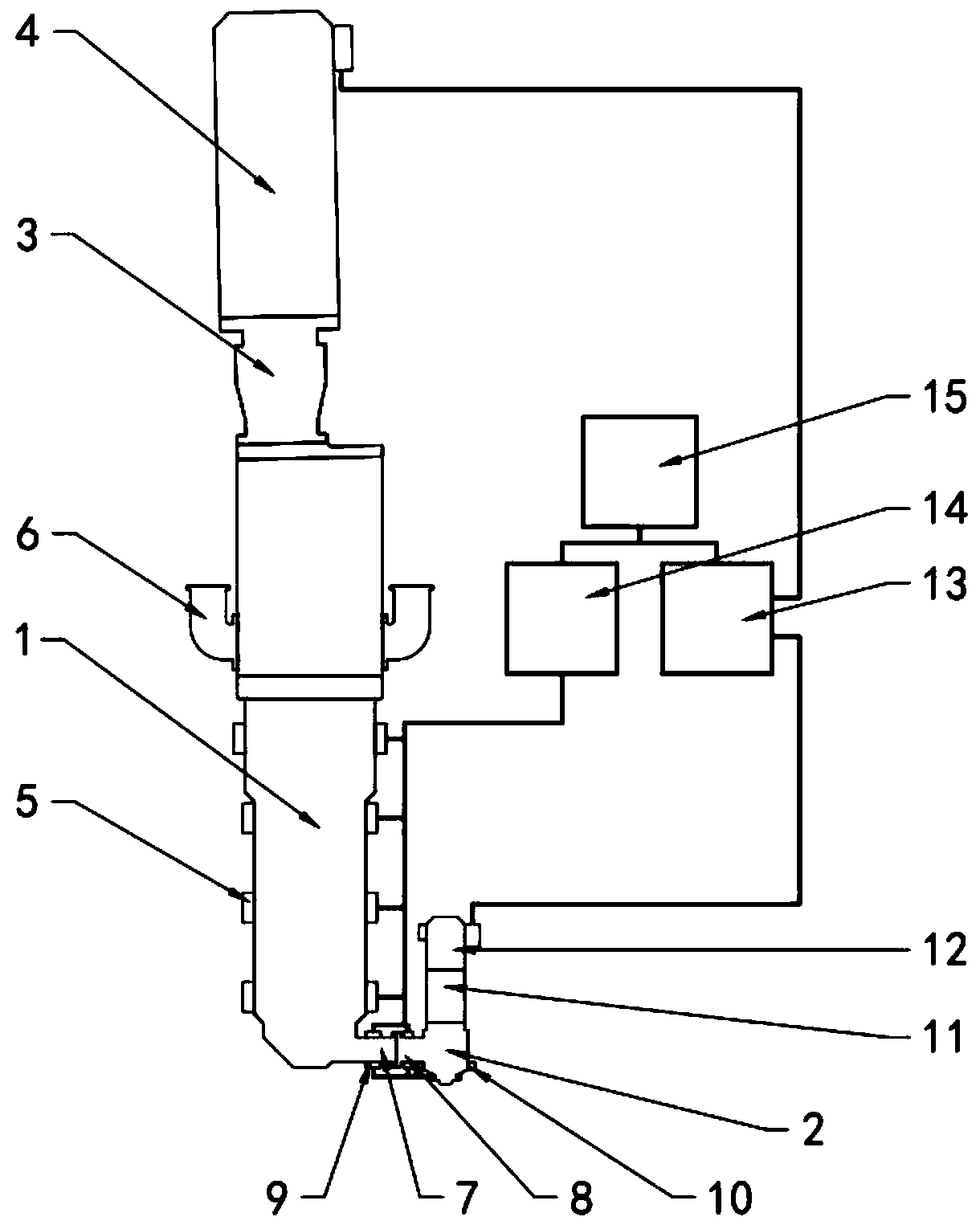

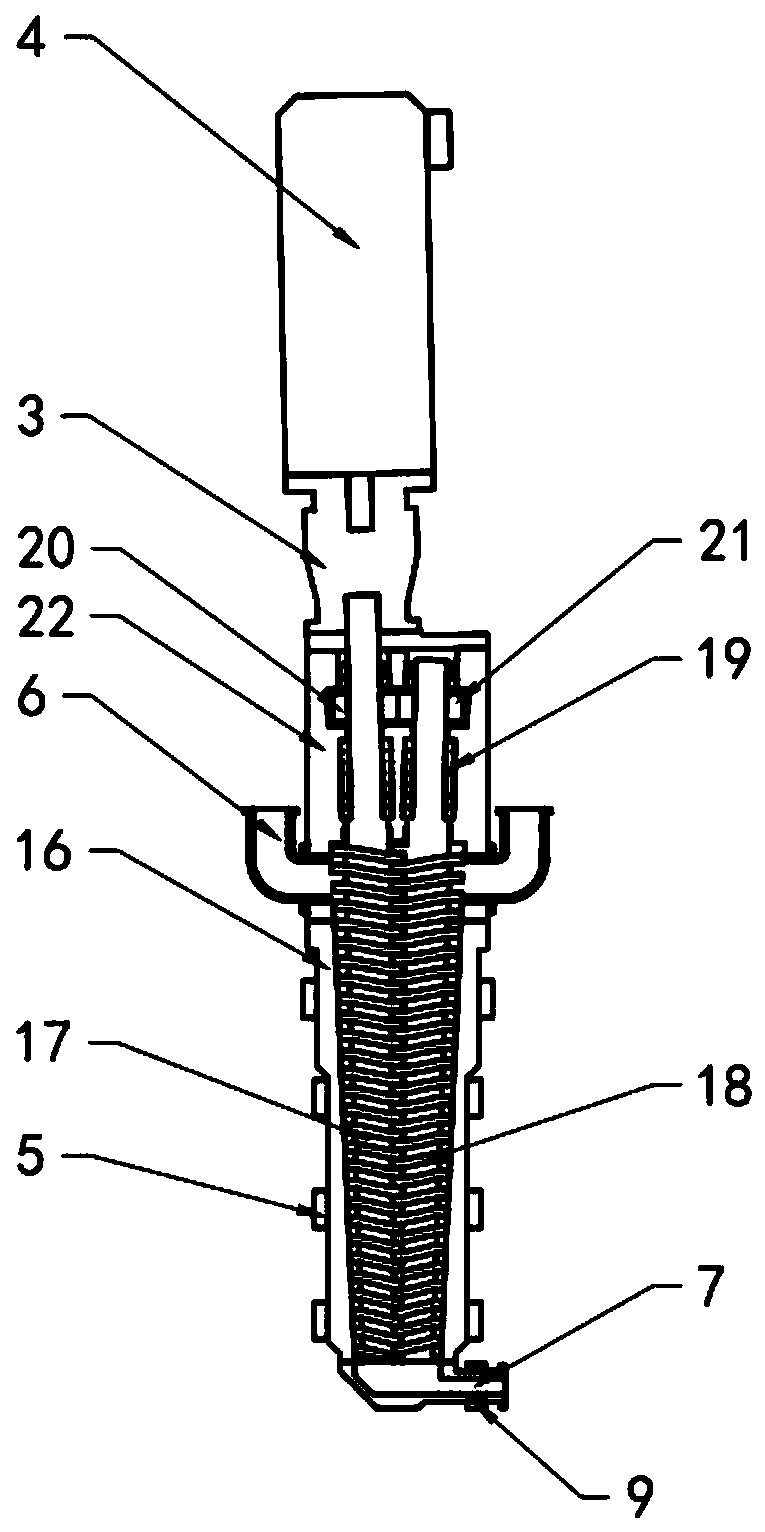

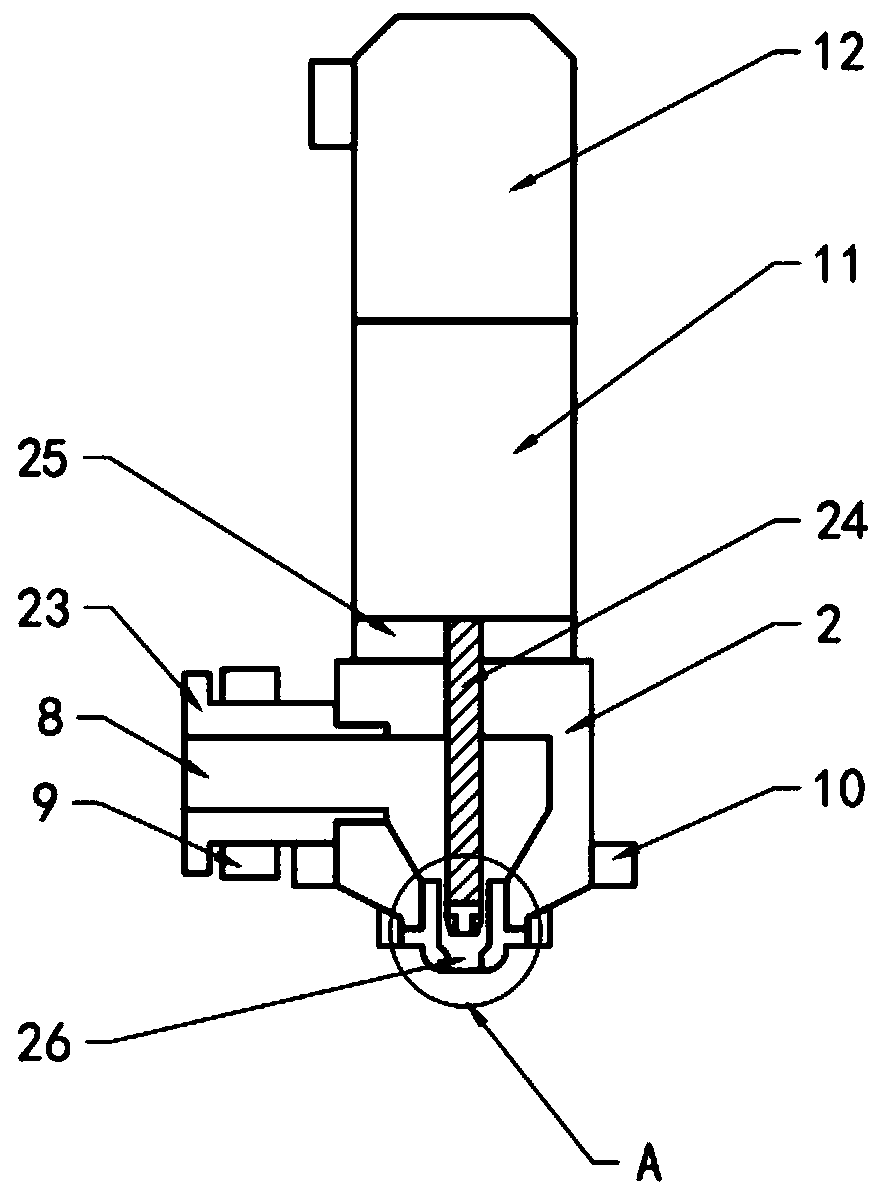

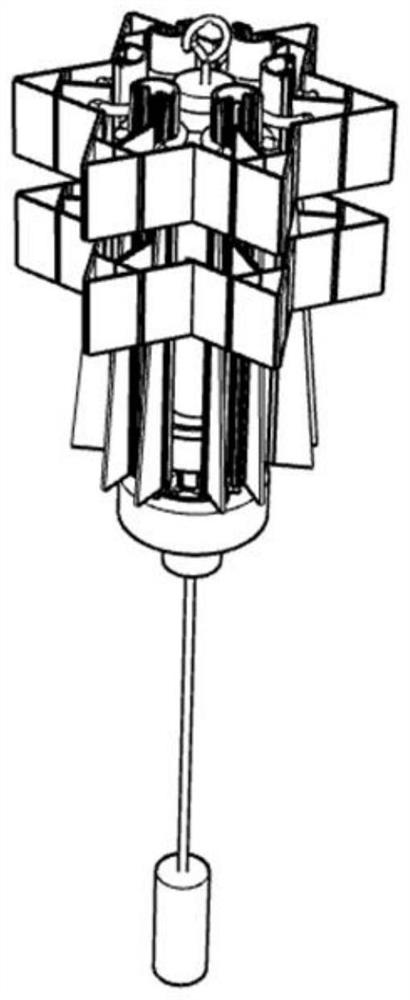

3D printing device for large-scale additive manufacturing

PendingCN110901053AHighly integratedHigh control precisionManufacturing heating elementsManufacturing material handling3d printThermal dilatation

The embodiment of the invention discloses a 3D printing device for large-scale additive manufacturing and belongs to the technical field of 3D printing. The device comprises a material melt extrusionmechanism and a printing head; the printing head is connected with a molten material flow control mechanism; and the printing head is fixedly connected with the material melt extrusion mechanism. According to the material melt extrusion mechanism, an extrusion mode applying a counter-rotating conical double-screw structure is adopted; the double-screw extrusion mechanism is driven in a direct connection manner, and therefore, the integration level of a driving structure is improved, and an extruder with the counter-rotating conical double-screw structure can be applied to a 3D printer. In screw clearances, apart from exclusion mechanical pressure, the thermal expansion pressure component of a molten material is not controlled by screws, and therefore, the printing head at the tail end of the 3D printing device is improved; the printing head is connected with the molten material flow control mechanism, so that the printing head is of a variable-caliber structure and can perform throttling control over molten fluid; and therefore, control precision and real-time performance are improved, and the requirements of an efficient large-scale FDM 3D printing process can be met.

Owner:陈祺睿

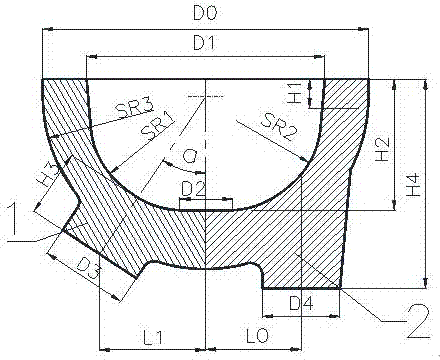

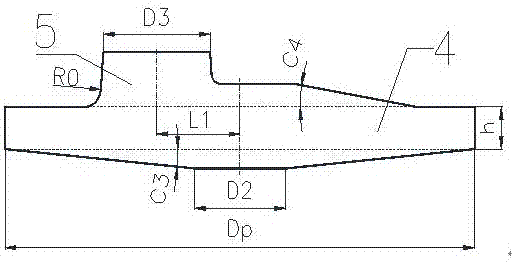

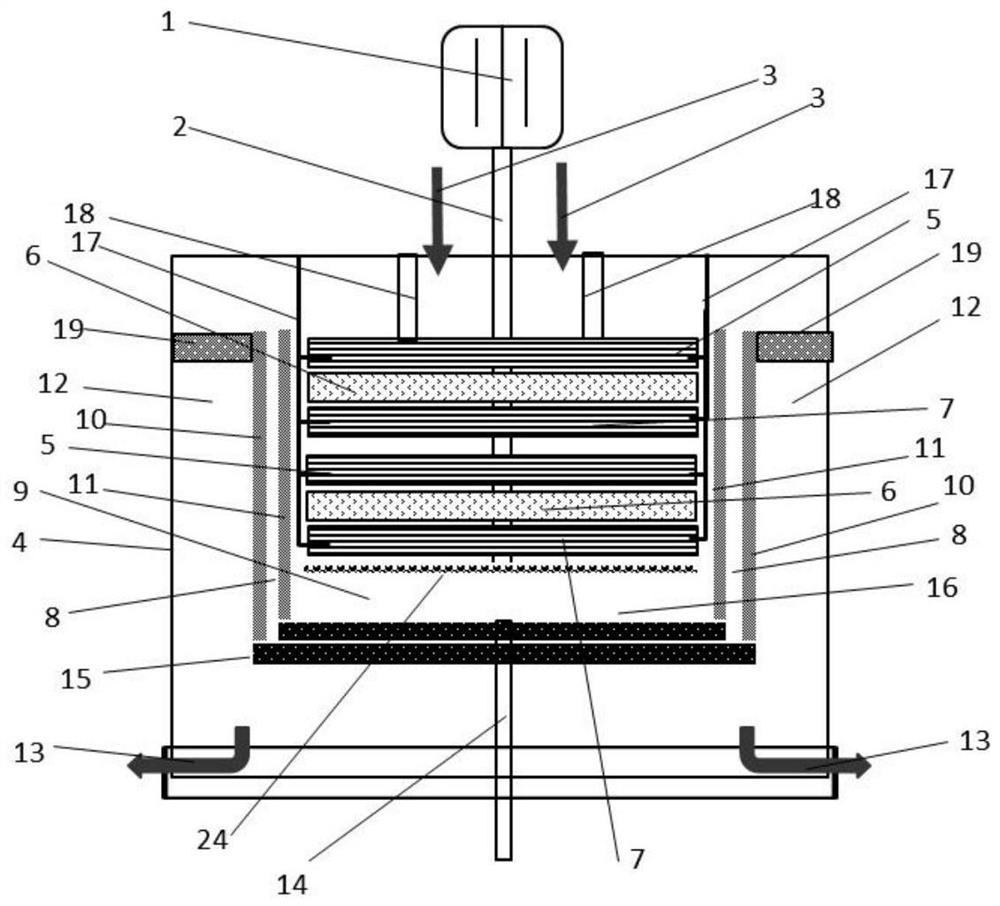

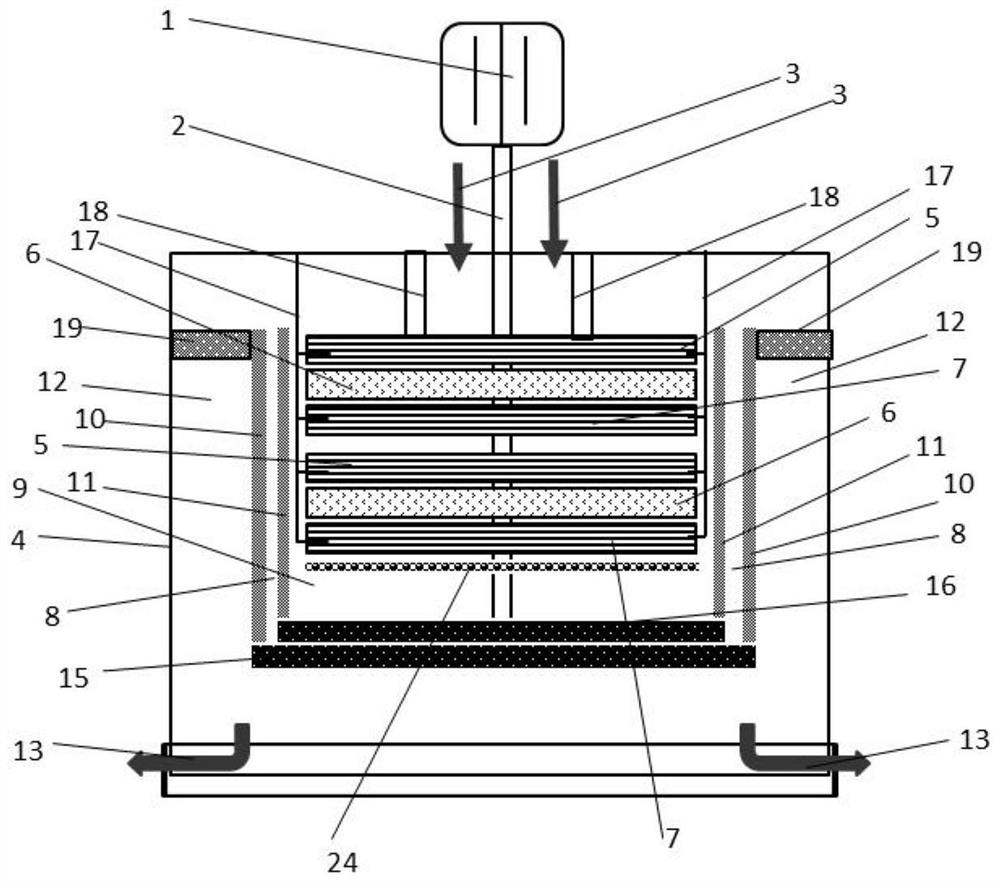

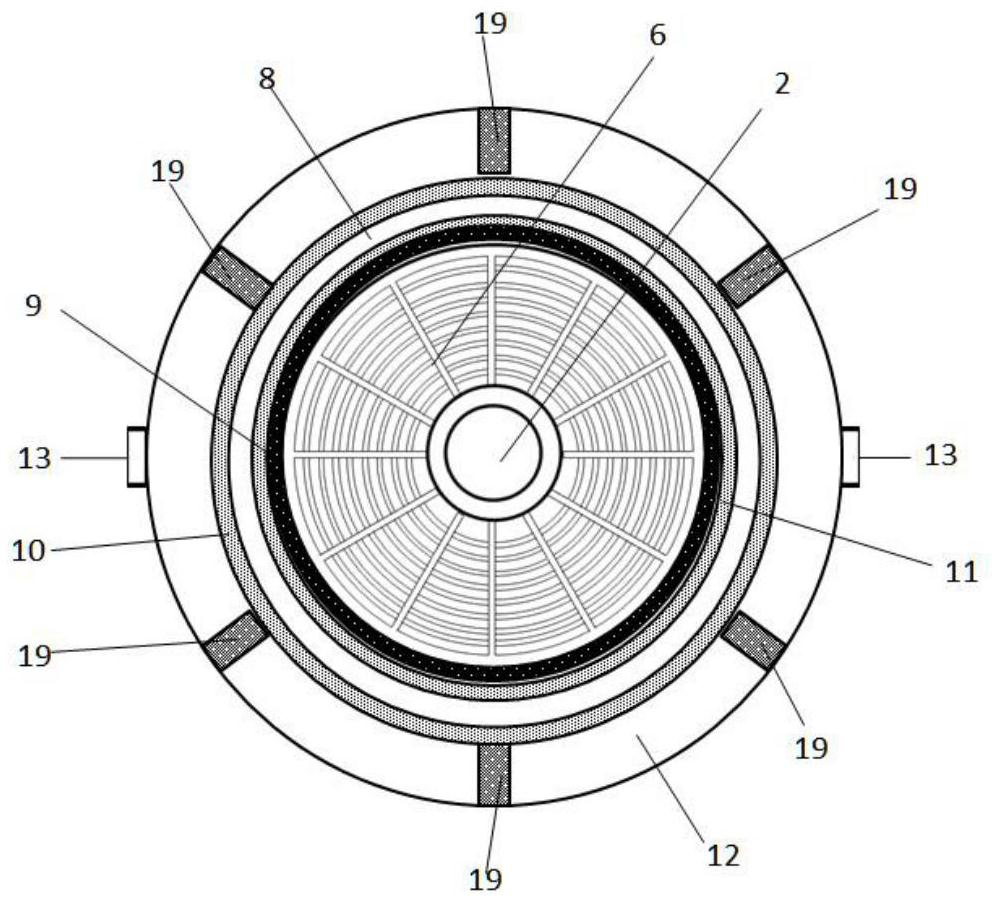

Integral forging and forming method for large-scale end socket forge piece of nuclear reactor with a plurality of protruding nozzles

ActiveCN107252866AReasonable dispersionSmall load capacityShaping toolsForging/hammering/pressing machinesNuclear reactorNuclear reactor core

The invention belongs to the technical field of forge piece forging, and particularly relates to an integral forging and forming method for a large-scale end socket forge piece of a nuclear reactor with a plurality of protruding nozzles. A cylindrical blank is prepared through implementation of the processes of removal of a head and a tail of a steel ingot, drawing out of upsetting, rolling and blanking and the like, and moulding bed formation is implemented on the cylindrical blank by adopting a flat-anvil male-die subarea rotary rolling and forging method, so that filling forming of the shapes of the nozzles of a middle prefabricated slab is achieved through a free forging method by means of a moulding bed. According to the integral forging and forming method for the large-scale end socket forge piece of the nuclear reactor with the multiple protruding nozzles, the shape and the size of the prefabricated slab can be effectively controlled, metal of the prefabricated slab is reasonably dispersed, and the situations that the internal organization is even, forming process line is distinct, the fibrous structure is good, and the contour shape is intact are achieved. Hot stamping technology deformation belongs to the scope of large displacement and small strain in nature, and the needed press machine loading force is small; hot stamping integral forming is easy to control the shape of a big end socket forge piece product, the heat loss in the forming process of the big end socket forge piece product is small, the heating temperature of a blank is low, the time is short, so that finish-forging formed grains are controlled to grow up, and the product quality is guaranteed.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

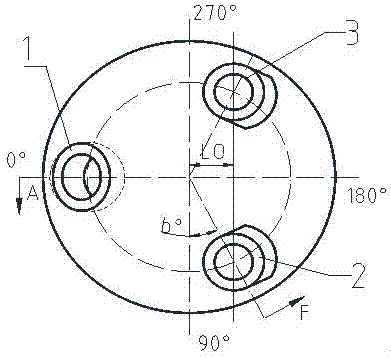

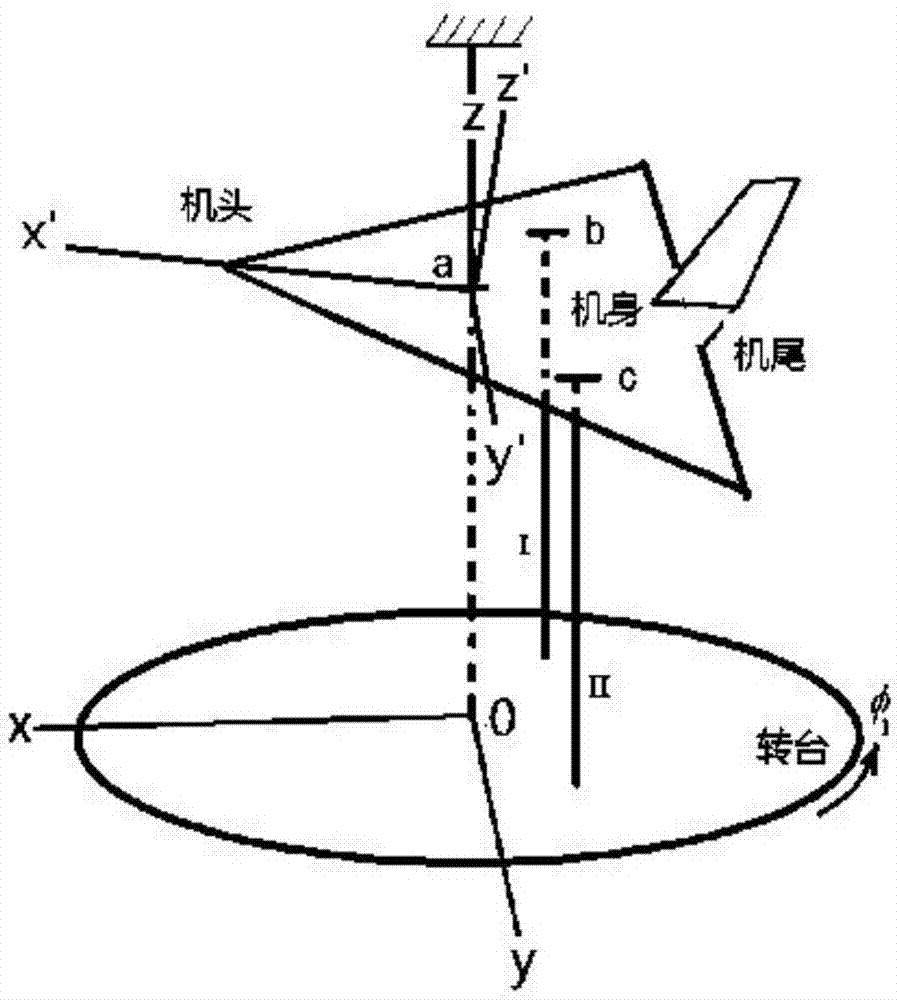

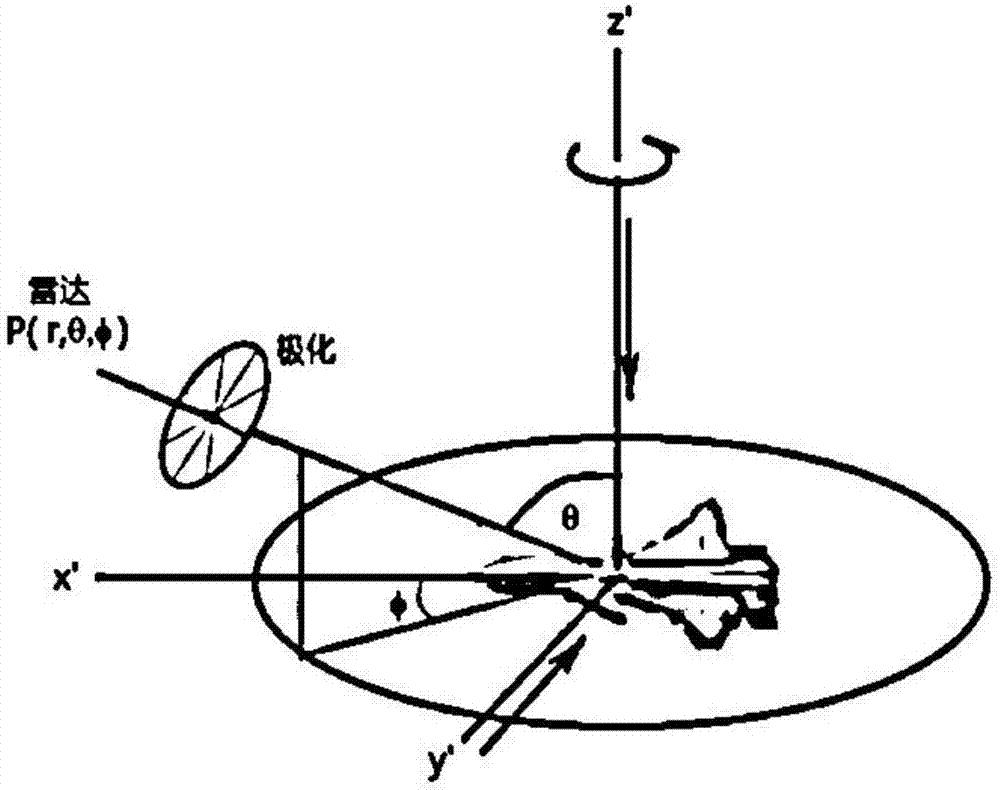

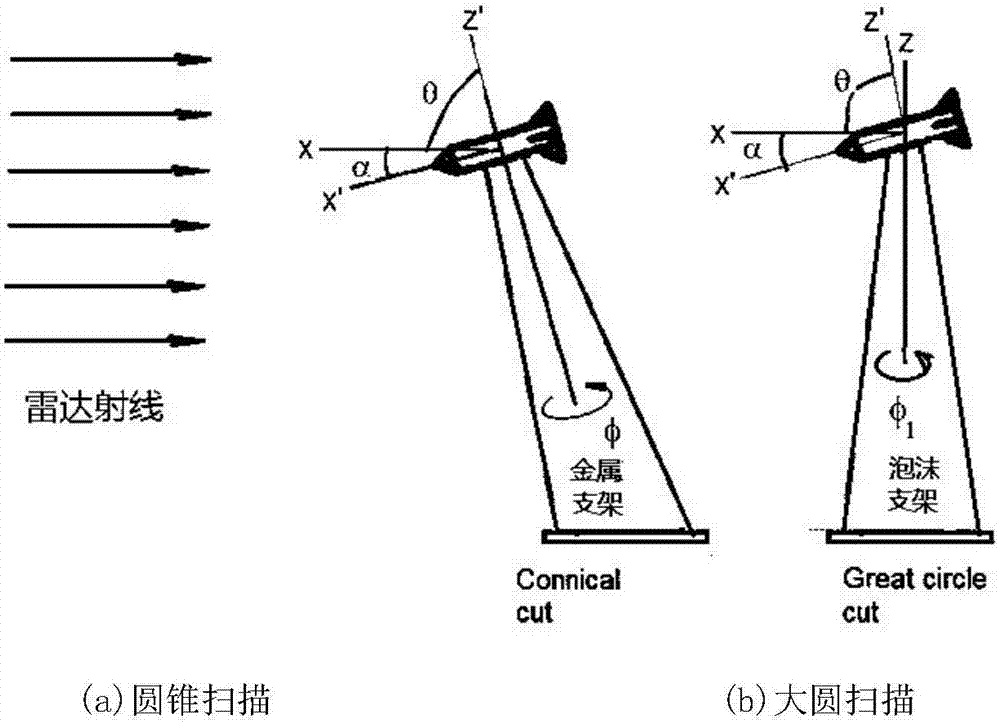

Method using two-support one-suspension support system to realize conical scanning

ActiveCN107957575ASmall load capacityIncreased load-bearing capacityWave based measurement systemsSupporting systemConical scanning

The invention relates to a method using two-support one-suspension support system to realize conical scanning; when the two-support one-suspension support system carries out a RCS test, a one-dimension rotary table is below a pitching rotation mechanism, the table surface is parallel to the ground, and the rotary table rotary shaft z is vertical to the ground; two poles are fixed on the rotary table and vertical to the rotary table surface; the two poles are mechanically connected with the plane in b and c points; a suspension rope fixed on the roof is connected with the a point on the back side of the plane, and overlaps with the rotary table axis; the plane can be fixed in the air through the a, b and c points. The other content of the invention is to use a multi-shaft linking mode to realize the conical scanning method; the rotary axis of a large scale target in a measuring process is vertical to the target self, and not vertical to the ground; compared with a conventional foam support and low scattering support, the two-support one-suspension support system is high in bearing ability, and the target erection mechanism cannot damage the target, thus providing excellent application prospects in RCS measurement of a 1:1 real equipment plane.

Owner:BEIHANG UNIV

Non-volatile memory device, non-volatile memory system and control method for the non-volatile memory device in which driving ability of a selector transistor is varied

ActiveUS7859914B2Total current dropShorten access timeRead-only memoriesDigital storageComputer scienceDiffusion layer

The control method includes a step of varying driving ability of a selector transistor which selects a diffusion layer in a selected memory cell and a diffusion layer of at least one non-selected memory cell which adjoins to the selected memory cell when the selected memory cell makes transition from a memory cell at one end to a memory cell at other end within a memory block.

Owner:INFINEON TECH LLC

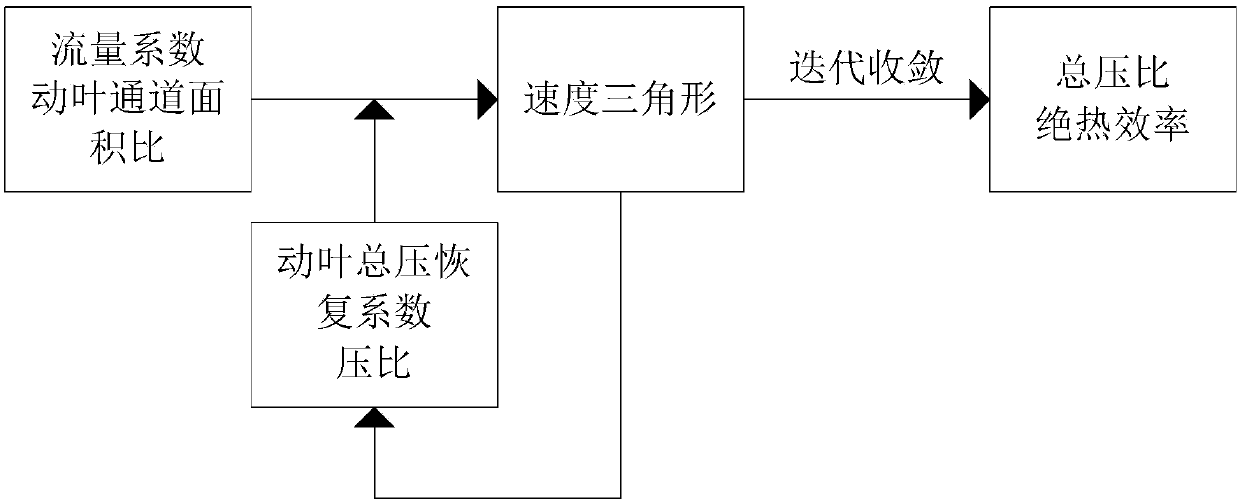

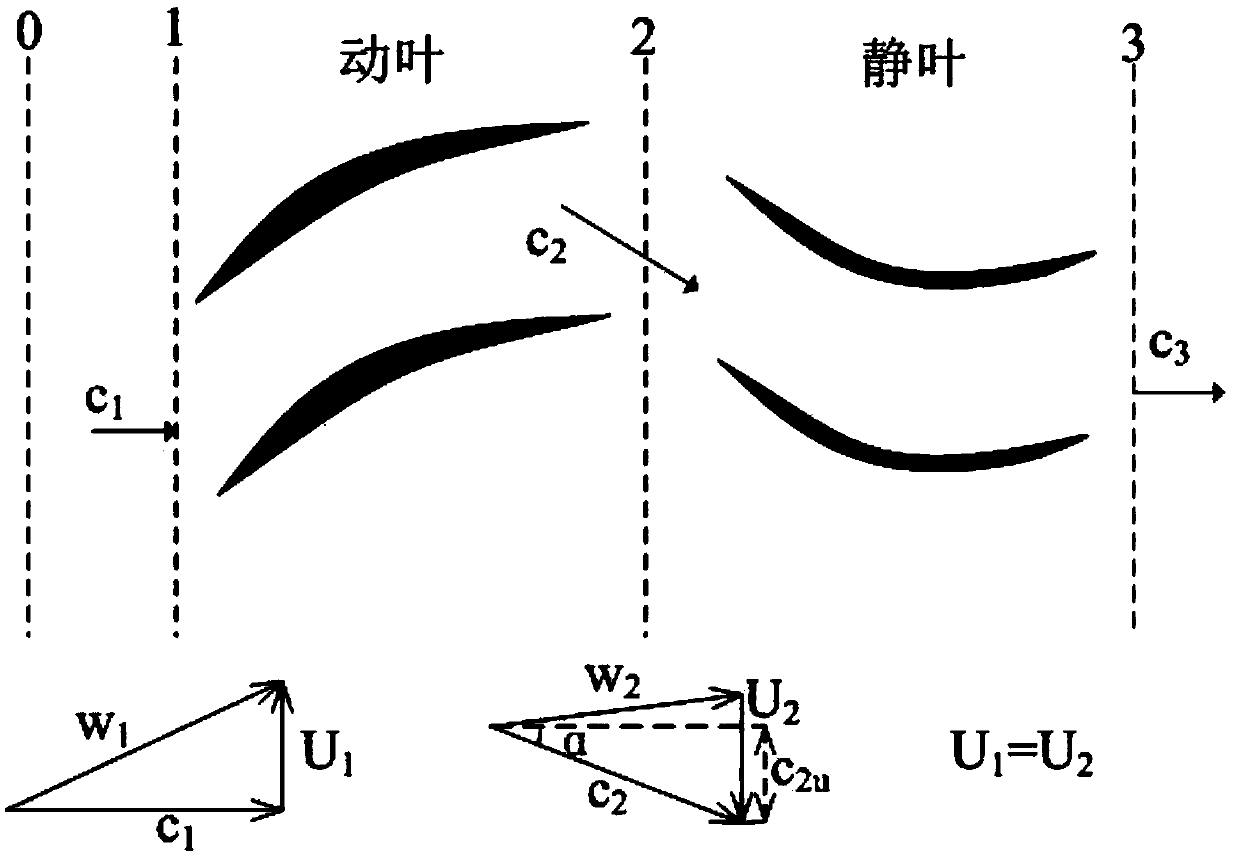

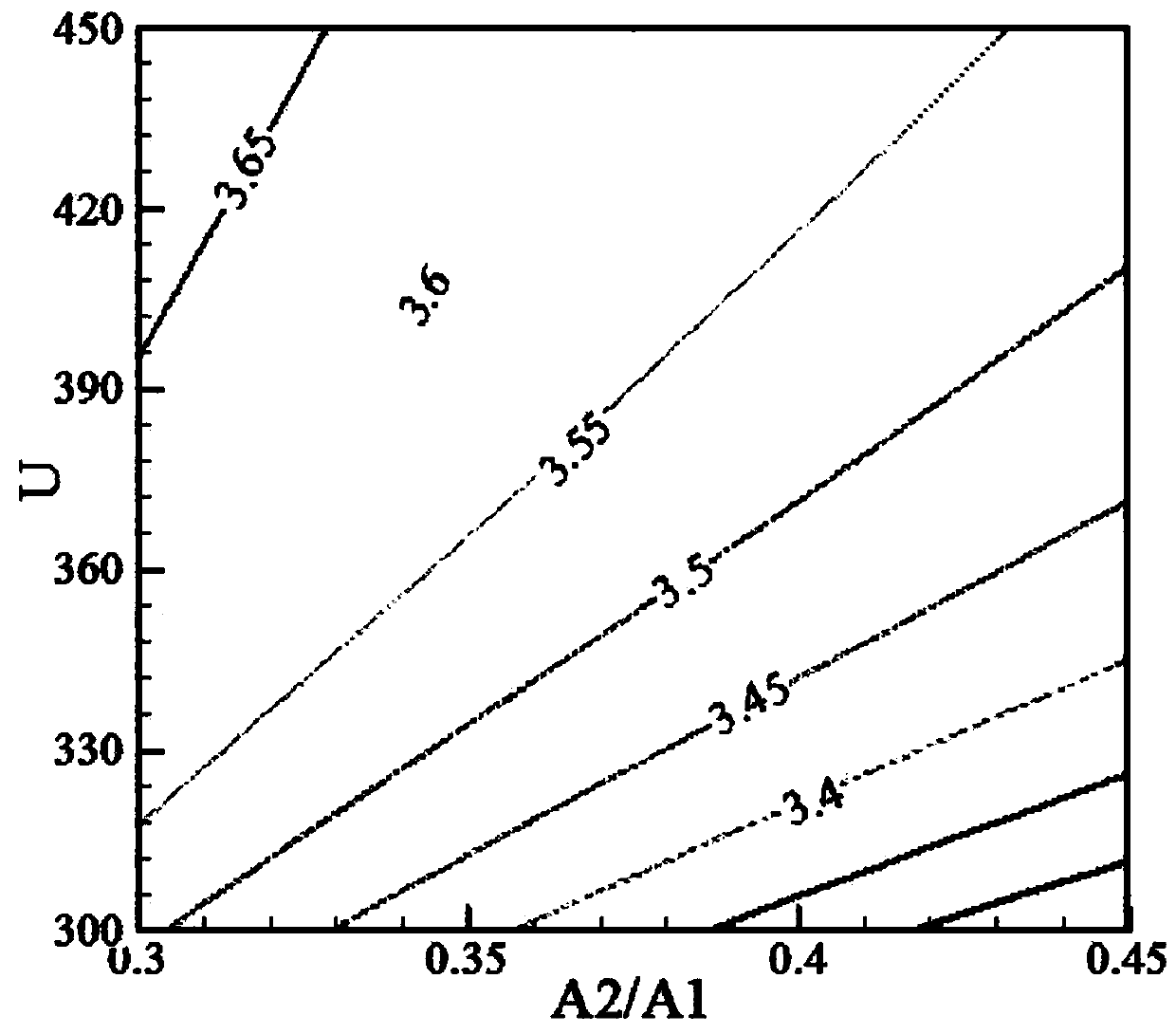

Axial supersonic inflow shock-in-stator fan

ActiveCN108131325AIncrease the total pressure recovery coefficientHigh strengthPump componentsPumpsShock waveStator

The invention relates to an axial supersonic inflow shock-in-stator fan (SSSF), and belongs to the technical field of mechanical devices and transportation. The SSSF provides a thermodynamic layout fan in a new form, and the thermodynamic layout fan includes axial supersonic inflow rotating vanes and shock stator vanes; the SSSF can directly face axial supersonic inflow, the interior of a rotatingvane channel stays in a fully-unfolded highly-axial supersonic flow state, and a stator vane channel decelerates flow into a subsonic speed through a shock wave system. The design process of the SSSFincludes one-dimensional scheme design, two-dimensional flow design, three-dimensional appearance design, intensity check and machining and testing of test pieces. Compared with a traditional subsonic or transonic fan, the SSSF has the advantages that the length and weight of an air inlet passage are greatly reduced; meanwhile, due to excellent load capacity of the supersonic inflow rotating vanes, the SSSF in a supersonic flight state has the advantages of being high in load and efficiency and light in weight.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

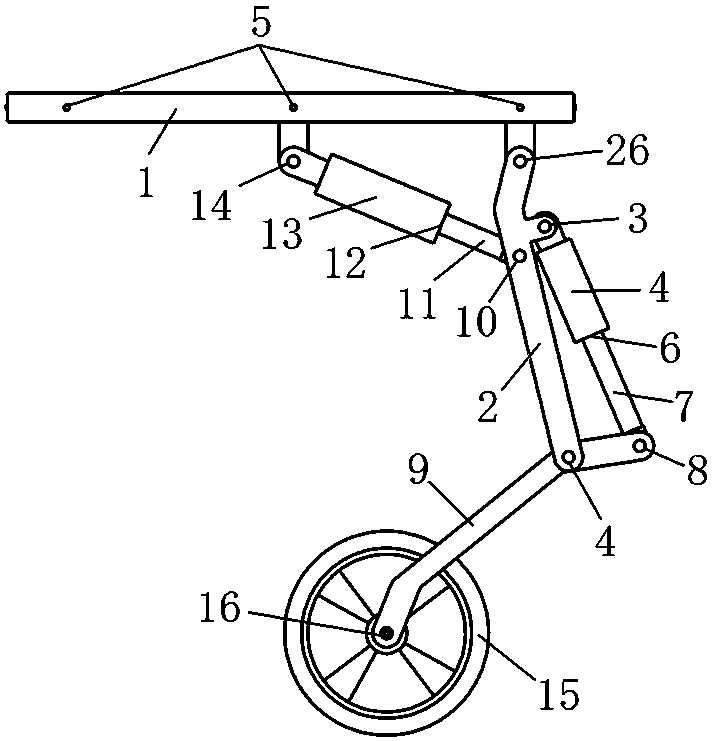

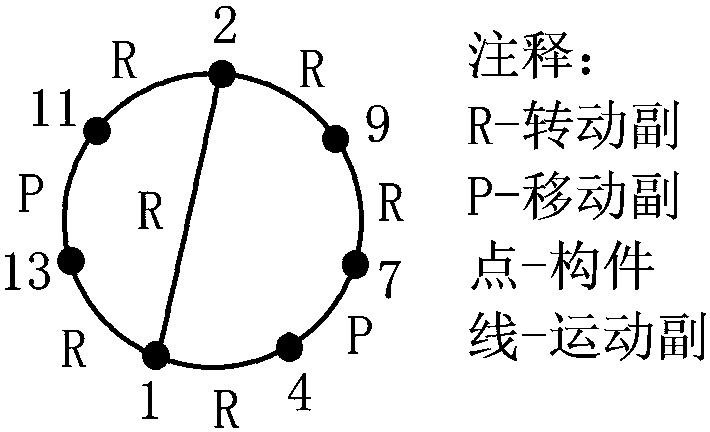

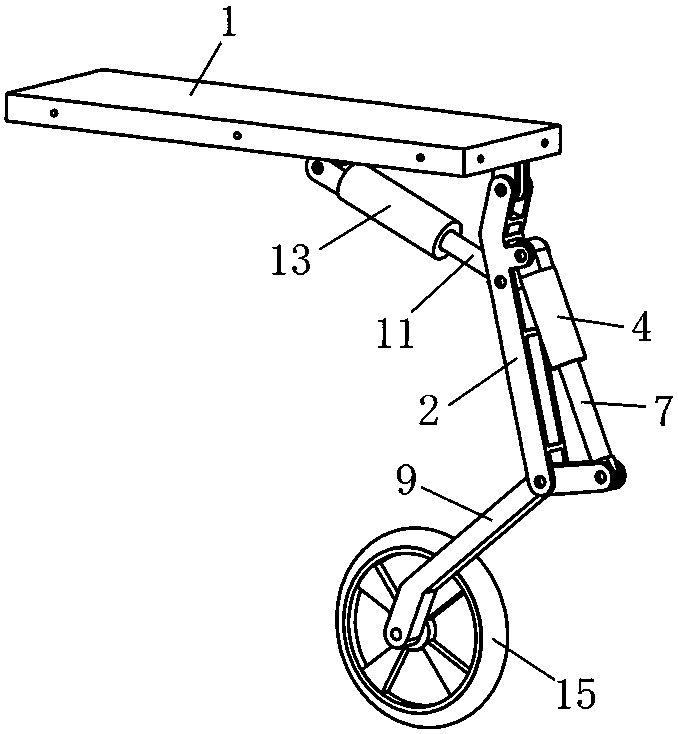

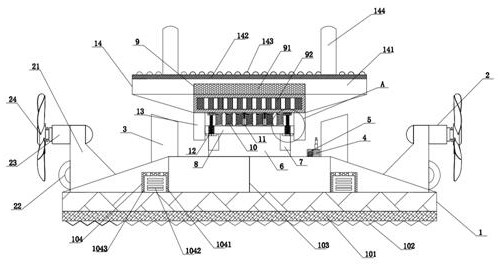

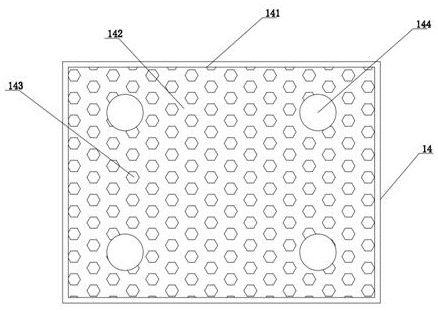

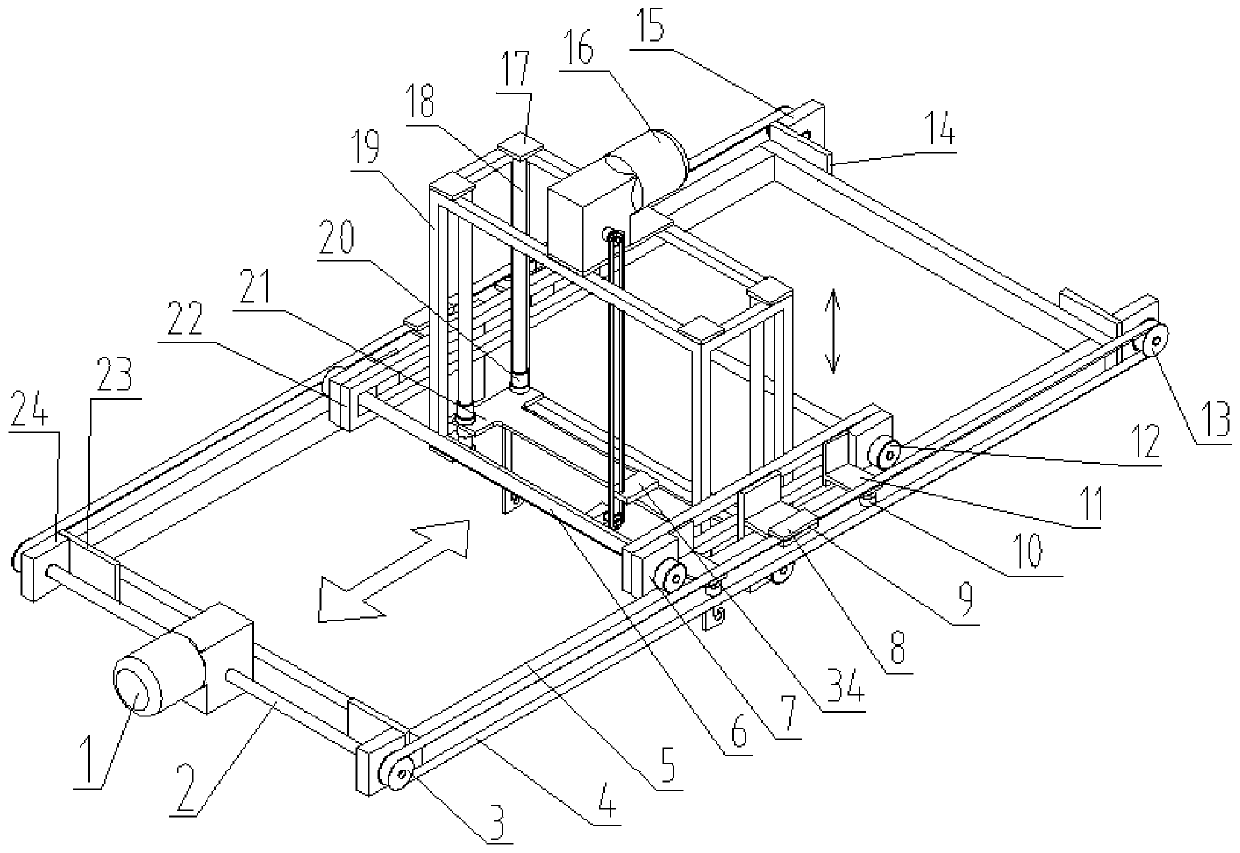

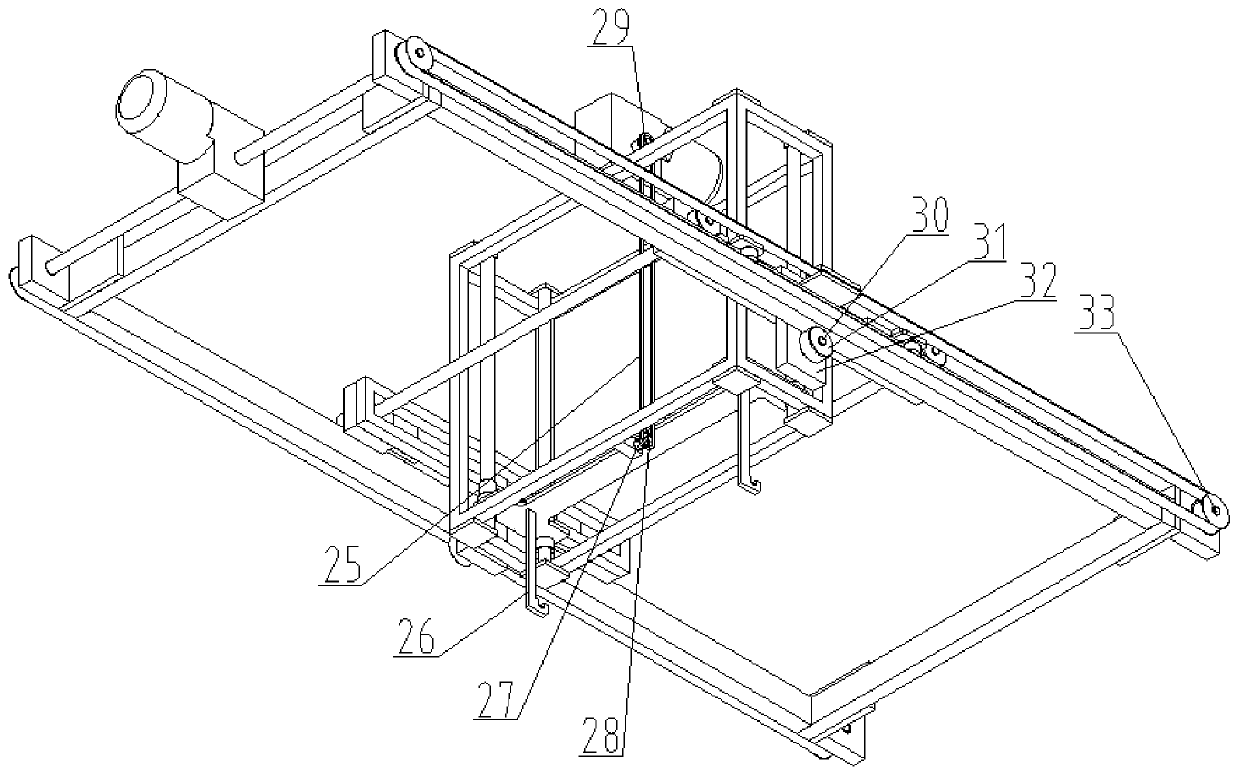

Electric-cylinder-driven modular robot transportation platform

PendingCN109747727AExcellent obstacle performanceCompact structureVehiclesComputer programmingTwo degrees of freedom

The invention relates to an electric-cylinder-driven modular robot transportation platform. The electric-cylinder-driven modular robot transportation platform includes two or more robot platform units, wherein each robot platform unit includes a robot wheel-leg mechanism and wheels, wherein the robot wheel-leg mechanism is a seven-rod two degree-of-freedom connecting rod mechanism including two sliding pairs, and includes two closed loop; and the wheels are arranged on the robot wheel-leg mechanism. The modular robot transportation platform replaces an existing flat car hydraulic transmissionsystem by connecting rod transmission and the two sliding pairs are active pairs and are driven by a servo electric cylinder. Under control of computer programming, the robot wheel-leg mechanism can realize a large space and highly flexible two-degree-of-freedom controllable movement, so as to enable the wheels to have a strong ability to overcome obstacles. Compared with an existing flat car, themodular robot transportation platform shortens the response time, reduces the failure rate, energy consumption and maintenance cost, also greatly improves the intelligent level, avoids the constraints of hydraulic pipelines, is easy to rebuild quickly, and can better meet the requirements of high-precision special transportation operations.

Owner:SHANDONG JIAOTONG UNIV

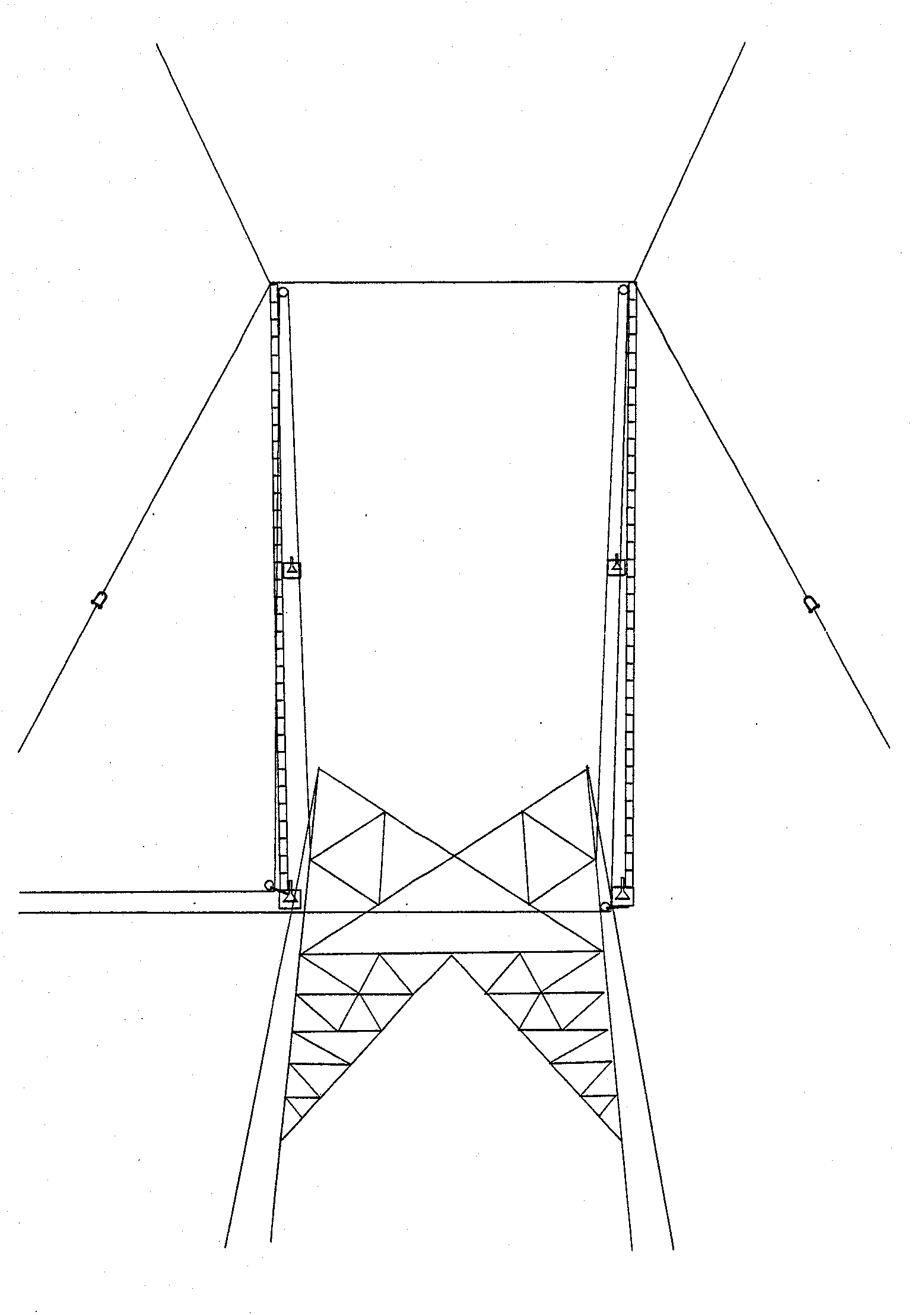

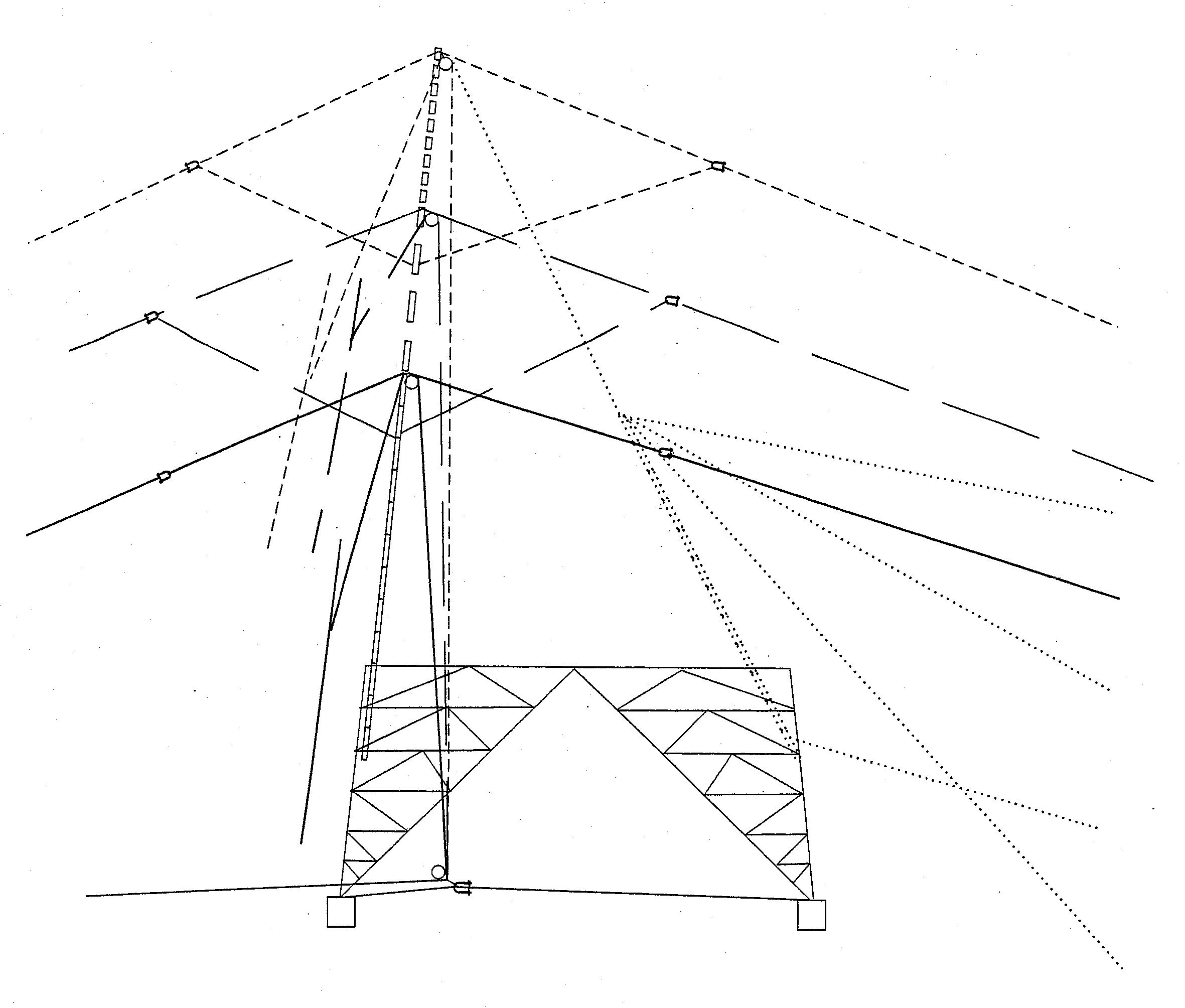

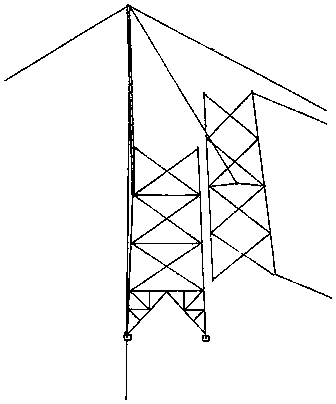

Method for assembling iron tower through high-voltage power transmission lines

InactiveCN104278874AReduce tensionSmall load capacityTowersBuilding material handlingEngineeringAlloy

The invention discloses a method for assembling an iron tower through high-voltage power transmission lines. The method resolves the problems that when existing large and medium iron towers are erected and installed, many tools and workers are needed, the occupied space is large, it is troublesome to transfer the large and medium iron towers to another site, the construction procedures are complex, the construction speed is low, and the safety coefficient is low. The method is characterized in that tools such as light aluminum alloy derrick masts, traction steel ropes and a winch grinder are adopted, and large, medium and small special-shaped high-voltage power transmission line iron towers are assembled through the methods that four branches are on floor and eight branches are pulled, high points are hoisted and low points are in place, a large surface is used for hoisting, and derrick masts are arranged inside and outside. The method has the advantages of being wide in application range, needing a few tools and constructors, convenient and rapid to transfer to another site, safe and efficient to install and the like, and can be widely used for assembling various large, medium and small special-shaped iron towers.

Owner:HUANGGANG POWER SUPPLY COMPANY HUBEI ELECTRIC POWER

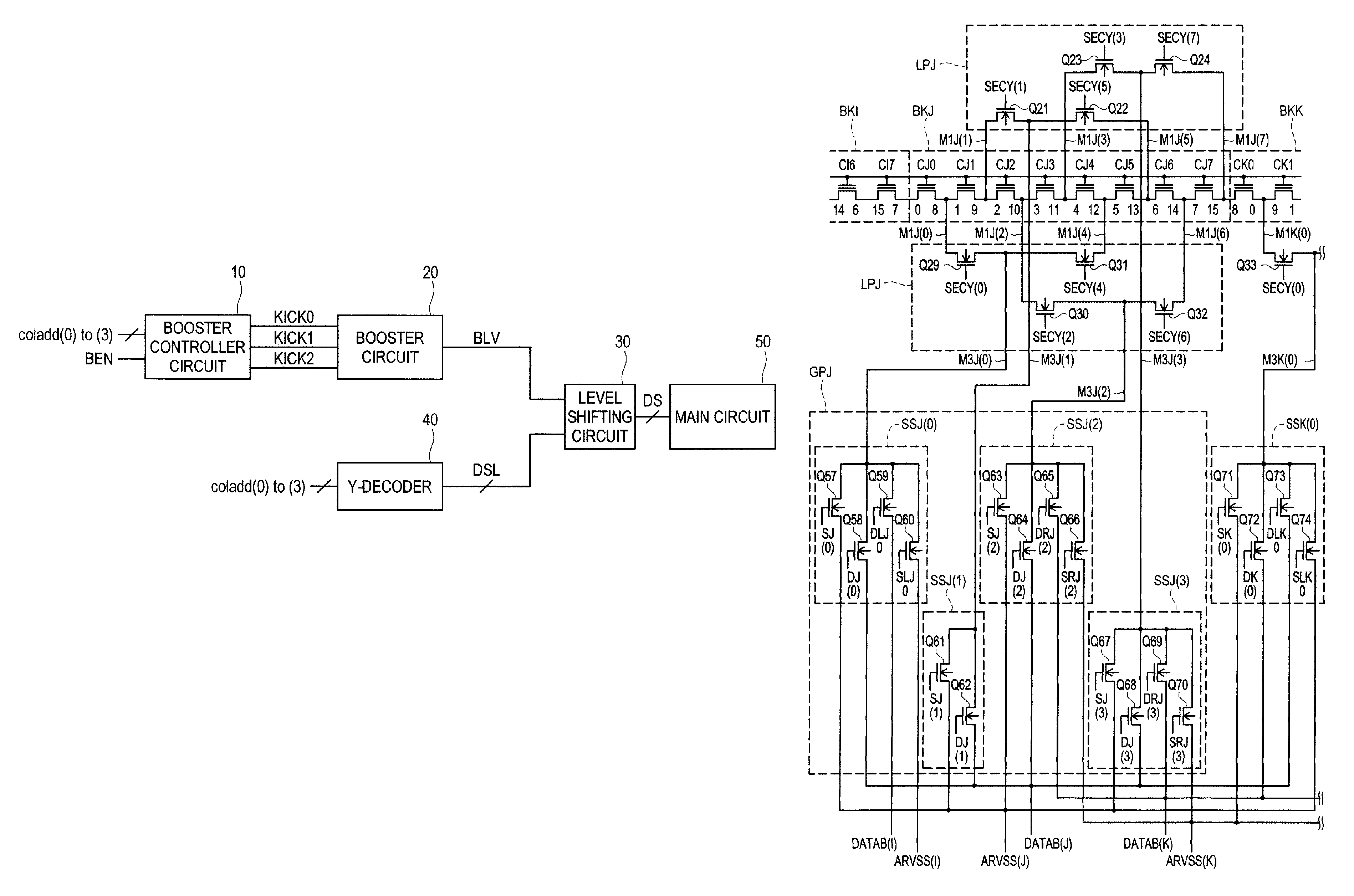

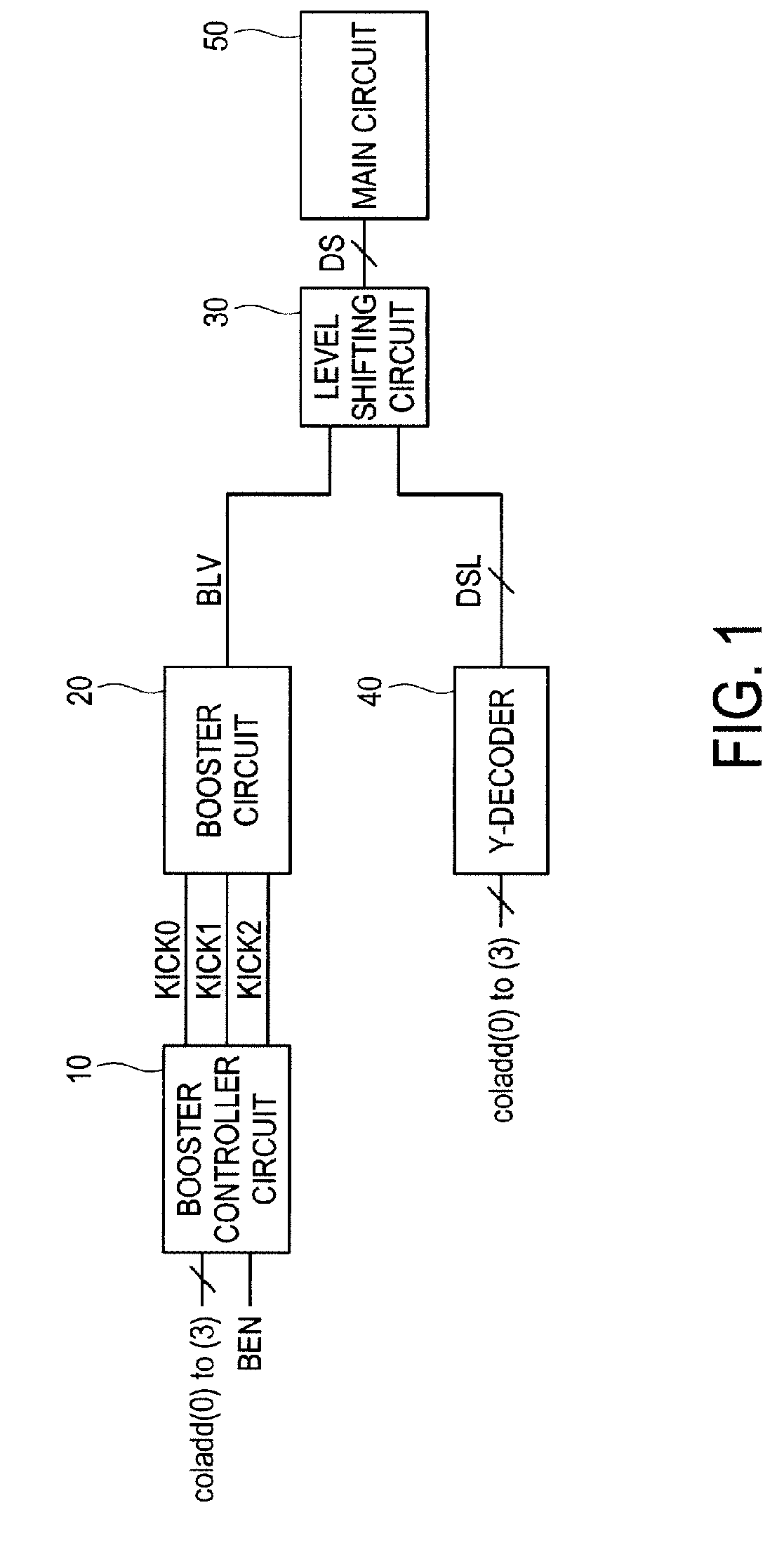

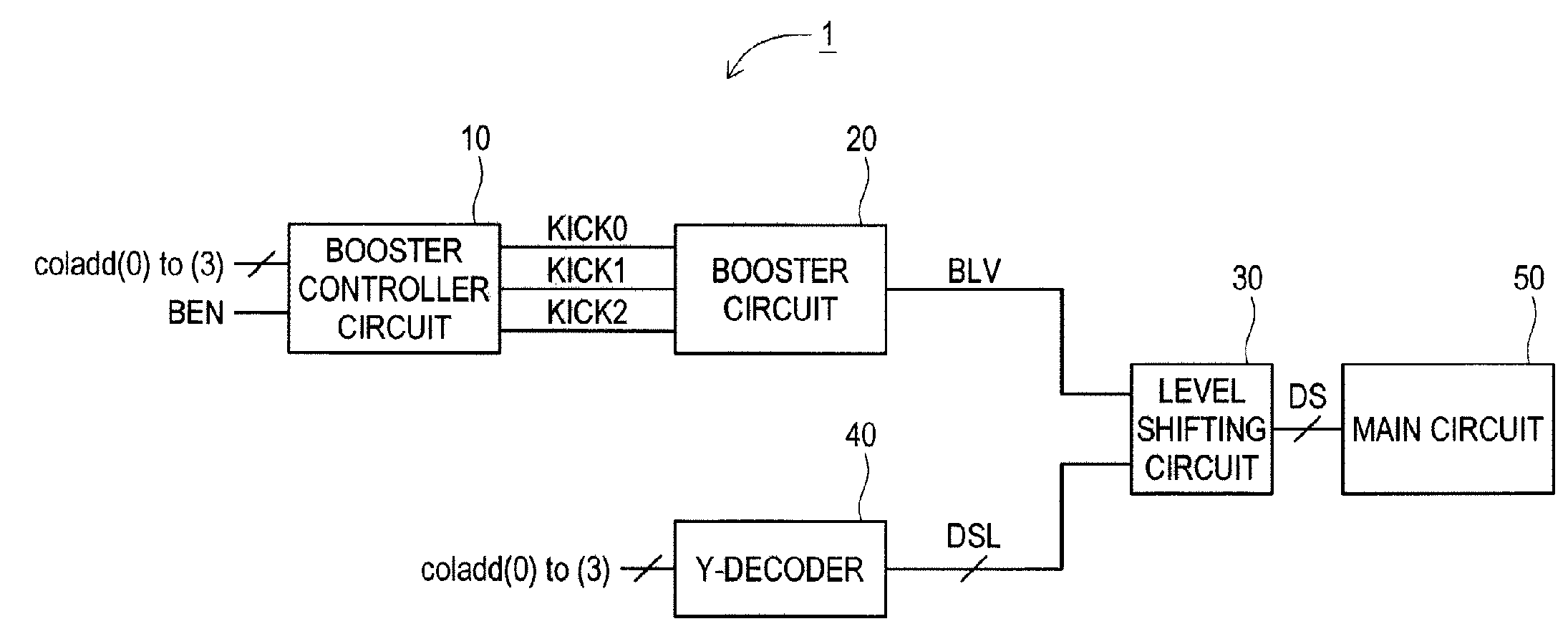

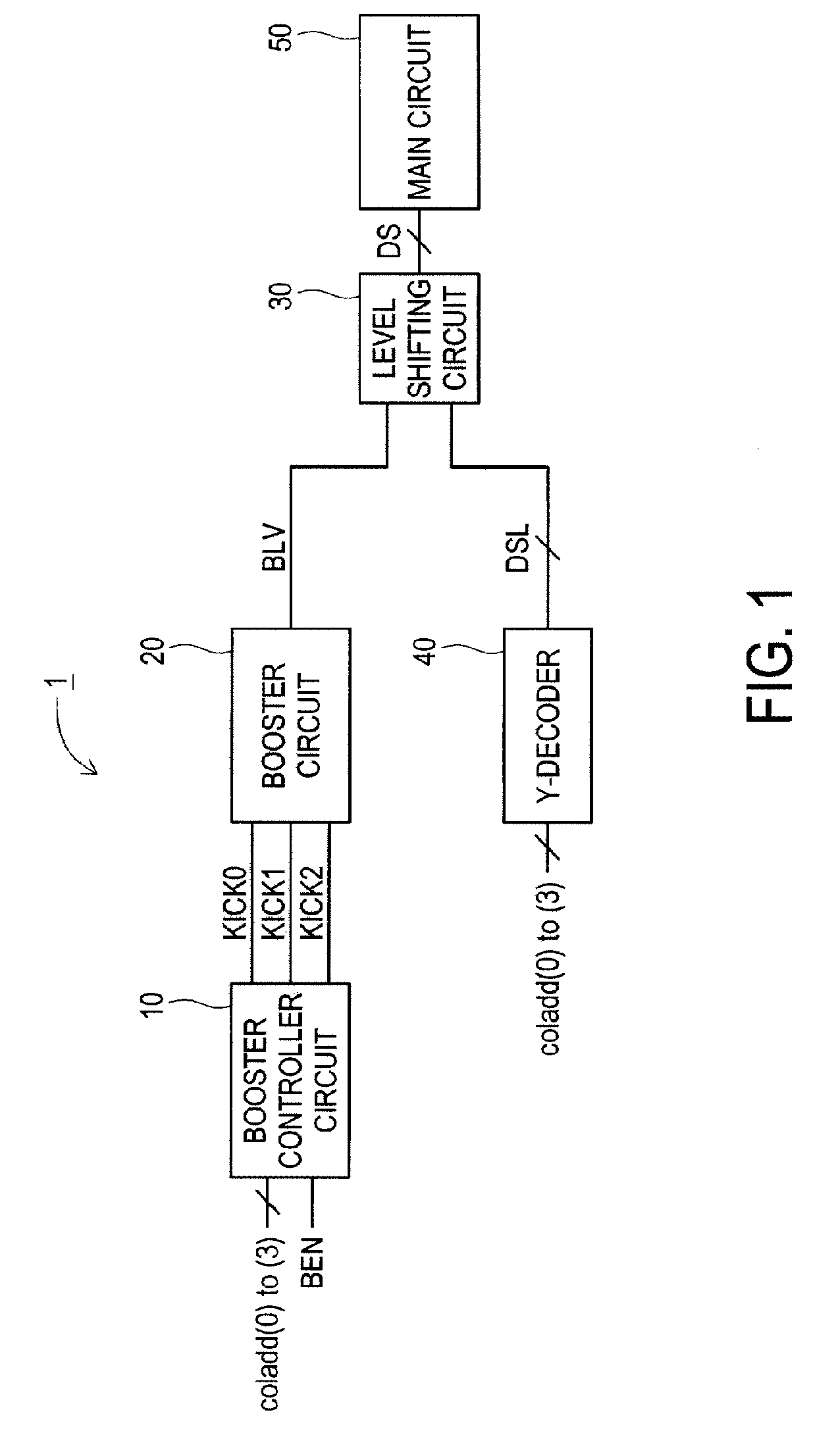

Non-volatile memory device, non-volatile memory system and control method for the non-volatile memory device

ActiveUS20080247233A1Total current dropShorten access timeRead-only memoriesDigital storageLevel shiftingAccess time

A nonvolatile memory device which can reduce consumption current and shorten access time and a control method thereof is provided. The nonvolatile memory device 1 comprises a booster controller circuit 10, a booster circuit 20, a level-shifting circuit 30, a Y-decoder 40, and a main circuit 50. A NAND gate ND1, a NOR gate NR1, and a NOR gate NR2 provided in the booster controller circuit 10 output kick signals KICK0 to KICK2. The booster circuit 20 comprises boosting systems B0, B1, B2 which respectively receive the kick signals KICK0, KICK1, and KICK2. The kick signals KICK0 and KICK1 outputted from the NAND gate ND1 and the NOR gate NR1 make transition to high level in accordance with the transition of column address coladd from address 7 to 8. Therefore, the boosting system B0 is activated in addition to the boosting system B1.

Owner:INFINEON TECH LLC

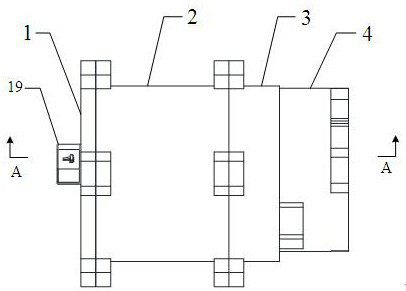

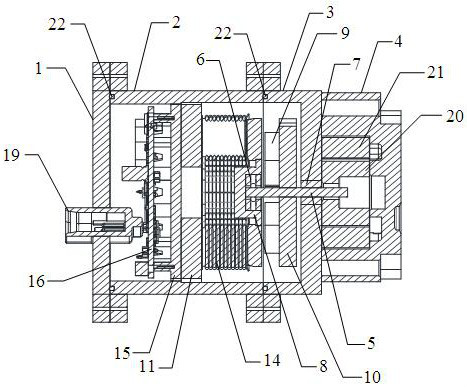

Double-bloomed drive wedge mechanism for automobile roof skylight

The invention discloses a double-bloomed drive wedge mechanism for an automobile roof skylight. The double-bloomed drive wedge mechanism comprises a left side reshaping mechanism, a right side reshaping mechanism and a lower die driving mechanism, wherein a first upper die driving block of the lower die driving mechanism drives a first-stage sliding block and drives a left second-stage sliding block to move towards the left side and a right second-stage sliding block to move towards the right side; a left side upper die driving block of the left side reshaping mechanism drives a left side lower die sliding block to move rightwards; a right side upper die driving block of the right side reshaping mechanism drives a right side lower die sliding block to move leftwards. The double-bloomed drive wedge mechanism has the advantages that the strength of the driving blocks is guaranteed, the wear among die components is reduced, the precision of a die is improved, and the service life of the die is prolonged.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

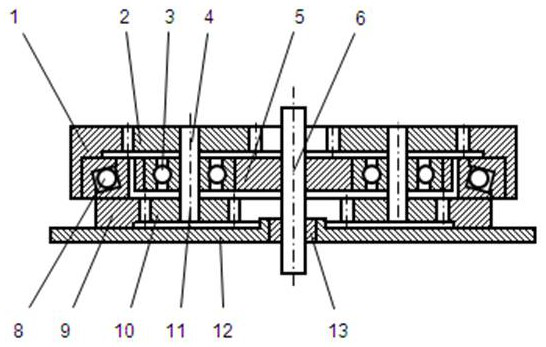

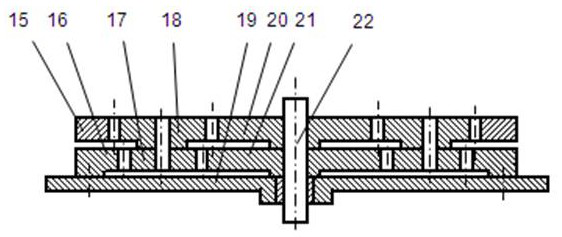

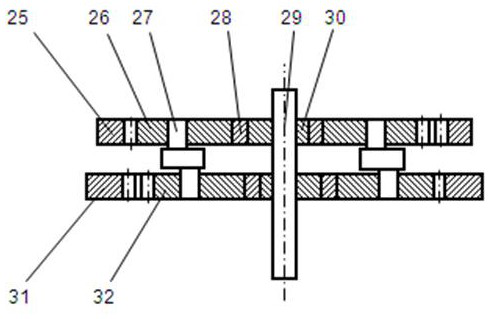

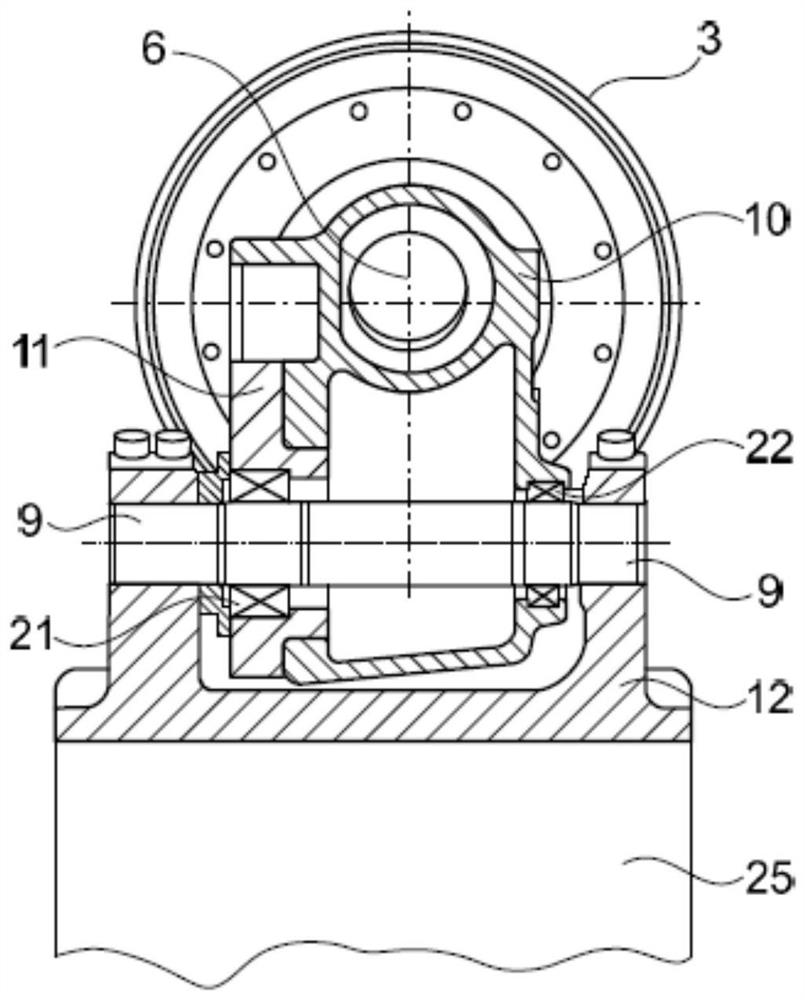

Co-location differential speed reducer

InactiveCN112013094ASmall backlash angleRich selection of gear ratiosDifferential gearingsReduction driveReducer

The invention discloses a co-location differential speed reducer which is a speed reducer with a co-location differential gear train. A transmission structure of the co-location differential speed reducer is designed by combining differential logics and multiple logics, the reduction ratio is negatively correlated with the difference value of two contrast rotating speeds, and the difference valuecan be infinitely close to zero from the positive direction and the negative direction, so that the reduction ratio can tend to be infinitely great or infinitely small, how large the reduction ratio is is not mainly determined by how large the multiple of geometrical parameters of assemblies of a transmission gear train is and is mainly determined by how approaches the multiple of geometrical parameters of two transmission gear trains is, under the condition that the sizes are equal, a wide output range and a large reduction ratio can be obtained, or under the same reduction ratio, the size issmaller or the load capacity is larger. On the basis, multiple zero-backlash transmission methods are adopted to reduce return difference, and multiple other technical means are matched to obtain more excellent comprehensive performance and a larger application range.

Owner:周承岗

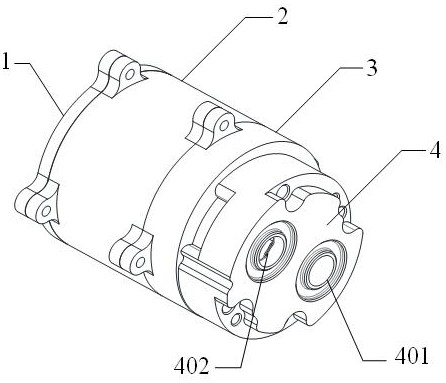

Disc type electronic oil pump

ActiveCN111934484AReduce axial sizeIncrease axial dimensionMagnetic circuit rotating partsRotary piston pumpsEngineeringOil pump

The invention discloses a disc type electronic oil pump which comprises a stator assembly, a rotor assembly and a pump assembly. The stator assembly comprises an end cover, a stator shell and a statorassembly located in the stator shell. The rotor assembly comprises a rotor shell and a rotor assembly located in the rotor shell. The pump assembly comprises a pump cover and a pump assembly locatedin the pump cover. The rotor assembly includes a rotor; a rotating shaft, a plane bearing, a shaft sleeve and a rotor, a plane bearing sleeves one end of the rotating shaft; one end of the stator assembly facing the rotor assembly is provided with a bearing seat; the plane bearing is arranged in the bearing seat, the other end of the rotating shaft penetrates through a through hole in the surfaceof the end, facing the pump assembly, of the rotor shell and stretches into the pump cover, the other end of the rotating shaft is sleeved with the pump assembly and a shaft sleeve, the shaft sleeve is arranged in the through hole of the rotor shell, and the rotor is sleeved with the rotating shaft. The plane bearing is adopted, so that high loading capacity and high rigidity can be realized in avery small space, and damage caused by large abrasion is avoided.

Owner:浙江睿驰同利汽车电子有限公司

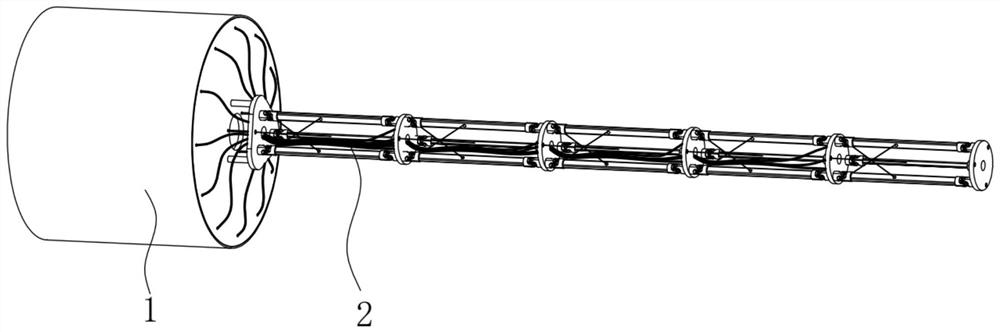

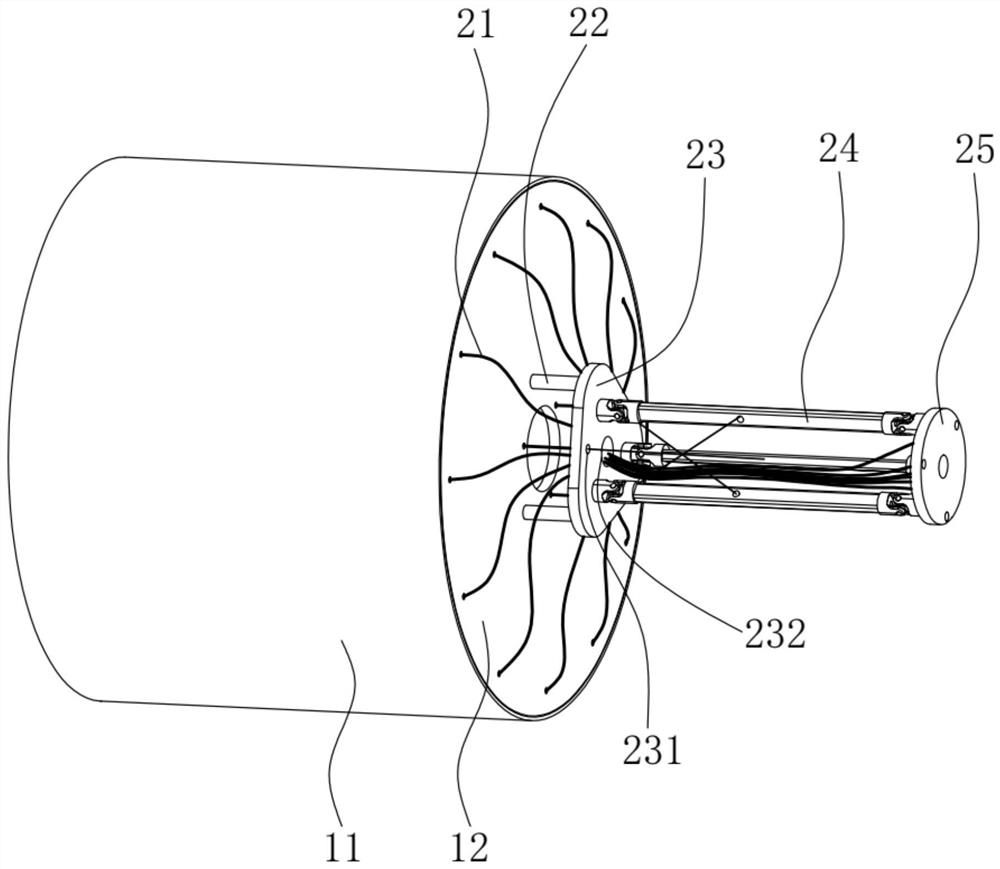

Large-load long-distance radiation-resistant high-precision snakelike arm

ActiveCN113733067AEasily brokenReduce stressProgramme-controlled manipulatorRadiation resistantClassical mechanics

The invention provides a large-load long-distance radiation-resistant high-precision snakelike arm which comprises a driving base body and a snakelike arm body. One end of the snakelike arm body is connected to the driving base body, and the snakelike arm body is formed by connecting parallel-connection parallel joints in series. Each parallel-connection parallel joint comprises a plurality of same movable connecting rod mechanisms which are connected in parallel. Each parallel-connection parallel joint further comprises platforms which are connected with the two ends of each of the multiple same movable connecting rod mechanisms connected in parallel. When the platform at one end of the two ends of each of the multiple same movable connecting rod mechanisms connected in parallel is fixed, the platform at the other end conducts spherical translational motion relative to the platform, and every two adjacent platforms are always kept parallel. Each movable connecting rod mechanism at least comprises a connecting rod. A plurality of driving units are installed in the driving base body, each driving unit is connected with the corresponding connecting rod in the parallel-connection parallel joints through a steel wire rope, each steel wire rope is connected with the corresponding connecting rod, and motors which are distributed in a centralized mode are used for driving the steel wire ropes to drive the parallel-connection parallel joints to achieve movement of the snake-shaped arm body.

Owner:HUNAN UNIV

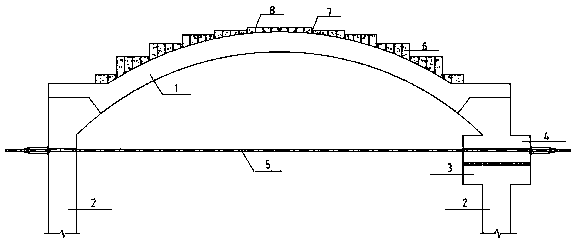

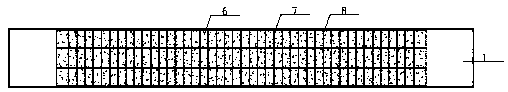

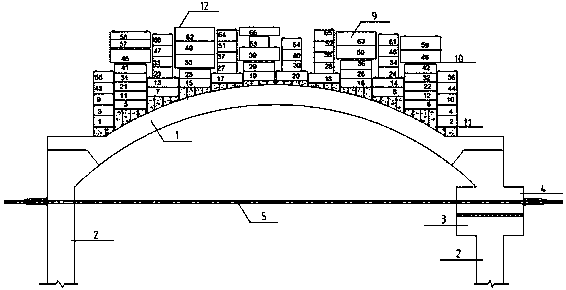

Construction method of arch structure in-situ surcharge load test

InactiveCN109507387ASmall load capacityLoad height reductionMaterial strength using tensile/compressive forcesEarth material testingCushionEngineering

The invention provides a construction method of an arch structure performance in-situ surcharge load test. According to the construction method of the arch structure performance in-situ surcharge loadtest, an existing crawler crane superlift counterweight is adopted for replacing traditional bagged iron sand or bagged sand, the surcharge load mass is little, the surcharge load height is reduced,the counterweight contact interface levelness and flatness are easy to control compared with those of the traditional bagged iron sand or bagged sand, secondly, the cushion levelness control precisionof a surcharge load base is high compared with that of a conventional bagged iron sand or bagged sand surcharge load base, the stiffness is high, and the safety of test operation is improved. Meanwhile, on the basis of guaranteeing safe construction, the surcharge load counterweight can be recovered to save resources. By contrast, the counterweight mass is reduced, the transportation cost is saved, and surcharge load duration is shortened, so that the construction cost is reduced.

Owner:YANGZHOU POLYTECHNIC INST

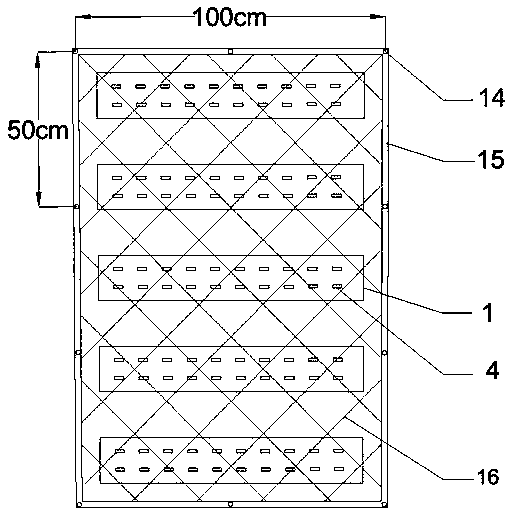

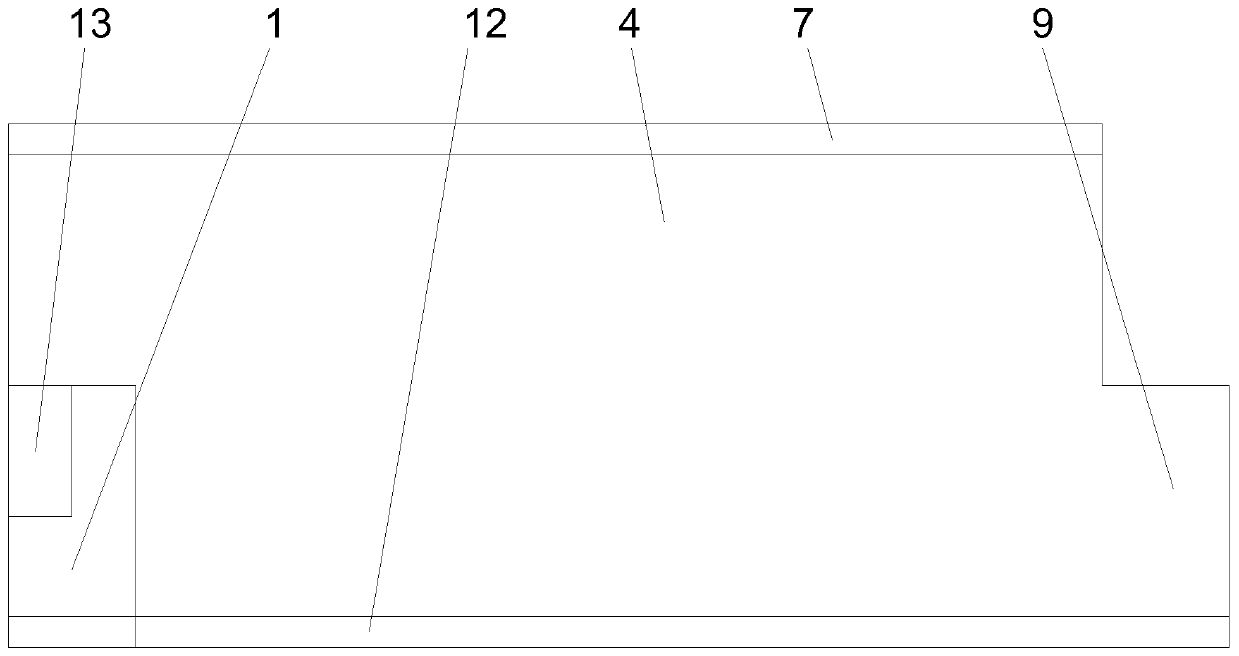

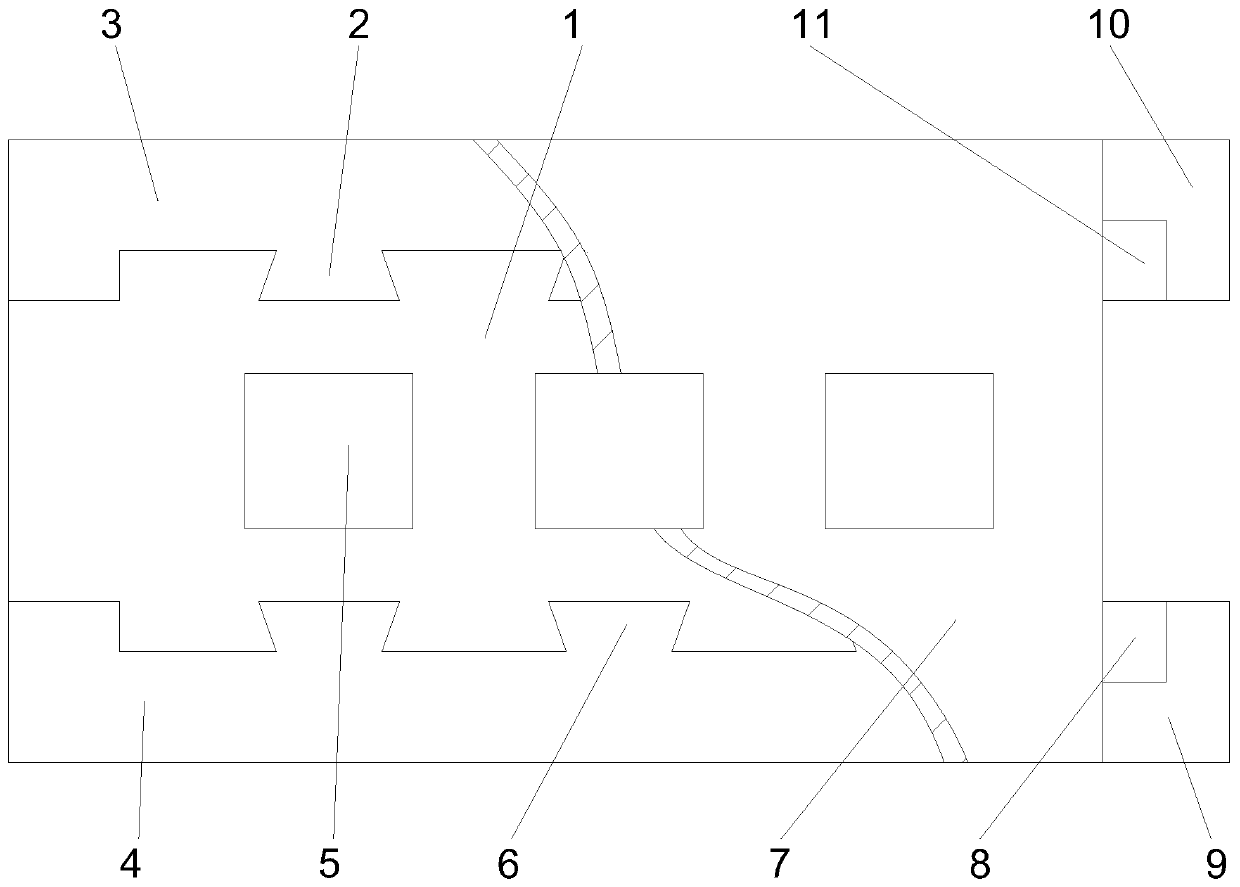

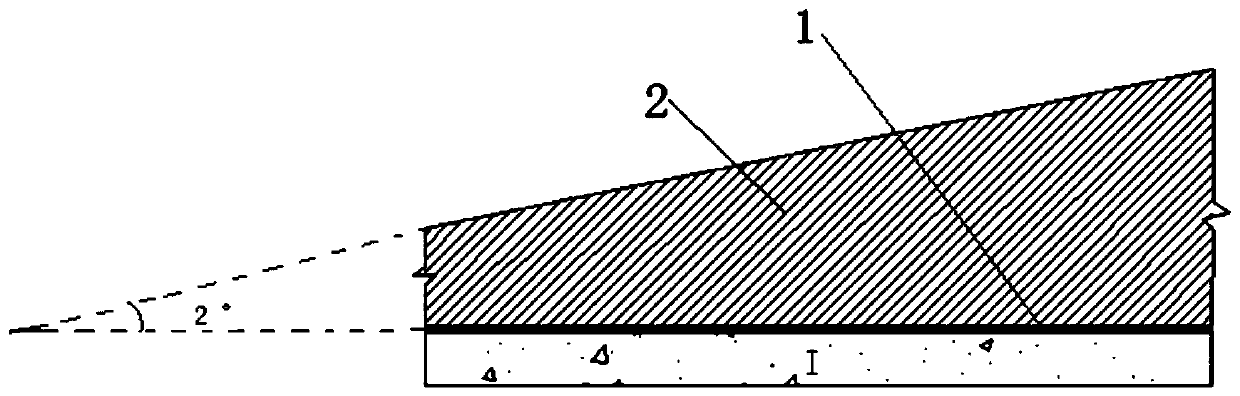

Novel integrated product for roof greening and construction method

InactiveCN108811942AFast constructionReduce weightGrowth substratesCulture mediaEngineeringGermination

The invention provides an integrated product for roof greening, belongs to light roof greening materials, and belongs to the field of building. The integrated product comprises seed bags, seed germination holes, a light resistance and water retaining layer, a water storage substrate, a barrier layer, a light growth substrate and an anti-seepage and root-resistant composite layer; the anti-seepageand root-resistant composite layer is arranged at the bottom, the light growth substrate is arranged above the anti-seepage and root-resistant composite layer, the barrier layer is arranged above thelight growth substrate, the water storage substrate is arranged above the barrier layer, the seed bags are arranged above the water storage substrate, the light resistance and water retaining layer isarranged above the seed bags, and the seed germination holes are formed in the light resistance and water retaining layer and arranged above the seed bags. A suitable growth environment can be provided for roof greening plants, the integrated product for roof greening can be installed and used without any modification to an original roof structure, and has the advantages of light weight, reasonable structure, safety and reliability, convenient installation and disassembly, low cost, wide adaptability, easy to popularize and so on.

Owner:SHANXI UNIV

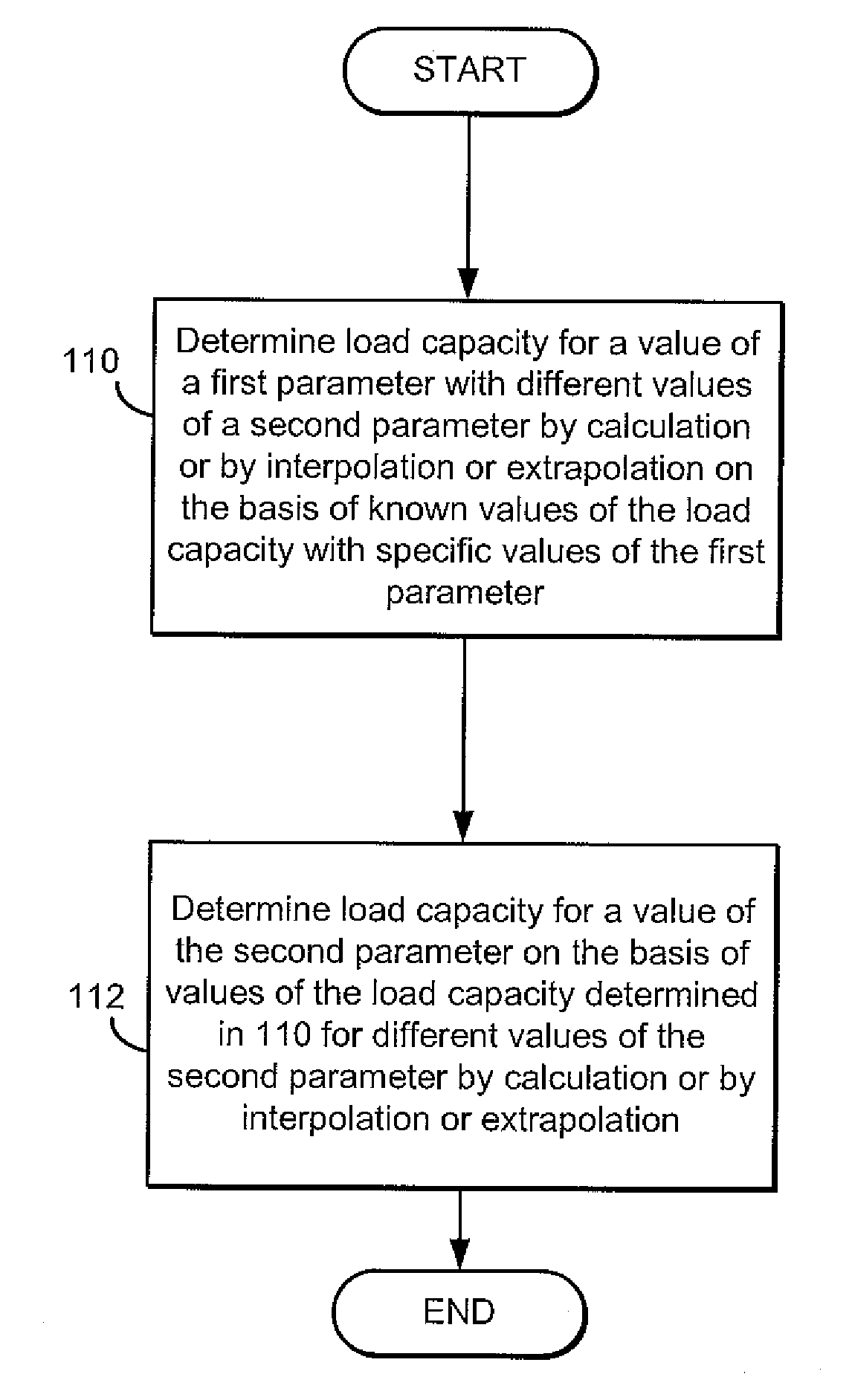

Method for Determining the Load Capacity of Cranes

ActiveUS20100250153A1Small load capacityOperational securityForce measurementWork measurementEngineeringLoad capacity

Owner:LIEBHERR WERK EHINGEN

Guimo brick for cement rotary kiln and preparation method of Guimo brick

ActiveCN110526688ATight masonryLess aggressiveFurnace componentsCeramic shaping apparatusInsulation layerBrick

The invention relates to a Guimo brick for a cement rotary kiln and a preparation method of the Guimo brick. A casting material is prepared from alumina, white corundum, silicon oxynitride, alpha-Al2O3, metal silicon powder, an antioxidant, an additive and a binder. When the Guimo brick is used, the joint is more tightly built, and the bricks are firmly connected with each other and are integrallystressed, so that bearing capacity is high; each Guimo brick is internally provided with a cavity, so that self weight is small, and the practical service life is ensured. According to a heat-resistant material of a first temperature-resistant layer and a second temperature-resistant layer on two sides of the transition zone brick of the cement rotary kiln, the characteristics that silicon oxynitride has good thermal shock stability and good erosion resistance on cement materials and salts are utilized, and simultaneously the principle that molten SiO2 and silicate and molten non-ferrous metals such as Al, Cu and the like do not infiltrate silicon oxynitride ceramic is utilized, so that a transition zone brick, made of the brick, of the cement rotary kiln does not generate kiln coatings easily. A heat insulation layer with a heat insulation cavity is adopted between the first temperature-resistant layer and the second temperature-resistant layer, so that heat insulation capacity is high, the heat conductivity coefficient is small, the temperature of a kiln cylinder is prevented from being high, energy consumption is low, and cost of the cement kiln is reduced.

Owner:郑州瑞泰耐火科技有限公司

Civil engineering construction bridge support

InactiveCN112411364APrevent crushingExtended service lifeWind energy with electric storageEnergy storageArchitectural engineeringStress sensors

The invention discloses a civil engineering construction bridge support which comprises a base, power generation devices are fixedly installed at the two sides of the top of the base, a protection supporting plate is fixedly connected to the inner sides of the power generation devices on the top of the base, a signal transmitter is fixedly installed in the inner side of the protection supporting plate, and a DSP controller is fixedly installed on the left side of the signal transmitter. A base block is fixedly installed in the middle of the top of the base, grooves are formed in the two sidesof the upper end of the base block, a bearing plate is fixedly installed at the top of the base block, damping springs are fixedly installed at the top of the bearing plate at equal intervals, and damping mechanisms are fixedly connected to the tops of the damping springs. A pressure sensor is fixedly installed in the middle between each damping mechanism and the bearing plate, and the pressure sensor is arranged between the damping springs. The support has high-strength anti-seismic and damping capacity, early warning can be conducted in advance, collapse of a supporting bridge and a buildingis prevented, the practicability and safety are high, and the support is worthy of application and popularization.

Owner:崔德念

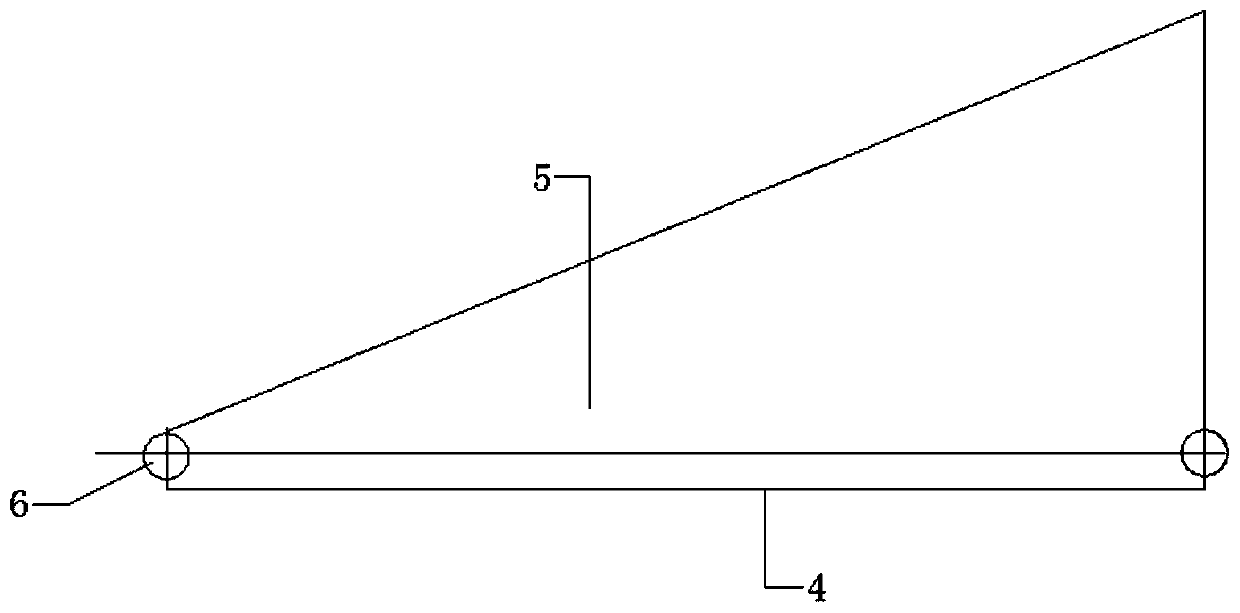

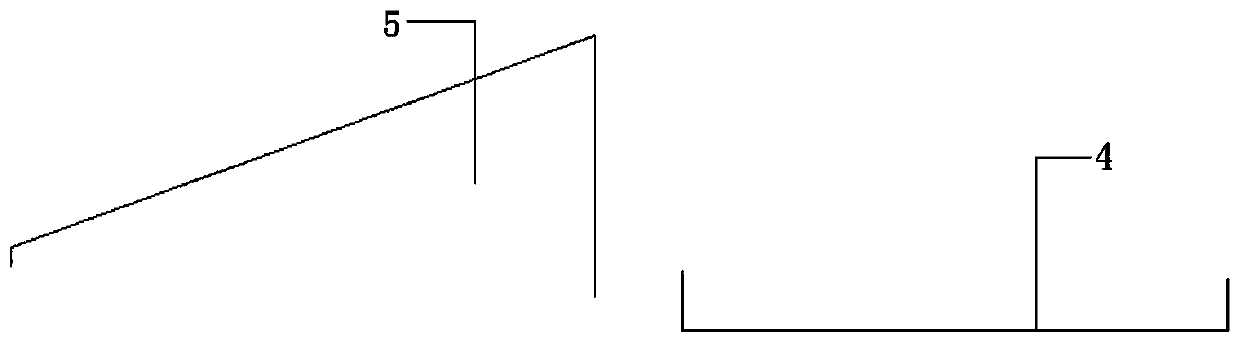

Preparation method and roof structure of an integrated material for slope finding, waterproofing and heat preservation for flat roofs

ActiveCN107417161BSmall load capacityReduce weightMouldsRoof drainageInsulation layerThermal insulation

The invention discloses a preparation method of a slope-forming, waterproof and heat-insulating integrated material for a plane roof and a roof structure. The preparation method comprises the process steps of adding 0.5 part of sand and 0.2 part of water to 0.3 part of a water-repellent polymer emulsion to mix into waterproof mortar; adding 8 parts by volume of one of polyphenyl granules or perlite or a ceramic light material to 1 part by volume of waterproof mortar, and carrying out stirring, injection molding and maintenance, wherein the proof structure comprises a slope-forming heat insulation layer and an adhesive layer brushed between the bottom layer of the slope-forming heat insulation layer and the roof panel; and the slope-forming heat insulation layer is formed by arranging multiple blocks of integrated ladder materials with the same slope and the same thickness. The roof structure does not need to be paved with a slope levelling layer, so that the weight and the construction cost of a plane roof slope-forming structure are further reduced; and the slope-forming layer and the heat insulation layer are made of the same material, so that the preparation method is simple in construction, low in cost and small in load, and the construction quality and the heat insulation effect can be ensured.

Owner:青岛土木建工集团有限公司

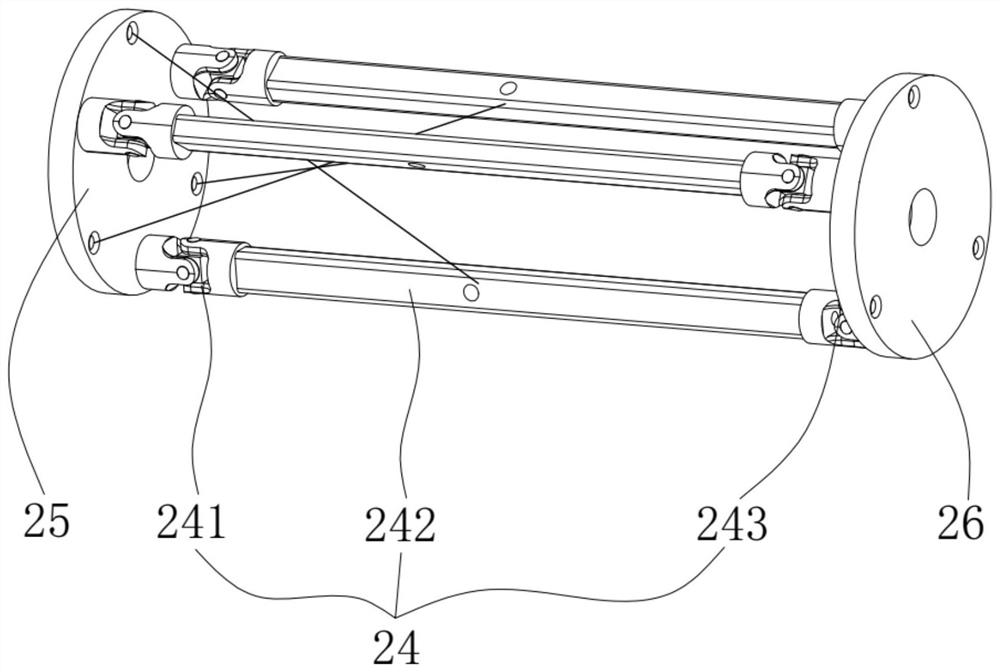

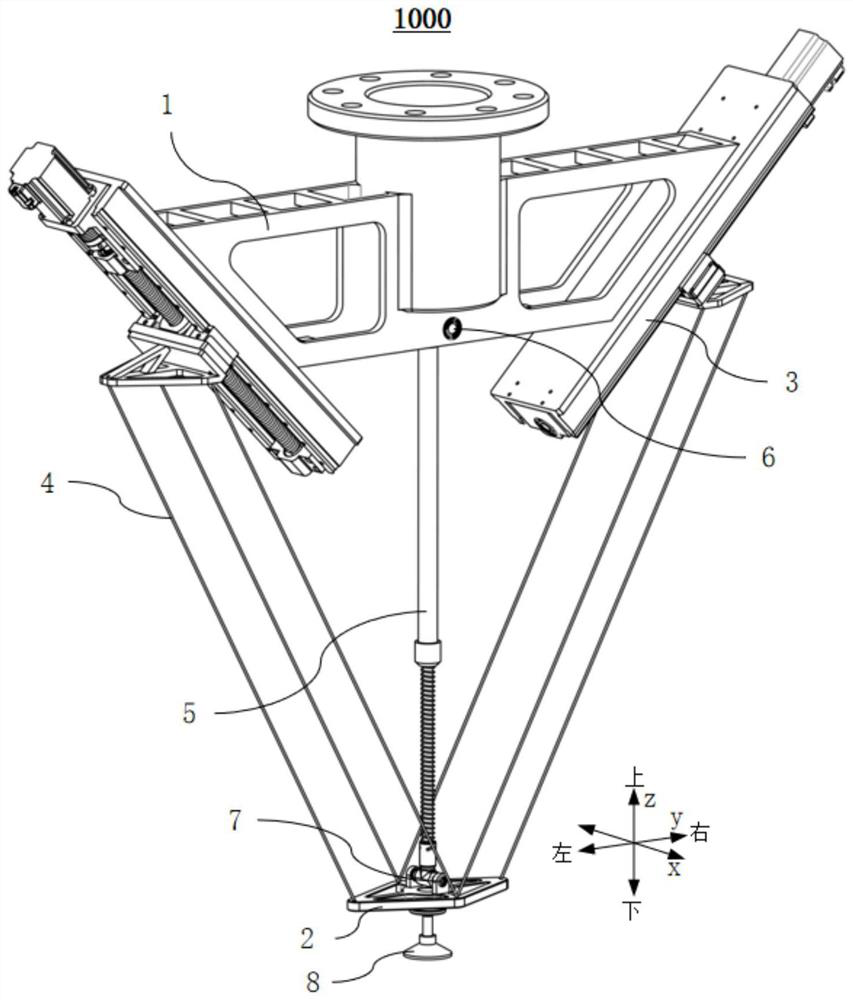

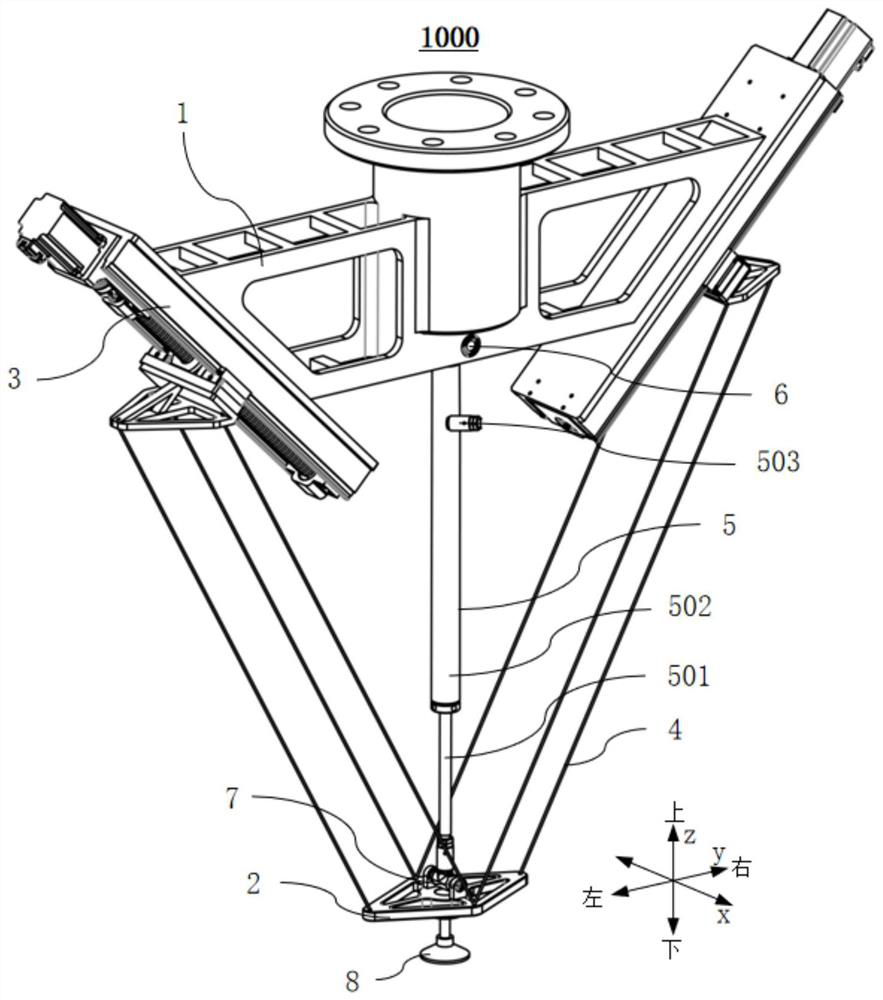

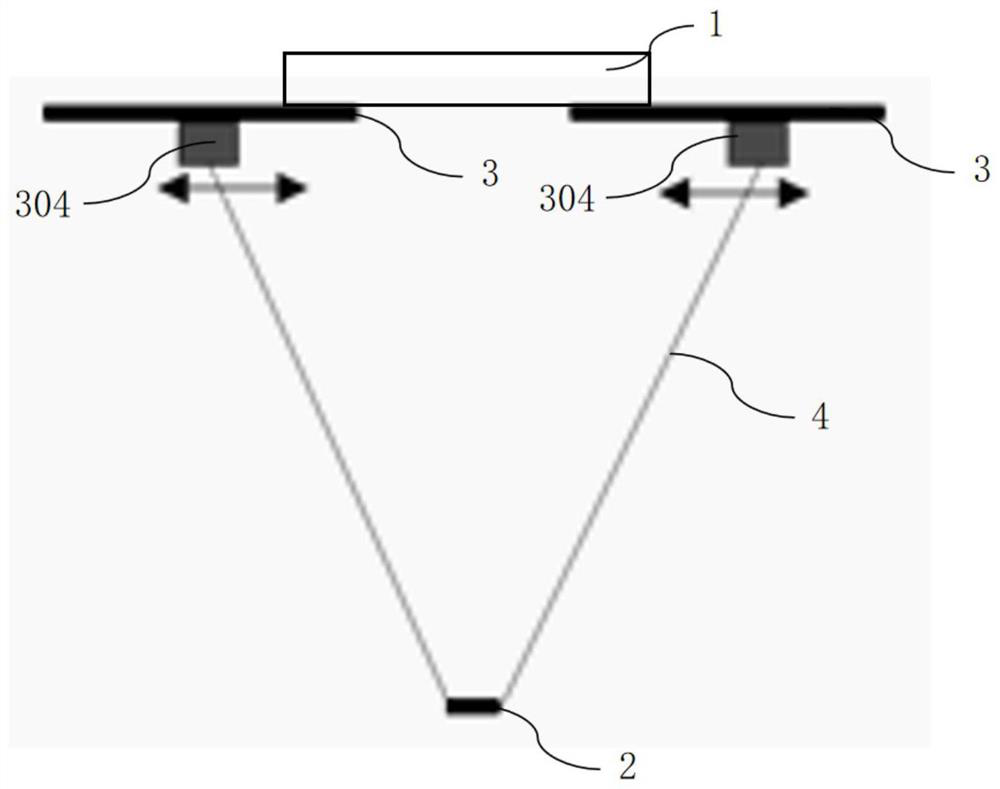

Rope-driven high-precision two-degree-of-freedom parallel robot

The invention discloses a high-precision two-degree-of-freedom parallel robot driven by ropes. The high-precision two-degree-of-freedom parallel robot comprises a rack, a movable platform, two driving assemblies, two parallel rope systems and an auxiliary tensioning assembly. Wherein the movable platform and the rack are oppositely arranged at an interval; the two driving assemblies are ball screw pair driving assemblies and are arranged on the left side and the right side of the rack in a bilateral symmetry mode. The two groups of parallel cable systems are arranged in bilateral symmetry and are positioned in the same mounting plane with the two groups of driving assemblies; one ends of the two parallel cable systems are connected to the two driving assemblies in a one-to-one correspondence mode, and the other ends of the two parallel cable systems are connected to the movable platform. The number of ropes of each group of parallel cable system is not less than three, and the lengths are all equal; the two ends of the auxiliary tensioning assembly are connected to the center of the rack and the center of the movable platform correspondingly and used for tensioning all the ropes in each parallel cable system all the time. According to the robot, positioning of the movable platform is more accurate, the parallel cable system is free of friction loss, and redundant driving is avoided.

Owner:TSINGHUA UNIV

Reverse recoil brake design method

InactiveCN105258551AGood for natural balanceShorten the lengthMuzzle attachmentAutomatic controlHigh pressure

The invention discloses a reverse recoil brake design method, belongs to the field of design of guns, and can solve the recoil problem of the guns. The reverse recoil brake design method is characterized by using an automatic shutter mounted in a shutter box for automatically controlling a moving direction of high-pressure air, so that the high-pressure air is exhausted from transverse outlet cylinders at two sides of a joint cylinder to convert the non-control distribution of pressure of the guns to the control distribution. The reverse recoil brake design method has main purposes of thoroughly eliminating the recoil force of the guns and quickly stopping the recoil motion of the guns.

Owner:黄渊干

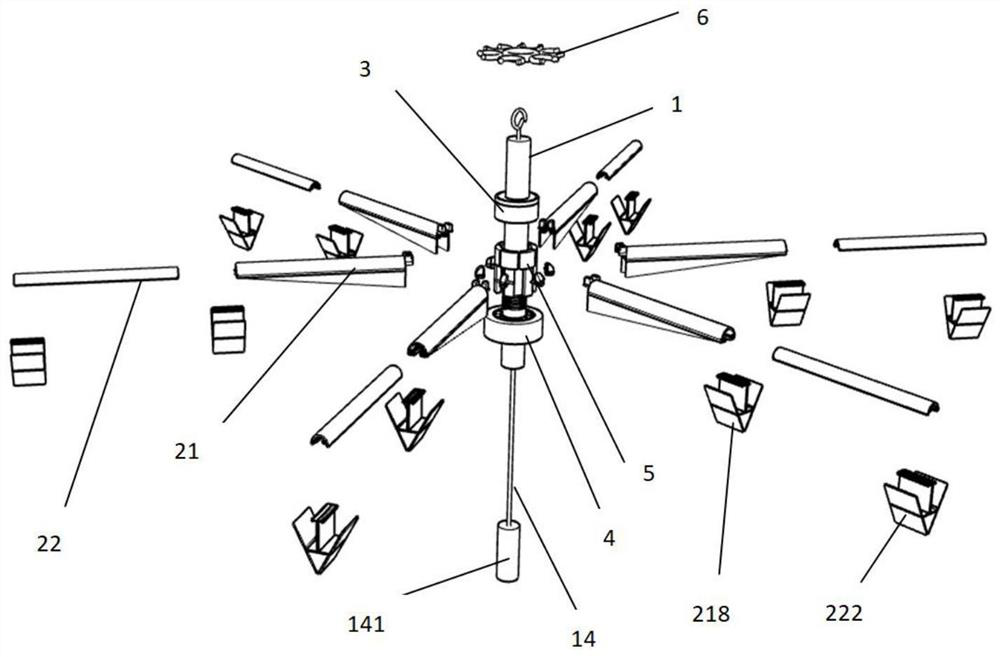

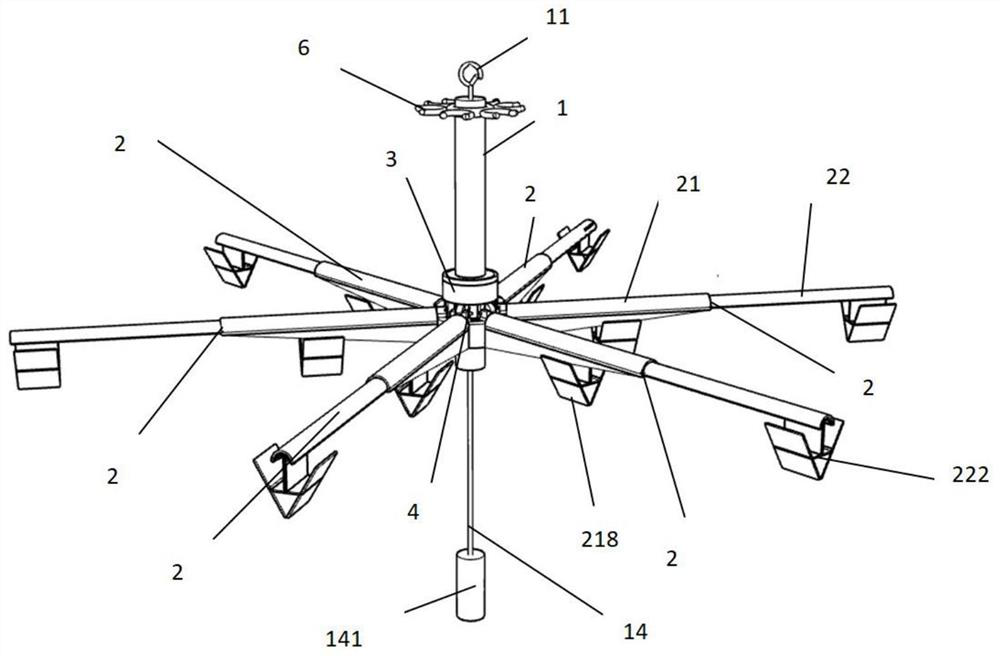

A folding hanger

The invention discloses a folding clothes hanger, which comprises an automatic lifting part, a main rod, a foldable hanging rod, an upper nut and a lower nut; the automatic lifting part is arranged on the top of the main rod; the main rod is provided with threads, and the upper nut and the lower nut pass through It can be rotated and fixed on the main rod; several foldable hanging rods can be detachably installed in the groove provided between the upper nut and the lower nut; several clips are arranged on the foldable hanging rod. The invention can be lifted, disassembled, and folded, which can fully meet the usage and cost requirements of most people in most cases.

Owner:HUBEI UNIV OF TECH

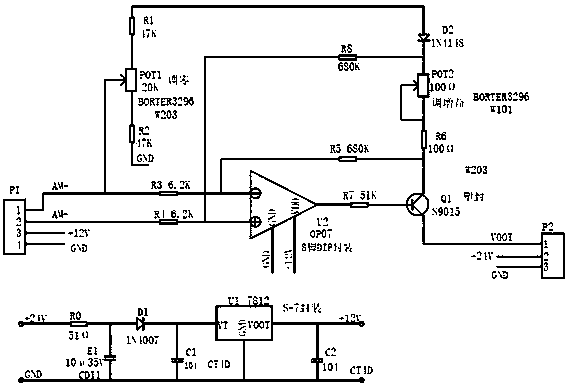

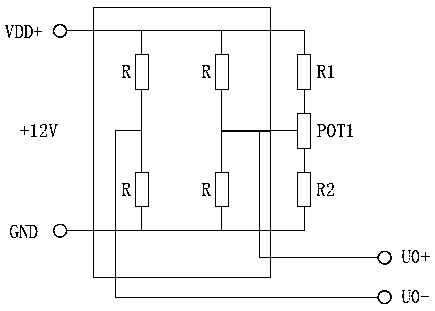

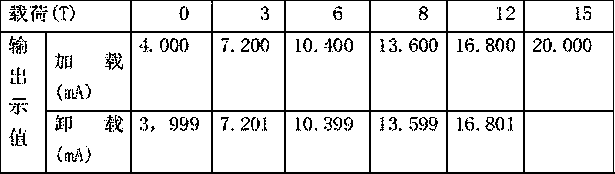

Load sensor signal transmitting device

InactiveCN111585532AEliminate distractionsImprove stabilityDifferential amplifiersDc-amplifiers with dc-coupled stagesCapacitanceSignal on

The invention discloses a load sensor signal transmitting device in the technical field of sensors. The load sensor signal transmitting device comprises an AC filter circuit, a zero setting circuit, adifferential voltage amplification circuit and a sampling circuit. The zero setting circuit is connected to the AC filter circuit. The differential voltage amplification circuit is connected to the AC filter circuit and the zero setting circuit. The sampling circuit is connected to the zero setting circuit and the differential voltage amplification circuit. The AC filter circuit comprises a resistor R0, an electromotive force E1, a diode D1, a capacitor C1, a three-terminal regulator U1 and a capacitor C2. One end of the resistor R0 is connected to a + 24V power supply, and one end of the diode D1 is connected with the other end of the resistor R0. According to the invention, the interference of noise on a voltage signal on a transmission line can be effectively eliminated, and the signalloss is reduced.

Owner:徐州电子技术研究所水电自动化工程处

Protection switch

ActiveCN109863569BReduce loadSmall load capacityElectric switchesArrangements responsive to excess currentElectrical conductorOvercurrent

A low-voltage protection switch has an external conductor section and a neutral conductor section, wherein a mechanical bypass switch is arranged in the external conductor section, and the semiconductor circuit device of the low-voltage protection switch is connected in parallel to the bypass switch. In the external conductor section A current measuring device is provided, which is connected to an electronic control unit of the protective switch, the electronic control unit being designed to actuate the bypass switch and the The semiconductor circuit arrangement provides that the undervoltage circuit breaker has at least one second current measuring device for measuring the first current through the bypass switch or the second current through the semiconductor circuit arrangement.

Owner:EATON INTELLIGENT POWER LTD

Basket conveying device of a glass washer

InactiveCN110238119ALow costSmall load capacityFlexible article cleaningCleaning using liquidsEngineeringMechanical engineering

The invention relates to the technical field of glass deep processing, and discloses a basket conveying device of a glass washer. The basket conveying device is characterized by comprising a driving belt device, a lifting frame, a rack and a lifting mechanism used for driving baskets to ascend and descend, the driving belt device is arranged on the rack, and the driving belt device comprises a driving belt capable of moving; and the lifting frame is connected with a driving belt, the driving belt can drive the lifting frame to horizontally move along the rack; and the lifting mechanism is arranged on the lifting frame. The device applies the belt-driven baskets, is simple in structure, low in cost and convenient to maintain.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

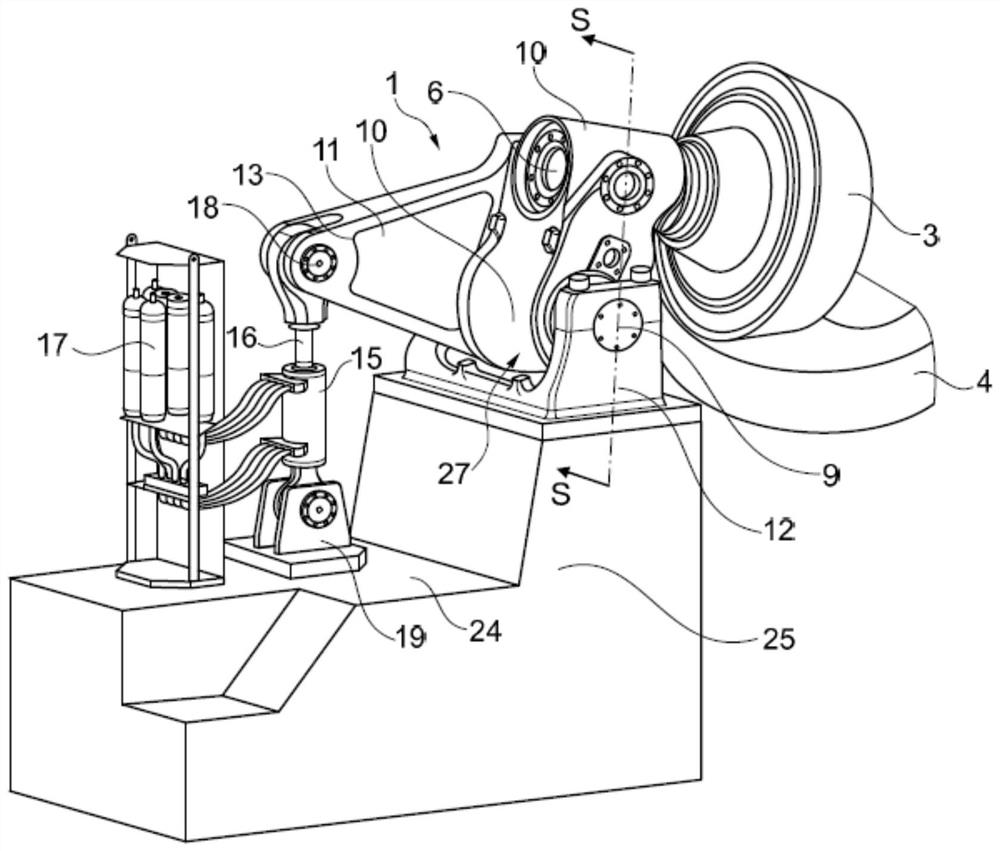

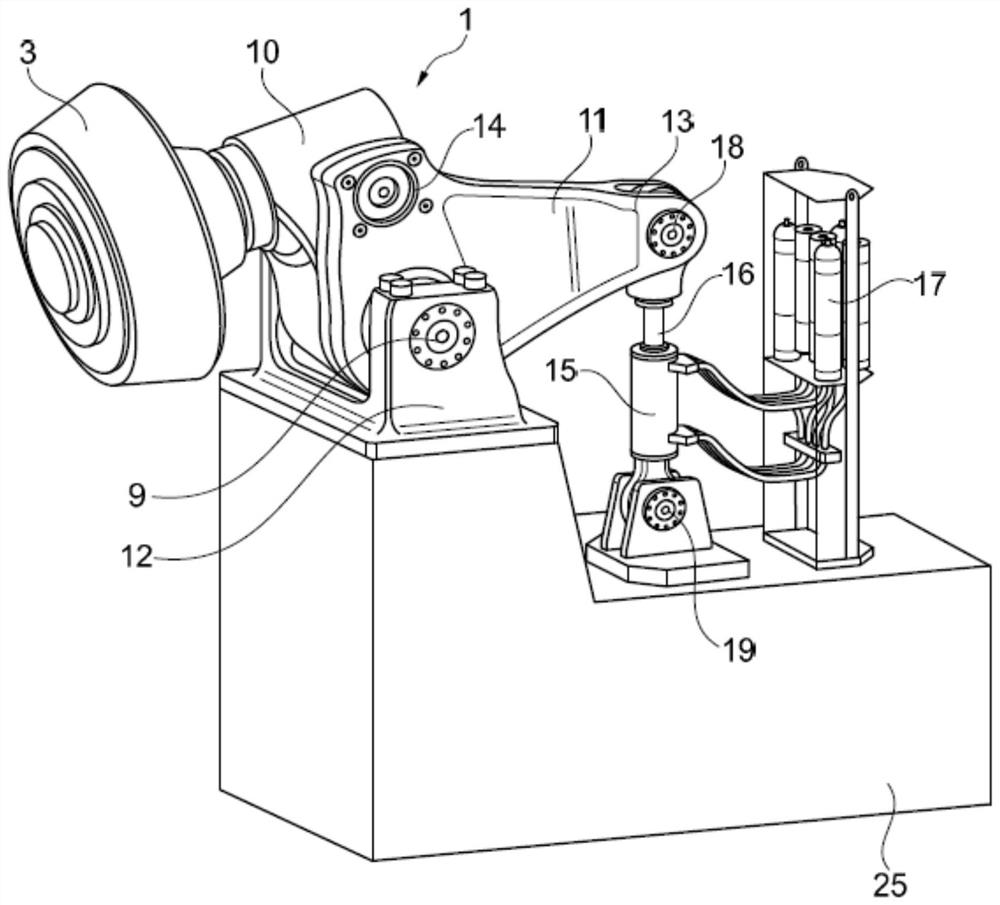

Lever system for force transmission

The invention relates to a lever system for force transmission for a grinding roller. It is intended to provide a more economical, simplified lever system which no longer needs integration into a mill stand but is more easily accessible for mounting and maintenance work. For that purpose, in particular an eccentrically arranged side lever is provided on the central swinging lever of the grinding roller, which side lever has a lever arm extending in the opposite direction to the grinding roller, and the force is transmitted to the swinging lever and the grinding roller via a lever arm of the side lever and a piston rod of the hydraulic cylinder.

Owner:LOESCHE GMBH

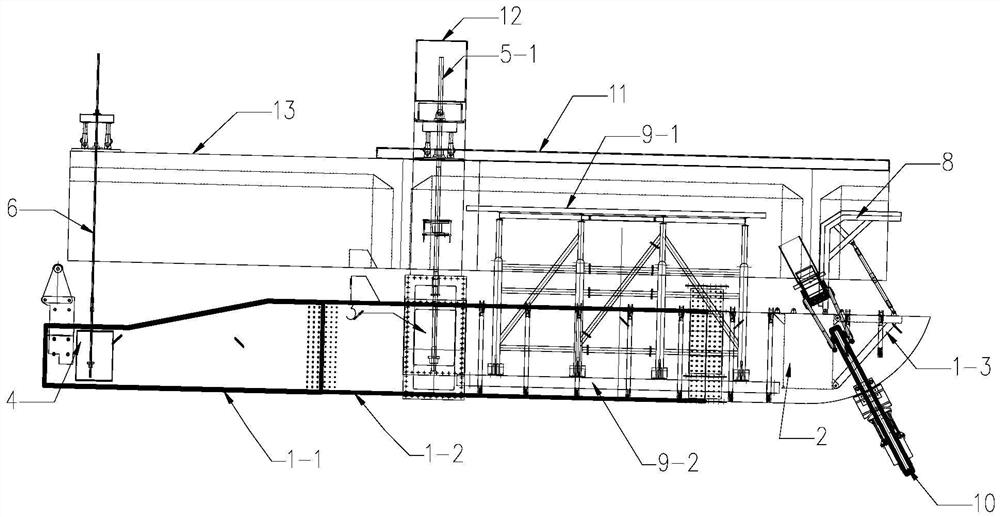

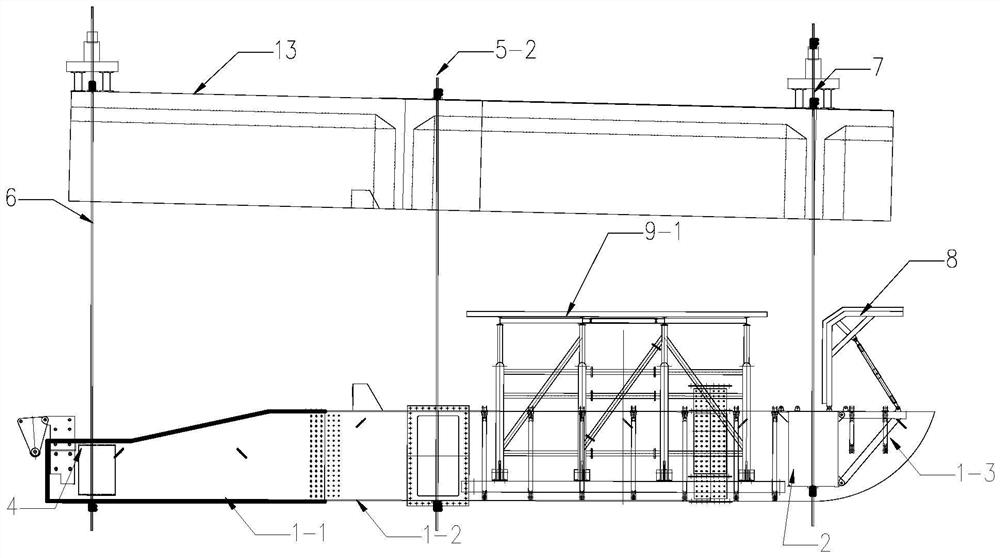

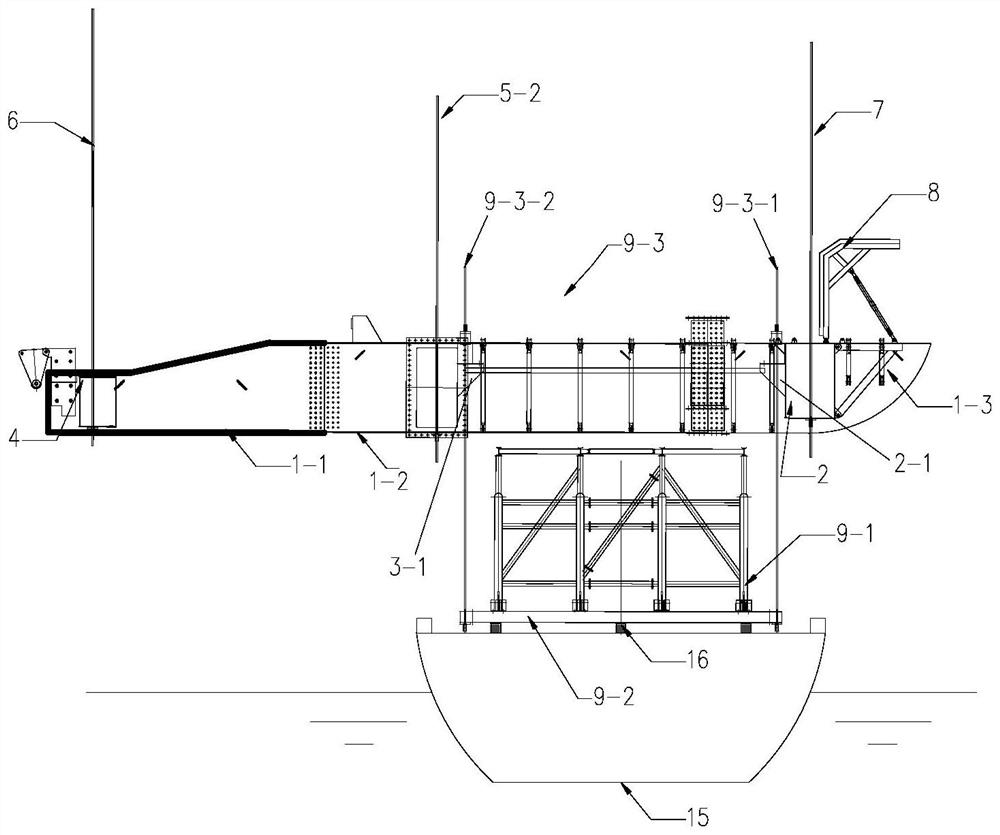

Sectional dismantling method for cable-stayed hanging basket

PendingCN114182651AMeet the load-bearing capacitySolve the problem that cannot be demolished as a wholeBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a segmental dismantling method for a cable-stayed hanging basket. The method comprises the following steps: 1, working before dismantling; 2, mounting a front suspender and replacing an anchoring middle suspender; 3, lowering the cable-stayed hanging basket for the first time; fourthly, the cable-stayed hanging basket is lowered for the second time, and a top plate formwork is dismantled; 5, dismounting a rear cross beam and a rear main longitudinal beam section of the hanging basket loading platform; 6, main longitudinal beam sections and front main longitudinal beam sections in the hanging basket load-carrying platform are dismantled; and 7, dismounting the front cross beam and the middle cross beam. The method is simple in step and reasonable in design, the whole cable-stayed hanging basket is decomposed into hanging basket assemblies to be disassembled and transported, the weight of the assemblies needing to be disassembled at a time is reduced, the bearing capacity of small and medium-sized ships in the mountainous river channel is met, and the problem that in the mountainous river channel, due to the large dead weight of the cable-stayed hanging basket, the cable-stayed hanging basket cannot be disassembled is solved. The problem that the whole water guy cable hanging basket cannot be lowered and dismantled due to the fact that no large bearing ship exists in a mountainous river channel is solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Mass transfer stretching instant dissolving device with cleaning structure and dissolving method of mass transfer stretching instant dissolving device

ActiveCN114653231ADissolve fastEasy to operateRotary stirring mixersTransportation and packagingPolymer sciencePolymer chemistry

The invention discloses a mass transfer stretching instant dissolving device with a cleaning structure and a dissolving method thereof.The device is composed of a liquid inlet, a stretching repeating unit and a mass transfer unit, the stretching unit is sequentially composed of an upper fixed fluted disc, a movable fluted disc and a lower fixed fluted disc from top, the upper fixed fluted disc, the movable fluted disc and the lower fixed fluted disc are each provided with a plurality of through holes, and the upper fixed fluted disc and the lower fixed fluted disc are fixed to a dissolving device shell; the surfaces, close to the movable fluted disc, of the upper fixed fluted disc and the lower fixed fluted disc are of short tooth structures and are evenly meshed with the short tooth structures on the two faces of the movable fluted disc, the stretching units are repeatedly arranged in series from top to bottom, each stretching unit further comprises a transmission shaft and a motor, a sweeping structure is arranged below each stretching unit, and a mass transfer unit is arranged on the periphery of each stretching unit in a surrounding mode. The mass transfer unit comprises an inner ring and an outer ring which can coaxially and reversely rotate, a polymer gel solution forms a uniform solution after passing through the mass transfer unit, the device is easy to install, and through the combined action of forced stretching and supergravity mass transfer, rapid dissolution of a polymer is achieved, and the dissolution efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com